Reflective road signs are essential for ensuring visibility and safety, especially at night or in low-light conditions. AS/NZS 1906.1 outlines the standards for how these signs should perform, detailing the necessary brightness and durability. Aluminium signs with retroreflective materials must meet these stringent requirements to remain effective, even in challenging weather. In Australia, these regulations are vital for road safety and ensuring that all signage complies with the law. OPTRAFFIC manufactures AS/NZS 1906.1-compliant aluminium signs, providing high-performance reflective road signs that ensure clear visibility and safety for all road users.

AS/NZS 1906.1 and Retroreflective Materials Overview

What is AS/NZS 1906.1?

AS/NZS 1906.1 is the industry standard in Australia and New Zealand for retro-reflective materials used in traffic signage. This standard specifies the performance and durability requirements for materials that ensure traffic signs are visible, especially in low-light conditions. Compliance with AS/NZS 1906.1 guarantees that materials reflect sufficient light to enhance visibility for road users, particularly at night or in poor weather.

The standard is enforced across all Australian states and territories, as well as in New Zealand, to ensure consistent safety across the road network.

In addition to AS/NZS 1906.1, which governs retro-reflective materials, signage manufacturers must also adhere to AS/NZS 1365 for aluminium quality and durability. To learn more about how AS/NZS 1365 shapes the quality and durability of aluminium signage, read our blog: How AS/NZS 1365 Shapes Aluminium Signage Quality and Durability in Australia and New Zealand. OPTRAFFIC ensures that all our signs comply with both standards, guaranteeing superior performance and long-lasting reliability.

The Crucial Role of Retroreflectivity in Road Safety

Retro-reflective materials play a vital role in road safety, especially for nighttime driving or during adverse weather conditions. These materials reflect light back toward its source, typically from vehicle headlights, which significantly enhances the visibility of road signs.

Key Benefits of Retroreflectivity:

- Enhanced Visibility: High-performance retro-reflective sheeting, such as 3M’s Diamond Grade DG3 Reflective Sheeting, reflects up to 60% of light, making signs significantly brighter and easier to see, even from a distance.

- Faster Recognition: Studies, including those by the University of Iowa, show that brighter signs enable faster reading. This reduces the time drivers spend looking away from the road, minimizing the potential for accidents.

- Improved Safety: Reflective road signs not only provide drivers with essential road condition information but also ensure visibility in difficult environmental conditions, such as rain or fog.

Retro-Reflective Materials in Aluminium Signage

Aluminium is a popular choice for traffic signs due to its strength, durability, and resistance to corrosion. When combined with retro-reflective sheeting, aluminium ensures that signs remain highly visible, even in extreme weather conditions.

Using retro-reflective materials on aluminium signs ensures they meet the requirements outlined in AS/NZS 1906.1. These signs reflect sufficient light to guide drivers safely, making them essential for road safety at all times of the day and in various weather conditions.

By adhering to AS/NZS 1906.1, sign manufacturers ensure that every reflective road sign is compliant with Australian and New Zealand regulations, contributing to a safer driving experience for all road users. For example, with the increasing number of SUVs and larger vehicles on Australian roads, the need for clear, visible signage has become even more critical. These vehicles, being higher off the ground, often present visibility challenges compared to standard vehicles. Properly maintained retroreflective signs ensure that all drivers can safely navigate the roads, even in low-light conditions or adverse weather.

To explore how reflective road signs help mitigate rising vehicle-pedestrian risks, read our blog: Reflective Road Signs: A Solution to Rising Vehicle-Pedestrian Risks in Australia.

Key Specifications for Reflective Road Signs

Types of Retroreflective Materials

Traffic signs rely on retro-reflective materials to ensure visibility, especially under low-light conditions or adverse weather. The type of retro-reflective material used can significantly impact a sign’s performance.

- Microprismatic Sheeting: This material features tiny prisms that reflect light directly back toward its source. Known for its superior brightness, microprismatic sheeting is ideal for high-traffic areas and warning or regulatory signs where visibility is critical.

- Glass Bead Sheeting: This traditional material uses small glass beads to reflect light. While it’s effective, it’s generally less bright than microprismatic sheeting. Glass bead sheeting is commonly used for guide signs and older road signage in low-traffic areas.

