When picking construction safety signs for hard jobs, you want strong ones. Aluminum Safety Signs, ACM Safety Signs, and Heavy-Duty Polyethylene Safety Signs are very tough. Aluminum does not rust or fade for up to ten years. ACM has two aluminum sheets and a polyethylene center. This makes it resist water, sunlight, and changes in temperature. Heavy-duty polyethylene signs are light and cheap. They are good for short-term use. Here is how they compare:

| Material | Lifespan (Years) | Resistance Features |

|---|---|---|

| Aluminum | 6 to 10 | Weather, rust, corrosion, minimal fading |

| ACM (Aluminum Composite) | Long-lasting | Moisture, temperature, UV, no warping |

| Heavy-Duty Polyethylene | Short-term | Lightweight, budget-friendly, less durable |

You need the right signs to keep your team safe. Signs help stop accidents and follow rules. Good safety signs protect everyone at your site. They help keep your workplace safe every day.

At OPTRAFFIC, we offer a variety of construction safety signs made from aluminum to meet the specific needs of your jobsite. Whether you’re looking for long-lasting aluminum signs for durability or budget-friendly polyethylene signs for short-term use, OPTRAFFIC provides reliable, high-quality solutions that ensure safety and compliance. Let us help you protect your workers and meet safety regulations with our top-of-the-line signage products.

Key Takeaways

- Pick aluminum safety signs if you want them to last long. They do not rust or fade. This makes them good for hard jobs.

- ACM safety signs are light and strong. They can handle bad weather. They show warnings all year.

- Use heavy-duty polyethylene signs for short jobs. They cost less and are simple to put up. But they do not last as long.

- Pick bright colors and big letters so people can see them. This helps workers spot dangers fast and stay safe.

- Check signs often and change any that are broken. Clear signs help keep your team safe and stop accidents.

Why Durable Construction Safety Signs Matter

Preventing Accidents and Injuries

You want workers to be safe every day. Strong safety signs help keep everyone safe. Clear signs show dangers before someone gets hurt. Many accidents happen when people miss warning signs. Sometimes, workers do not see danger zones.

OSHA says safety signs can save lives. If you follow OSHA rules, you lower injury risks.

Here is how accidents happen and how signs help:

| Type of Accident | Statistics/Impact | Prevention Strategies |

|---|---|---|

| Struck-by Incidents | 15% of worker deaths; 484 deaths in 2022 | Use clear signs for hazard zones and add barriers. |

| Falls | 395 deaths in 2022, over one-third of all deaths | Signs show fall dangers and remind about safety gear. |

| Slips and Trips | 450,540 cases in 2022 with missed work from falls, slips, and trips | Signs warn about wet floors and keeping walkways clean. |

Safety signs do more than warn people. They help workers follow safety rules. Signs help workers avoid danger. Studies show safety signs help workers spot hazards and stay safe. Using good signs builds a safe workplace. Fewer accidents happen when you use the right signs.

Maintaining Visibility in Harsh Conditions

Construction sites have tough weather. Rain, snow, dust, and low light make signs hard to see. If signs fade or break, workers miss warnings. This puts them at risk. You need signs that stay bright and clear.

- Reflective signs are easy to see at night.

- UV coatings stop signs from fading in sunlight.

- Waterproof signs stay readable in storms.

New safety signs use strong materials like aluminum and ACM. These signs resist weather and stay clear. You protect your team by picking signs that last.

Choosing strong safety signs makes your site safer. Workers can see hazards even in bad weather. Good signs mean fewer accidents and a safer place for everyone.

Top 3 Most Durable Safety Signs

Aluminum Safety Sign

Aluminum safety signs are the strongest for construction sites. They last for many years and give clear warnings. Aluminum does not rust or fade, so signs stay bright. Your team stays safe from hazards. You also follow workplace safety signage rules.

Here is a quick look at aluminum safety signs and how long they last:

| Type of Aluminum Sign | Durability Rating | Key Features |

|---|---|---|

| Coated Aluminum | 5 to 7 years | Resists chipping, cracking, rust, and fading |

| Engineering Grade Reflective Aluminum | Up to 7 years | Enhanced weather resistance and retro-reflectivity |

| High Intensity Prismatic Reflective | 7 to 10 years | Superior durability and reflectivity |

| Diamond Grade Reflective Aluminum | Over 10 years | Maximum durability and resistance to fading |

You get these benefits:

- Corrosion resistance keeps signs strong in rain and snow.

