Scegliere il giusto grado riflettente per segnaletica di cantiere non si tratta solo di renderli visibili; si tratta di garantire che i conducenti possano leggerli in tempo per reagire adeguatamente. Guida notturna, piovere, e la nebbia sono tutte condizioni che riducono drasticamente la visibilità, aumentando la probabilità di incidenti. Questo blog esplora il motivo per cui è importante scegliere il giusto rivestimento retroriflettente segnaletica di cantiere in base a fattori ambientali come le condizioni meteorologiche e di illuminazione.

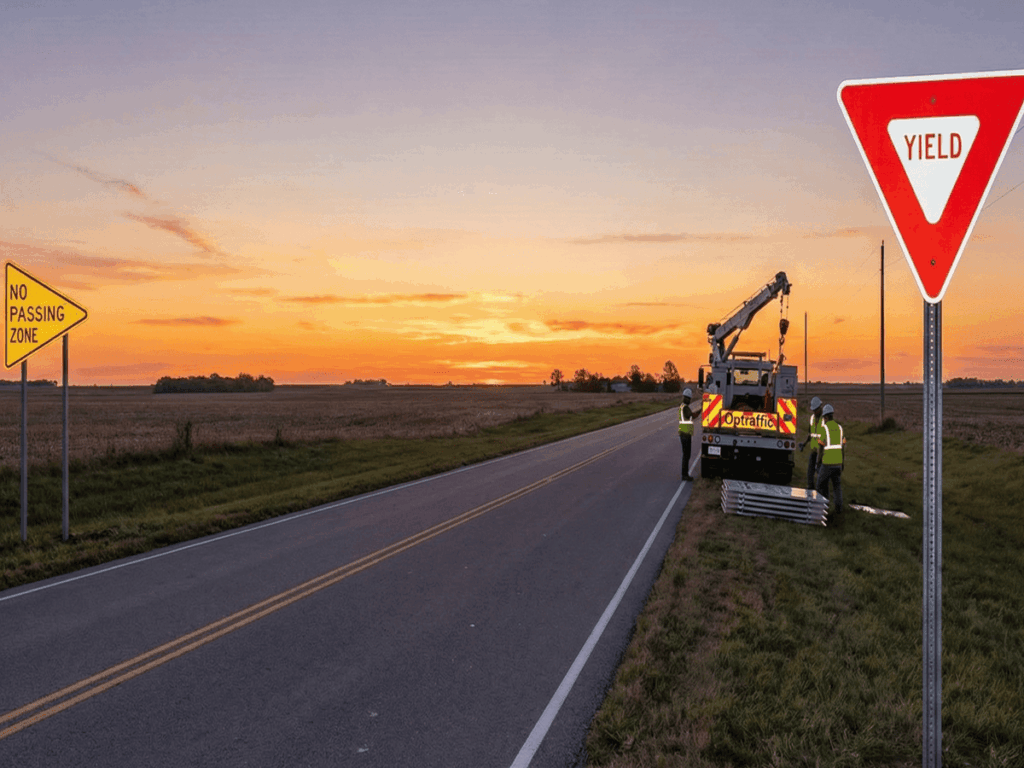

A OPTRAFFICO, comprendiamo il ruolo fondamentale dell'alta qualità segnaletica da cantiere personalizzata giocare nel garantire la sicurezza nelle zone di lavoro. Il nostro marchio si impegna a fornire segnaletica da cantiere durevole e affidabile che funzioni eccezionalmente bene nelle condizioni più difficili. Con un focus sull'innovazione, qualità, e conformità, OPTRAFFIC offre soluzioni retroriflettenti progettate per massimizzare la visibilità, anche in condizioni di scarsa illuminazione e condizioni meteorologiche avverse. Che si tratti di lavori stradali temporanei o di zone di costruzione a lungo termine, OPTRAFFIC garantisce che la vostra segnaletica soddisfi i più elevati standard di sicurezza, contribuendo a garantire la sicurezza sia dei lavoratori che degli autisti.

Perché scegliere il giusto potere riflettente per la segnaletica dei cantieri edili è fondamentale per la notte, Piovere, e condizioni di nebbia

L'importanza della visibilità nei segnali di cantiere in condizioni di scarsa illuminazione

Segnali di cantiere sono fondamentali per guidare i conducenti attraverso le zone di lavoro, ma devono essere visibili in diverse condizioni di luce. Di notte, i conducenti fanno affidamento sui fari dei loro veicoli per vedere i segnali. Tuttavia, l'intensità e la qualità della retroriflessione determinano la qualità con cui i fari illuminano i segnali. Cartelli riflettenti da cantiere deve restituire la luce al conducente in modo tale da garantire che il messaggio sia visibile da una distanza sufficiente.

