IL Amministrazione per la salute e la sicurezza sul lavoro ha regole chiare per le barriere stradali. Queste regole aiutano a garantire la sicurezza dei lavoratori e delle persone. L'OSHA vuole che ogni azienda utilizzi barriere stradali che seguano rigide regole di sicurezza. Buone barricate riducono gli incidenti e mostrano dove si trova il pericolo.

A Optraffic, forniamo barriere stradali che soddisfano i rigorosi standard di sicurezza OSHA. La nostra alta qualità barriere stradali del traffico sono progettati per migliorare la sicurezza, Ridurre al minimo gli incidenti, e garantire il rispetto dei requisiti legali. Per ulteriori approfondimenti sulle barriere stradali e sulla scelta di quelle giuste per le tue esigenze, Dai un'occhiata al nostro blog, Tutto quello che devi sapere sulle barricate del traffico in vendita.

Requisiti OSHA per le barricate

Requisiti chiave OSHA per le barricate

In 2026, L'OSHA ha regole su quanto devono essere alte e luminose le barricate. Queste regole aiutano a garantire la sicurezza dei lavoratori e delle persone. Le barricate devono avere una certa altezza. Tipo 1 e digitare 2 le barricate devono essere almeno 36 pollici di altezza. Tipo 3 le barricate devono essere almeno 5 piedi di altezza. Le barricate devono avere strisce arancioni e bianche che riflettono la luce. Le strisce scendono con un angolo di 45 gradi. Il modo in cui puntano le strisce dipende dal traffico e dalla corsia. La zavorra aiuta le barricate a rimanere in piedi e facilmente visibili. L'OSHA dice di non utilizzare oggetti pesanti come cemento o rocce per la zavorra. I sacchi di sabbia vanno bene, ma è consentito un solo sacchetto di sabbia per gamba.

| Aspetto | Requisiti OSHA 2026 |

|---|---|

| Altezza | Tipo 1 & 2 barricate: minimo 36 pollici di altezza; Tipo 3 barricate: minimo 5 piedi di altezza |

| Visibilità | Strisce retroriflettenti arancioni e bianche con un angolo di 45 gradi verso il basso; il posizionamento dipende dalla direzione del traffico e dalla posizione della corsia |

| Zavorramento | Le barricate devono essere adeguatamente sostenute per resistere al vento e mantenere la visibilità; la zavorra dovrebbe evitare materiali pesanti come cemento o rocce; sacchi di sabbia limitati a un'altezza di sacco di sabbia sulle gambe del segnale |

L'OSHA vuole inoltre che vengano utilizzati dispositivi avanzati per il traffico. Questi includono attenuatori montati su camion, bacheche, e luci lampeggianti. Questi dispositivi aiutano i conducenti a vedere prima le barricate. Di notte è necessaria una buona illuminazione. I lavoratori dovrebbero indossare giubbotti riflettenti e utilizzare fari e segnali LED. I datori di lavoro devono insegnare ai lavoratori come utilizzare le barricate e i dispositivi stradali. Le nuove tecnologie come il GPS e le zone di lavoro intelligenti aiutano tutti a rimanere al sicuro.

Nota: L'OSHA afferma che tutte le barricate devono essere controllate e riparate spesso in modo che funzionino bene e possano essere viste.

Standard MUTCD e ANSI

Le regole OSHA dicono che devi seguire le più recenti MUTCD E Standard ANS. L'undicesima edizione del MUTCD è iniziata a gennaio 18, 2024. Fornisce regole per i dispositivi di controllo del traffico come le barricate. Questa edizione contiene nuove regole per la progettazione della segnaletica e il modo in cui i segnali riflettono la luce. ANSI/ASSP A10.47-2021 fornisce le regole per la sicurezza delle zone di lavoro. Copre come pianificare, impostare, prendere nota, e gestire barricate e altri dispositivi. Questi standard aiutano a prevenire gli infortuni e gli incidenti stradali.

| Standard/Edizione | Data di entrata in vigore | Aggiornamenti chiave relativi alle barriere stradali |

|---|---|---|

| MUTCD 11a edizione | Gen 18, 2024 | Definisce gli standard nazionali per i dispositivi di controllo del traffico; aggiornamenti per la progettazione della segnaletica e la retroriflessione. |

| ISI/SSS 10.47-2021 | 2021 (2026 aggiornamento) | Stabilisce i requisiti minimi per la sicurezza della zona di lavoro, compreso l'uso e l'installazione della barricata. |

