सही सामग्री चुनना बोलार्ड विनिर्माण और मजबूत ट्रैफ़िक बोलार्ड बनाने के लिए महत्वपूर्ण है. बोलार्ड का उपयोग लोगों को कठिन परिस्थितियों में सुरक्षित रखने के लिए किया जाता है. उनकी ताकत सावधान परीक्षण और चेक से आती है. निर्माता अनुचित परिणामों से बचने के लिए कई नमूनों का परीक्षण करते हैं. उदाहरण के लिए, ई-ग्लास और कार्बन पर परीक्षण किए जाते हैं 20 निर्धारित नियमों के तहत समय. गणित उपकरण परिणामों की जांच करते हैं, दिखा 95% ताकत के अंतर में आत्मविश्वास. ये चरण सुनिश्चित करते हैं कि बोलार्ड क्रैश को संभाल सकते हैं या लंबे समय तक रह सकते हैं.

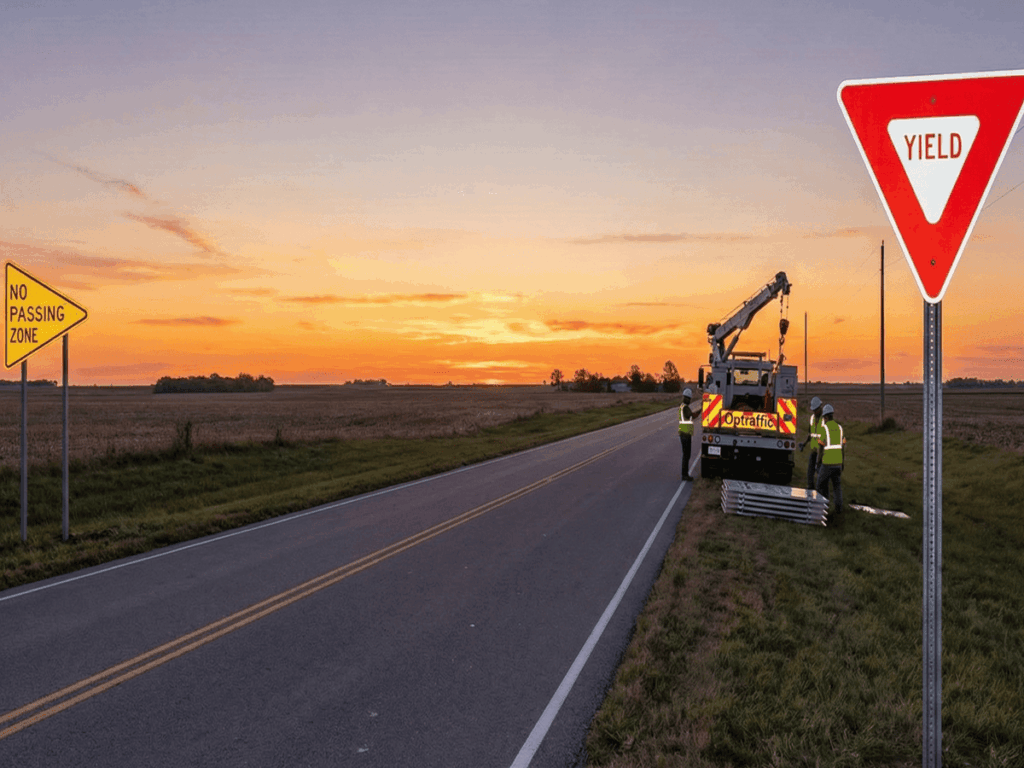

Optraffic प्रस्ताव बिक्री के लिए यातायात बोलार्ड यह इन उच्च मानकों को दर्शाता है, पूरी तरह से परीक्षण की गई सामग्री और सख्त गुणवत्ता नियंत्रण प्रक्रियाओं का उपयोग करना. उनके उत्पादों को मांग वाले वातावरण में मज़बूती से प्रदर्शन करने के लिए डिज़ाइन किया गया है, टिकाऊ सुरक्षा प्रदान करना और सार्वजनिक स्थानों की सुरक्षा जरूरतों को पूरा करना, सुविधाएँ, और ट्रैफ़िक क्षेत्र.

चाबी छीनना

- सही सामग्री चुनना मजबूत बोल्ड बनाने के लिए महत्वपूर्ण है. स्टील और कंक्रीट जैसी सामग्रियों में अलग -अलग उपयोग और ताकत होती है.

