Le basi del cono del traffico svolgono un ruolo vitale nel mantenere la stabilità e la trazione su varie superfici. Il loro design incorpora forme e materiali specifici per ottimizzare la distribuzione e l'attrito del peso. Materiali comuni come PVC, gomma, e la plastica contribuisce a queste proprietà in modi unici.

Per esempio, Le basi di gomma offrono un'ottima presa su superfici lisce, mentre le basi ponderate quadrate resistono alla mancia in condizioni ventose. Queste caratteristiche garantiscono che i coni di sicurezza pesante rimangono efficaci in ambienti difficili.

OPTsegna i coni stradali sono progettati pensando a questi principi, con basi appositamente progettate che migliorano la stabilità e la trazione. Che si tratti di una base di gomma per una presa superiore o una base quadrata ponderata per resistere al vento, Segni OPT garantisce la durata e l'affidabilità in tutte le condizioni. Questi coni di sicurezza offrono prestazioni di lunga durata, renderli una scelta ideale per ambienti sia ad alto traffico che impegnativo.

Lo scopo della progettazione della base del cono del traffico

Le basi del cono del traffico fungono da base per stabilità e funzionalità. Il loro design garantisce che i coni rimangono dritti ed efficaci in ambienti diversi, Dalle zone di costruzione alle strade ad alto traffico. Concentrandosi sulle funzioni chiave e sull'ottimizzazione della forma, Queste basi migliorano la sicurezza e le prestazioni.

Funzioni chiave della base

Stabilità e resistenza alla mancia

La base di un cono di traffico svolge un ruolo fondamentale nella prevenzione della mancia. Una base ben progettata abbassa il centro di gravità del cono, rendendolo più stabile contro forze esterne come il vento o le bozze del veicolo. Per esempio, Le basi ponderate quadrate resistono alla mancia in esterno, condizioni ventose. Le basi di gomma forniscono proprietà non slip, rendendoli ideali per superfici interne lisce. Queste caratteristiche assicurano che i coni rimangano in atto, anche in ambienti impegnativi.

Durata e prestazioni a lungo termine

La durata è un'altra funzione essenziale delle basi del cono del traffico. Materiali come la gomma e il PVC resistono all'usura da un uso ripetuto. Le basi progettate per i coni di sicurezza pesante spesso incorporano materiali robusti per sopportare scenari di tempo e clima ad alto impatto. Questa durata garantisce prestazioni a lungo termine, Ridurre la necessità di sostituti frequenti.

Forme di base comuni e i loro benefici

Basi quadrate per un contatto di superficie più ampio

Basi quadrate offrire una superficie più ampia, Migliorare la stabilità su un terreno irregolare o morbido. Questo design distribuisce in modo uniforme il peso, rendendolo adatto all'uso esterno in condizioni ventose o instabili. Le basi ponderate quadrate sono particolarmente efficaci nelle zone di costruzione o nelle aree ad alto traffico in cui la stabilità è cruciale.

Basi circolari per una distribuzione del peso uniforme

Basi circolari eccelle nella distribuzione uniforme del peso attorno al cono del traffico. Questa forma riduce al minimo il rischio di ribaltamento mantenendo l'equilibrio, Soprattutto sull'appartamento, superfici di livello. Le basi circolari sono spesso utilizzate in aree con sfide ambientali moderate.

Basi ponderate per coni di sicurezza pesante

Basi ponderate Migliora la stabilità aggiungendo massa alla fondazione del cono. Queste basi sono ideali per i coni di sicurezza pesante, che sono spesso utilizzati in aree ad alto rischio come autostrade o cantieri. Il peso aggiunto garantisce che il cono rimane in posizione verticale, anche in venti forti o condizioni di traffico intenso.

Nota: Diverse forme e materiali di base soddisfano casi d'uso specifici. Ad esempio, Le basi ottagonali aumentano il contatto superficiale per la stabilità, Mentre le basi pieghevoli danno la priorità alla portabilità per l'uso di emergenza.

