تعتبر علامات المرور العاكسة مهمة جدًا للحفاظ على آمنة للناس على الطرق الأسترالية. تساعد هذه العلامات السائقين على رؤية المعلومات الرئيسية, حتى في الليل أو عندما يكون الطقس سيئًا. تستخدم علامات حركة البناء مواد خاصة لتسهيل رؤية وتحذير السائقين من التغييرات المقبلة. تشير الدراسات إلى أن علامات حركة مرور عاكسة أفضل وعلامات حركة البناء تساعد السائقين على إشعار العلامات عاجلاً, رد فعل بسرعة أكبر, وتوقف عندما يحتاجون إلى.

في أوبترافيك, نحن رائدون توقيع الشركة المصنعة مع قاعدة عملاء شاسعة, تقديم جودة عالية علامات المرور للبيع التي تلبي المعايير الأسترالية. يضمن إنتاجنا الداخلي أفضل مراقبة الجودة, ونحن ملتزمون بتوفير حلول لافتات متينة وموثوقة للحفاظ على أمان الطرق.

الوجبات الرئيسية

- أغطية عاكسة على علامات المرور تساعد السائقين على رؤية العلامات في الليل. كما أنه يساعد في الطقس السيئ. هذا يجعل الطرق أكثر أمانًا للجميع.

- تستخدم أستراليا قواعد صارمة مثل AS/NZS 1906 و 1742. هذه القواعد تتأكد. كما أنها تجعل العلامات سهلة القراءة.

- هناك ثلاث فئات من الأغطية العاكسة. فصل 1 جيد للشوارع الهادئة. فصل 2 يستخدم في أماكن مع بعض حركة المرور. فصل 3 هو الأفضل للطرق السريعة المزدحمة والمناطق الخطرة.

- يجب تنظيف علامات المرور والتحقق منها كثيرًا. هذا يبقيهم مشرقًا ويعمل بشكل جيد. يساعد السائقين على رؤية التحذيرات والبقاء آمنين.

- من المهم اختيار الأغطية العاكسة الصحيحة. اتباع قواعد الرعاية يساعد المجالس على الحفاظ على الطرق آمنة. كما أنه يجعل العلامات تدوم لفترة أطول.

علامات ومعايير حركة مرور عاكسة

AS/NZS 1906 ملخص

AS/NZS 1906 هي قاعدة علامات المرور العاكسة في أستراليا ونيوزيلندا. تقول هذه القاعدة كيف يجب أن تعمل المواد حتى يرى السائقون العلامات جيدًا, حتى في الليل أو في الطقس السيئ. يتحدث عن الانعكاس, متانة, واللون. These rules help keep people safe by making sure signs stay easy to see for a long time. Research shows dirt and damage make reflective traffic signs work less well. على سبيل المثال, studies using mobile LiDAR and photolog technology found dirt, sign height, and air pollution change how much light signs reflect. Cleaning and checking signs often helps them follow the rules and keeps roads safer.

مثل 1742 و mutcd

مثل 1742 gives the rules for using reflective traffic signs on Australian roads. It tells where to put signs, what shapes and colours to use, and how to make them simple to read. ال دليل أجهزة مراقبة حركة المرور الموحدة (Mutcd) يعمل مع 1742. It explains how to use signs, إشارات, and markings so everyone gets clear messages. Studies show that damaged signs do not reflect light as well, which is important at night. If signs do not follow these rules, قد يفوت السائقون التحذيرات ويمكن أن تحدث الحوادث. غالبًا ما يساعد التحقق من علامات وإصلاحها في الحفاظ على أمان الطرق وتتأكد من اتباع القواعد.

لمعرفة المزيد عن معايير علامة الطريق وكيف تختلف عبر المناطق, تحقق من مدونتنا على فهم معايير علامة السلامة على الطرق: Mutcd (الولايات المتحدة الأمريكية), مثل 1742 (أستراليا), و Vienna Convention (أوروبا).