- परीक्षण, जैसे दुर्घटना और वजन परीक्षण, जांचें कि क्या बोलार्ड कठिन हैं. ये परीक्षण सुनिश्चित करते हैं कि वे सुरक्षित और विश्वसनीय हैं.

- पर्यावरण के अनुकूल सामग्री का उपयोग करने से ग्रह में मदद मिलती है. पुनर्नवीनीकरण सामग्री बोलार्ड बनाने से प्रदूषण को कम कर सकती है.

- विशेष डिजाइन बोलार्ड्स विशिष्ट सुरक्षा जरूरतों को पूरा करने में मदद करते हैं. सामग्री और आकृतियों को बदलने से उन्हें अपने स्थानों में बेहतर काम मिलता है.

- क्रैश-परीक्षण किए गए बोलार्ड सार्वजनिक स्थानों को सुरक्षित रखते हैं. वे कार के हमलों को रोकते हैं और जोखिम भरे क्षेत्रों में लोगों की रक्षा करते हैं.

बोलार्ड विनिर्माण में सामग्री सोर्सिंग

सामग्री का चयन करने के लिए मानदंड

ट्रैफ़िक बोलार्ड के लिए सही सामग्री चुनना बहुत महत्वपूर्ण है. मजबूत सामग्री लंबे समय तक चलती है और कठिन मौसम को संभालती है. उदाहरण के लिए, स्टेनलेस स्टील और एल्यूमीनियम में अलग -अलग ताकत और जीवनकाल होता है. बोलार्ड का उद्देश्य भी मायने रखता है. ट्रैफ़िक नियंत्रण के लिए बोलार्ड्स को पैदल यात्री सुरक्षा के लिए अलग -अलग सामग्रियों की आवश्यकता है. दुर्घटना रेटिंग, K रेटिंग की तरह, दिखाएँ कि बोलार्ड वाहनों को कितनी अच्छी तरह से रोकते हैं.

बेहतर ढंग से समझने के लिए कि ये रेटिंग आपकी सामग्री की पसंद और समग्र सुरक्षा रणनीति को कैसे प्रभावित करती हैं, ब्लॉग पढ़ें क्रैश-रेटेड बोलार्ड्स ने समझाया: क्या आपको वास्तव में के-रेटिंग की आवश्यकता है? यह टूट जाता है कि के-रेटिंग का क्या मतलब है, जब वे आवश्यक हों, और वे वास्तविक दुनिया के परिदृश्यों में बोलार्ड के प्रदर्शन को कैसे प्रभावित करते हैं.

कार्बन स्टील और कंक्रीट जैसी अच्छी सामग्री बोलार्ड को मजबूत बनाती है. ये सामग्रियां कठोर परिस्थितियों में बोलार्ड्स को अच्छी तरह से काम करने में मदद करती हैं. ध्यान से चुनकर, बोलार्ड सुरक्षा नियमों को पूरा कर सकते हैं और मज़बूती से काम कर सकते हैं.

नैतिक और टिकाऊ सोर्सिंग प्रथाओं

पर्यावरण के अनुकूल तरीके से सुरक्षा बोल्ड बनाना अब और अधिक महत्वपूर्ण है. ग्रीन प्रैक्टिस ग्रह को कम नुकसान पहुंचाता है और वैश्विक लक्ष्यों का समर्थन करता है. पुनर्नवीनीकरण सामग्री का उपयोग करने और कचरे को काटने से पर्यावरण में मदद मिलती है. उदाहरण के लिए, पर्यावरण के अनुकूल सामग्री बोलार्ड को अच्छा दिखती है और अपने कार्बन पदचिह्न को कम करती है.

नैतिक सोर्सिंग सख्त वैश्विक नियमों का पालन करता है. प्रमाणपत्र आईएसओ और एएसटीएम सिद्ध सामग्री सुरक्षित और उच्च गुणवत्ता वाले हैं. नैतिक और हरे तरीकों का उपयोग करके, आप ग्रह की मदद करते हैं और बोलार्ड को मजबूत रखते हैं.