- High-Intensity Sheeting: Combining both microprismatic and glass bead technologies, high-intensity sheeting offers a balance of brightness and durability. It is designed for long-term use on regulatory, warning, and informational signs, providing higher performance and longevity than standard sheeting.

Performance Standards and Testing

Reflective road signs must meet stringent performance criteria to ensure their durability and effectiveness. AS/NZS 1906.1 specifies the necessary standards for retro-reflective materials to guarantee signs remain visible over time.

- Brightness and Reflectivity: AS/NZS 1906.1 measures how much light the material reflects from various angles. The higher the retroreflectivity, the better the material performs under low-light conditions.

- Weather Resistance: Signs must withstand environmental factors like rain, wind, and UV exposure without losing reflectivity. Materials are tested for resistance to dirt accumulation, weathering, and cleaning processes.

- Testing Methodology: Specialized testing machines (e.g., retroreflectometers, luminance meters, weathering chambers, dust and dirt test chambers, temperature chambers) simulate real-world conditions by shining light on signs and measuring the light reflected back. This ensures that the materials meet the minimum retroreflectivity requirements and will remain effective throughout their lifespan.

Application Techniques for Aluminium Reflective Signs

Applying retro-reflective materials to aluminium signs requires precision to ensure longevity and consistent performance. The right application techniques prevent issues such as peeling or bubbling, which could compromise the sign’s effectiveness.

- Surface Preparation: Before applying retro-reflective sheeting, the aluminium surface must be thoroughly cleaned to remove any debris or contaminants. This ensures optimal adhesion and prevents premature material failure.

- Adhesion Techniques: To ensure durability, rollers or presses are used to apply the material to the aluminium. In some cases, heat is used to further bond the material to the substrate, improving the sign’s resistance to environmental wear.

- Material Guides: Traffic sign manufacturers should follow material-specific guides for the application process. These guides outline the best practices to ensure that the material performs well under varying conditions and remains intact for years.

Proper application ensures that retro-reflective materials stay adhered to the aluminium, ensuring that the sign retains its brightness and durability in all weather conditions.

Road Signs in Australia: Compliance and Safety

AS/NZS 1906.1 and MUTCD Alignment

The AS/NZS 1906.1 standard governs the retro-reflectivity of traffic signs in Australia, aligning with the Manual of Uniform Traffic Control Devices (MUTCD), which outlines the broader regulations for traffic control devices. While the MUTCD defines the general design, installation, and placement of road signs, AS/NZS 1906.1 focuses on the specific performance characteristics of retro-reflective materials.

These two standards ensure consistency in road signage across the country, establishing requirements for:

- Reflectivity: Determining the minimum brightness for effective visibility.

- Durability: Ensuring materials withstand environmental exposure and maintain visibility over time.

By adhering to both the MUTCD and AS/NZS 1906.1, road sign manufacturers and authorities ensure that all road signs are not only consistent in design but also comply with national safety standards, improving road safety across Australia.

Visibility and Safety Implications

The visibility of road signs is directly linked to road safety. Effective signage helps drivers make quick, informed decisions, reducing the risk of accidents. The use of retro-reflective materials plays a key role in ensuring that signs are visible under low-light conditions and during adverse weather, such as rain or fog.

Signs that meet AS/NZS 1906.1 standards ensure that retro-reflective materials perform optimally, even under the toughest conditions. This is particularly important for regulatory signs, like speed limits and stop signs, where timely recognition is critical.

Here’s how varying visibility levels directly affect safety:

| Visibility Level | Driver Reaction Time | Distance to Recognize Sign | Crash Risk | Average Driver Response Time (ms) |

|---|---|---|---|---|

| High | <1 second | 200-300 meters | Low | 400-800 ms (immediate action) |

| Medium | 1-2 seconds | 150-200 meters | Moderate | 800-1200 ms (slower response) |

| Low | 2-3 seconds | 100-150 meters | High | 1200-1800 ms (delayed reaction) |

Legal Requirements and Consequences

Compliance with AS/NZS 1906.1 is not only a matter of road safety but also a legal requirement for all road signs in Australia. Non-compliance can lead to significant consequences, including:

- Legal Liability: Authorities and manufacturers may face legal action if signs do not meet the prescribed retro-reflective standards. For example, if a stop sign or speed limit sign is not visible due to poor retro-reflectivity, and this causes a driver to miss the sign and subsequently cause an accident, the responsible authorities could face lawsuits from victims or their families. They may be required to pay damages or compensation.

