فصل 3 علامات الطرق العاكسة هي الأصعب على البيئة في أستراليا. إنهم بحاجة إلى مواد خاصة ويستخدمون الكثير من الطاقة. فصل 1 والطبقة 2 تستخدم العلامات مواد أسهل. لكن ما زالوا يعانون من مشاكل في إعادة التدوير والنفايات. يهتم الأشخاص الذين يعملون مع الطرق بالاستدامة. يريد صانعو السياسة والمستشارين أيضًا مساعدة البيئة. يحاولون جميعًا جعل السلامة على الطرق أفضل للكوكب.

في أوبترافيك, نحن ملتزمون بتوفير إشارات مرور عاكسة عالية الجودة التي تلبي المعايير الأسترالية مع مراعاة الاستدامة البيئية. يعمل فريقنا على التأكد من أن حلول السلامة على الطرق فعالة ومسؤولة بيئيًا.

لمعرفة المزيد حول معايير صفائح إشارات المرور العاكسة في أستراليا وكيفية مساهمتها في الاستدامة, تحقق من مدونتنا على نظرة عامة على معايير ألواح علامات المرور العاكسة في أستراليا.

علامات الطريق العاكسة في أستراليا

نظرة عامة على فئات الأغطية

هناك ثلاث فئات رئيسية من الأغطية لإشارات الطرق العاكسة في أستراليا. فصل 1 أغطية مشرق جدًا ويستخدم لعلامات السلامة المهمة, بينما فصل 2 أغطية ليس ساطعًا ويستخدم في الأماكن التي تحتاج إلى قدر أقل من الضوء. على الجانب الآخر, فصل 3 أغطية هو الأكثر سطوعًا ويستخدم في الأماكن التي يصعب رؤيتها أو ذات الإضاءة السيئة. تساعد هذه الفصول السائقين على ملاحظة العلامات ليلاً أو عندما يكون الطقس سيئًا.

تظهر الأبحاث في أستراليا أن جعل إشارات الطرق أكثر انعكاسًا يمكن أن يقلل من الحوادث ليلاً. على سبيل المثال:

- دراسة في 55 الأماكن التي تم العثور عليها أ 6% انخفاض في حوادث المرور الليلية بعد أن أصبحت الإشارات أكثر سطوعًا.

- وأظهرت الاختبارات باستخدام أجهزة المحاكاة أن الإشارات الأكثر سطوعًا تساعد السائقين على البقاء في حاراتهم والقيادة بالسرعة المناسبة ليلاً.

- النظر إلى أكثر 50 دراسات, وجد الخبراء أن العلامات الأكثر سطوعًا تعني عادةً حوادث أقل, لكن التغيير يكون صغيرًا في بعض الأحيان.

المواد المستخدمة

تستخدم الشركات مواد مختلفة لصنع لافتات الطرق العاكسة. هذه المواد يجب أن تستمر لفترة طويلة, تألق جيدا, وعدم الإضرار بالبيئة. بعض المواد الشائعة هي:

- البوليستر

- فينيل

- البولي

- البولي بروبيلين

- مواد هجينة

كل مادة لها نقاطها الجيدة. البوليستر يلمع بشكل مشرق. مادة البولي كربونات قوية. تمزج المواد الهجينة الميزات للعمل بشكل أفضل.

| مادة | وضع الانعكاس | المزايا | القيود |

|---|---|---|---|

| خلات السليلوز | انقلاب | من السهل اكتشافه, أنماط ضوء خاصة, يعمل بشكل جيد | يمكن الخلط بينه وبين نترات السليلوز |

| نترات السليلوز | انقلاب | علامة جيدة, نمط ضوء واضح | يمكن الخلط بينه وبين خلات السليلوز |

| البوليستر | انقلاب | إشارات مشرقة, من السهل اكتشافه, نمط ضوء واضح | يحتاج إلى معرفة خاصة لاكتشافه |

| ملاحظات عامة | وضع التحويل يجعل العلامات أكثر سطوعًا ويسهل اكتشافها | ليست مشرقة في الأوضاع الأخرى |

التطبيقات النموذجية

فصل 1 تستخدم علامات الطريق العاكسة لإشارات التوقف, إعطاء علامات الطريق, وقواعد العلامات حيث يجب على الناس رؤيتها بوضوح, بينما الطبقة 2 تستخدم اللافتات لعلامات وقوف السيارات, أسماء الشوارع, وعلامات المعلومات. بالإضافة إلى ذلك, فصل 3 تستخدم العلامات في الأماكن الخطرة مثل المنعطفات الحادة, مناطق المدرسة, أو تقاطعات كبيرة. تساعد هذه الاستخدامات في الحفاظ على سلامة الجميع على الطرق, خاصة في الليل أو عندما يصعب الرؤية.