- UV resistance helps colors and graphics stay bright.

- You only need mild soap and water to clean them.

Advantages:

| Advantages of Aluminum Safety Signs | Description |

|---|---|

| Durability | Aluminum is one of the toughest materials for signs. It lasts a long time. |

| Weather Resistance | It does not get damaged by rain or sun. You can use it outside. |

| Cost-effectiveness | It costs more at first, but you save money because it lasts longer. |

| Customization Options | You can make aluminum signs fit your needs. |

Disadvantages:

| Disadvantages of Aluminum Safety Signs | Description |

|---|---|

| Higher Upfront Costs | Aluminum signs cost more to buy than some other types. |

| Storage/Transport Challenges | They are hard to store and move because they are stiff. |

Tip: Pick aluminum safety signs for busy areas and long projects. They are the best choice when you need signs that last.

ACM Safety Sign

Safety signs made from Aluminum Composite Material (ACM) are ideal for demanding tasks. Featuring a design with two aluminum layers and a polyethylene core, these signs are both lightweight and highly durable. Their construction ensures resistance to bending and fading, even under harsh weather conditions.

ACM construction safety signs are great for outdoor use. Your warnings stay clear all year. The material does not get damaged by water, sunlight, or heat. Hazards stay marked, so workers stay safe.

Pros:

- Light design makes them easy to put up.

- Strong build stops bending and breaking.

- They stay readable in all kinds of weather.

Cons:

- ACM safety signs cost more than simple plastic ones.

- You might need special tools to put them up.

Note: Use ACM safety signs where weather is rough or signs get moved a lot. They are reliable and last in tough places.

Heavy-Duty Polyethylene Sign

Heavy-duty polyethylene safety signs are good if you want to save money. They are light and easy to move. Polyethylene does not get ruined by water or chemicals. Your signs stay readable in wet or dirty places.

Use heavy-duty polyethylene construction safety signs for short jobs or temporary danger zones. These signs warn workers about hazards without costing much. You keep your site safe and follow workplace safety rules.

Pros:

- Low price makes these safety signs easy to afford.

- Light material lets you set up and take down fast.

- Water and chemical resistance keeps warnings clear.

Cons:

- Polyethylene safety signs do not last as long as aluminum or ACM.

- They can fade or crack if left in the sun too long.

Alert: Pick heavy-duty polyethylene safety signs for quick jobs or short-term hazards. You save money and keep your site safe.

Comparison Table: Durability and Best Use Cases

| Safety Sign Type | Durability | Best Use Case |

|---|---|---|

| Aluminum | 5-10+ years | Long-term, high-traffic construction |

| ACM | 7+ years | Outdoor, harsh weather, frequent use |

| Heavy-Duty Polyethylene | 1-3 years | Temporary hazards, short-term jobs |

You need to choose the right construction safety signs for your site. Aluminum and ACM safety signs protect best against hazards and weather. Heavy-duty polyethylene safety signs help with danger zones for a short time. You make your workplace safer and protect your team every day.

Construction Safety Signs Comparison

Durability

You need signs that last a long time. Aluminum signs are very strong. They do not rust or fade easily. But if they get chipped, they might rust. ACM signs are even better. They will not rust, even if scratched. ACM signs are lighter than aluminum signs. Polyethylene signs are the lightest. But they do not last as long as the others. You might have to buy new ones more often. Look at this table to see how each sign compares:

| Material Type | Durability Features | Weight Comparison |

|---|---|---|

| Aluminum | Noted for its durability; can rust if chipped or scratched. | Heavier than ACM and Poly |

| ACM | Lightweight, superb outdoor durability, will not rust if chipped or scratched. | About half the weight of aluminum |

| Polyethylene | Lightweight, but less durable. | Lightest option |

Pick ACM signs for jobs that last a long time. Use polyethylene signs for short jobs or quick roadwork.