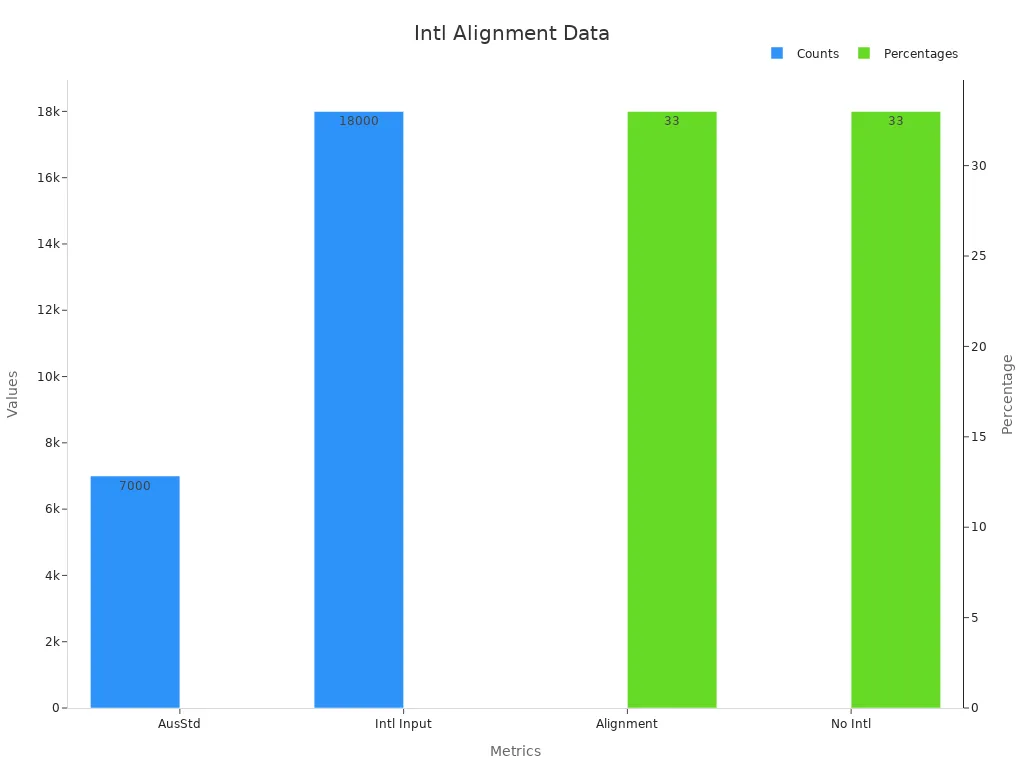

المحاذاة الدولية

تطابق أستراليا العديد من قواعدها مع إرشادات دولية لمواكبة التكنولوجيا الجديدة في العلامات والسلامة على الطرق. المعايير تعمل أستراليا مع مجموعات مثل ISO و IEC لتقديم وتحديث القواعد. حوالي ثلث القواعد الأسترالية هي نفس القواعد الدولية, لكن بعض, مثل البناء والصحة, لديهم قواعدهم المحلية الخاصة. من هنا, يمكن لأستراليا استخدام أفكار جديدة وأفضل طرق من البلدان الأخرى. يوضح الرسم البياني أدناه كيف تقارن قواعد أستراليا بالقواعد الدولية.

ملحوظة: تساعد مطابقة القواعد العالمية أستراليا على جعل الطرق أكثر أمانًا وتتيح لافتات حركة مرور عاكسة استخدام أحدث التقنيات.

فئات من الأغطية العاكسة

تساعد الأغطية العاكسة للسائقين على رؤية علامات الطرق في الطقس السيئ أو في الليل. في أستراليا, هناك ثلاث فئات رئيسية من الأغطية العاكسة. كل فصل له ميزاته واستخداماته الخاصة. إن اختيار الفصل المناسب يبقي الطرق آمنة ويتأكد من أن العلامات تتبع القواعد.

