MUTCD reflectivity standards tell how bright road signs must be. These rules help people see signs at night and when it is dark. Traffic management companies put up MUTCD compliant signs to keep drivers safe. Reflective materials make signs easier to see after dark. This helps drivers notice signs better. Studies show that brighter signs can lower crashes by up to 25% at curves and intersections. The MUTCD makes sure all signs have the right amount of reflectivity.

For organizations looking to purchase large quantities of MUTCD-compliant traffic signs, OPTRAFFIC is the ideal choice. Known for providing high-quality, compliant signage solutions, OPTRAFFIC ensures that traffic management companies and large-scale buyers receive products that meet the highest standards of visibility and safety.

Key Takeaways

- MUTCD standards make sure road signs are easy to see. This is important at night. It can lower crashes by 25%.

- Using good reflective materials helps drivers see signs from far away. This gives drivers more time to react.

- Checking and fixing signs often is very important. It keeps signs safe and following the rules for everyone.

- Picking the right reflective sheeting depends on the road and traffic. This helps people see signs better and stay safe.

- Smart technologies can help signs be easier to see. They also help signs follow the rules. This makes roads safer for all.

What Is MUTCD Compliant Sign and Why It Matters

MUTCD’s Role in Road Sign Uniformity

The MUTCD makes rules for traffic control devices. These rules make sure all road signs look and work the same everywhere. This means stop signs and warning markers are easy to spot. Drivers can recognize signs fast, even in new places. The MUTCD says signs must follow rules for what they say, where they go, their size, shape, and color. States can change the rules a little, but they must still follow the main rules. This keeps signs easy to see and understand. It also helps stop confusion and danger for everyone on the road.

Tip: When signs look the same, drivers can decide faster, even at night or when it is hard to see.

| Definition of MUTCD Compliant Sign | Legal Implications of Non-Compliance |

|---|---|

| Makes sure traffic control devices are the same, including what they say, where they are, their sizes, shapes, and colors. | If a crash happens and someone gets hurt, cities can get in trouble if signs do not follow MUTCD. Also, safety devices might not count if they do not follow the rules. |

Many states, like Delaware, say you must follow the MUTCD by law. Cities can lose money for road work if they do not follow these rules. Not following the rules can also cause legal trouble, especially if someone gets hurt in a crash.

Impact on Road Safety and Visibility

MUTCD compliant signs help keep people safe. They make sure every sign is clear and easy to see. The manual wants to stop bad injuries and deaths. Reflective materials are important for making signs bright, especially at night or when it is dark. When signs use the right reflective sheeting, drivers can see them from far away. This gives drivers more time to react and stay safe.

- MUTCD compliant signs can:

- Lower injury and deadly crashes by 18 percent.

- Cut crashes in the dark by 27.5 percent.

- Drop lane departure crashes at night by 25 percent.

Traffic management companies care a lot about visibility. They pick reflective materials that follow MUTCD rules so signs are easy to see all the time. Good visibility helps stop crashes and keeps everyone safer on the road.

MUTCD Reflectivity Requirements for Compliance

Key MUTCD Sections on Retroreflectivity

The MUTCD has rules for how bright road signs must be. These rules help drivers see signs better and stay safe. Some parts of the manual talk about these rules:

- Section 2A.21 says traffic signs need retroreflective materials.

- Section 2A.22 gives more details about retroreflectivity standards.

- Section 2A.07 says regulatory, warning, and guide signs must use retroreflective sheeting or lights.

These rules help companies pick the right reflective materials for signs. The MUTCD makes sure every sign is bright enough at night and when it is dark.

Note: Retroreflective signs bounce car headlights back to drivers. This makes signs easier to see and helps stop crashes at night.

Reflectivity Classes and RA Values

The MUTCD puts reflective sheeting into three main classes. Each class has different brightness, how long it lasts, and how well it reflects light. The RA value shows how much light goes back to drivers.