Visibility

Good safety signs help keep people safe. ACM signs are easy to see from far away. They work well for fast-moving traffic zones. Plastic signs are okay for short jobs, but they fade quickly. Use bright colors like yellow, orange, or red. These colors help people notice danger. ANSI says to use the right color for each hazard. For example, orange is best for roadwork and construction.

| Color | Effectiveness | Use Cases |

|---|---|---|

| Fluorescent Yellow | Very easy to see, even for color-blind people. | Safety signs, clothing in dangerous areas. |

| Fluorescent Orange | Stays bright in cloudy weather; shines more in sunlight. | Work zones, construction areas. |

| Red | Good for emergencies; stands out in the dark. | Stop signs, fire alarms. |

- Bright colors like red and yellow get attention.

- Black on yellow or white on red is easy to read.

Weather Resistance

Construction sites have rain, sun, and snow. ACM signs can handle all kinds of weather. They stay strong in heat, wind, and cold. Aluminum signs also do well in bad weather. But if they get damaged, they might rust. Polyethylene signs do not get ruined by water or chemicals. But they might crack if it gets very cold. You want signs that keep workers safe all year.

| Material Type | Weather Resistance | Additional Features |

|---|---|---|

| ACM | High temperatures, sun, wind, rain, snow | Sturdy and long-lasting performance |

| Polyethylene | Extreme weather, high winds, heavy rain, extreme temperatures | Resistant to corrosion and cracking |

Wash your signs every few months with soap and water. Check the hardware once a year to keep your site safe.

Cost

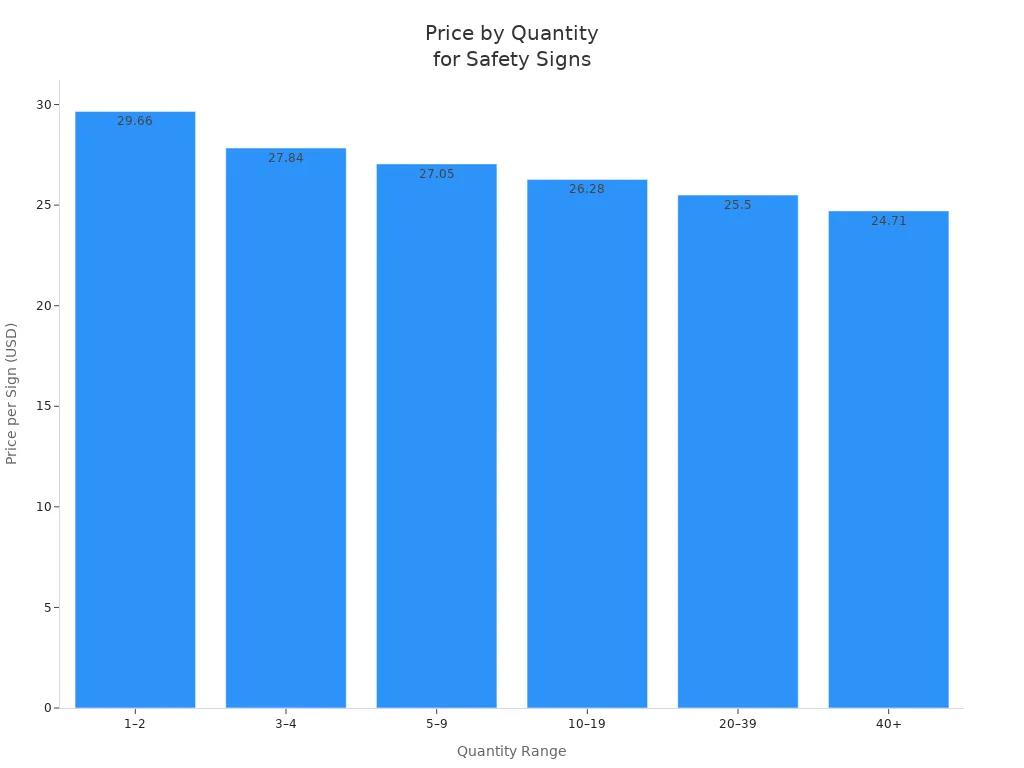

You want to spend your money wisely. Aluminum and ACM signs cost more at first. But you do not have to replace them as often. Polyethylene signs are cheaper, but you need to buy them more often for new jobs. Here is a table to compare prices:

| Material Type | Price Range |

|---|---|

| Aluminum Composite | $13.15 – $20.65 |

| Polyethylene Signs | $14.30 – $17.90 |

Buy more signs at once to save money on your next project.