فصل 1 سمات

فصل 1 أغطية عاكسة يستخدم أكثر لعلامات حركة البناء حيث لا تكون حركة المرور ثقيلة للغاية. تحتوي هذه اللوحات على ظهر لزج يمكن للعمال أن يقشروا ويتمسكوا به, أسطح ناعمة. لا توجد حاجة إلى حرارة لوضعها. فصل 1 يعمل بشكل جيد في درجات الحرارة العادية وسهلة الاستخدام.

| فصل | نوع لاصق وطريقة التطبيق | تحمل درجة الحرارة | الخصائص الرئيسية |

|---|---|---|---|

| 1 | حساسة للضغط, لصق الذات; قشر وعصا | درجات الحرارة القياسية; لا حاجة للحرارة | الأكثر شيوعا; تثبيت بسيط على سلس, الأسطح النظيفة |

فصل 1 الأغطية العاكسة تعطي الانعكاس الأساسي. إنه جيد للعلامات في شوارع المدينة, طرق الأحياء, والأماكن مع خطر أقل. مثل أشخاص مثل هذا الفصل لأنه رخيص وبسيط للاستخدام. ولكن قد لا يكون مشرقًا بما يكفي للطرق السريعة المزدحمة أو الأماكن المظلمة.

فصل 2 سمات

فصل 2 أغطية عاكسة أكثر إشراقًا من الفصل 1. يحتاج إلى الحرارة للالتصاق, لذلك يستخدم العمال مكبس الحرارة لوضعه. هذا يجعل الرابطة قوية وطويلة الأمد. فصل 2 غالبًا ما يستخدم التكنولوجيا الدقيقة, مما يجعل العلامات تلمع أكثر في الضوء المنخفض.

| وجه | التفاصيل الداعمة |

|---|---|

| التكنولوجيا العاكسة | يستخدم حبة زجاجية محسنة وتكنولوجيا micromormatic مع قذيفة شفافة واقية, زيادة الانعكاس مقارنة بالطبقة 1. |

| مقاييس الأداء | الحد الأدنى من الانعكاس 180 CD/LX/M², حوالي ثلاثة أضعاف الفصل الدراسي 1, تحسين الرؤية في الإضاءة المنخفضة والطقس المعاكس. |

| متانة | ضمان 10 ل 12 سنين; مقاومة للأشعة فوق البنفسجية, رُطُوبَة, وتغيرات درجة الحرارة, ضمان الوضوح على المدى الطويل والسطوع. |

| التطبيقات | يستخدم عادة للحد من السرعة, تحذير, اتجاهي, والعلامات التنظيمية في المناطق الحضرية, ريفي, وبيئات الطرق السريعة. |

| الامتثال التنظيمي | تلبي معايير مثل bs en 128991:2007, ضمان الموثوقية التشغيلية والامتثال للسلامة. |

| فعالية التكلفة | التكلفة الأولية الأعلى من الفصل 1 ولكن متوازنة مع عمر أطول وتحسين أداء السلامة, مما يجعلها فعالة من حيث التكلفة للطرق المتوسطة السرعة. |

فصل 2 الأغطية العاكسة هي الأفضل للعلامات على الطرق السريعة الأصغر, زوايا المدينة, والأماكن مع بعض حركة المرور. يساعد السائقين على رؤية علامات أفضل في الليل أو عندما تمطر أو تكون ضبابية. تستخدم العديد من المجالس الفصل 2 لتحذير وعلامات الحكم حيث تكون هناك حاجة إلى سلامة إضافية.

فصل 3 سمات

فصل 3 أغطية عاكسة هو ألمع نوع. يحتوي على ظهر لزج يمكن تحريكه قبل الضغط عليه لأسفل. لا توجد حاجة للحرارة أو المواد الكيميائية. هذا يجعل من السهل ضبطه أثناء التثبيت.

| فصل | نوع لاصق وطريقة التطبيق | تحمل درجة الحرارة | الخصائص الرئيسية |

|---|---|---|---|

| 3 | منخفضة, لاصق حساس للضغط | يمكن إعادة وضعه حتى 100 درجة فهرنهايت دون أضرار | لا حاجة للحرارة أو المذيب; يسمح بإعادة وضع الأسطح الملساء |

فصل 3 الأغطية العاكسة هي الأفضل للعلامات على الطرق السريعة, مفترق طرق كبير, والأماكن مع الكثير من الخطر. يضيء بشكل مشرق في الظلام أو عندما تمطر. يمكن للسائقين رؤية هذه العلامات من بعيد, مما يساعد على إيقاف الحوادث. يتم اختيار هذا الفصل للطرق المزدحمة أو حيث تهم السلامة معظمها.

