La selezione dei materiali di Bolard giusti può portare a risparmi significativi sia nel tempo che in denaro lungo la linea. Opzioni durevoli come acciaio inossidabile e poliuretano richiedono una manutenzione minima, rendendoli ideali per i luoghi in cui la manutenzione è impegnativa. I bollari sono esposti a vari elementi come il tempo, inquinamento, e uso frequente, che può contribuire al loro deterioramento. Scegliendo materiali di bollard robusti, È possibile ridurre i costi di manutenzione ed estendere la durata della vita.

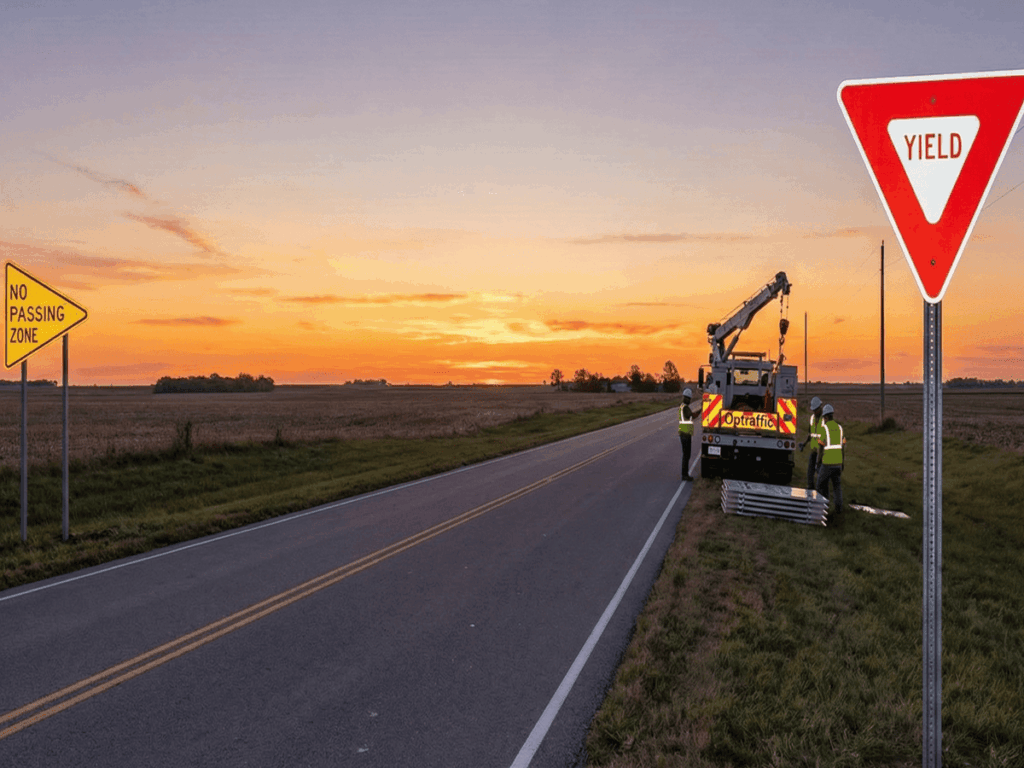

OpTraffic offre una vasta selezione di resistenti Bollard soluzioni, Compreso l'acciaio inossidabile, poliuretano, e altri materiali di lunga durata progettati per esibirsi in condizioni difficili. Con particolare attenzione all'affidabilità e all'efficienza in termini di costi, Optraffic aiuta i clienti a ridurre al minimo la manutenzione a lungo termine mantenendo alti standard di sicurezza in tutto il pubblico, commerciale, e spazi industriali.

Takeaway chiave

- Scegli materiali forti come l'acciaio inossidabile e il poliuretano per risparmiare denaro e far durare i bollari più a lungo.

- Pensa al tempo e all'inquinamento quando scegli i materiali di bollard in modo che possano gestire condizioni difficili.

- I bilanci di poliuretano sono fantastici per le aree trafficate perché si piegano quando sono colpiti, Necessità di meno riparazioni.

- I proiettili in acciaio inossidabile sono facili da cura e non arrugginiti, che è perfetto per le città.

- Guarda tutti i costi, Come l'acquisto e il mantenimento, per scegliere i migliori materiali di bollard.