सामग्री प्रकार और उनके अनुप्रयोग

बोलार्ड विनिर्माण में, विभिन्न सामग्रियों को विभिन्न उद्देश्यों के लिए चुना जाता है. इस्पात, ठोस, और पॉलिमर सामान्य विकल्प हैं, प्रत्येक एप्लिकेशन के आधार पर अद्वितीय लाभ प्रदान करता है.

| सामग्री प्रकार | संघात प्रतिरोध | सर्वोत्तम उपयोग |

|---|---|---|

| इस्पात | मध्यम | वाहनों से बचाता है, लेकिन एक बार का उपयोग |

| ठोस | उच्च | भारी दुर्घटनाओं को संभालता है, लंबे समय तक रहता है |

| पॉलीमर | लचीला | धीमी गति से प्रभावों के लिए अच्छा है, वार उल्टा पड़ना |

स्टील के बोलार्ड्स मजबूत वाहन सुरक्षा की आवश्यकता वाले स्थानों के लिए महान हैं. कंक्रीट बोलार्ड अच्छी तरह से काम करते हैं जहां भारी दुर्घटनाएं हो सकती हैं. पॉलिमर धीमी गति वाले क्षेत्रों के लिए सबसे अच्छे हैं और हिट के बाद ठीक हो सकते हैं. यह जानना कि प्रत्येक सामग्री क्या करती है, आपको सही लेने में मदद करता है.

मजबूत सुरक्षा बोलार्ड की आवश्यकता तेजी से बढ़ रही है. अमेरिका में।, स्वचालित बाधाओं के लिए बाजार हिट हो सकता है $6 के द्वारा अरब 2025. इससे पता चलता है कि सुरक्षा नियम कैसे मांग कर रहे हैं. यूरोप में, कानून बेहतर सुरक्षा पर ध्यान केंद्रित करते हैं, खासकर आतंकवाद के खिलाफ. इन रुझानों से पता चलता है कि सही सामग्री चुनना इतना महत्वपूर्ण क्यों है.

क्रैश रेटिंग और स्थायित्व के लिए परीक्षण प्रक्रियाएं

इन-हाउस परीक्षण विधियाँ

इन-हाउस टेस्ट की जांच करें कि क्या रोड बॉलार्ड सुरक्षित और मजबूत हैं. ये परीक्षण वास्तविक जीवन की स्थितियों की नकल करते हैं, यह देखने के लिए कि बोलार्ड कैसे प्रदर्शन करते हैं. क्रैश टेस्ट दिखाते हैं कि क्या कोई बोलार्ड किसी वाहन को रोक या पुनर्निर्देशित कर सकता है. लोड परीक्षण यह देखने के लिए वजन जोड़ें कि क्या बोलार्ड मजबूत रहता है. स्थायित्व परीक्षण गर्मी की तरह खराब मौसम के लिए बोलार्ड को उजागर करता है, ठंडा, या बारिश.

| परीक्षण पद्धति | यह क्या करता है |

|---|---|

| दुर्घटना परीक्षण | परीक्षण अगर बोलार्ड वाहनों को रोक या पुनर्निर्देशित कर सकते हैं. |

| भार परीक्षण | चेक करता है कि क्या बोलार्ड टूटे बिना भारी वजन पकड़ सकते हैं. |

| स्थायित्व परीक्षण | कठोर मौसम के खिलाफ बोल्डर्ड्स को यह देखने के लिए कि क्या वे लंबे समय तक चलते हैं. |

ये परीक्षण सुनिश्चित करते हैं कि रोड बोलार्ड दुर्घटनाओं और कठिन मौसम को संभाल सकते हैं. निर्माता सुरक्षित और विश्वसनीय बोलार्ड बनाने के लिए इन परीक्षणों का उपयोग करते हैं.

तृतीय-पक्ष प्रमाणपत्र और मानक

बाहरी समूह अपनी गुणवत्ता और सुरक्षा की पुष्टि करने के लिए बोलार्ड की जांच करते हैं. एएसटीएम जैसे समूह, इवा, और पीए ने परीक्षण के लिए सख्त नियम निर्धारित किए. उदाहरण के लिए:

- एएसटीएम बताते हैं कि यू.एस. में दुर्घटनाओं के लिए बोलार्ड का परीक्षण कैसे करें.

- इवा 14 दुनिया भर में वाहन सुरक्षा के लिए बाधाओं की जाँच करता है.

- नहीं 68 इमारतों के पास मजबूत प्रभावों के लिए बोलार्ड का परीक्षण करता है.