Secondo la FHWA (Amministrazione federale delle autostrade), condizioni legate al meteo, compresa la pioggia, nebbia, e neve, sono responsabili di una parte significativa degli incidenti stradali negli Stati Uniti. Infatti, Sopra 77% degli incidenti stradali si verificano durante la pioggia o la nebbia. Queste condizioni meteorologiche compromettono drasticamente la visibilità e la trazione del manto stradale, con la sola nebbia che contribuisce a più di 38,700 incidenti all'anno. Ciò rende chiaro che la segnaletica dei cantieri edili deve essere progettata per resistere e funzionare bene in questi ambienti difficili, garantendo che i conducenti possano reagire in tempo anche quando le condizioni sono tutt’altro che ideali.

Problemi di visibilità legati alle condizioni meteorologiche nelle zone di costruzione

La pioggia e la nebbia causano la dispersione della luce dei fari, riducendo sensibilmente la distanza di leggibilità della segnaletica di cantiere. Le superfici stradali bagnate spesso provocano abbagliamento, rendendo più difficile per i conducenti leggere messaggi importanti come “lavori stradali da percorrere” o “chiusura corsia”. Questo problema è aggravato dalla nebbia, che può ridurre la portata visibile a pochi metri, rendendo ancora più difficile per i conducenti notare i segnali in tempo.

Il manuale della capacità autostradale 2000 evidenzia come uniforme una pioggia leggera può ridurre la velocità dell'autostrada fino a 13%, con forti piogge che hanno causato una diminuzione ancora più significativa, fino a 16%. Allo stesso modo, nebbia e scarsa visibilità possono causare riduzioni di velocità che vanno da 10% A 12%. Quando i conducenti si muovono più lentamente, la loro capacità di reagire ai segnali, soprattutto nelle zone ad alta velocità come le zone di costruzione, viene compromessa.

La segnaletica di sicurezza nei cantieri deve essere leggibile da una lunga distanza per fornire ai conducenti tempo sufficiente per reagire, Soprattutto quando la visibilità è scarsa. Se i segnali stradali dei cantieri non sono sufficientemente retroriflettenti, gli automobilisti potrebbero non vederli finché non sarà troppo tardi, potenzialmente portando a pericolose manovre dell’ultimo secondo, bruschi cambi di corsia, o avvisi mancati.

Le zone di lavoro presentano anche ulteriori problemi di visibilità, come gli avvicinamenti ad alta velocità, spostamenti di corsia, e barriere edilizie, che accrescono ulteriormente l’urgenza di garantire che la segnaletica sia visibile e leggibile. Secondo il Manuale della capacità autostradale, la neve e la pioggia possono ridurre la velocità a flusso libero sulle autostrade fino a 17% Durante la forte pioggia, e la neve può causare riduzioni di capacità che vanno da 12% A 30%. Ciò rallenta il traffico e riduce il tempo a disposizione dei conducenti per spostarsi in sicurezza nell'area di lavoro. Se la segnaletica del cantiere non soddisfa gli standard di visibilità, diventa più probabile che i conducenti effettuino manovre non sicure o non rispondano in tempo agli avvisi critici.

Cosa controlla effettivamente il "grado riflettente" nelle condizioni di guida reali

Nozioni di base sulla retroriflessione: Cosa succede quando i fari incontrano il materiale retroriflettente

Il rivestimento retroriflettente è progettato per riflettere la luce proveniente dai fari di un veicolo verso il conducente. Questo processo è fondamentale per la visibilità notturna perché consente al conducente di vedere il segnale mentre si avvicina. Tuttavia, non tutti i materiali retroriflettenti sono uguali. L'intensità della riflessione determina quanto sarà visibile un segnale da una determinata distanza.

ASTM D4956 e AASHTO M 268 definire gli standard di retroriflessione per la segnaletica stradale, specificando la quantità di luce restituita al conducente in base ai diversi tipi di teli. I rivestimenti prismatici ad alta intensità forniscono una retroriflessione più forte rispetto ai rivestimenti di tipo tecnico, soprattutto in condizioni meteorologiche a scarsa o avversa.

Visibilità vs leggibilità: Come la “luminosità” da sola non è sufficiente

Un segnale può essere luminoso ma non garantire comunque la leggibilità di notte o in condizioni di pioggia. Il contrasto tra il testo e lo sfondo è un fattore cruciale per la leggibilità. Se il contrasto non è sufficiente, o se il segnale non è sufficientemente riflettente, apparirà sbiadito sotto i fari, rendendo difficile per i conducenti leggere il messaggio in tempo. Il contrasto garantisce che il conducente possa distinguere il testo e le frecce del segnale dallo sfondo, soprattutto in caso di pioggia o nebbia dove la visibilità è già ridotta.