Fattori chiave che influenzano la manutenzione del bollard

Esposizione ambientale (Tempo atmosferico, UV, Corrosione)

I bollari sono sempre esposti al tempo e all'ambiente. Piovere, nevicare, e l'umidità può causare ruggine su alcuni materiali come l'acciaio al carbonio. I raggi UV della luce solare possono sbiadire, far sembrare i bollari vecchi. Vicino agli oceani, L'aria e l'acqua salate fanno sì che la corrosione avvenga più velocemente. L'acciaio inossidabile è una scelta migliore in queste aree perché dura più a lungo. Le città hanno bisogno di prove in grado di gestire l'inquinamento e l'invecchiamento dell'ambiente. La raccolta di materiali che resistono alla ruggine aiuta a rimanere forti con meno lavoro.

Frequenza di impatto o contatto

Dove vengono posizionati i bollari stradali colpiscono la frequenza con cui vengono colpiti. In aree trafficate, veicoli o persone possono imbattersi in loro molto. I padri flessibili in poliuretano sono fantastici qui. Si piegano e tornano a forma, Quindi le riparazioni sono rare. In punti più tranquilli, I materiali più forti come il cemento o l'acciaio inossidabile sono migliori. Se la sicurezza è importante, Bolli più duri proteggono meglio dai danni.

Requisiti estetici (Dipinto vs. Finiture non dipinte)

Come gli appaiono i bollari sono importanti negli spazi pubblici o commerciali. I bilanci dipinti hanno bisogno di ritocchi per rimanere piacevoli. Quelli non verniciati, come l'acciaio inossidabile, sembra moderno e hai bisogno di meno cure. L'inquinamento nelle città può rendere sporchi i bollari dipinti più velocemente. Scegliere finiture naturali significa meno pulizia e mantiene i bollari che sembrano puliti.

Inquinamento urbano e danni quotidiani

La vita della città può essere difficile per i bollari del traffico. Inquinamento dalle auto, fabbriche, e la costruzione lascia sporcizia su di loro. Col tempo, Questo sporco fa sembrare i bollari disordinati e logori. In aree trafficate, lo sporco si accumula rapidamente, Quindi è necessaria la pulizia spesso per mantenerli belli.

L'uso quotidiano danneggia anche i bollari. Le persone si appoggiano a loro, Le biciclette vengono incatenate a loro, E le auto potrebbero imbattersi in esse. Queste azioni possono causare graffi, ammaccature, o vernice scheggiata. I billari dipinti necessitano di un fissaggio regolare per rimanere ordinati. I proiettili in acciaio inossidabile resistono a graffi e macchie, rendendoli migliori per le città.

L'inquinamento può anche causare ruggine. Pioggia acida e lo smog indebolisce alcuni materiali nel tempo. I paletti in acciaio al carbonio necessitano di rivestimenti speciali per fermare la ruggine in luoghi inquinati. Senza cure, Si consumano più velocemente e costano di più per sostituire. I paletti in acciaio inossidabile e poliuretano durano più a lungo e hanno bisogno di meno lavoro per rimanere forti.

Scegliere il materiale di bollard giusto consente di risparmiare tempo e denaro. L'acciaio inossidabile sembra moderno e combatte l'inquinamento e il danno. I paletti di poliuretano si piegano quando sono colpiti ma non rompere. Materiali forti significano meno manutenzione e paletti più belli nelle aree di città trafficate.

Confronto dei materiali di bollard: Professionisti, Contro, e esigenze di manutenzione

Basta di acciaio al carbonio

Acciaio al carbonio I bollari sono forti e convenienti. Funzionano bene in luoghi che necessitano di barriere difficili. Ma hanno bisogno di cure regolari per fermare la ruggine e stare bene.

Professionisti:

- Molto forte e protegge bene dagli impatti.

- Più economico in anticipo, Così tante persone possono permetterselo.

- Ottimo per le aree che necessitano di alta sicurezza.

Contro:

- Arruggini facilmente in luoghi bagnati o salati.

- Ha bisogno di ridipingere spesso per evitare la ruggine.

- I costi per la manutenzione possono crescere nelle città inquinate.

Esigenze di manutenzione:

I bollari in acciaio al carbonio necessitano di cure regolari. Devi dipingerli o ricoprirli per bloccare l'umidità e lo sporco. Controllali spesso per catturare la ruggine o danneggiare presto. Sono forti ma hanno bisogno di più lavoro, Quindi non sono fantastici per i luoghi in cui la manutenzione è dura.

Basta di acciaio inossidabile

Acciaio inossidabile I bollari sembrano belli e durano a lungo. Non arrugginiscono o si consumano facilmente, anche in maltempo o aree sporche. Risparmiano tempo e denaro perché hanno bisogno di poca cura.

Professionisti:

- Non arrugginito, anche in luoghi salati o inquinati.

- Sembra moderno e si adatta bene alle città o alle imprese.