لفهم سبب الاستثمار في الفصل 3 الأغطية العاكسة خيار ذكي, اقرأ مدونتنا: تكلفة السلامة: لماذا الاستثمار في الفصل 3 الأغطية العاكسة تستحق ذلك لسلطات الطرق الأسترالية.

اختيار الفصل الصحيح

يعتمد اختيار الأغطية العاكسة الصحيحة على أشياء كثيرة. يحتاج كل طريق ومكان إلى التفكير الدقيق. فيما يلي بعض النقاط للمساعدة في الاختيار:

- إعادة الانفعال: هذا يعني مدى جودة الأغطية التي ترسل الضوء إلى السائقين. الأغطية الدقيقة تعطي مشرقًا, شعاع ضيق لرؤية بعيدا. تنتشر أغطية حبة الزجاج للضوء لرؤية ما يصل إلى قرب.

- تشتت الضوء: بعض الأنواع تعمل بشكل أفضل للعلامات التي شوهدت من بعيد, آخرون للعلامات التي شوهدت عن قرب.

- سطوع: الأغطية الساطعة للغاية مهمة للعلامات على الطرق السريعة أو الخطرة.

- متانة: تدوم الأغطية القوية لفترة أطول ولا تحتاج إلى استبدالها كثيرًا, حتى في الطقس السيئ.

- التصاق والمرونة: الجزء اللزج وكيف يساعده في التمسك بأسطح مختلفة.

- نوع السطح: سلس, تساعد الأسطح النظيفة على تلتصق الأغطية بشكل أفضل وتألق أكثر.

- أنظمة: قواعد مثل AS/NZS 1906, مثل 1742, ويقول mutcd كيفية استخدام الأغطية العاكسة للعلامات.

- بيانات المنتج: أشياء مثل السماكة, الحياة في الهواء الطلق, وإذا كان يمكن طباعته عند مساعدة مطابقة الأغطية مع الوظيفة.

نصيحة: اختر دائمًا فئة الأغطية العاكسة بناءً على مدى انشغال الطريق, كم من الضوء هناك, ونوع العلامات المطلوبة. للطرق السريعة المزدحمة أو الأماكن المظلمة, فصل 3 عادة ما يكون أكثر أمانًا. للشوارع الهادئة أو العلامات قصيرة الأجل, فصل 1 أو الفصل 2 قد يكون كافيا.

إن اختيار الفصل المناسب يتأكد من أن العلامات سهلة رؤيتها, تلبية قواعد السلامة, وتساعد على إبقاء الجميع آمنين على الطريق.

الأداء وزيادة السلامة على الطرق

إعادة الانفعال

إعادة الانفعال هو مدى جودة الإشارة التي ترسل المصابيح الأمامية للسيارات إلى السائقين. هذا يساعد الناس على رؤية العلامات في الليل أو عندما يكون الطقس سيئًا. تستخدم الأغطية العاكسة لتكنولوجيا جديدة لجعل علامات الطرق الرئيسية أكثر إشراقًا. يمكن رؤية هذه العلامات من بعيد. اختبارات مثل ASTM E1710 تحقق من مقدار الإضاءة التي تعكس العلامات. ينظف, اللافتات الجافة تتألق بشكل أفضل, لكن الأوساخ, ماء, والسن يمكن أن يصلوا إلى 28% أقل مشرقا. يساعد التعلم الآلي الآن في تخمين كيف يتغير الانعكاس بمرور الوقت. هذا يساعد المجالس على معرفة متى تنظف أو إصلاح العلامات. غالبًا ما يحافظ التحقق من علامات التحقق والتنظيف على مشرق وسهل رؤيته في الليل. هذا يساعد على جعل الطرق أكثر أمانًا للجميع.