Nell'ambito della segnaletica di cantiere, la retroriflettenza e il contrasto sono i due fattori di prestazione più importanti. IL MUTCD (Manuale sui dispositivi di controllo del traffico uniforme) delinea la retroriflessione minima richiesta per la segnaletica utilizzata di notte e in caso di maltempo, ma gli appaltatori dovrebbero andare oltre il minimo per garantire che la segnaletica rimanga visibile in tutte le condizioni.

Perché le zone di lavoro sono più severe sulla segnaletica: Cambiamenti di velocità, Cambi di corsia, Fonti di abbagliamento, e disordine visivo

Le zone di costruzione spesso presentano zone ad alta velocità, spostamenti di corsia, e disordine visivo come attrezzature parcheggiate e barriere. Questi elementi possono ostacolare la capacità del conducente di leggere i segnali in tempo. Per esempio, un segnale che non è sufficientemente retroriflettente potrebbe apparire visibile alla luce del giorno ma diventare difficile da leggere nella nebbia notturna o nella pioggia. La ridotta distanza di visibilità in questi ambienti aumenta il rischio di reazioni tardive, come una frenata improvvisa, sterzando, o deviazioni di corsia.

Per contrastare questo, gli appaltatori devono selezionare segnaletica di cantiere che offre un'elevata visibilità in una varietà di condizioni. Quando si scelgono materiali retroriflettenti, dovrebbero considerare fattori come i limiti di velocità, condizioni meteorologiche, e geometria stradale (curve, creste, ecc.).

Gli appaltatori di base dell'autorità dovrebbero allinearsi

MUTCD: I segnali utilizzati di notte devono essere retroriflettenti o illuminati

Il MUTCD stabilisce standard chiari per la retroriflessione dei segnali di controllo del traffico utilizzati di notte. Questi standard richiedono che i segnali siano retroriflettenti o illuminati per essere visibili in condizioni di scarsa illuminazione. Il MUTCD specifica inoltre i requisiti retroriflettenti per la segnaletica utilizzata durante il giorno e la notte, con standard aggiuntivi per la segnaletica nelle zone di lavoro. Gli appaltatori devono allineare la segnaletica del cantiere con queste linee guida per garantire che siano conformi alle normative federali.

ASTM D4956 e AASHTO M 268: Le principali norme che regolano la retroriflettenza

ASTM D4956 fornisce lo standard per i rivestimenti retroriflettenti negli Stati Uniti. Definisce i criteri di prestazione per il livello tecnico, Alta intensità, e materiali prismatici utilizzati nei segnali stradali di costruzione. Questo standard aiuta gli appaltatori a scegliere la pendenza appropriata in base alle condizioni di traffico previste, tempo atmosferico, e durata del progetto. AASHTO M 268 delinea standard di prestazione simili, fornendo ulteriori indicazioni per produttori e appaltatori nella scelta dei materiali riflettenti.

Perché la pioggia e la nebbia cambiano il significato di "buona riflettività".

Abbagliamento notturno e perdita di contrasto: Perché la leggenda/freccia si cancella

In condizioni di pioggia, le strade bagnate diffondono la luce e riducono la capacità dei segnali di riflettere la luce verso il conducente. Ciò può portare a un bagliore che oscura il messaggio del segnale. Senza un'adeguata retroriflettenza, i segnali di sicurezza nei lavori di costruzione diventano difficili da leggere, soprattutto quando i fari si riflettono sulle superfici bagnate, creando confusione.

Nebbia e spray riducono la distanza di leggibilità: Perché i conducenti hanno bisogno di messaggi leggibili prima

Nebbia e spruzzi riducono ulteriormente la distanza di visibilità, a volte solo a pochi metri. In queste condizioni, è importante che i conducenti siano in grado di leggere i segnali di pericolo dei cantieri da una distanza maggiore per avere il tempo di reagire. Il rivestimento prismatico può fornire una migliore leggibilità in caso di nebbia offrendo una gamma più ampia di angoli di riflessione.

Perché il rivestimento prismatico grandangolare aiuta in caso di nebbia e pioggia

Il rivestimento prismatico ha un angolo di retroriflessione più ampio rispetto al rivestimento a sfere. Ciò lo rende più efficace in condizioni di nebbia o pioggia perché può riflettere la luce da una gamma più ampia di angolazioni. Il rivestimento prismatico di alta qualità aiuta i conducenti a vedere i segnali da più lontano, anche quando la loro visibilità è limitata dalle condizioni meteorologiche.

Famiglie di lamiere e appaltatori di "qualità" si incontrano effettivamente

Rivestimento di livello tecnico (Tipo I.): Dove funziona, Dove diventa un rischio

Il rivestimento di qualità tecnica è il materiale retroriflettente più basilare, comunemente usato per zone a bassa velocità e uso a breve termine. Tuttavia, non è adatto per lavori notturni o zone ad alta velocità dove è richiesta una maggiore retroriflessione. Per la segnaletica di cantiere in zone ad alta velocità o con condizioni meteorologiche avverse, Si consiglia la lamiera di tipo III/IV o prismatica.