- Dura a lungo con poca manutenzione, rimanere dall'aspetto professionale.

Contro:

- Costa all'inizio di più rispetto ad altri bollari.

- Non duro come il calcestruzzo in punti ad alto impatto.

Esigenze di manutenzione:

I padiglioni in acciaio inossidabile hanno bisogno di pochissime cure. Pulirli a volte con sapone e acqua per mantenerli lucenti. Resistono alla ruggine e ai graffi, rendendoli fantastici per le aree trafficate. I paletti idraulici in acciaio inossidabile sono molto forti e durano a lungo, anche in condizioni difficili.

Basta di cemento

I padri di cemento sono pesanti e molto forti. Proteggono bene dagli impatti e sono ottimi per gli spazi pubblici. Il loro peso li mantiene stabili, anche sotto pressione.

Professionisti:

- Super forte e le gesti di impatto bene.

- Perfetto per parcheggi e aree affollate.

- Costa meno in anticipo rispetto ai bilanci in acciaio inossidabile.

Contro:

- Può scheggiare o rompersi nel tempo.

- Difficile da muoversi perché sono pesanti.

- Ha bisogno di essere riparati per stare bene.

Esigenze di manutenzione:

I proiettili in cemento hanno bisogno di controlli per crepe o danni. Correggi le patatine per farli funzionare e avere un bell'aspetto. Proteggono bene ma hanno bisogno di più cure in luoghi con molti impatti o maltempo.

Poliuretano / Basta flessibile

Poliuretano I bollari sono speciali perché si piegano quando sono colpiti. Questo li rende fantastici per i luoghi in cui le auto o le persone toccano spesso i paletti. Non danneggiano i veicoli e tornano alla loro forma originale, rimanere utile per molto tempo.

Perché scegliere Bolli in poliuretano?

- Impatto resilienza: Questi bollari prendono colpi e rimbalzano. Ciò significa meno riparazioni e risparmia denaro.

- Design leggero: Sono facili da spostare e installare. Questo li rende perfetti per configurazioni temporanee o aree di traffico.

- Resistenza alle intemperie: I padri di poliuretano non vengono danneggiati dalla pioggia, nevicare, o luce solare. Durano a lungo e hanno bisogno di poca cura.

- Costo-efficacia: Costano meno dei bollari pesanti come il cemento ma funzionano ancora bene.

Esigenze di manutenzione

I bilanci di poliuretano hanno bisogno di pochissime cure. Lavali con acqua e sapone per tenerli puliti. Non hanno bisogno di ridipingere o a prova di ruggine perché resistono al maltempo. Se hai bisogno di bollari per aree trafficate o uso temporaneo, Il poliuretano è una scelta intelligente.

Mancia: Usa i bilanci poliuretanici nei parcheggi, piste ciclabili, o zone pedonali. Guidano il traffico senza aver bisogno di correzioni costanti.

Basta di plastica o composito

I proiettili in plastica e composito sono buoni per i luoghi che necessitano di opzioni facili da fare. Questi bollari sono abbastanza convenienti e abbastanza forti per molti usi. Non sono duri come i bollari pesanti ma sono leggeri e resistono ai danni meteorologici, rendendoli utili in molte situazioni.

Vantaggi dei billari di plastica o composito

- Economia: I bilanci di plastica sono economici e funzionano bene senza costare troppo.

- Bassa manutenzione: Non arrugginiscono o si sbiadiscono e hanno bisogno di poca cura. Pulirli a volte li fa sembrare belli.

- Installazione leggera e facile: I paletti compositi sono leggeri e semplici da configurare. Questo li rende fantastici per i punti temporanei o bassi.

- Resistenza alle intemperie: Basta di plastica maneggia la pioggia, nevicare, e luce solare bene, durando a lungo.

Esigenze di manutenzione

I bollari di plastica hanno bisogno di pochissima manutenzione. Pulirli con acqua e sapone delicato per rimuovere lo sporco. Non arrugginano o hanno bisogno di rivestimenti speciali, Quindi le riparazioni sono rare.

Nota: I bilanci di plastica sono i migliori per i luoghi con poco traffico o dove sembra più importante. Per aree ad alta sicurezza, Scegli materiali più forti come i proiettili in cemento o in acciaio inossidabile.

Costo totale di proprietà (TCO): Materiale vs. Manutenzione

Investimento iniziale vs. Manutenzione a lungo termine

Quando si raccolgono i paletti, Pensa al prezzo iniziale e ai costi futuri. All'inizio i provinciali in cemento e in acciaio possono sembrare economici. Ma hanno bisogno di più cure nel tempo, che aumenta le spese. Per esempio, I proiettili in acciaio al carbonio dipinto devono essere ridipinti spesso per fermare la ruggine. Le aree bagnate o inquinate rendono questa manutenzione più dura e costosa.

