In che modo le barriere riempite d'acqua rendono i lavori stradali e i cantieri più sicuri e migliori? Negli ultimi dieci anni, il settore è cambiato molto. Le persone ora vogliono soluzioni di sicurezza che possano adattarsi e durare a lungo. Le aziende utilizzano l’illuminazione a LED che consente di risparmiare energia. Utilizzano anche plastica riciclata e tecnologia intelligente. Queste cose aiutano le persone a vedere meglio e a proteggere l’ambiente. Le barriere riempite d'acqua sono una buona scelta. Sono facili da spostare e facili da vedere in molte situazioni. Queste nuove idee dimostrano che le persone si preoccupano maggiormente della sicurezza pubblica e della buona gestione dei siti.

Optraffic offerte barriere piene d'acqua designed for maximum safety and ease of use. Our barriers provide excellent visibility, adaptability, and environmental benefits, making them ideal for construction sites and roadworks. Explore our range today to ensure your site is safer, più efficiente, ed ecologico.

Takeaway chiave

- Water filled barriers are light when empty. They become heavy when filled. This makes them easy to move. They are also strong enough to protect people. They help control traffic too.

- These barriers make places safer by absorbing crash impacts. They are easy to see because of their bright colours. They have reflective strips as well. You can connect them easily to fit different sites.

- They save time and money because they are quick to set up. Puoi usarli ancora e ancora. You do not need heavy machines to put them in or take them out.

- Water filled barriers work well in many places. You can use them at roadworks, cantieri, eventi, ed emergenze. They help keep workers, conducenti, e i pedoni sicuri.

- Picking the right barriers is important. Following the correct steps for installation and maintenance keeps everyone safe for a long time. It also makes sure you follow UK rules.

Water Filled Barriers Overview

Definizione

Water filled barriers help keep people safe on roads and worksites. They are used to control traffic and protect workers. These barriers have a plastic shell that is empty at first. Workers fill them with water when they get to the site. When there is no water inside, Sono leggeri e facili da trasportare. Quando riempito con acqua, they become heavy and hard to move. This makes them good for stopping cars or showing people where to go.

Caratteristiche chiave

Water filled barriers are different from other barriers because of their special design and useful features.

- Sono leggeri quando sono vuoti, Quindi sono facili da spostare e configurare.

- Quando riempito con acqua, they stay in place and do not tip over easily.

- They are made from strong HDPE plastic that does not break easily and can handle bad weather.

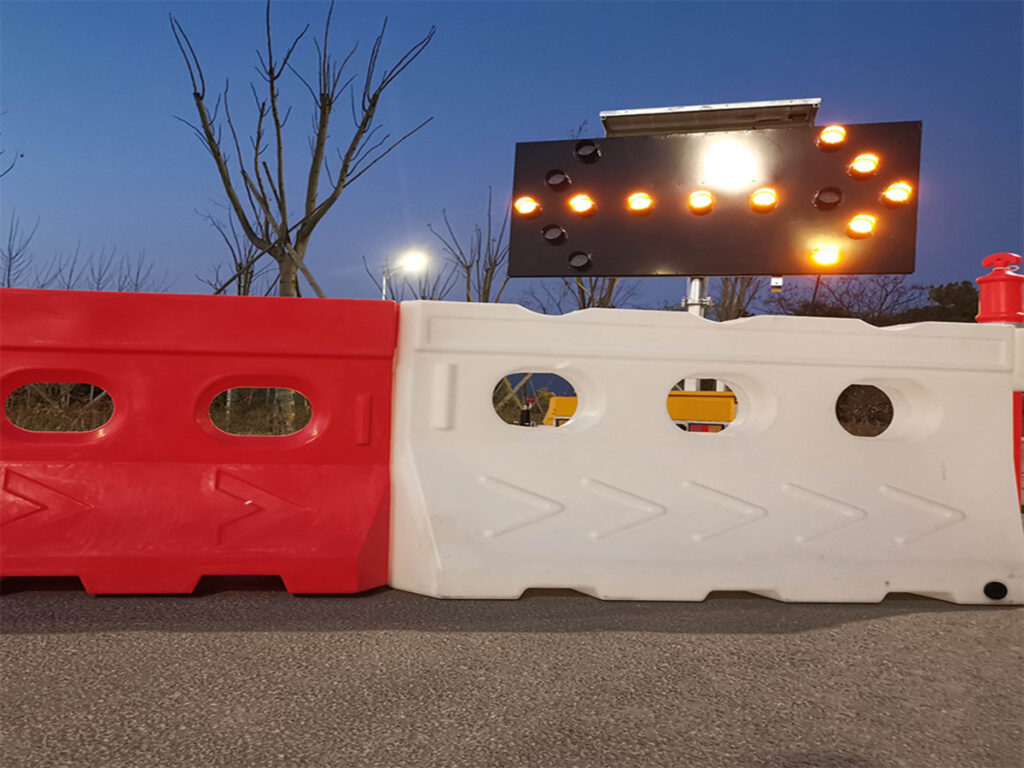

- Bright colours and shiny strips help people see them, Anche quando è buio.

