تواجه شركة Elon Musk’s Tunnel Company نقص حركة المرور: كيف تعتبر الاستجابة السريعة B2B أمرًا ضروريًا للسلامة

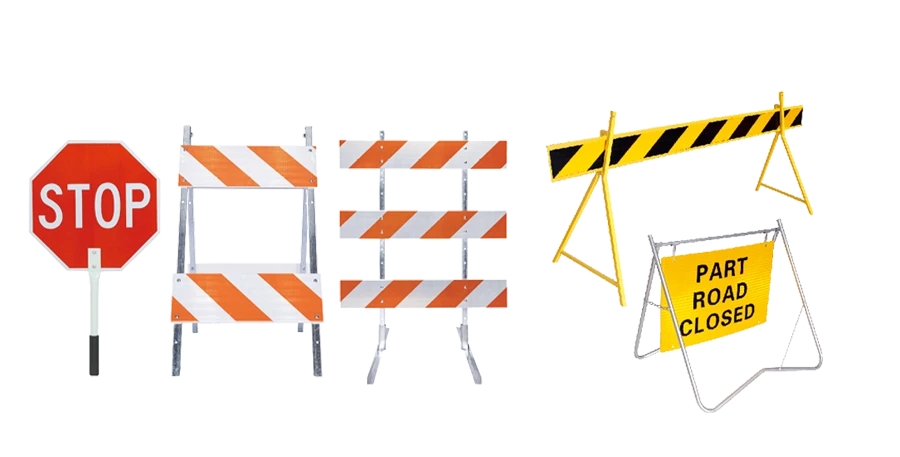

ال Boring Company, led by Elon Musk, faces an unexpected challenge—a shortage of traffic cones. This issue poses significant risks to workplace safety, particularly in high-stakes tunneling projects. Road cone suppliers are critical in providing the necessary road cones that play a vital role in marking hazardous zones and guiding workers, ensuring smooth operations and accident prevention. بدونهم, construction sites become vulnerable to safety breaches and operational delays.

Rapid response from road cone suppliers becomes essential in such scenarios. Addressing supply chain disruptions quickly ensures workplace safety remains uncompromised. Businesses must prioritize efficient procurement strategies to meet urgent demands and maintain project momentum.

Understanding the Traffic Cone Shortage in High-Stakes Projects

The Impact of Traffic Cone Shortages on Large-Scale Construction Projects

Traffic cone shortages can disrupt the progress of large-scale construction projects, particularly those requiring precise safety measures. These shortages often lead to increased costs and delays, as project managers scramble to source alternative solutions. Without adequate traffic cones, construction zones may lack proper demarcation, exposing workers and equipment to unnecessary hazards. This not only jeopardizes safety but also risks violating regulatory compliance standards.

Several factors amplify the impact of such shortages. على سبيل المثال:

- Increased costs arise from last-minute procurement or reliance on lower-quality alternatives.

- Delays occur when projects halt due to insufficient safety equipment.

- High-quality road cones, when unavailable, force frequent replacements, further straining budgets.

In high-profile projects like Elon Musk’s tunneling ventures, these challenges can escalate quickly. The absence of reliable traffic cones compromises worker safety and slows down operations, creating a ripple effect on timelines and budgets. Consistent access to durable, high-quality road cones ensures long-term savings and uninterrupted progress.

Why Consistent Access to Safety Equipment is Vital for Tunneling Projects

Tunneling projects demand rigorous safety protocols due to their complex and hazardous environments. Traffic cones play a pivotal role in marking danger zones, guiding vehicles, and ensuring smooth workflows. Their absence increases the likelihood of accidents, equipment damage, and operational inefficiencies.

Underground construction sites, such as those managed by the Boring Company, face unique challenges. Limited visibility and confined spaces heighten the need for clear safety markers. A shortage of traffic cones disrupts these critical safety measures, exposing workers to preventable risks. علاوة على ذلك, delays in acquiring essential equipment can halt operations, leading to financial losses and reputational damage.

Reliable suppliers capable of meeting urgent demands are indispensable for such projects. They ensure that safety equipment arrives on time, minimizing hazards and maintaining operational efficiency. Consistent access to traffic cones not only safeguards workers but also supports the timely completion of high-stakes projects.

Why Fast Delivery is Critical for Safety and Efficiency

Time-Sensitive Nature of Safety Equipment in Construction

Construction projects operate on tight schedules, where delays can cascade into significant setbacks. Safety equipment, مثل المخاريط المرورية, plays a crucial role in maintaining worker safety and ensuring smooth workflows. For tunnel workers, the absence of these tools can lead to safety risks to workers and disrupt operations. Underground environments, with their confined spaces and limited visibility, demand immediate access to safety equipment to prevent accidents and maintain efficiency.