المتانة والطقس

تعني المتانة كم من الوقت تظل الإشارة مشرقة وسهلة القراءة. سوء الأحوال الجوية مثل البرد, رياح, والبرق يمكن أن يضر العلامات. تظهر تقارير الطقس الشرعي عند حدوث العواصف وإذا تضررت العلامات. هذه التقارير تساعد المجالس وشركات التأمين على تحديد ما إذا كان هناك حاجة إلى استبدال العلامات. الأغطية العاكسة الجيدة لا تتلاشى, كسر, أو قشر, حتى بعد سنوات من الشمس أو المطر. الانعكاس القوي يعني أن العلامات تبقى آمنة وسهلة رؤيتها في كل الطقس. تثق المجالس في هذه المواد للحفاظ على الطرق آمنة ووقف العلامات التي تحتاج إلى تغييرها كثيرًا.

تأثير الرؤية

الرؤية مهمة للغاية للسلامة على الطرق. تساعد فصول الأغطية العاكسة المختلفة للأشخاص على رؤية العلامات بشكل أفضل في أماكن مختلفة. تبحث الدراسات في مدى جودة اكتشاف الأشخاص مع مواد مختلفة:

| يذاكر (سنة) | الأغطية/الفصل | مسافة الرؤية/الكشف | النتيجة/الإحصاء |

|---|---|---|---|

| ألين (1970) | سترة عاكسة | مسافة الرؤية | 234م مقابل 118 م (أعلى مع العاكس) |

| كول (1984) | أبيض مقابل الأقراص السوداء | تردد الكشف | 46% مقابل 35% (أبيض أعلى) |

| أوينز (2007) | مائل عاكسة | تردد الاعتراف | كلاهما 97% |

تساعد المواد الفلورسنت وعاكسة السائقين على رؤية ومعرفة العلامات بشكل أسرع, خاصة في الليل. علامات أكثر إشراقًا تعني أن السائقين يتفاعلون بشكل أسرع وتفوت عدد أقل من التحذيرات. تشير التقارير إلى أن أفضل وضوح ينقص, خاصة في مفترق الطرق المزدحمة. مشاهدة أشياء مثل الوفيات, الإصابات, وتساعد أرقام التحطم المجالس على معرفة ما إذا كانت مواد جديدة تعمل. البيانات المحلية والشيكات العادية لمساعدة المجالس تبقي الطرق آمنة للجميع.

متطلبات الامتثال والسلامة

الهيئات التنظيمية

تشاهد العديد من المجموعات علامات حركة البناء في أستراليا. سلطات طريق الدولة والإقليم, يحب النقل لنيو ساوث ويلز و Vicroads, تأكد من اتباع القواعد. تتأكد هذه المجموعات من أن علامات حركة البناء سهلة رؤيتها وتستمر لفترة طويلة. المعايير تكتب أستراليا وتحديث القواعد الرئيسية, مثل AS/NZS 1906 و 1742. تحقق المجالس المحلية أيضًا من علامات حركة البناء على طرقها. يساعد مفتشو السلامة من خلال التحقق من العلامات والتأكد من اتباع القواعد. يساعد المديرون الذين يهتمون بالسلامة الجميع على اتباع القواعد بشكل أفضل.

يساعد إجراء فحوصات منتظمة والحفاظ على السجلات الجيدة في العثور على المشكلات ويظهر المكان الذي يمكن أن تتحسن فيه الأمور.

- تحقق تقارير التدقيق ما إذا تم اتباع القواعد وأظهر ما يحتاج إلى إصلاح.

- غالبًا ما يساعد الاحتفاظ بسجلات واضحة والتحقق منها الجميع على متابعة القواعد.

- يساعدهم عمال التدريب والتعليم على معرفة القواعد والبقاء آمنين.

- غالبًا ما يتأكد التحقق من السجلات من أنها على صواب وحديثة.