La scienza del contatto e della trazione superficiale

In che modo l'area della superficie influisce sull'attrito

Aree di contatto più grandi e il loro ruolo in presa

La superficie di una base di cono di traffico influenza direttamente la sua presa sul terreno. Un'area di contatto più grande aumenta il forza di attrito tra la base e la superficie. Questa presa migliorata impedisce al cono di scivolare, anche su superfici lisce o scivolose. Per esempio, Le basi quadrate con ampio contatto superficiale sono particolarmente efficaci nel mantenere la stabilità su terreni irregolari. Queste basi distribuiscono il peso del cono su un'area più ampia, Garantire che rimanga saldamente al posto.

La relazione tra distribuzione del peso e attrito

Distribuzione del peso svolge un ruolo fondamentale nel massimizzare l'attrito. Le basi progettate con una distribuzione del peso pari creano una pressione costante attraverso la superficie. Questa pressione uniforme migliora la capacità della base di resistere al movimento causato da forze esterne come le bozze del vento o del veicolo. Le basi circolari eccellono in questo aspetto, Mentre la loro forma garantisce una distribuzione del peso equilibrata, Ridurre il rischio di ribaltamento o scorrimento.

Proprietà materiali e il loro ruolo nella trazione

Basi di gomma per alta attrito e presa

La gomma è un materiale popolare per le basi del cono del traffico grazie alla sua elevata durata e flessibilità. Queste proprietà consentono alle basi di gomma di fornire una trazione eccellente su varie superfici, comprese strade bagnate o ghiacciate. IL elasticità di gomma migliora la sua presa, rendendolo ideale per gli ambienti in cui la stabilità è fondamentale. La tabella seguente evidenzia i vantaggi delle basi di gomma:

| Materiale | Proprietà | Benefici |

|---|---|---|

| Gomma | Alta durata, flessibile | Fornisce stabilità e trazione in ambienti diversi |

Le basi di gomma sono spesso utilizzate in coni di sicurezza pesante, Garantire che rimangano stabili in aree ad alto rischio come autostrade o zone di costruzione.

Basi di plastica per efficienza leggera e di costo

Le basi di plastica offrono una soluzione leggera ed economica per i coni del traffico. I coni di plastica per impieghi pesanti si comportano bene in condizioni di umido e asciutto, grazie al loro Proprietà resistenti alle intemperie. Queste basi sono facili da gestire e conservare, renderli adatti a configurazioni temporanee o aree con sfide ambientali moderate. La loro versatilità garantisce prestazioni affidabili nelle zone ad alto traffico.

Mancia: Scegliere il materiale giusto per una base di cono di traffico dipende dall'ambiente e dalle condizioni specifiche. La gomma offre una presa superiore, Mentre la plastica offre un equilibrio di efficienza e durata.

Fattori di stabilità nella progettazione del cono del traffico

Distribuzione del peso e centro di gravità

In che modo le basi a basso ponderano impediscono la mancia

La distribuzione del peso svolge un ruolo cruciale nella stabilità dei coni del traffico. Le basi progettate con la maggior parte del peso del cono concentrato nella parte inferiore creano un baricentro basso. Questo design riduce il rischio di ribaltamento quando forze esterne, come le bozze del vento o del veicolo, Applicare la pressione.

Le basi a bassa ponderazione aiutano anche i coni a rimanere eretti su superfici irregolari. Ancorando il peso del cono più vicino a terra, Queste basi migliorano l'equilibrio e impediscono il calo. Questa funzione è particolarmente importante per i coni di sicurezza pesante utilizzati in ambienti ad alto rischio come autostrade o zone di costruzione.

L'importanza di un centro di gravità stabile

UN centro di gravità stabile garantisce che i coni di traffico possano resistere alle forze esterne senza ribaltare. Quando il peso è distribuito uniformemente, Il cono mantiene l'equilibrio anche se posizionato su superfici inclinate o irregolari. Le basi circolari e quadrate contribuiscono a questa stabilità diffondendo il peso attraverso un'area più grande. Questo design riduce al minimo le possibilità di appoggiarsi o caduta del cono, Garantire prestazioni coerenti in varie condizioni.