- Replacement Costs: Non-compliant signs may need to be replaced, which can result in substantial costs for both authorities and manufacturers.

For example, if a local government installs 500 traffic signs that do not meet AS/NZS 1906.1 retro-reflective standards, and each sign costs $200 to replace, the total replacement cost would be:

500 signs × $200 per sign = $100,000

- Increased Accident Risk: Poor visibility and delayed reactions from drivers due to substandard signage can lead to accidents, heightening the risk to public safety.

Adherence to AS/NZS 1906.1 and MUTCD standards is essential for ensuring road signs provide the necessary visibility and durability to maintain road safety. Compliance with these standards helps minimize risks, prevent accidents, and protect manufacturers and authorities from legal repercussions. By ensuring all signage meets these requirements, Australia’s road infrastructure remains reliable, clear, and safe for all users.

Benefits of AS/NZS 1906.1-Compliant Aluminium Signage

Durability and Maintenance

AS/NZS 1906.1-compliant aluminium signs are designed to withstand Australia’s harsh weather conditions, offering superior durability. These signs resist fading, peeling, and environmental damage, ensuring that the retro-reflective materials remain bright and effective over time. The materials are securely bonded to the aluminium substrate, reducing the risk of scratches or damage.

Maintenance is minimal. These signs require only occasional cleaning with mild soap, significantly reducing the need for frequent repairs or replacements. This not only saves time but also lowers ongoing costs for maintenance teams.

Consistent Quality and Performance

AS/NZS 1906.1 ensures that every regulatory sign meets high visibility standards, regardless of location. The standard defines the retro-reflective properties, brightness, and performance criteria, ensuring that signs are visible day or night, in all weather conditions—whether it’s fog, rain, or bright sunlight.

This consistent quality enables drivers to recognize and react to signs quickly, reducing confusion and improving road safety. Compliance with the standard ensures uniformity in signage, meaning no matter where a driver is, they can rely on the visibility and performance of the signs.

Cost-Effectiveness

Although the initial investment in AS/NZS 1906.1-compliant signs may be higher, the long-term benefits far outweigh the costs. These high-quality signs last longer and require fewer replacements, which ultimately reduces maintenance and repair expenses for councils and road managers.

In addition to saving on direct costs, reliable signage helps prevent accidents, which can reduce the need for emergency services, lower insurance premiums, and minimize the financial impact of accidents on local authorities.

If you’d like to explore the balance between cost and quality in reflective sheeting of signs, and understand what’s truly worth the investment in road signage, read our blog: Cost vs. Quality in Reflective Sheeting: What’s Worth the Investment in Road Signage?

Real-World Applications of AS/NZS 1906.1-Compliant Aluminium Signage

Use in Regulatory, Warning, and Guide Signs

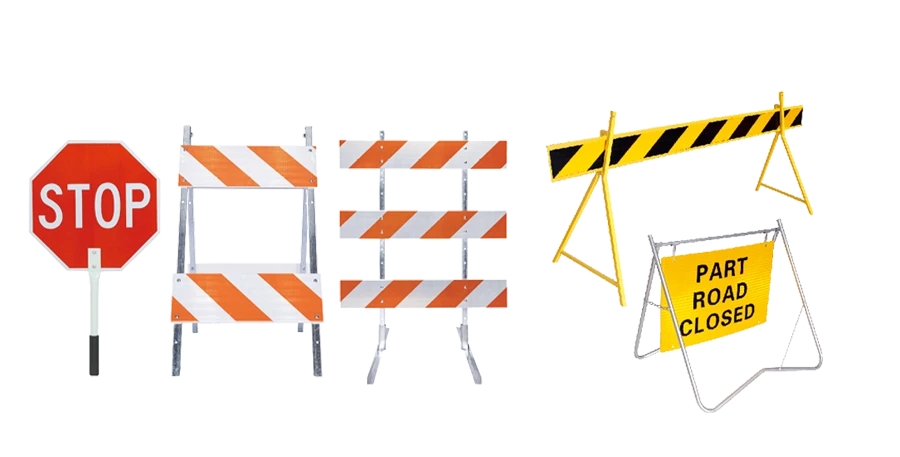

AS/NZS 1906.1-compliant aluminium signs are essential for various types of traffic signage across Australia, playing a key role in road safety. These signs are crucial for informing drivers of the rules they must follow, warning them of potential dangers, and guiding them with accurate directions.