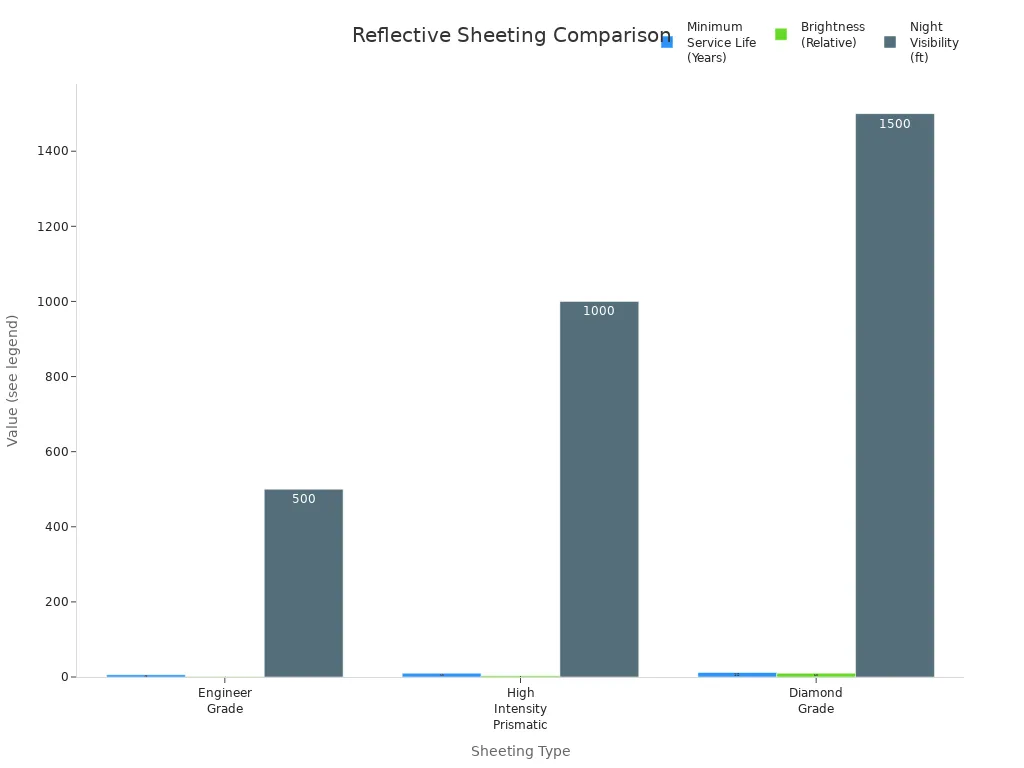

| Feature | Engineer Grade | High Intensity Prismatic | Diamond Grade |

|---|---|---|---|

| Minimum Service Life | 5-7 Years | 10 Years | 12 Years |

| Brightness | 1x | 3x | 10x |

| Night Visibility | ~500ft | ~1,000ft | ~1,500ft |

- Engineer Grade sheeting lasts up to seven years. It lets drivers see signs from 500 feet away.

- High Intensity Prismatic sheeting lasts ten years. It is three times brighter and can be seen from 1,000 feet.

- Diamond Grade sheeting lasts twelve years. It is ten times brighter and can be seen from 1,500 feet.

The MUTCD also gives minimum RA values for each sign type:

| Sign Type | Minimum RA Value (candelas per lux per meter squared) |

|---|---|

| White-on-Red | 35 |

White-on-red and white-on-green signs need a contrast ratio of 4:1. The MUTCD stopped using this rule for white-on-green signs in 1998.

Minimum Standards for MUTCD Compliant Signs

Traffic management companies must follow rules for sign size, color, and reflectivity. The MUTCD says public agencies must keep signs above the minimum brightness. These rules make sure all drivers can see signs clearly.

| Sign Color | Sheeting Type | Minimum Retroreflectivity Level |

|---|---|---|

| Black on White | Type I | ≥ 50 cd/lx/m² |

| Black on Yellow | Type I | ≥ 50 cd/lx/m² |

| White on Red | Type I | ≥ 35 cd/lx/m² |

- Regulatory signs (black on white) must be at least 50 cd/lx/m².

- Warning signs (black on yellow or orange) cannot use Type I sheeting.

- Agencies must keep signs above these levels. This rule started on June 13, 2014.