Considerazioni ambientali

Resistenza al vento e il suo impatto sulla stabilità

La resistenza del vento influisce significativamente sulla stabilità dei coni di traffico. Forti raffiche Può spingere i coni di sicurezza se le loro basi mancano di peso sufficiente o di superficie. Basi ponderate contrasta questa forza ancorando il cono saldamente a terra.

Prestazioni su superfici irregolari o inclinate

I coni di traffico affrontano spesso sfide su superfici irregolari o inclinate. Basi con contatto di superficie più ampio, come disegni quadrati o ottagonali, distribuire il peso in modo più efficace. Questa funzione consente al cono di adattarsi al terreno irregolare senza perdere stabilità. Le basi di gomma migliorano anche la presa sulle superfici inclinate, prevenire lo scorrimento o la mancia. Questi elementi di design assicurano che i coni si esibiscano in modo affidabile, anche in ambienti impegnativi come i cantieri o le strade colline.

Test e ottimizzazione del mondo reale

Test di laboratorio per trazione e stabilità

Simulare varie condizioni di terra

I test di laboratorio svolgono un ruolo vitale nell'ottimizzazione dei progetti di base del cono del traffico. Gli ingegneri simulano diverse condizioni di terra per valutare come i coni si comportano su superfici come asfalto, calcestruzzo, E ghiaia. Questi ambienti controllati consentono ai ricercatori di testare l'interazione tra il materiale di base e la superficie. Per esempio, Le basi di gomma subiscono test su superfici bagnate e asciutte per misurare la presa e la resistenza allo scorrimento. Le simulazioni replicano anche terreni irregolari per valutare come le basi quadrate o ponderate mantengono la stabilità. Questo processo garantisce che i coni di sicurezza si esibiscano in modo affidabile in diversi ambienti.

Misurare soglie di ribaltamento e coefficienti di attrito

I test di laboratorio misurano anche soglie di ribaltamento e coefficienti di attrito. Test di soglia di ribaltamento Determina la forza massima che un cono può resistere prima di cadere. Gli ingegneri usano tunnel del vento per simulare forti raffiche e bozze dei veicoli, Garantire che la base del cono possa resistere a queste forze. Test del coefficiente di attrito Misurare la presa tra la base e la superficie. Basi con coefficienti di attrito più elevati, come quelli fatti di gomma, fornire una migliore trazione. Queste misurazioni aiutano a perfezionare la progettazione di coni di sicurezza pesante, Garantire che rimangano stabili in aree ad alto rischio come le autostrade.

Prestazioni sul campo in diverse condizioni

Test su superfici bagnate e ghiacciate

Il test sul campo valuta come i coni di traffico si comportano in condizioni del mondo reale. Le superfici bagnate e ghiacciate presentano sfide significative per la stabilità e la trazione. Gli ingegneri posizionano coni di sicurezza con vari design di base su queste superfici per osservare le loro prestazioni. Le basi di gomma spesso eccellono in questi test a causa della loro alta attrito ed elasticità. I test sul campo confermano che queste basi impediscono lo scorrimento e la mancia, anche in condizioni scivolose. Ciò garantisce che i coni di sicurezza rimangono efficaci durante il tempo avverso.

Valutazione delle prestazioni in ambienti di vento alto

Ambienti ad alto vento richiedere coni con stabilità eccezionale. Test sul campo in aree aperte, come autostrade o zone di costruzione, Valuta come le basi ponderate e i bassi centri di gravità migliorano la resistenza al vento. Gli ingegneri monitorano come i coni di sicurezza resistono alle raffiche e alla turbolenza indotta dal veicolo. Disegni come basi ponderate quadrati dimostrano prestazioni superiori ancorando il cono saldamente a terra. Questi test convalidano l'efficacia dei coni di sicurezza pesante nel mantenere la stabilità in condizioni estreme.