Below are the common applications for AS/NZS 1906.1-compliant signage:

| Application Type | Description |

|---|---|

| Regulatory Signs | Indicate road rules, such as speed limits, stop signs, or no-parking zones, ensuring legal compliance. |

| Warning Signs | Alert drivers to potential hazards like roadworks, sharp bends, or wildlife crossings. |

| Guide Signs | Provide direction, distances, and route details to assist navigation. |

These signs use retro-reflective materials to ensure visibility day and night, improving driver awareness and safety.

Industrial and Commercial Applications

Beyond traffic signs, AS/NZS 1906.1-compliant aluminium signs are also widely used in industrial and commercial settings. These signs help maintain safety standards, guide people through facilities, and ensure clear communication of important information.

| Application Type | Description |

|---|---|

| Building Signage | Display building names, room numbers, and emergency exits, providing clear guidance to visitors. |

| Pole Signs | Mounted on poles, these signs communicate rules or warnings, such as parking regulations or safety notices. |

| Safety Signage | Warn workers about hazards like high voltage, heavy machinery, or other potential dangers, using retro-reflective materials for visibility. |

These applications are essential for workplace safety and help businesses adhere to regulatory standards.

Performance in Harsh Conditions

Aluminium signs with retro-reflective coatings are designed to withstand Australia’s harsh climate—from intense sunlight to heavy rainfall and dust storms. AS/NZS 1906.1-compliant signage maintains its reflectivity and clarity over time, even after prolonged exposure to the elements.

These signs are highly resistant to fading, peeling, and damage, which reduces the frequency of replacements and maintenance. They can be easily cleaned with mild soap and water, ensuring long-lasting performance and enhanced visibility, year-round.

AS/NZS 1906.1 gives clear rules for reflective aluminium road signs. These rules help makers build signs that stay bright and last long. Following the rules makes roads safer and keeps signs legal. Road workers and sign makers save money because signs work well. New retroreflective materials will make signs even easier to see and better for the planet. People should learn about new rules and ideas to keep roads safe.

If you’d like to learn more about the latest in reflective traffic signs sheeting standards, you can read our blog: Overview of Reflective Traffic Signs Sheeting Standards in Australia.

FAQ

Is OPTRAFFIC compliant with AS/NZS 1906.1 standards?

Yes, OPTRAFFIC proudly ensures that all our signs meet the AS/NZS 1906.1 standards for retroreflective materials. Our aluminium signs are designed to provide maximum visibility and durability, ensuring they meet the strict requirements for brightness, longevity, and weather resistance. This compliance guarantees that OPTRAFFIC signs are safe, effective, and easy to see, no matter the time of day or weather conditions.

What does AS/NZS 1906.1 cover in traffic signage?

AS/NZS 1906.1 gives rules for retroreflective materials on road signs. The standard tells how bright and tough these materials must be. It helps keep signs easy to see and safe for everyone.

Why do aluminium signs need retroreflective materials?

Aluminium signs use retroreflective materials to stay bright at night. These materials reflect car headlights in bad weather. Drivers can read messages quickly and stay safe.

How do authorities test retroreflective road signs?

Authorities use machines to check how much light signs reflect. They test signs from different angles and after bad weather. Signs must pass these tests before they go on roads.

What happens if a sign does not meet AS/NZS 1906.1?

Signs that do not meet the standard can be unsafe. Authorities may get fined or have to change the signs. Following the rules helps protect drivers and keeps roads safe.

Can businesses use OPTRAFFIC AS/NZS 1906.1-compliant signs?

Yes, businesses can confidently use OPTRAFFIC’s AS/NZS 1906.1-compliant signs in various applications, such as safety signage in workplaces, car parks, and public areas. The high-performance reflective materials in OPTRAFFIC signs ensure they are visible and clear, enhancing safety and compliance with regulations.