التأثير البيئي

مواد خام

يستخدم المصنعون العديد من المواد مثل PVC, أكريليك, حبات زجاجية, والعناصر المنشورية. تؤثر هذه المواد على البيئة بطرق مختلفة. يمكن أن يساعد استخدام البوليمرات الحيوية والخرز الزجاجي المعاد تدويره في تقليل انبعاثات الكربون. وهذا أفضل من استخدام المواد التقليدية. تشير الدراسات إلى أن المواد المعاد تدويرها يمكن أن تقلل من ثاني أكسيد الكربون بمقدار حوالي 30%. ويغير نوع المادة الخام أيضًا مدى تأثيرها على ظاهرة الاحتباس الحراري. أحبار الجسيمات الفضية النانوية أسوأ بالنسبة للكوكب من الأحبار النحاسية. تقوم الركائز الحيوية بتخزين الكربون من النباتات. يتم الآن استخدام المزيد من المواد الصديقة للبيئة, مثل الدهانات المائية والمحتوى المعاد تدويره. تريد المدن والمجالس هذه الخيارات المستدامة.

انبعاثات التصنيع

صنع علامات الطريق العاكسة يخلق التلوث ويستهلك الطاقة. يمكن للمصانع إطلاق مركبات عضوية متطايرة, مُسَمًّى المركبات العضوية المتطايرة. كما أنهم يستخدمون الكثير من القوة, خاصة مع المواد المتقدمة. تستهلك طباعة الشاشة طاقة أقل ولكنها تحتاج إلى حبر أكثر. تستهلك طباعة الهباء الجوي المزيد من الطاقة وتضر بالبيئة بشكل أكبر. القواعد في أستراليا ودول أخرى تدفع المصانع إلى أن تكون أكثر نظافة. ويجب عليهم استخدام مواد أكثر أمانًا والحد من التلوث واستخدام الطاقة.

خدمة الحياة والمتانة

كم من الوقت تدوم الإشارة يهم البيئة. العلامات التي تستمر لفترة أطول لا تحتاج إلى استبدالها كثيرًا. وهذا يوفر الموارد والطاقة. يمكن أن تستمر العلامات العاكسة الزرقاء لمدة تصل إلى 35 سنين. علامات بيضاء تدوم 16 سنين, والعلامات الحمراء الأخيرة 10 سنين. يمكن للنماذج الجديدة أن تخمن متى ستتوقف الإشارات عن الانعكاس بشكل جيد. وهذا يساعد على التخطيط بشكل أفضل ويقلل من النفايات. إن جعل اللافتات تدوم لفترة أطول أمر جيد للبيئة.

نهاية الحياة وإعادة التدوير

التخلص من العلامات القديمة أمر صعب. تستخدم العديد من إشارات الطرق مادة PVC, والذي يصعب إعادة تدويره. أقل من 1% يتم إعادة تدوير لافتات PVC. يذهب معظمهم إلى مكب النفايات أو يتم حرقهم بموجب قواعد صارمة. علامات PET وHDPE أسهل في إعادة التدوير. PET لديه 18.5% معدل إعادة التدوير, والبولي ايثيلين عالي الكثافة لديه 8.9%. هذه هي أكثر قبولا في برامج إعادة التدوير. من الصعب إعادة تدوير PVC بسبب الكلور والمواد المضافة. تحاول بعض الشركات تجربة الأفلام القابلة للتحلل والبوليمرات الحيوية. ولكن هذه قد لا تستمر طويلا. يمكن أن يساعد التخطيط للتخلص منها والعمل مع القائمين على إعادة التدوير في جعل اللافتات أكثر استدامة.

مقارنة الطبقة

فصل 1 الملف البيئي

علامات الطريق التي تستخدم Class 1 الأغطية العاكسة مصنوعة من مواد أساسية مثل أفلام الأكريليك أو البوليستر, مع الخرز الزجاجي في الداخل. تحتاج هذه المواد إلى طاقة أقل لتصنيعها مقارنة بالأصناف الأعلى. تستخدم المصانع أساليب أبسط, لذا فهي تنتج قدرًا أقل من التلوث. فصل 1 علامات تدوم عن 7 ل 10 سنين. لأنها لا تدوم طويلا, يجب استبدالها في كثير من الأحيان. وهذا يجعل المزيد من النفايات مع مرور الوقت. ليس الكثير من الدرجة 1 يتم إعادة تدوير العلامات, خاصة إذا كانوا يستخدمون PVC. معظم الطبقة 1 وينتهي الأمر باللافتات في مكب النفايات لأن إعادة التدوير صعبة على هذه المواد.

ملحوظة: فصل 1 من السهل رؤية العلامات ولا تضر البيئة كثيرًا في البداية, لكنها تنتج المزيد من النفايات لأنها لا تدوم طويلا.