MUTCD Sezione 3F.01 spiega come progettare e utilizzare le barricate. Barricate di tipo III hanno bisogno di strisce bianche e rosse che riflettano la luce. Queste barricate mostrano dove finiscono le strade o le corsie si chiudono. Sezione 3F.02 parla di coni e altri dispositivi di canalizzazione. Questi devono essere sufficientemente alti e avere delle fasce che riflettano la luce. Tutti i dispositivi devono essere puliti e luminosi in modo che le persone possano vederli.

| Sezione | Descrizione | Punti chiave |

|---|---|---|

| 3F.01 Barricate | Standard di progettazione e utilizzo | Le barricate devono soddisfare i criteri di progettazione di Tipo III con strisce retroriflettenti; utilizzato per le chiusure. |

| 3F.02 Dispositivi di canalizzazione | Norme per i coni, marcatori | Altezze minime specificate; sono necessarie bande retroriflettenti; i colori devono essere l'arancione o il colore del pavimento. |

Visibilità e zavorramento

È molto importante rendere le barriere stradali facilmente visibili. Le barricate devono avere strisce arancioni e bianche brillanti. La posizione delle strisce dipende dal traffico. La zavorra impedisce alle barricate di cadere in caso di vento o maltempo. L'OSHA non ti consente di utilizzare oggetti pesanti per la zavorra. I sacchi di sabbia sono i migliori, ma è consentito un solo sacchetto di sabbia per gamba. Questa regola ferma un peso eccessivo che potrebbe ferire qualcuno o rompere qualcosa.

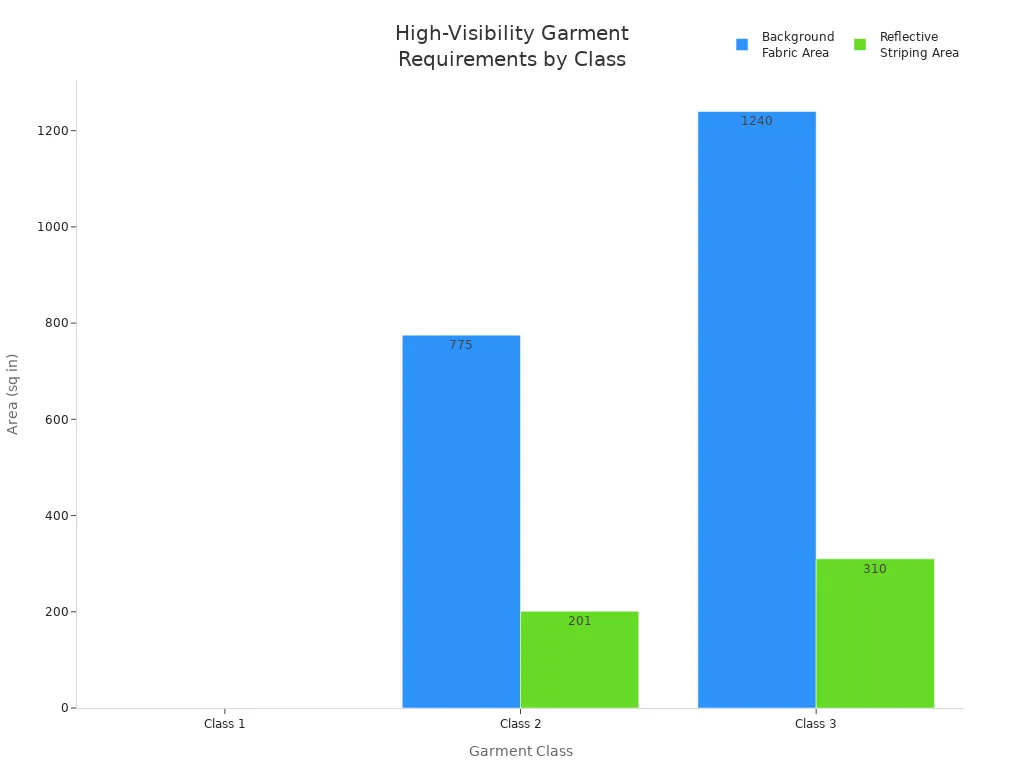

I lavoratori in prossimità delle barricate devono indossare indumenti ad alta visibilità. L'OSHA afferma che questi vestiti devono soddisfare ANSI/ISEA 107 standard. Gli abiti dovrebbero essere arancioni o gialli per il lavoro diurno. Di notte, gli abiti devono riflettere la luce ed essere visti almeno dall'alto 1,000 piedi di distanza. Classe 2 e classe 3 gli indumenti proteggono meglio i lavoratori in prossimità delle auto in movimento.