- You can connect them together to fit many different places.

- They work well for short or medium jobs, like keeping cars apart or helping with crowds at events.

- They are fast to put up and take down, so you do not need big machines.

- You can use them again and change where they go if you need to.

Mancia: You can empty water filled barriers and move them to new places. This is good for jobs that change a lot.

Materiali

Most water filled barriers are made from HDPE plastic. This plastic is very strong and does not break easily. It can stand up to sun, piovere, and wind without getting damaged. Some traffic barriers use other materials, like fibreglass mixed with plastic, to make them strong but not too heavy. The material you pick changes how well the barrier works, how long it lasts, and how easy it is to move. The way the barriers are made, like using special moulds, also changes how they look and how much they cost. HDPE barriers are popular because they are strong, curva, e durano a lungo.

Evolution of Road Barriers

Traditional Barriers

Molto tempo fa, road workers used heavy barriers for safety. They used concrete and steel to keep cars away from work areas. These strong barriers kept people safe but caused problems. Moving concrete barriers needed special machines. Setting them up took a lot of time. Workers found it hard to move them quickly if plans changed.

Negli anni '90, workers started using hollow plastic barriers. These were lighter than concrete ones. People could carry them by hand. But because they were light, they sometimes moved when hit. Even with water inside, they did not always pass safety tests. Engineers tried putting steel inside to make them stronger. This made new problems. Barriers with steel could still move too much in a crash. They also needed more space between the barrier and the work area. Many sites did not have enough room for this extra space.

Nota: Old barriers kept workers safe but made roadwork slow and hard to change.

Rise of Water-Filled Barriers

Water-filled barriers made roadwork safer and easier. Designers wanted barriers that were strong, flessibile, e facile da usare. They made the plastic shell better and made sure it could hold enough water. These new barriers passed tough safety rules for roadwork. Workers could move empty barriers without machines. Filling them with water made them heavy enough to stop cars.

Water-filled barriers did more than just keep people safe. Their bright colours and shiny strips helped drivers and workers see them. Teams could join barriers together in many shapes and sizes. This helped protect both cars and people in different places. Oggi, water-filled barriers are very important for roadwork. They help keep sites safe and help work go faster.

Barriere riempite d'acqua: Applicazioni

Water filled barriers are used in many places today. Their design lets them fit many different needs. These barriers help with traffic, siti di costruzione, big events, ed emergenze. Using them keeps people and property safer.

Gestione del traffico

Traffic management needs good ways to keep roads safe. Water filled barriers are important for this. They help guide cars through work zones and show where roads are closed. They also protect accident sites. Their bright colours and shiny parts make them easy to see. This helps drivers notice them in busy or dangerous places.

- Water filled barriers stay in place when filled, even in strong wind or heavy traffic.

- Teams can join them together in many shapes for different traffic needs.

- They are quick to put up and take down, so they work well for short-term road changes.

Cities use these barriers to keep work areas safe and traffic moving. If a car hits them, they absorb some of the force. This means people are less likely to get hurt than with hard barriers. They are also easier to move and set up than old barriers, so many people choose them now.

Cantieri

Building sites can be dangerous for workers and drivers. Water filled barriers help keep work areas apart from traffic. They guide cars safely around building zones. Teams can put empty barriers where they want, connect them, and fill them with water or sand to make them steady.

- Bright colours and shiny strips warn drivers about danger.

- Fast setup and removal save time and money.

- They absorb hits, which helps keep people safe if there is a crash.

- Puoi usarli di nuovo, which is better for the environment.

Road jobs use these barriers because they are easy to move as the site changes. They do not need much care and last a long time, Quindi risparmiano denaro. You can add signs or logos to them to fit special needs and rules.

Events and Pedestrian Safety

Big events like concerts and races need good crowd control. Water filled barriers make strong borders that drivers can see. This stops cars from going into places where people walk and keeps everyone safer.

- Barriers help guide people and stop them from going into unsafe places.

- Their bright look makes drivers slow down and keeps walkers safe.

- They are easy to move and set up for short events.

Event teams use these barriers to keep order and mark off special areas. UN 2021 report says using water filled barriers can cut problems by up to 30%. You can change their shape quickly, so they work well for busy events and keep everyone safe.

Emergency and Military Use

Emergencies and military jobs often need fast safety setups. Water filled barriers are good for making safe borders at crash sites or closed roads. Quando vuoto, they are light and easy to move.

- Emergency teams use them to make safe areas and protect people.

- Military groups use them for extra safety in risky places.

- You can join them in many ways to fit different needs.