Bollardi in acciaio inossidabile e poliuretano necessitano di meno manutenzione. L'acciaio inossidabile non arruggini o si gratta facilmente, Quindi le riparazioni sono rare. I paletti di poliuretano si piegano quando sono colpiti e tornano a forma, Risparmio di denaro sulle correzioni. Questi materiali costano all'inizio di più ma risparmiano più tardi perché durano più a lungo.

Migliore materiali corrispondono alle tendenze di oggi nella pianificazione urbana. Le città vogliono design più forti ed ecologici, che necessitano di bisogni durevoli. Scegliere i bollari con bassa manutenzione si adatta a questi obiettivi e risparmia nel tempo.

Ad alto traffico vs. Aree a basso traffico

Laddove i bollari del traffico sono posizionati influisce sulla scelta del materiale migliore. In aree trafficate, I bollari di sicurezza del traffico vengono colpiti spesso da auto o persone. I padri di cemento sono forti e proteggono bene in questi punti. Ma possono rompersi o chip, Necessità di riparazioni per rimanere utili.

I paletti di poliuretano funzionano bene in luoghi affollati. Si piegano quando sono urtati e tornano a forma, Needing meno fissaggio. Questi bollari sono perfetti per i parcheggi, piste ciclabili, e marciapiedi in cui gli impatti accadono molto.

In aree più tranquille, I paletti in acciaio inossidabile sono una scelta intelligente. Sembrano moderni e durano a lungo senza troppe cure. Questi bollari sono perfetti per i fronti degli affari o le case con poco traffico.

Confronto di esempio: Acciaio inossidabile vs. Acciaio di carbonio dipinto 10 Anni

Confrontiamo l'acciaio inossidabile e i paletti di acciaio al carbonio dipinto in dieci anni.

| Materiale | Costo iniziale | Esigenze di manutenzione | Costo totale 10 Anni |

|---|---|---|---|

| Basta di acciaio inossidabile | Più alto | Pulizia occasionale | Inferiore |

| Acciaio di carbonio dipinto | Inferiore | Reinicurazione frequente e controllo della ruggine | Più alto |

I paletti in acciaio inossidabile costano più in anticipo ma risparmiano più tardi. Hanno solo bisogno di pulire a volte per rimanere piacevoli. Ini Bolli in acciaio al carbonio dipinto sono inizialmente più economici ma hanno bisogno di una riverniciatura regolare per fermare la ruggine. Oltre dieci anni, L'acciaio di carbonio dipinto costa di più a causa di frequenti correzioni.

Questo dimostra perché pensare ai costi totali è importante. La raccolta di materiali durevoli come l'acciaio inossidabile o il poliuretano risparmia denaro e fa funzionare bene i bittali per anni.

Raccomandazioni basate sul caso d'uso

Per i gestori di proprietà: Resistenza alla corrosione e manutenzione minima

I manager della proprietà hanno bisogno di paletti che durano a lungo e hanno bisogno di poca cura. Acciaio inossidabile E fondazioni zincate resistere alla ruggine e risparmiare denaro. Questi materiali proteggono la tua proprietà e minori i costi di manutenzione.

Ecco un confronto dei tipi di fondazione:

| Tipo di fondazione | Durata di servizio | Costo di manutenzione annuale |

|---|---|---|

| Ancori elicoidali (Zincato) | 75-120+ anni | $0-$125 |

| Basamenti in cemento | 50-100 anni | $250-$750 |

| Fondazioni in legno | 20-40 anni | $350-$900 |

Ancori elicoidali durano il più lungo e costano il minimo da mantenere. Col tempo, Risparmiano e offrono una forte protezione.

Quando si guarda ai costi totali, Le opzioni resistenti alla corrosione sono migliori:

| Fattore di costo | Ancori elicoidali | Fondazioni tradizionali |

|---|---|---|

| Costo totale del ciclo di vita | $35,000-$43,000 | $55,000-$75,000 |

Raccogliendo durevole, I paletti resistenti alla ruggine mantengono la tua proprietà al sicuro. Questa scelta risparmia denaro e riduce le riparazioni mentre sembra professionale.

Per le compagnie di noleggio di attrezzature: Facile da installare, Opzioni a bassa manutenzione

Le compagnie di noleggio di attrezzature hanno bisogno di proiettili che siano semplici da impostare. Poliuretano E Materiali compositi sono leggeri e hanno bisogno di poca manutenzione.