| Classe | Area del tessuto di sfondo (mq) | Area a strisce riflettenti (mq) | Distanza di visibilità | Ambiente tipico | Esempi di lavoratori |

|---|---|---|---|---|---|

| 1 | Minimo (più basso) | Minimo (più basso) | Traffico a bassa velocità (<25 mph) | Addetti al parcheggio, manutenzione nelle zone protette | Non per le zone di lavoro autostradali |

| 2 | 775 | 201 | Migliore visibilità in condizioni di scarsa illuminazione; per il traffico >25 mph | Squadre di costruzione stradale, guardie che attraversano | Necessario in prossimità di autostrade con barriere di protezione |

| 3 | 1240 | 310 | Visibile da 1,280 piedi; per il traffico veloce (>50 mph) | Addetti alla manutenzione autostradale, soccorritori | Necessario per l'interazione diretta con il traffico |

I datori di lavoro devono assicurarsi che i lavoratori indossino gli abiti giusti per il loro lavoro. Queste regole aiutano a garantire la sicurezza e la visibilità dei lavoratori vicino alle barricate.

Tipi di barricate del traffico

Tipo 1, 2, E 3 Barricate

Tipo 1, 2, E 3 le barricate vengono utilizzate nelle zone di lavoro. Aiutano a proteggere le persone e le auto. Ogni tipo ha caratteristiche speciali per la sicurezza e l'essere visti.

- Tipo 1 e digitare 2 le barricate hanno strisce arancioni e bianche. Le strisce sono retroriflettenti e oblique 45 gradi. Questo aiuta gli automobilisti e le persone a sapere dove andare.

- Tipo 1 e digitare 2 le barricate devono essere almeno 2 piedi lunghi. Tipo 3 le barricate devono essere almeno 4 piedi lunghi.

- Tutte le barricate devono stare dritte e non cadere. Un buon supporto li fa lavorare bene.

- In luoghi con nebbia, nevicare, o curve acute, è possibile aggiungere spie luminose. Ciò rende le barricate più facili da vedere.

- Le barricate devono consentire il passaggio alle persone ipovedenti. La guida inferiore non dovrebbe essere superiore a 2 centimetri da terra. Gli spazi tra le rotaie non dovrebbero essere più grandi di 2 pollici.

- La parte retroriflettente deve essere liscia e sigillata. Ciò mantiene i colori brillanti tutto il giorno e la notte.

- Se una barricata si danneggia e non riflette la luce, deve essere sostituito immediatamente.

Mancia: Tipo 3 le barricate vengono utilizzate per chiusure stradali o estremità delle corsie. Tipo 1 E 2 le barricate aiutano a guidare il traffico e a mantenere i lavoratori al sicuro.

Coni, Botti, e delineatori

Coni, barili, E Delineatori vengono utilizzati anche nelle zone di lavoro. Aiutano a guidare auto e persone in sicurezza.

- L'OSHA dice coni, barili, e i delineatori possono essere realizzati in plastica LDPE. L'LDPE ha bloccanti UV per mantenere i colori brillanti e forti.

- Le basi sono realizzate in gomma riciclata. Possono pesare 10 libbre, 16libbre, o 30 libbre. Questo aiuta a evitare che si ribaltino.

- Il sistema a cono delineatore del bordo del tetto è conforme all'OSHA 1926.502 regole. Utilizza LDPE e una base in gomma.

- Tutti questi prodotti soddisfano MUTCD e NCHRP 350 regole. Ciò significa che sono sicuri per le persone e le automobili.

- Le basi in LDPE e gomma si piegano se un'auto le colpisce. Ciò aiuta a proteggere i lavoratori e le persone.