These traffic barriers are good for quick road blocks and traffic control in emergencies. Rimangono costanti e sono facili da vedere, even when things are tough. Water filled barriers help keep people safe and make work go smoothly.

Benefits of Water-Filled Barriers

Safety and Impact Absorption

Water-filled barriers help keep people safe at roadworks and worksites. They are made to take in the force from crashes. This lowers the chance of someone getting hurt. Alcuni tipi, like the Yodock barrier, use special Energy Disbursement Cells. These are made from strong polyethylene. These barriers have passed tough crash tests. They also meet rules set by the Federal Highway Administration.

- The barriers spread out the force from a crash, so there is less damage.

- They keep workers and drivers safe.

- Many people trust them because they work well and have certificates.

Water-filled barriers make roads and worksites safer for everyone. They are good at taking in hits, so people trust them for road jobs and traffic control.

Visibility and Modularity

Water filled barriers are easy to see because they are bright and have shiny strips. This helps drivers and walkers spot danger, Anche in caso di maltempo. Teams can join the barriers together in many ways.

Teams can change the shape of the barriers fast to fit new needs.

Questo li rende utili per molti lavori, like guiding cars or keeping crowds safe. Their bright look and flexible design help teams plan for safety.

Portability and Installation

Water filled barriers are light when empty, Quindi i lavoratori possono spostarli facilmente. They do not need big machines to set up. Quando riempito con acqua, they stay in place and protect people.

- They are quick to put up and take down, che consente di risparmiare tempo.

- You can use them again at other sites, Quindi risparmiano denaro.

Because they are easy to move, teams can change things fast and keep everyone safe.

Costo-efficacia

Water-filled barriers are a smart choice for short jobs or when things change often. The table below shows how they compare to concrete barriers:

| Tipo di barriera | Costo iniziale | Manutenzione & Durabilità | Lifespan Cost Considerations |

|---|---|---|---|

| Barriere piene d'acqua | Usually cost less at first | Can get damaged or leak; need more care | Puoi usarli di nuovo; good for short jobs; lighter and easier to move and store |

| Barriere di cemento | Cost more at first | Last longer and need less care | Better for long jobs even though they cost more at first; heavy and need special machines to move |

Water filled barriers cost less to move and set up. This makes them a good pick for many roadwork teams.

Impatto ambientale

Water-filled barriers are better for the environment because you can use them again and they are not heavy. Nuovi materiali, like nanocellulose films, might make barriers even greener in the future. These new materials are strong and can be recycled or break down naturally. Studies show that making barriers lighter helps the environment more than just making them recyclable.

Water filled barriers already help the planet because they can be used again and need less energy to move.

Picking water-filled barriers helps teams protect the environment and keep people safe.

Water Filled Barriers vs Other Barriers

Barriere di cemento

Concrete barriers have been used for a long time. They are strong and can stop big vehicles. These barriers do not move much when hit. But they do not soak up the force from crashes. This means drivers and people walking can get hurt more. Concrete barriers are very heavy and need special machines to move. Teams need more people and time to put them in place. Col tempo, concrete can break down and cost more to fix.

| Aspetto | Barriere riempite d'acqua | Barriere di cemento |

|---|---|---|

| Sicurezza | Absorb impact better, riducendo gli infortuni e i decessi; alta visibilità; safer crash cushion | Minimal deflection; solid protection for workers; can stop large vehicles but less impact absorption |

| Costo | Cost-efficient; cheaper upfront and over time; lower transportation and labour costs | Higher setup costs; heavy equipment and man-hours needed; degrade over time |

| Ease of Deployment | Lightweight when empty; portatile; facile da installare, rimuovere, e memorizzare; modular and customisable | Heavy and immobile; difficult to store; not customisable; slow to deploy |

Nota: Water filled barriers are cheaper to move and set up. Teams fill them with water at the site, so they are quick to use.

Metal Barriers

Metal barriers are very strong and stiff. They are used in places that are more dangerous. These barriers push cars away if there is a crash. But they do not soak up the crash energy. Hitting a metal barrier can badly damage cars and hurt drivers. Metal barriers are heavy and hard to move. Teams find it tough to change where they are. They work best in places where they stay for a long time.

- Water filled barriers soak up crash energy and keep people safer.

- Metal barriers are good for places that do not change, but they are riskier in crashes.

- Water filled barriers are easy to move and change, so they are good for short jobs or events.

Strengths and Limitations

Each barrier type has its own good points. Water filled barriers are easy to see, soak up hits, and are simple to use. Teams can put them up fast for roadwork, eventi, o siti di costruzione. Concrete and metal barriers are strong and good for places that need to stay safe for a long time. But they are hard to move and can be more dangerous for drivers.

Mancia: Water filled barriers are flexible and safe for changing jobs. Concrete and metal barriers are best for strong, long-lasting safety.