Fast delivery of safety equipment becomes essential in these scenarios. A delay in receiving traffic cones or other safety tools can halt progress, forcing crews to wait and increasing labor costs. Tunnel workers rely on these tools to demarcate hazardous zones and guide vehicles, ensuring their safety and the project’s continuity. Companies that prioritize rapid delivery mitigate these risks, safeguarding both timelines and budgets.

Challenges of Supply Chain Disruptions in Underground Projects

Supply chain disruptions pose unique challenges for underground construction projects. These disruptions can lead to material shortages, poor-quality supplies, and unplanned delays, all of which directly impact worker safety and project efficiency. The following table highlights some of the key challenges faced by construction companies:

| Challenge | Impact |

|---|---|

| Material Shortages | Increased prices and delays in construction schedules due to waiting for supplies. |

| Poor Supply Quality | Sub-standard materials leading to increased costs and potential project failures. |

| Lack of Transparency | Difficulty in tracking supply chain issues, causing unexpected delays and budget overruns. |

| Unplanned Events | Additional delays and costs due to unforeseen circumstances affecting project timelines. |

For tunnel workers, these challenges amplify safety risks to workers. Poor-quality materials, such as substandard traffic cones, compromise safety protocols and increase the likelihood of accidents. بالإضافة إلى ذلك, delays in acquiring essential equipment disrupt workflows, forcing crews to work under unsafe conditions or halt operations entirely. Companies must address these challenges by partnering with reliable suppliers who can ensure timely delivery of high-quality safety equipment.

Fast delivery not only reduces safety risks to workers but also ensures that projects remain on schedule. By addressing supply chain disruptions proactively, construction companies can protect their workers and maintain operational efficiency.

How OPTsigns Can Help with Rapid Traffic Cone Delivery

OPTsigns’ Ability to Meet Urgent Demands for Construction Projects

OPTsigns has established itself as a reliable partner for construction companies facing urgent safety equipment needs. Their rapid traffic cone delivery services stand out due to several unique features:

- A stable supply of high-quality traffic cones, even during peak demand periods, ensures uninterrupted project workflows.

- Timely deliveries prioritize workplace safety and operational efficiency, especially in high-pressure environments.

- The capacity to handle large orders without compromising quality guarantees that safety standards are consistently met.

These capabilities make OPTsigns a dependable choice for large-scale projects requiring immediate solutions. By addressing urgent demands effectively, they help construction companies maintain safety protocols and meet tight deadlines.

Leveraging Reliable Partners and Optimized Supply Chains for Timely Delivery

OPTsigns’ success in delivering traffic safety equipment on time stems from their optimized supply chain and strong partnerships. Their ability to meet diverse project requirements is evident in their track record:

| Evidence Description | Outcome |

|---|---|

| Provided a wide range of traffic cones, warning posts, and delineators for national highway projects | Delivered on time, meeting safety standards |

| Supplied significant quantities of traffic safety equipment for large urban construction projects | Ensured smooth traffic management during peak phases |

| Handled extensive orders for international sporting events | Ensured timely delivery and compliance with safety standards |

By streamlining logistics and collaborating with reliable partners, OPTsigns ensures that construction companies receive the equipment they need when they need it. This approach minimizes delays, reduces risks, and supports the successful completion of high-stakes projects.

B2B Solutions for Quick and Reliable Traffic Safety Equipment Procurement

Why Quick Response is Essential in B2B Traffic Safety Procurement

Quick response in B2B traffic safety procurement ensures uninterrupted workflows and minimizes risks in high-stakes projects. Construction companies, especially those managing complex environments like a tunnel, rely on road cone suppliers to deliver safety equipment promptly. Delays in procurement can lead to unsafe conditions, project downtime, and increased costs.

Reliable road cone suppliers streamline the procurement process by offering efficient communication, inventory management, and logistics. Their ability to respond quickly to urgent demands allows construction teams to maintain safety standards without compromising deadlines. على سبيل المثال, a tunneling project may require immediate delivery of traffic cones to mark hazardous zones. A supplier with a robust response system ensures these needs are met without delay.

In addition, quick response fosters trust between suppliers and construction companies. It demonstrates the supplier’s commitment to supporting project goals and maintaining safety. This reliability becomes critical in environments where safety equipment directly impacts worker well-being and operational efficiency.