- Questi dispositivi sono impilabili e dotati di maniglie. Ciò li rende facili da installare e spostare.

Barricate, coni stradali, barili, e i delineatori aiutano tutti a mantenere le persone al sicuro. Tipo 3 barricate e grandi botti danno la protezione più forte. Coni e delineatori sono utili per cambi rapidi e per indicare la strada nelle zone di lavoro.

| Tipo di dispositivo | Materiale | Requisiti di altezza/lunghezza | Funzione chiave | Uso comune |

|---|---|---|---|---|

| Tipo 1 & 2 Barricata | LDPE, Riflessivo | 2 minimo dei piedi | 45° strisce retroriflettenti | Guida alla corsia, Sicurezza dei lavoratori |

| Tipo 3 Barricata | LDPE, Riflessivo | 4 minimo dei piedi | Chiusura totale della strada/corsia | Chiusura stradale, deviazione |

| Cono | LDPE, Base di gomma | Standard di altezza MUTCD | Impilabile, flessibile, Resistente ai raggi UV | Canalizzazione, configurazione rapida |

| Barile | LDPE, Base di gomma | Standard di altezza MUTCD | Alta visibilità, resistente all'impatto | Principali barriere della zona di lavoro |

| Delineatore | LDPE, Base di gomma | Standard di altezza MUTCD | Sottile, flessibile, facile da spostare | Barriere pedonali e stradali |

Posizionamento e manutenzione

Posizionamento corretto

L'OSHA ha regole su dove posizionare le barricate. I lavoratori devono allestire barricate per guidare le auto e proteggere le persone. Il binario superiore dovrebbe essere abbastanza alto da poter essere visto da conducenti e pedoni. L'altezza è importante in modo che i conducenti possano vedere le barricate da molto lontano. Questo aiuta anche in caso di maltempo o di notte.

Le barricate devono sempre stare dritte. Al di fuori, il vento e la pioggia possono rovesciarli. L'OSHA consiglia di utilizzare materiali resistenti che durino nel tempo. Tipi I., Ii, e III le barricate sono forti e facili da vedere. I lavoratori devono controllare che le barricate non cadano né si muovano. Le strisce devono rimanere pulite e luminose in modo che le persone le notino.

Mancia: Metti le barricate in linea retta senza spazi vuoti. Se ci sono spazi, i conducenti potrebbero confondersi e i lavoratori potrebbero farsi male.

Manutenzione e sostituzione

Controllare le barricate spesso mantiene tutti al sicuro. L'OSHA dice di controllare tutti i dispositivi di sicurezza ogni giorno. I lavoratori dovrebbero verificare la presenza di crepe, ammaccature, colori sbiaditi, o strisce mancanti. Se una barricata è rotta o difficile da vedere, deve essere sostituito velocemente.

- Guarda le barricate ogni giorno prima di iniziare il lavoro.

- Cambia qualsiasi barricata con crepe o strisce sbiadite.

- Pulisci le strisce in modo che brillino al buio.

- Utilizzare solo barricate che seguono le regole OSHA e MUTCD.

La sostituzione delle barricate rotte impedisce rapidamente incidenti e multe. Buone barricate mantengono i lavoratori e le persone al sicuro. Il rispetto di queste regole garantisce che ogni zona di lavoro sia sicura e legale.

Rispettare i requisiti OSHA

Conseguenze legali e sulla sicurezza

Se le aziende non seguono le regole OSHA per le barriere stradali, devono affrontare grossi problemi. L'OSHA può comminare multe $16,500 per ogni errore. Se un'azienda continua a infrangere le regole, le multe diventano ancora più grandi. Queste multe aiutano a mantenere i lavoratori e il pubblico al sicuro nelle zone di lavoro. Non seguire le regole può causare arresti anomali, lesioni, o anche morti. Le barricate non sicure possono confondere le persone e mettere a rischio lavoratori e conducenti. Concentrarsi sulla sicurezza aiuta a fermare questi pericoli.

Gli audit di sicurezza aiutano le aziende a individuare i problemi nei loro piani di sicurezza. Gli audit significano il controllo delle apparecchiature, guardando la formazione, e osservare le zone di lavoro. Quando i lavoratori aiutano con gli audit, costruisce una squadra che ha a cuore la sicurezza. Risolvere rapidamente i rischi riduce il rischio di incidenti e fa risparmiare denaro sulle multe.