क्रैश-रेटेड बोलार्ड का परीक्षण यह देखने के लिए किया जाता है कि वे कितना बल ले सकते हैं. वाहन के आकार से ASTM F3016 और ASTM F2656 रैंक बोल्ड जैसे नियम, रफ़्तार, और नुकसान की गहराई. ASTM F3016 परीक्षण धीमी क्रैश, जबकि ASTM F2656 तेजी से दुर्घटनाओं पर ध्यान केंद्रित करता है.

| मानक | यह क्या परीक्षण करता है | वाहन भार | स्पीड |

|---|---|---|---|

| एएसटीएम एफ 3016 | फुटपाथ जैसी जगहों पर टेस्ट धीमी गति से दुर्घटनाग्रस्त हो जाता है. | 5,000 एलबीएस | 10, 20, 30 मील प्रति घंटा |

| एएसटीएम F2656 | बड़े वाहनों के साथ तेजी से दुर्घटनाग्रस्त हो जाता है. | 15,000 एलबीएस | 30, 40, 50 मील प्रति घंटा |

ये नियम सुनिश्चित करते हैं कि बोलार्ड सार्वजनिक और निजी स्थानों के लिए सुरक्षित हैं.

बोलार्ड पुल टेस्ट की भूमिका

बोलार्ड पुल टेस्ट मापता है कि एक बोलार्ड कितना मजबूर कर सकता है. यह दिखाता है कि बोलार्ड कितना मजबूत और विश्वसनीय है. मौसम परिणाम बदल सकता है, लेकिन परीक्षण उपयोगी डेटा देता है.

क्रैश-रेटेड बोलार्ड दुर्घटना बलों को अवशोषित करके क्षेत्रों की रक्षा करते हैं. बोलार्ड पुल टेस्ट जैसे परीक्षण साबित करते हैं कि वे वाहन हिट के खिलाफ अच्छी तरह से काम करते हैं. इन-हाउस परीक्षणों का उपयोग करके, बाहरी प्रमाणपत्र, और विशेष परीक्षण, निर्माता मजबूत और सुरक्षित बोल्ड का निर्माण करते हैं.

वाहन बाधा तंत्र इंजीनियरी

प्रदर्शन मांगों के लिए मिलान सामग्री

सामग्री को वाहन बाधाओं की जरूरतों को पूरा करना चाहिए. प्रत्येक सामग्री दुर्घटनाओं के दौरान विभिन्न बलों को संभालती है. उदाहरण के लिए, एएसटीएम सी 40 टेस्ट से पता चलता है कि बोलार्ड वाहनों को तौलना बंद कर देते हैं 2,430 पर एलबीएस 42.6 से कम के साथ एमपीएच 24 क्षति के इंच. भारी वाहनों के लिए रेटिंग, पसंद 5,000 पर एलबीएस 30 मील प्रति घंटा, अंडर से कम नुकसान 12 इंच.

| विवरण परीक्षण | वाहन भार | रफ़्तार | नुकसान की गहराई |

|---|---|---|---|

| एएसटीएम सी 40 टेस्ट | 2,430 एलबीएस | 42.6 मील प्रति घंटा | < 24″ |

| इंजीनियर रेटिंग | 5,000 एलबीएस | 30 मील प्रति घंटा | < 12″ |

मानकों की तरह नहीं 68 बोलार्ड्स ने नियोजित दुर्घटनाओं का विरोध करने में मदद की. नहीं 170-1 धीमी गति से दुर्घटनाओं पर ध्यान केंद्रित करता है, यह पार्किंग स्थल के लिए अच्छा है. ये नियम सुरक्षा जरूरतों को पूरा करने वाली सामग्रियों को चुनने में मदद करते हैं.

- नहीं 13: कारखानों में यातायात को संभालता है.

- नहीं 68: नियोजित वाहन दुर्घटनाओं के लिए टेस्ट बोलार्ड.

- नहीं 170-1: धीमी गति से दुर्घटनाओं के लिए बॉलार्ड्स की जाँच करता है.

सीएडी मॉडलिंग और तनाव सिमुलेशन

सीएडी जैसे कंप्यूटर टूल बोलार्ड डिजाइन में सुधार करते हैं. सीएडी दिखाता है कि बोलार्ड कैसे दिखते हैं और बलों पर प्रतिक्रिया करते हैं. LS-DYNA सम्मेलनों के अध्ययन से पता चलता है कि कंप्यूटर परीक्षण क्रैश परिणाम से मेल खाते हैं. ये उपकरण समय बचाते हैं और उन समस्याओं को पाते हैं जो अकेले गणित याद आती हैं.