Nota: I test del mondo reale garantiscono che i coni del traffico soddisfino gli standard di sicurezza e si esibiscano in modo affidabile in ambienti diversi.

Il design della base del cono del traffico svolge un ruolo vitale nel garantire stabilità e trazione. Gli ingegneri considerano attentamente la forma, materiale, e contatto di superficie per ottimizzare le prestazioni. Principi scientifici come l'attrito, distribuzione del peso, e le proprietà dei materiali guidano questi design, Garantire che i coni di sicurezza rimangono efficaci in diversi ambienti.

Le innovazioni nella progettazione del cono del traffico continuano a migliorare la sicurezza e l'efficienza:

- Coni stradali pieghevoli Migliora la portabilità per l'uso di emergenza.

- Coni di traffico del tubo di looper Consenti accessori come il nastro di avvertimento per una migliore visibilità.

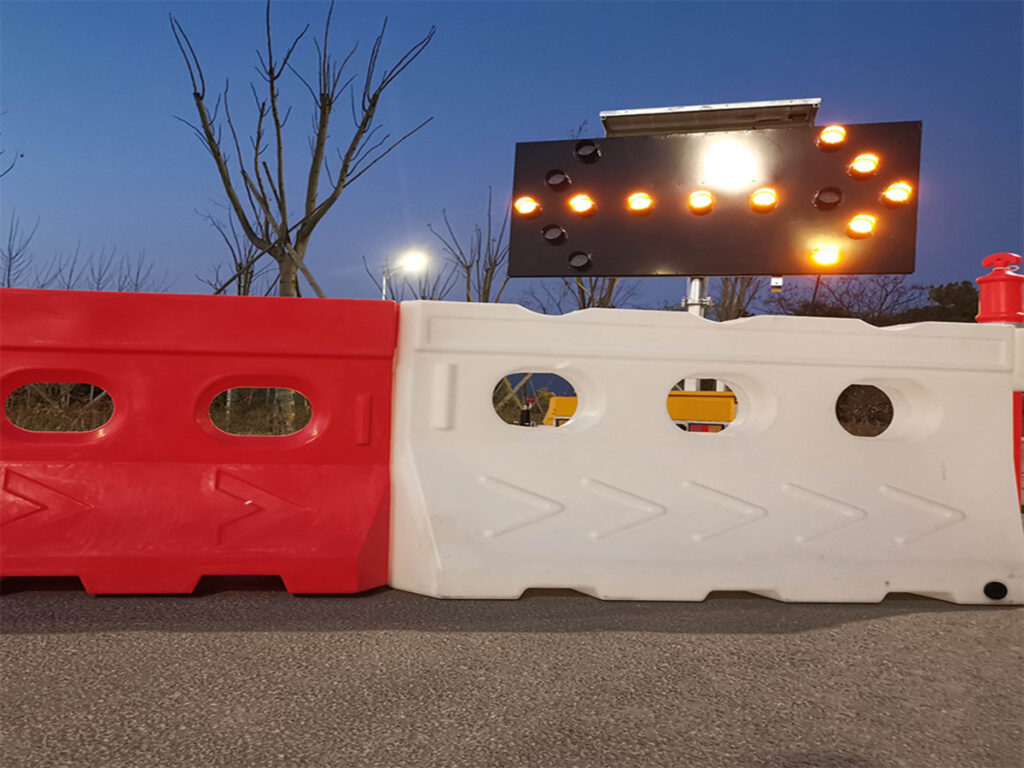

- Coni di traffico ponderati Resistere alla mancia in condizioni ventose.

- Coni di traffico a LED migliorare la visibilità in impostazioni in condizioni di scarsa illuminazione.

Questi progressi dimostrano l'impegno in corso nella creazione di soluzioni di gestione del traffico più sicure e affidabili.