MUTCD reflectivity standards are important for road safety. Half of all traffic deaths in the United States happen at night. The crash rate at night is almost three times higher than during the day. Retroreflective signs help drivers see better, even if they are tired or have been drinking. These rules keep drivers safe and make roads better for everyone.

Tip: Checking and updating signs often helps companies follow the rules and keep roads safe.

Choosing MUTCD Compliant Signs and Materials

Selecting Reflective Sheeting

Picking the right reflective sheeting is very important. It helps teams follow MUTCD rules. Teams must think about many things to keep signs safe and legal. Where the sign is and how many cars pass by matter a lot. Busy roads need stronger materials because signs wear out faster. The MUTCD says how bright each sign must be. For example, overhead guide signs need white sheeting with at least 250 cd/lx/m². Warning signs need black-on-yellow sheeting with at least 50 cd/lx/m². Stop signs need white sheeting with at least 35 cd/lx/m² and red sheeting with at least 7 cd/lx/m². ANSI/ISEA 107-2020 gives rules for how bright and tough reflective materials must be in the U.S. Teams should check and change signs often to keep them bright at night.

Tip: Teams should look at signs often to make sure they follow the rules and are easy to see.

Matching Materials to Road Types

Different roads need different reflective materials. Cities need sheeting that works well when it is dark and there are lots of people walking. Highways need brighter materials so drivers can see signs from far away. How fast cars go, the weather, and safety needs all matter when picking materials. Using the right sheeting for each road helps teams follow the rules and keeps drivers safe.

Working with Approved Vendors

Picking approved vendors makes sure all signs follow MUTCD rules. Vendors must give products that have the right colors and sizes. The table below shows what to look for when picking vendors:

| Requirement | Description |

|---|---|

| Approved Faceplate Colors | Must match the sign’s use (Yellow for public roads, White for private, Fluorescent Yellow-Green for school zones, Safety Orange for temporary speed management) |

| New Plaque Dimension | Needed when mounting beneath Speed Limit signs for clarity |

| Display Requirements | Must show steady characters, remain blank when no vehicle is detected, and avoid flashing |

| Compliance Deadline | Agencies must comply by January 18, 2026. Early action helps avoid product backlogs and risks |

Note: Following these rules helps teams avoid delays and keeps all signs legal.

Installation and Maintenance for Safety and Compliance

Proper Installation of MUTCD Compliant Warning Signs

Teams must use the right steps to put up MUTCD compliant warning signs. This helps signs last longer and stay easy to see. Workers use reflective materials so drivers can see signs at night or in bad weather. Sometimes, they add LED signs or flashing lights for school zones or special highway warnings. Crews check signs often. They clean signs and look for any damage. If trees or cars block a sign, workers move them. These actions keep both workers and drivers safe. They also help teams follow the rules.

- Use reflective materials so signs are bright at night.

- Add LED signs or flashing lights for school zones.

- Clean and check signs often.

- Move things that block signs.

Routine Inspections and Retroreflectivity Testing

Regular checks help agencies keep MUTCD compliant warning signs working well. Workers use two main ways to test if signs are bright and easy to see:

| Method | Description |

|---|---|

| Nighttime Visual Inspections | Trained workers drive by signs at night. They look for problems, damage, or things blocking the sign. They write down what they find and check signs on a set schedule. |

| Measured Sign Retroreflectivity | Workers use special tools called retroreflectometers. These tools measure how bright a sign is. This works best when used with night checks. It helps teams spend money wisely and avoid problems. |

Training helps workers do better checks. Teams learn to spot problems and use tools the right way. This makes sure signs meet MUTCD standards.

Upgrading and Replacing Non-Compliant Signs

Agencies must fix or swap out MUTCD compliant warning signs that do not meet the rules. They follow these steps:

- Check all custom highway warning signs and school zone signs to see if they follow MUTCD rules.

- Sort signs into three groups: compliant, partly compliant, or not compliant. Teams plan which signs to fix first based on how easy they are to see and how safe they are.

- Pick trusted companies that sell reflective materials that meet the latest rules.

Upgrading to better reflective materials does not cost much compared to the whole sign budget. Local governments spend about $27.5 million over ten years. States spend about $11.8 million. This spending helps stop expensive problems from crashes caused by hard-to-see signs.