- يساعد استخدام أجهزة الكمبيوتر للحفاظ على السجلات الأشخاص على رؤية التغييرات بسرعة واتخاذ خيارات جيدة.

شهادة واختبار

يوضح الاختبار وإصدار الشهادات أن علامات حركة البناء تتبع جميع القواعد. تستخدم الشهادة الشيكات داخل وخارج الشركة. تنظر هذه الشيكات إلى أنظمة الجودة وإذا تم اتباع القواعد. عمليات التفتيش تستخدم المظهر, الاختبار, واختيار العينات للعثور على أي مشاكل. اختبار الشيكات إذا كانت العلامات آمنة, قوي, ونوعية جيدة. تعطي المجموعات الخارجية شهادات عندما تلبي العلامات القواعد. يجب التحقق من هذه المجموعات للتأكد من قيامها بعمل جيد. تستخدم عملية ISO الشيكات, تمرين, والبحث عن فجوات للتأكد من اتباع القواعد.

- يتحقق الشهادات إذا تم اتباع أنظمة الجودة والقواعد.

- إن النظر إلى العلامات واختبارها يساعد في التأكد من أنها جيدة.

- التحقق من المجموعات التي تقدم شهادات تتأكد من أنها ماهرة.

الصيانة والتفتيش

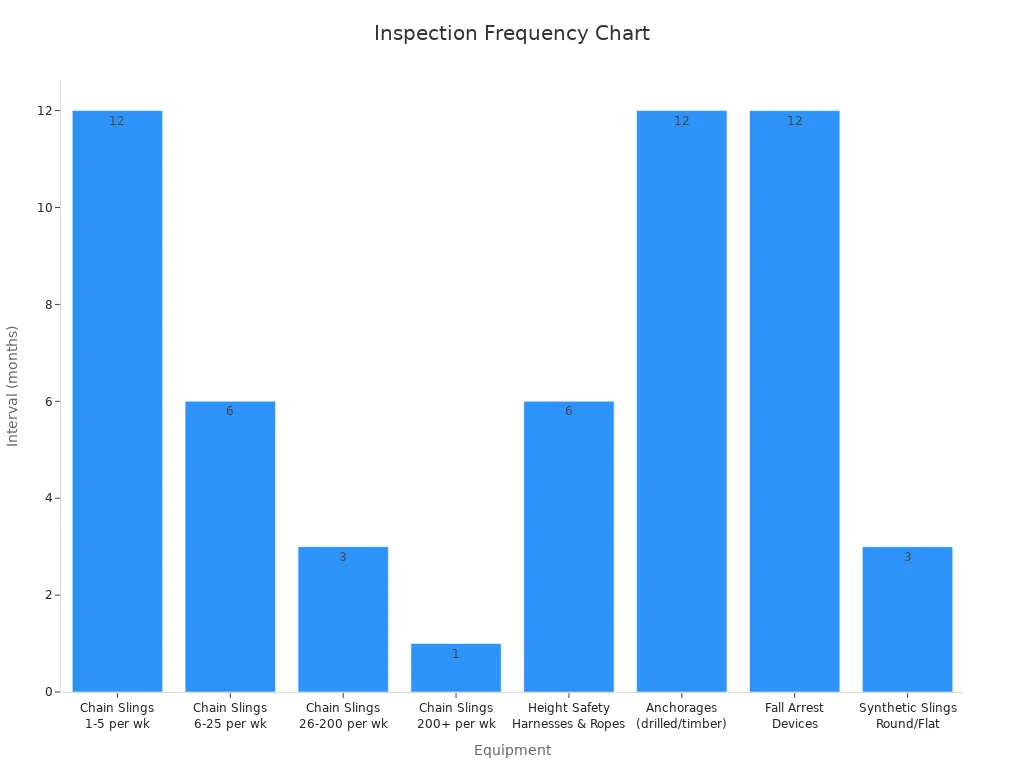

إن الحفاظ على علامات حركة البناء تعمل بشكل جيد يعني فحصها وإصلاحها في كثير من الأحيان. تخطط المجالس وسلطات الطرق لإيجاد الأضرار أو التلاشي. يجب أن تكون سجلات التثبيت والتحقق صحيحة وسهلة العثور عليها. الصيانة الوقائية تعني النظر في العلامات في كثير من الأحيان وتحديد المشكلات الصغيرة قبل أن تزداد سوءًا. يعتمد عدد المرات التي يتم فيها التحقق من العلامات على ما هي وكم يتم استخدامها.