| अध्ययन शीर्षक | प्रमुख निष्कर्ष | क्रियाविधि |

|---|---|---|

| 12TH अंतर्राष्ट्रीय LS-DYNA सम्मेलन | कंप्यूटर परीक्षण क्रैश परिणामों से मेल खाते हैं और समय बचाते हैं. | बल पल्स परीक्षण और मॉडलिंग. |

| 13TH अंतर्राष्ट्रीय LS-DYNA सम्मेलन | K12 क्रैश के लिए बेहतर बोलार्ड डिजाइन. | LS-DYNA का उपयोग करके गतिशील विश्लेषण. |

तनाव परीक्षण से पता चलता है कि दुर्घटनाओं के दौरान बोलार्ड कैसे खींचते हैं और ताकत को रोकते हैं. यह सुनिश्चित करता है कि बोलार्ड सुरक्षित हैं और वास्तविक जीवन में अच्छी तरह से काम करते हैं.

कस्टम डिजाइन और सामग्री चयन

कस्टम डिजाइन विशेष परियोजनाओं के लिए बोलार्ड्स को बेहतर काम करते हैं. स्टेनलेस स्टील लंबे समय तक रहता है और जंग का विरोध करता है, इसे एक मजबूत विकल्प बनाना. टीबीके मेटल अद्वितीय आवश्यकताओं के लिए कस्टम बोलार्ड पर केंद्रित है. यह सुनिश्चित करता है कि बोलार्ड मजबूत हैं और थोड़ी देखभाल की आवश्यकता है.

| प्रमाण | विवरण |

|---|---|

| स्थायित्व और संक्षारण प्रतिरोध | स्टेनलेस स्टील मजबूत रहता है और जंग का विरोध करता है. |

| परियोजना आवश्यकताओं के लिए अनुकूलन | कस्टम डिजाइन विशेष सुरक्षा आवश्यकताओं को पूरा करते हैं. |

| कम रखरखाव और उच्च प्रभाव शक्ति | सामग्री को कम देखभाल की आवश्यकता होती है और मजबूत दुर्घटनाओं को संभालने की आवश्यकता होती है. |

कस्टम डिजाइन सामग्री और उपयोग के लिए सामग्री से मेल खाता है. यह सुनिश्चित करता है कि ट्रैफिक बोलार्ड सुरक्षित रहें, अच्छा लगना, और क्रैश मांगों को पूरा करें.

वास्तविक दुनिया के अनुप्रयोग और केस स्टडी

कैसे बोलार्ड सुरक्षा और सुरक्षा के साथ मदद करते हैं

स्थानों को सुरक्षित और सुरक्षित रखने के लिए बोलार्ड महत्वपूर्ण हैं. हमलों के दौरान वाहनों को रोकने के लिए क्रैश-रेटेड बोलार्ड बनाए जाते हैं. वे सुरक्षा नियमों को पूरा करने के लिए कठिन परीक्षणों से गुजरते हैं. ये बोलार्ड विभिन्न आकारों और गति की कारों को अवरुद्ध कर सकते हैं. यह उन्हें हवाई अड्डों और सरकारी इमारतों जैसे स्थानों की रक्षा के लिए महान बनाता है.

सुरक्षा प्रदान करते हुए सजावटी बोलार्ड्स अच्छे लगते हैं. वे सार्वजनिक स्थानों को सुंदर बनाते हैं और अभी भी बाधाओं के रूप में काम करते हैं. लचीला बोलार्ड, रबर या प्लास्टिक से बना, धीमी गति वाले क्षेत्रों के लिए अच्छे हैं. हिट होने पर वे झुकते हैं, कारों को कम नुकसान पहुंचाना. वे भी सस्ते और बदलने में आसान हैं.

क्रैश-रेटेड बोलार्ड की वास्तविक जीवन की सफलता की कहानियाँ

क्रैश-रेटेड बोलार्ड ने वास्तविक स्थितियों में अच्छा काम किया है. उदाहरण के लिए, दुकानों पर रोड बोलार्ड ने कारों को उनमें दुर्घटनाग्रस्त होने से रोक दिया है. ऊपर 30,000 बोलार्ड की तुलना में अधिक से अधिक की स्थापना की गई है 1,000 भंडार. इससे पता चलता है कि वे लोगों और इमारतों को सुरक्षित रखने में महान हैं.

| क्या हुआ | नंबर |

|---|---|

| बोलार्ड स्थापित किया गया | 30,000+ |

| संरक्षित स्थान | 1,000+ |

ये रोड बोलार्ड दुर्घटनाओं को रोककर व्यस्त क्षेत्रों की रक्षा करते हैं. वे लोगों को सुरक्षित रखते हैं और इमारतों और फुटपाथों को नुकसान पहुंचाते हैं.