Prismatico ad alta intensità/alta intensità (Tipo III/IV): La zona di lavoro predefinita

La pellicola prismatica ad alta intensità è ideale per la segnaletica stradale di costruzione di notte o in condizioni di scarsa illuminazione. Fornisce una forte retroriflessione notturna ed è perfetto per aree con traffico ad alta velocità o scarsa illuminazione. Questa copertura è la scelta predefinita per le zone di lavoro in cui la visibilità è un problema.

Prismatico ad altissima/ultra-alta intensità (Tipo VIII/XI): La scelta Premium per le zone ad alto rischio

Il rivestimento prismatico di Tipo VIII o Tipo XI fornisce il massimo livello di retroriflessione. È meglio per progetti a lungo termine, zone ad alta velocità, e aree con frequenti condizioni meteorologiche avverse. Questo telo offre visibilità e contrasto eccellenti in condizioni di pioggia o nebbia.

Perline vs. Prismatico: Perché l'angolo di visione, Uniformità, e la questione della "luminosità utilizzabile".

La pellicola con perline può subire prestazioni ridotte in caso di pioggia e nebbia a causa del suo stretto angolo retroriflettente. Il rivestimento prismatico offre un angolo riflettente più ampio e fornisce un migliore contrasto e uniformità, rendendolo l'opzione migliore per le zone di lavoro con condizioni meteorologiche avverse.

Un metodo di selezione pratico che mira alla leggibilità notturna in caso di pioggia/nebbia

Fare un passo 1: Imposta l'obiettivo di leggibilità come problema di distanza, Non è un problema di luminosità

Inizia considerando la distanza di visibilità necessaria di notte o in condizioni di pioggia. In zone ad alta velocità, la retroriflettenza diventa il fattore più importante, non solo luminosità.

Fare un passo 2: Decidi di quanto “margine meteorologico” ha bisogno il lavoro

Se la zona di costruzione è soggetta a pioggia o nebbia frequenti, dare la priorità al rivestimento prismatico o ad alta intensità. Questi materiali offrono prestazioni superiori e garantiscono la sicurezza del conducente in condizioni meteorologiche avverse.

Fare un passo 3: Abbina il margine alla famiglia di fogli

Per zone ad alta velocità, per garantire una leggibilità chiara da una distanza sufficiente è necessario un rivestimento prismatico ad alta intensità o di Tipo IV/Tipo XI. In zone a bassa velocità o asciutte, un rivestimento di qualità ingegneristica potrebbe essere sufficiente.

Fare un passo 4: Controllo del rischio di abbagliamento e dell'uniformità

Evitare l'uso di materiali di bassa qualità che causano abbagliamento o retroriflessione irregolare. Ciò garantisce una leggibilità costante sotto i fari, piovere, e nebbia.

Conclusione

La scelta del grado corretto della segnaletica del cantiere è fondamentale per la sicurezza del conducente durante la notte, piovere, e condizioni di nebbia. Per zone ad alta velocità e progetti a lungo termine, il rivestimento prismatico ad alta intensità offre la migliore visibilità. Per zone a velocità ridotta o progetti solo diurni, può essere sufficiente un rivestimento di qualità ingegneristica, ma dovrebbe essere potenziato per il lavoro notturno o per condizioni meteorologiche avverse.

Con attenzione selezionando i giusti materiali riflettenti e garantendo il corretto posizionamento della segnaletica, gli appaltatori possono ridurre significativamente il rischio di incidenti nelle zone di costruzione e aiutare gli autisti a reagire in tempo per evitare situazioni pericolose.

Domande frequenti

Perché il materiale prismatico ad alta intensità è consigliato per la segnaletica dei cantieri in caso di maltempo?

Il materiale prismatico ad alta intensità offre una migliore leggibilità notturna e funziona bene in condizioni di umidità e nebbia. Fornisce una riflessione coerente su ampi angoli di visione, garantendo la visibilità a distanza.

La segnaletica di livello tecnico può essere utilizzata nelle zone di costruzione ad alta velocità?

Non è raccomandato, poiché i segnali di livello tecnico non forniscono visibilità o contrasto sufficienti in condizioni di scarsa illuminazione o di maltempo. Il rivestimento prismatico ad alta intensità è l'opzione migliore per le zone ad alta velocità.

Come posso verificare se un segnale di cantiere sarà visibile in caso di pioggia o nebbia?

Eseguire un test notturno e un test su strada bagnata per verificare l'abbagliamento e la leggibilità. Se il segnale si offusca o sbiadisce sotto i fari o in condizioni di pioggia, potrebbe essere necessario aggiornarlo a un materiale prismatico di qualità superiore.