| تردد الصيانة | الأنشطة والسجلات الرئيسية |

|---|---|

| أسبوعي | علامات نظيفة; ابحث عن الأوساخ أو الضرر; تحقق مما إذا كانوا يتألقون. |

| شهريا | تحقق من كيفية عقد العلامات; إصلاح أو تغيير الأجزاء المكسورة. |

| سنوي | احصل على محترف للتحقق من العلامات ومدى تألقها. |

| حفظ السجل | الحفاظ على السجلات الرقمية للقواعد, ضمان, وعلامات تتبع. |

نصيحة: الحفاظ على علامات حركة البناء في باردة, مكان جاف بعيدًا عن الشمس. التعامل مع العلامات بلطف حتى لا يتم خدشها أو عازمة, والتي يمكن أن تجعلها أقل لامعة وآمنة.

التحقق من العلامات في كثير من الأحيان وتخزينها بشكل جيد يساعدهم على العمل بشكل أفضل. هذا يبقيهم يتبعون القواعد ويساعد على الحفاظ على أمان الطرق.

التطبيقات: علامات حركة البناء وأكثر من ذلك

الأغطية العاكسة مهمة للغاية للعديد من العلامات في أستراليا. علامات حركة البناء, عاكس الاتجاه الرئيسي لافتات الطريق, تنظيمي, تحذير, وتوجيه العلامات كلها تستخدمه. تساعد هذه العلامات السائقين في العثور على طريقهم والبقاء آمنين على كل طريق. يعتمد نوع الأغطية العاكسة على المكان الذي تسير فيه العلامة ومدى خطورة المنطقة.

الاستخدام الحضري والريفي

المدن لديها طرق مزدحمة والكثير من العلامات. تستخدم علامات حركة البناء في المدن لافتات الطرق الرئيسية العاكسة لمساعدة السائقين مع التحويلات وأعمال الطرق. يجب أن تكون هذه العلامات سهلة رؤيتها مع جميع أضواء المدينة والضوضاء. في الريف, غالبًا ما تكون الطرق مظلمة وهادئة. علامات مرور البناء واللافتات الرئيسية الاتجاهية العاكسة تساعد السائقين على تحديد التغييرات أو المخاطر أمامها. أظهرت الدراسات التي أجريت في ولاية كونيتيكت وكارولينا الجنوبية ذلك أكثر إشراقًا توقف العلامات يعني عدد أقل من الحوادث, خاصة في مفترق الطرق الهادئ. لا تكلف الترقية إلى أغطية عاكسة أفضل كثيرًا ولكنها تجعل الطرق أكثر أمانًا. يستخدم كل من المدينة والبلد هذه العلامات لمساعدة السائقين والحفاظ على الطرق آمنة.

مناطق عالية الخطورة

تحتاج بعض الأماكن إلى مزيد من العناية للحفاظ على سلامة الناس. المناطق عالية الخطورة هي الطرق السريعة, المنعطفات الحادة, ومناطق البناء. علامات المرور مع لافتات الطرق الرئيسية العاكسة للرقم الماسي هي الأسهل في رؤيتها. هذه العلامات تساعد السائقين على إشعار الخطر من بعيد, حتى في المطر أو الضباب. يقول مديرو المرور أن استخدام أفضل المواد العاكسة في هذه الأماكن يساعد السائقين على التصرف بشكل أفضل ويوقف المزيد من الحوادث. الطلاء الخاص على العلامات تبقيهم مشرقًا وواضحًا, حتى بعد العواصف أو إذا حاول شخص ما إتلافهم.