हम अच्छे प्रतिष्ठानों से क्या सीखते हैं

अच्छा बोलार्ड सेटअप इस बात पर प्रकाश डालते हैं कि सही सामग्री का चयन क्यों बोल्डार्ड मैन्युफैक्चरिंग में महत्वपूर्ण है. क्रैश-रेटेड बोलार्ड उच्च जोखिम वाले क्षेत्रों के लिए आदर्श हैं जहां वाहन के हमलों को रोकना एक प्राथमिकता है. सजावटी बोलार्ड सुरक्षा और दृश्य अपील को जोड़ते हैं, उन्हें शहरी स्थानों के लिए उपयुक्त बनाना. लचीले बोलार्ड कम गति वाले क्षेत्रों में अच्छी तरह से काम करते हैं-वे टिकाऊ हैं, प्रभावी लागत, और अंतिम करने के लिए बनाया गया.

इन उदाहरणों से पता चलता है कि नौकरी के लिए सही ट्रैफ़िक बोलार्ड क्यों चुनना महत्वपूर्ण है. सही प्रकार को चुनने से बाधाएं बेहतर काम करती हैं और लंबे समय तक स्थानों को सुरक्षित रखती हैं.

बोलार्ड बनाने की प्रक्रिया से पता चलता है कि परीक्षण क्यों महत्वपूर्ण है. सावधान परीक्षण सुनिश्चित करें कि ट्रैफिक बोल्ड सुरक्षित हैं और अच्छी तरह से काम करते हैं. कंपनियां अब बढ़ती जरूरतों को पूरा करने के लिए मानक तरीकों का उपयोग करती हैं. कई लोग पैसे बचाने और तेजी से कार्य करने के लिए स्थानीय स्तर पर बोलार्ड भी बनाते हैं.

सुरक्षित रहने का मतलब है मजबूत और स्मार्ट डिजाइनों का उपयोग करना. यह जानने के लिए बोलार्ड विवरण की जाँच करें कि सामग्री उन्हें कैसे अंतिम बनाती है. यह देखने के लिए कि हमारे बोलार्ड आपकी मदद कैसे कर सकते हैं.

अक्सर पूछे जाने वाले प्रश्न

बॉलार्ड्स से बने हैं?

बोलार्ड स्टील का उपयोग करते हैं, ठोस, या पॉलिमर. स्टील मजबूत है, कंक्रीट लंबे समय तक रहता है, और पॉलिमर आसानी से झुकते हैं. प्रत्येक सामग्री क्रैश को रोकने या अच्छी दिखने जैसी विभिन्न नौकरियों में फिट बैठता है.

सुरक्षा के लिए बोलार्ड का परीक्षण कैसे किया जाता है?

टेस्ट की जाँच करें कि क्या बोलार्ड सुरक्षित और मजबूत हैं. क्रैश परीक्षण देखें कि क्या वे वाहनों को रोकते हैं. लोड परीक्षण ताकत की जांच करने के लिए वजन जोड़ें. मौसम परीक्षण से पता चलता है कि क्या वे गर्मी से बचते हैं, ठंडा, या बारिश.

क्यों भौतिक चयन बोलार्ड के लिए महत्वपूर्ण है?

सामग्री तय करती है कि बोलार्ड तनाव को कैसे संभालते हैं. स्टील या कंक्रीट जैसे मजबूत लंबे समय तक रहता है और सुरक्षित रहता है. सही सामग्री लेने से बोलार्ड कठिन परिस्थितियों में अच्छी तरह से काम करने में मदद करते हैं.

क्या बोलार्ड को विशिष्ट परियोजनाओं के लिए अनुकूलित किया जा सकता है?

हाँ, विशेष जरूरतों को पूरा करने के लिए बोलार्ड बनाए जा सकते हैं. आप सामग्री चुन सकते हैं, आकार, और नौकरी पर आधारित दिखता है. कस्टम बोलार्ड सुरक्षा नियमों को पूरा करते हैं और अच्छे भी दिखते हैं.

क्या प्रमाणपत्रों को मिलना चाहिए?

Bollards ASTM F3016 जैसे प्रमाणपत्रों की आवश्यकता है, एएसटीएम F2656, नहीं 68. ये साबित करते हैं कि बोलार्ड सुरक्षित हैं, मज़बूत, और क्रैश-परीक्षण किया गया. वे वैश्विक नियमों का पालन करते हैं और मज़बूती से काम करते हैं.