Customized Solutions for Large-Scale Projects

Large-scale projects, such as tunneling operations, often require tailored solutions to meet their unique demands. Road cone suppliers that offer customized services can address these specific needs effectively. على سبيل المثال, a tunnel project may need cones with enhanced visibility or durability to withstand harsh underground conditions.

Suppliers providing customized solutions collaborate closely with project managers to understand their requirements. They ensure that the traffic cones meet safety regulations and align with the project’s operational goals. This approach not only enhances safety but also improves efficiency by reducing the need for frequent replacements or adjustments.

علاوة على ذلك, customization extends to delivery schedules and order quantities. Suppliers capable of scaling their services to match project demands ensure that construction teams receive the right equipment at the right time. This flexibility supports seamless operations, even in the most challenging environments.

By offering tailored solutions, road cone suppliers play a vital role in the success of large-scale projects. Their ability to adapt to specific requirements ensures that safety and efficiency remain top priorities.

The Consequences of Delayed Traffic Safety Equipment Delivery

Delays Can Lead to Safety Risks and Increased Costs

Delays in delivering traffic safety equipment can have severe consequences for construction projects. Workers rely on tools like traffic cones to maintain safe environments and prevent accidents. When these tools are unavailable, safety violations become more likely, exposing workers to unnecessary risks. على سبيل المثال, poorly marked zones can lead to vehicle collisions or injuries caused by unmarked hazards. These incidents not only endanger lives but also result in legal liabilities and regulatory penalties.

Financially, delays in safety equipment delivery can escalate project costs. Construction teams often face increased labor expenses as workers wait for essential tools to arrive. بالإضافة إلى ذلك, project managers may need to procure temporary solutions, which are often more expensive and less effective. These unplanned expenses strain budgets and disrupt financial planning. In high-stakes projects, such as tunneling operations, these delays can jeopardize overall timelines, leading to missed deadlines and reputational damage.

Real-World Examples of Supply Chain Failures in Construction

Supply chain failures have historically caused significant disruptions in the construction industry. Unplanned events, such as natural disasters and labor shortages, often lead to delays in delivering critical materials. These disruptions can halt progress, forcing companies to reassess timelines and budgets. In severe cases, projects may even face cancellation due to prolonged delays.

ال Covid-19 Pandemic serves as a prominent example of supply chain breakdowns. Factory closures and lockdowns disrupted manufacturing processes, creating shortages of essential construction materials. Labor shortages caused by quarantines further compounded the issue, delaying the movement of goods across supply chains. These challenges highlighted the importance of reliable suppliers and proactive logistics management in mitigating risks.

By addressing these supply chain vulnerabilities, construction companies can reduce delays and maintain operational efficiency. Partnering with dependable suppliers ensures timely delivery of safety equipment, safeguarding workers and minimizing project disruptions.

Rapid response to traffic cone shortages ensures workplace safety and prevents costly delays in construction projects. Partnering with reliable suppliers like OPTsigns mitigates risks through:

- Timely deliveries that avoid project disruptions.

- High-quality standards that reduce equipment failures.

- Financial flexibility and stability to handle demand spikes.

- Clear communication that fosters trust and minimizes misunderstandings.

Proactive B2B strategies remain essential for high-stakes tunneling and construction projects. These approaches ensure safety, كفاءة, and timely project completion, safeguarding both workers and budgets.

التعليمات

What role do traffic cones play in tunneling projects?

Traffic cones ensure safety by marking hazardous zones and guiding workers in tunneling environments. They help maintain order and prevent accidents in confined spaces like the vegas loop. Their absence disrupts workflows and increases risks.

How does a reliable supply system benefit construction projects?

A reliable supply system ensures timely delivery of essential equipment like traffic cones. This minimizes delays, reduces costs, and maintains safety standards. For projects like the vegas loop, an efficient system supports uninterrupted progress and operational efficiency.

Why is fast delivery critical for tunneling projects?

Fast delivery prevents delays in tunneling projects by ensuring immediate access to safety equipment. Underground environments, such as the vegas loop, demand quick responses to maintain safety and efficiency. Delays can lead to increased costs and safety risks.

How does OPTsigns address urgent demands for traffic cones?

OPTsigns leverages an optimized supply system to meet urgent demands. Their ability to deliver high-quality traffic cones quickly supports projects like the vegas loop. This ensures safety and helps construction teams meet tight deadlines.

What makes the vegas loop unique in terms of safety requirements?

The vegas loop operates in a confined, high-traffic environment, requiring rigorous safety measures. A robust system of traffic cones and other equipment ensures smooth operations. Reliable suppliers play a crucial role in meeting these unique demands.