دراسات الحالة

تُظهر قصص الحياة الحقيقية سبب مسألة لافتات الطرق الرئيسية الاتجاهية والاتجاهية العاكسة. غيرت مدينة واحدة العلامات القديمة لألحاق جديدة مع مواد عاكسة عالية الكثافة في معبر مزدحم. بعد هذا, أبقى السائقون على سرعة حدود أكثر وكان هناك عدد أقل من الحوادث. في الريف, علامات حركة البناء مع أفضل لافتات الطرق الرئيسية عاكسة الاتجاه ساعد السائقين على رؤية الالتفافات في الليل, لذلك لم يضيعوا. يستخدم صناع الآن مواد صديقة للبيئة وطلاءات قوية, لذا فإن العلامات تدوم لفترة أطول وأفضل لكوكبها. تساعد هذه التغييرات في علامات حركة البناء واللافتات الرئيسية للاتجاهية العاكسة للجميع على البقاء آمنًا وإيجاد طريقهم.

تستخدم علامات حركة البناء أنواعًا مختلفة من الأغطية العاكسة لعدة أسباب. فصل 1, 2, و 3 تساعد المواد في علامات البقاء سهلة رؤيتها في كل الطقس. بعد AS/NZS 1906 و 1742 التأكد من أن علامات حركة البناء تتبع القواعد وتبقي الناس آمنة. يجب أن ينظر الناس إلى علامات حركة البناء في كثير من الأحيان وتنظيفها عندما يتسخون. فيما يلي قائمة مرجعية للمساعدة:

- اختر الفصل المناسب لعلامات حركة البناء.

- تحقق من علامات حركة البناء لأي ضرر.

- غسل علامات حركة البناء في كثير من الأحيان.

- تغيير علامات حركة البناء إذا كانت تبدو باهتة.

- انظر إلى AS/NZS 1906 و 1742 للحصول على تحديثات جديدة.

غالبًا ما يساعد الاهتمام في علامات المرور العاكسة على إبقاء الجميع آمنين على الطريق.

التعليمات

ما هو الغرض الرئيسي من الأغطية العاكسة على علامات المرور?

تساعد الأغطية العاكسة للسائقين على رؤية العلامات في الليل أو عندما تمطر. ترتد المصابيح الأمامية للسيارات إلى عيون السائق. هذا يجعل الطرق أكثر أمانًا ويساعد على التوقف عن حوادث.

كم مرة يجب أن تفحص المجالس وعلامات حركة المرور النظيفة?

تحتاج المجالس إلى النظر في العلامات كل أسبوع عن الأوساخ أو الضرر. يجب عليهم إجراء فحوصات أكبر كل شهر للعثور على المزيد من المشكلات. كل عام, يقوم الخبراء بفحص العلامات للتأكد من أنها مشرقة وآمنة.

غالبًا ما تبقي علامات التنظيف سهلة رؤيتها وتساعدهم على الاستمرار لفترة أطول.

أي فئة من الأغطية العاكسة تناسب الطرق السريعة الأفضل?

فصل 3 الأغطية العاكسة هي الأفضل للطرق السريعة. إنه ألمع وأسهل أن نرى. يمكن للسائقين اكتشاف هذه العلامات من بعيد, حتى في المطر أو الضباب.

هل تتطابق المعايير الأسترالية إلى القواعد الدولية لعلامات المرور?

تشبه المعايير الأسترالية العديد من القواعد الدولية. هذا يتيح لأستراليا استخدام التكنولوجيا الجديدة والأفكار الجيدة للسلامة على الطرق.

| معيار | تنسيق |

|---|---|

| AS/NZS 1906 | تطابق ISO |

| مثل 1742 | يطابق MUTCD |

يمكن أن تؤثر الأغطية العاكسة على السلامة على الطرق?

نعم, إذا كانت الأغطية متسخة أو مكسورة, لا يلمع الكثير. قد لا يرى السائقون تحذيرات مهمة. يجب على المجالس إصلاح أو تغيير العلامات المكسورة بسرعة للحفاظ على سلامة الطرق.