Nota: Le regole OSHA valgono per molti lavori, come l'edilizia e l'agricoltura. Seguire queste regole aiuta a garantire la sicurezza di tutti sul lavoro.

Migliori pratiche per la conformità

Per seguire le regole OSHA, le aziende dovrebbero utilizzare buone misure di sicurezza. Questi passaggi aiutano a mantenere le zone di lavoro sicure e a proteggere i lavoratori ogni giorno.

- Utilizzare lo standard OSHA 29 Cfr 1926.200 per controllare il traffico e garantire la sicurezza dei lavoratori.

- Insegnare a tutti i lavoratori il controllo del traffico, abitudini sicure, e come utilizzare l'attrezzatura di sicurezza.

- Cercare i rischi prima di iniziare il lavoro, come punti ciechi o strade trafficate.

- Parla con i leader locali, equipaggi, e il pubblico sui piani delle zone di lavoro.

- Apporre segnali chiari, impostare i limiti di velocità, e utilizzare zone cuscinetto per tenere i lavoratori lontani dalle auto.

- Scegli i giusti strumenti di controllo del traffico, come barricate, coni, e segnalatori.

- Controlla e ripara spesso tutti i dispositivi in modo che siano facili da vedere e funzionino bene.

- Preparati alle sorprese creando piani di riserva.

- Sorvegliare le zone di lavoro e modificare i passaggi di sicurezza, se necessario.

- Insegnare al pubblico la sicurezza nelle zone di lavoro in modo che guidino in sicurezza.

Molte aziende utilizzano lezioni online, come il corso sulla segnaletica dell’OSHA Education Center, Segnali, e barricate. Questi corsi aiutano i lavoratori e i capi a imparare come fermare gli incidenti, affiggere cartelli, e tipologie di barricate. La formazione e gli audit aiutano tutti a rimanere pronti e a rendere il luogo di lavoro più sicuro.

Le principali regole di barricata OSHA per 2025 diciamo di usare strisce arancioni e bianche che riflettono la luce. Ogni tipo di barricata deve essere della giusta altezza. Le barricate dovrebbero essere facili da aggirare per tutte le persone. Le aziende devono controllare spesso le loro barricate e apportare modifiche quando cambiano le regole.

Le aziende dovrebbero considerare il modo in cui utilizzano spesso le barricate e utilizzare gli strumenti OSHA per stare al passo con le nuove regole. Buoni piani di sicurezza mantengono i lavoratori al sicuro e rendono il posto di lavoro migliore per tutti.

Domande frequenti

Qual è lo scopo principale delle barriere stradali nelle zone di lavoro?

Le barricate stradali mantengono i lavoratori al sicuro e aiutano gli automobilisti a sapere dove andare. Bloccano le aree in cui le persone non dovrebbero entrare. Le barricate impediscono gli incidenti e proteggono chiunque si trovi nella zona di lavoro.

Con quale frequenza le aziende dovrebbero ispezionare le barriere stradali??

Le aziende devono controllare le barricate stradali ogni giorno prima dell’inizio dei lavori. I lavoratori cercano le parti rotte, strisce mancanti, o colori sbiaditi. I controlli rapidi aiutano a mantenere la zona di lavoro sicura per tutti.

I lavoratori hanno bisogno di indumenti speciali vicino alle barricate?

SÌ. I lavoratori devono indossare indumenti ad alta visibilità conformi agli standard ANSI/ISEA 107 regole. Questi indumenti aiutano gli autisti a vedere i lavoratori da molto lontano, Anche quando è buio.

Cosa succede se un'azienda non segue le regole barricate OSHA?

L'OSHA può comminare multe $16,500 per ogni errore. Le barricate non sicure possono causare lesioni alle persone o incidenti. Le aziende devono seguire le regole per evitare problemi e garantire la sicurezza dei lavoratori.

Le aziende possono utilizzare qualsiasi materiale per zavorrare le barricate?

NO. L'OSHA non ti consente di utilizzare oggetti pesanti come cemento o rocce. I sacchi di sabbia sono i migliori. Ogni gamba della barricata di sicurezza dovrebbe avere un solo sacco di sabbia per mantenerla stabile e sicura.