Bolletti poliuretanici Piega quando colpito e torna a forma. Ciò riduce i costi di danno e riparazione. Basta composita Resistere al tempo e rimanere pulito con un lavaggio occasionale.

Questi bollari funzionano bene per le configurazioni temporanee. Guidano il traffico e proteggono le attrezzature senza bisogno di cure costanti.

Mancia: Utilizzo Bolletti poliuretanici nei parcheggi o nelle zone di costruzione. Gestiscono bene gli impatti e risparmiano denaro sulle riparazioni.

Per le aree pubbliche urbane: Bilanciamento della durata con il fascino visivo

Gli spazi pubblici hanno bisogno di paletti forti e belli. Basta di acciaio inossidabile Resistere alla ruggine e rimanere elegante, Migliorare i progetti urbani.

I bollari di metallo proteggono le aree trafficate e abbinano stili diversi. Sono disponibili in molte forme, dimensioni, e colori per adattare l'ambiente.

In che modo i bollari aiutano le città:

- I bollari di metallo mantengono le persone al sicuro in luoghi affollati.

- I disegni personalizzati corrispondono a edifici e strade.

- Abbinarli a lampade e panchine rende gli spazi migliori.

Bollei durevoli proteggono le persone e aggiungono bellezza alle città. Acciaio inossidabile Le opzioni durano a lungo e hanno bisogno di poca cura.

Nota: Scegli i bollari che bilanciano sicurezza e stile per le aree pubbliche. Questo mantiene gli spazi sicuri e attraenti.

Scegliere i Ballard del traffico giusto risparmiano tempo e denaro in seguito. L'acciaio inossidabile e il poliuretano sono ottime scelte per la cura duratura e facile. L'acciaio inossidabile non arruggini o si gratta, Quindi è perfetto per le aree trafficate. I proiettili in poliuretano si piegano indietro dopo i colpi e a volte hanno bisogno di una semplice pulizia.

Ecco una rapida occhiata:

| Tipo di materiale | Esigenze di manutenzione |

|---|---|

| Basta di acciaio inossidabile | Hai bisogno di poca cura, Ottimo per i luoghi pubblici affollati. |

| Bolletti poliuretanici | Ha solo bisogno di pulizia occasionale, manutenzione molto bassa. |

L'uso di questi materiali riduce i costi di riparazione e li fa funzionare più a lungo. Per assicurarti di scegliere il materiale di bollard più durevole ed economico per le tue esigenze, Esplora il blog Come scegliere il miglior materiale per il traffico per il tuo progetto. Offre approfondimenti sugli esperti sulla selezione dei materiali giusti che bilanciano le prestazioni, manutenzione, e costo.

Domande frequenti

Qual è il miglior materiale di bollard per le esigenze a bassa manutenzione?

Acciaio inossidabile E poliuretano sono ottime opzioni. L'acciaio inossidabile non arruggini o si gratta facilmente. Il poliuretano si piega indietro dopo essere stato colpito. Entrambi hanno bisogno di poca cura, rendendoli perfetti per luoghi affollati.

Quante volte dovrebbe essere mantenuta i bollari?

Dipende dal materiale e dalla posizione. Acciaio inossidabile E poliuretano I bollari hanno solo bisogno di pulire a volte. I proiettili in acciaio al carbonio dipinto devono essere ridipinti spesso, Soprattutto nelle aree bagnate o inquinate.

I bollari possono resistere alle condizioni meteorologiche estreme?

SÌ, Alcuni materiali gestiscono bene il maltempo. Acciaio inossidabile resiste alla ruggine in luoghi salati o bagnati. Poliuretano I bollari sopravvivono alla luce solare, piovere, e neve senza danni. Sono fantastici per l'uso all'aperto.

Sono i bastoncini flessibili abbastanza durevoli per le aree ad alto traffico?

Basta flessibile, Piace poliuretano, Lavora bene in luoghi impegnativi. Prendono colpi e si rimbalzano, Necessità di meno riparazioni. Ma non sono i migliori per le aree di alta sicurezza.

Come faccio a scegliere il materiale di bollard giusto per la mia proprietà?

Pensa alla tua posizione, traffico, e esigenze di manutenzione. Per facile cura, scegliere acciaio inossidabile O poliuretano. Per sicurezza, calcestruzzo O acciaio al carbonio potrebbe essere migliore. Abbina il materiale alle tue esigenze specifiche.

Mancia: Parla con un esperto di bollard per trovare la scelta migliore per il tuo budget e proprietà.