Choosing the Right Signage for Construction Site Safety

Assessing Site Conditions

Look at your construction site before picking safety signs. Each site has its own dangers. Dust, water, and shaking can hurt signs. You need signs that stay easy to read. Use bright colors and big letters so workers see them from far away. Check for places with lots of rain, hot sun, or much movement. Pick strong materials like aluminum for tough areas. Check your signs often and change any broken ones to keep everyone safe.

| Factor | Description |

|---|---|

| Visibility | Signs must be easy to read from far away. Use bright colors and big letters. |

| Compliance | Signs should follow rules about size and color. |

| Maintenance | Check signs often and replace broken ones quickly. |

| Customization | Make signs fit your site’s dangers and needs. Use other languages if needed. |

| Effective Communication | Signs must show clear pictures or words to help people stay safe. |

Matching Sign Features to Needs

Select safety signs tailored to your site’s specific hazards. Use caution signs for minor risks, warning signs for moderate dangers, and danger signs for severe hazards. Opt for bold lettering and bright colors to ensure visibility. Choose durable materials suitable for your local weather conditions. Incorporate QR codes for quick access to digital safety information. Update signs to address unique risks or accommodate the languages your team speaks. Ensure every sign provides clear instructions, such as “Wear safety gear.”

- Use bold letters and bright colors for easy reading.

- Pick strong materials so signs last longer.

- Change signs for your site’s special dangers.

Compliance and Regulations

Adhere to all safety regulations when selecting signs. OSHA and ANSI provide guidelines on sign types, wording, and colors. Use danger signs for life-threatening hazards, caution signs for moderate risks, and safety instruction signs to guide workers’ actions. Ensure signs have rounded corners and secure fasteners. Use clear, simple language for readability. Complying with these standards ensures a safer workplace and helps prevent penalties.

| Sign Type | Description |

|---|---|

| Danger Signs | Show hazards that can cause death or bad injury. |

| Caution Signs | Show dangers that are not deadly but still risky. |

| Safety Instruction Signs | Tell workers what to do to stay safe. |

Tip: Always check local and national rules before putting up new signs.

Budget Considerations

You want to keep your site safe without spending too much. Pick strong signs that last so you save money. Choose materials that work for your weather to avoid extra costs. Buy many signs at once to save money and keep them looking the same. Only buy signs you need for each danger. Clear signs stop confusion and accidents, which saves money later.

- Balance good quality and price for safety.

- Buy many signs at once to save money.

- Pick the right material for your site’s weather.

If you follow these steps, you keep workers safe, follow the rules, and make your site safer every day.

You want your team to have the best safety signs. Aluminum signs last a long time and give clear warnings. ACM signs are good for bad weather and busy sites. Heavy-duty polyethylene signs work for short jobs. Aluminum signs are best for most hard jobs. They last longer and handle tough weather. These signs show you care about safety.

Good construction safety signs warn workers and last in storms. They help you follow OSHA rules. You save money and keep people safe.

| Material Type | Typical Lifespan | Maintenance Needs | Resistance to Fading |

|---|---|---|---|

| Aluminum | 6–10 years | Low | Excellent |

| Polyethylene | 1–3 years | High | Poor |

You should check your site and pick signs that fit your needs. Use stronger safety signs to protect your team and make your site safer.

FAQ

What makes a construction safety sign durable?

You get durability from strong materials like aluminum or ACM. These signs resist weather and last for years. You keep your team safe because the signs stay clear and readable, even in tough conditions.

How often should you replace construction safety signs?

Check your signs every few months. Replace any sign that fades, cracks, or breaks. You protect your workers and keep your site safe by using clear, visible safety signs at all times.

Can you use the same safety sign for indoor and outdoor construction sites?

You can use some signs for both. Choose aluminum or ACM for outdoor use. These materials handle rain and sun. For indoor jobs, heavy-duty polyethylene works well. Pick the right sign for each construction area.

Why do you need reflective safety signs?

Reflective signs help workers see warnings at night or in low light. You reduce accidents and improve safety. Reflective signs work best for busy construction zones or areas with moving vehicles.

How do you choose the right size for a construction safety sign?

Pick a size that workers can see from far away. Use big letters and bright colors. You make your construction site safer when everyone can read the safety message quickly.