Best Practices for Water-Filled Barriers

Selection and Compliance

Picking the right water-filled barriers means knowing what your site needs. Teams should check how big, pesante, and strong the barriers are. Barriers must follow UK safety rules like BS One 1317. Teams should pick products that show clear certificates. Checking local council rules helps stop problems. Renting barriers is good for short jobs or events. Buying is better if you use them often or for a long time. Teams should look at costs and where to store barriers before choosing.

Mancia: Always look for clear certificate marks to make sure the barriers follow UK rules.

Installation Guide

Putting barriers in the right way keeps them safe and steady. Teams should do these steps:

- Put empty barriers where you want them.

- Join barriers with the links or fasteners they have.

- Fill each barrier with water to the right level.

- Check for leaks or loose parts.

- Add shiny strips or signs if you need them.

Workers should wear safety gear when putting up barriers. Teams should check barriers after filling to make sure they are steady. Good setup makes the site safer and more secure.

Maintenance and Storage

Looking after barriers helps them last longer. Teams should:

- Wash barriers with gentle soap and water to get rid of dirt.

- Check barriers for cracks, perdite, or weak places.

- Tighten any loose parts or fasteners.

- Keep barriers out of strong sun and very hot places.

- Store barriers in a dry, cool spot to stop damage.

| Componente | Materiale | Maintenance and Storage Practices | Durata della vita prevista |

|---|---|---|---|

| Terminals & Giunzioni | Alluminio | Be careful with them and store them well | 10–20 anni |

| Straps | Acciaio inossidabile, Alluminio | Use and look after them the right way | 10–20 anni |

| Tubes | PP and PE | Keep in dark, dry places; clean and check often | 5–10 anni |

Regular care keeps barriers strong and ready for every job.

Tendenze future

Innovations in Design

Water-filled barriers have changed a lot lately. Designers use stronger materials that last longer. Questi materiali possono gestire il maltempo. Bright colours help drivers and workers see barriers from far away. This makes roads and worksites safer. Modular designs let teams join barriers in many ways. This helps them fit all kinds of projects.

I recenti miglioramenti includono:

- Barriers made with advanced polymers for more strength and flexibility.

- Parts that connect easily for fast setup and removal.

- Ready-made pieces that save time when installing.

- Digital tools that help teams plan and check barrier layouts before work starts.

These changes make barriers more reliable and simple to use. They also help teams finish jobs faster and keep everyone safer.

Smart Barriers and IoT

Technology is now very important for safety. Smart water-filled barriers use sensors and wireless systems to spot problems. These barriers can send alerts if they move or get damaged. Teams can check the barriers from far away using mobile devices.

Some smart barriers use fibre optic sensors to notice pressure or movement changes. This helps teams fix problems before they get worse. Automated guidance systems can help put barriers in the right place every time.

Smart barriers help teams keep sites safe with less work and more control.

Sostenibilità

Sustainability is more important than ever before. Makers now use recycled plastics like polystyrene and polyethylene terephthalate to build barriers. Some barriers use rubber from old tyres or cellulose from plants. These choices help cut down on waste and protect the planet.

When barriers are old, they can be cleaned and used again. Some new barriers use special chemistry so they can be broken down and rebuilt many times without losing strength. This closed-loop recycling means less waste and more reuse.

| Materiale utilizzato | Fonte | Beneficio |

|---|---|---|

| Recycled polymers | Plastic bottles, tyres | Riduce i rifiuti delle discariche |

| Cellulose derivatives | Plants | Biodegradable and renewable |

| Closed-loop membranes | Advanced chemistry | Può essere riciclato più volte |

These steps help water-filled barriers support a cleaner and greener future.

Water filled barriers give good safety and can be used in many ways. Teams can put them in place fast and move them when needed. These barriers help keep workers and people safe. Using the right steps makes sure each barrier works well and follows all rules.

For more information on selecting the right traffic barricades for your needs, Dai un'occhiata al nostro blog, Tutto quello che devi sapere sulle barricate del traffico in vendita.

Domande frequenti

What is the main purpose of water-filled barriers?

Water-filled barriers help keep people safe. Guidano il traffico, tutelare i lavoratori, and mark off dangerous areas. Teams use them on roads, agli eventi, and on building sites.

How do you install a water-filled barrier?

- Place the empty barrier where needed.

- Connect it to other barriers if required.

- Fill it with water until full.

- Check for leaks and make sure it stands firm.

Mancia: Always follow the manufacturer’s instructions for best results.

Can water-filled barriers be reused?

SÌ, teams can empty and move these barriers to new locations. They last for many uses if cared for properly. Regular checks help keep them in good condition.

Are water-filled barriers suitable for all weather conditions?

Water-filled barriers work well in rain, vento, e sole. The strong plastic shell resists damage from weather. Teams should check barriers after storms to ensure safety.