Tip: Training workers often helps them put up and care for MUTCD compliant warning signs the right way. This keeps drivers safe and helps teams follow the rules.

Addressing Challenges in Road Sign Reflectivity

Managing Over-Reflectivity and Glare

Traffic teams sometimes have problems when signs are too bright. This can make glare that distracts drivers. Over-reflectivity makes it harder to see at night or with strong headlights. Teams pick materials based on the road and how fast cars go. Engineer Grade is good for parking lots and slow roads. Diamond Grade works best for fast roads and busy intersections. LED-enhanced signs help drivers see better when it is dark. Glare screens block sunlight or headlights on highways. These ideas make driving more comfortable and safer for everyone.

To learn more about the challenges of over-reflectivity and how to balance sign brightness for optimal safety, check out our blog, Why Road Signs Don’t Need to Shine the Brightest. This blog offers a deeper look into the issue and how to find the right balance for different road environments.

Environmental Impacts on Reflectivity

Weather and the environment can make signs less reflective. UV light can break down glue and prisms. This makes signs dull and easy to break. Very hot or cold weather can make the sheeting crack or peel off. Road salt and chemicals can damage metal and wear away coatings. This happens a lot in cold places. Wet weather and humidity can lift films and let dirt hurt the sign face. IRC Code 67 says teams must check signs at least two times a year. This includes rainy seasons to keep signs easy to see and read.

| Environmental Factor | Impact on Reflective Signs |

|---|---|

| UV Exposure | Dulls and weakens reflective surfaces |

| Temperature Extremes | Causes cracking and peeling |

| Road Salt & Chemicals | Corrodes and erodes coatings |

| Moisture & Humidity | Lifts films, allows contaminants to attack sign face |

Regular checks help teams find fading early. They also check sign posts and cut plants so signs stay easy to see.

Smart Technologies for Future Compliance

New smart technology helps teams keep mutcd compliance and make signs easier to see. LED signs can change brightness when it gets lighter or darker. This cuts down glare and saves power. Sensors watch sign condition and tell teams if reflectivity gets too low. Automated testing tools help teams check signs faster and better. These new tools help keep roads safe and signs working well, even when things change.

- Faded or non-reflective panels often cause reflectivity problems.

- Reflective materials are important for seeing signs at night or in bad weather.

- Regular checks and new signs keep everything compliant and easy to see.

Tip: Smart systems help teams fix reflectivity problems fast. This keeps roads safer for everyone.

MUTCD reflectivity standards make roads safer because signs are easy to see at night. Traffic management companies give tools and teach workers so agencies can follow the rules and keep signs bright. Cities can stay compliant by keeping lists of signs, checking that signs meet retroreflectivity levels, and looking at signs often. The table below shows what is coming next for reflective technology in road signs.

| Trend | Description |

|---|---|

| Shift to Microprismatic Films | More signs will use microprismatic technology for better nighttime visibility. |

| Durability and Longevity | New films last longer and help save money on repairs. |

| Integration of Smart Technologies | Signs with sensors can check reflectivity and help keep people safe. |

| Regional Growth | The Asia-Pacific area is growing fast and making new ideas. |

FAQ

What makes MUTCD compliant signs different from regular signs?

MUTCD compliant signs must follow strict rules for colors and shapes. They use approved warning sign colors and shapes. These signs meet retroreflective standards. Agencies put these signs on highways, crossings, and at curves and intersections.

Why do highway warning signs use specific sheeting and colors?

Highway warning signs need special sheeting to be easy to see. MUTCD codes say what colors and shapes each warning sign should have. Yellow and orange are the main warning sign colors. Sheeting helps drivers see crossing signs at night.

How often should agencies inspect warning signs for retroreflective performance?

Agencies check warning signs two times every year. They look at the sheeting, colors, and shapes. They use tools to test how bright the signs are. Regular checks keep MUTCD compliant signs bright and easy to see.

What types of sheeting are used for curve and intersection warning signs?

Curve and intersection warning signs use prismatic sheeting. This sheeting lasts longer and reflects more light. Agencies pick sheeting by following MUTCD codes, warning sign colors, and shapes. Prismatic sheeting works well for crossings and highways.