فصل 2 الملف البيئي

فصل 2 تستخدم علامات الطريق العاكسة مواد أقوى مثل البولي كربونات أو الفينيل الخاص. هذه تستمر لفترة أطول من الفصل 1 علامات. وما زالوا يستخدمون الخرز الزجاجي لعكس الضوء. صنع الطبقة 2 تستخدم العلامات المزيد من الطاقة والموارد. فصل 2 يمكن أن تستمر العلامات حتى 12 سنين, لذلك لا يحتاجون إلى الاستبدال كثيرًا. لكنهم ما زالوا يضرون بالبيئة لأنهم يستخدمون البلاستيك وأشياء أخرى يصعب إعادة تدويرها. تستخدم بعض المجالس أفلامًا تعتمد على PET في الفصل الدراسي 2 علامات, والتي هي أسهل لإعادة التدوير. حتى مع هذه التغييرات, معظم الدرجة 2 من الصعب إعادة تدوير اللافتات لأنه لا يوجد الكثير من الأماكن التي يمكنها القيام بذلك.

- فصل 2 علامات تستمر لفترة أطول من الدرجة 1 علامات.

- They still add to landfill waste because recycling is not easy.

فصل 3 الملف البيئي

فصل 3 reflective road signs use the most advanced materials and ways to make them. These signs often use prismatic technology with layers of polycarbonate, أكريليك, or mixed polymers. Making these signs needs more energy and makes more pollution. But Class 3 signs are the brightest and last the longest, often more than 15 سنين.

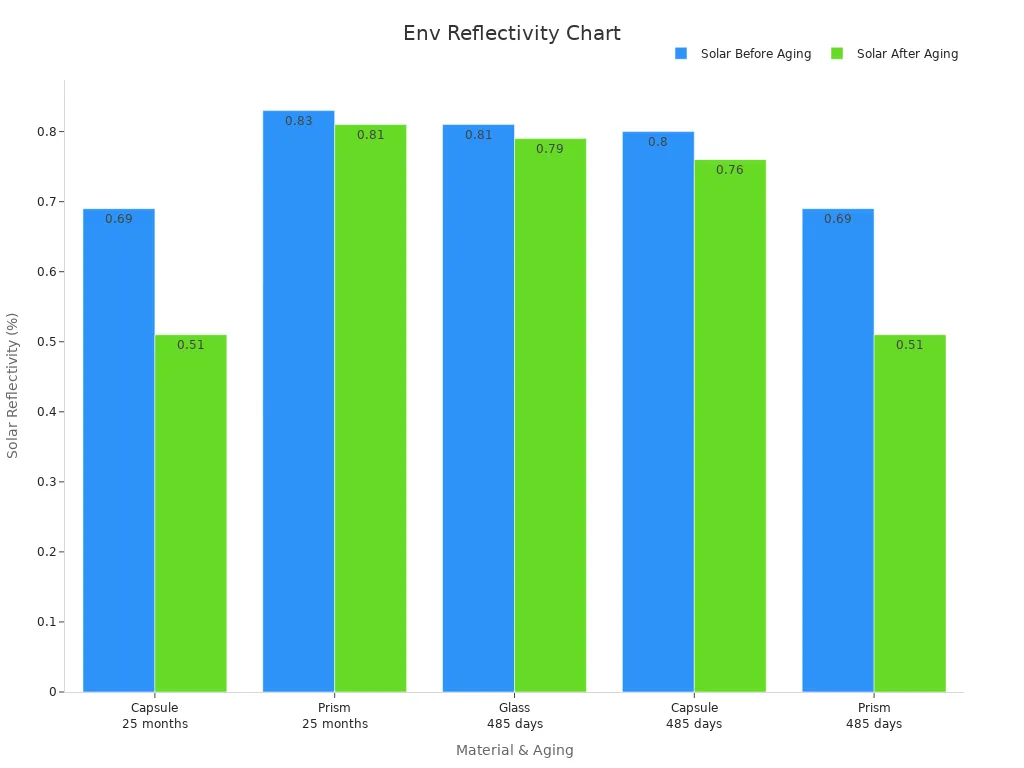

Researchers have looked at different Class 3 مواد, like glass bead, capsule, and prism types. Prism materials last the longest and keep shining even after being outside for a long time. Capsule types break down faster and lose their shine because they crack. Adding a glass cover to prism materials helps them stand up to bad weather and pollution.

| Retro-reflective Material Type | Aging Duration | Solar Reflectivity Before Aging (%) | Solar Reflectivity After Aging (%) | Solar Reflectivity After Cleaning (%) | Retro-reflectivity Before Aging (%) | Retro-reflectivity After Aging (%) | Retro-reflectivity After Cleaning (%) |

|---|---|---|---|---|---|---|---|

| Capsule | 25 شهور | 0.69 | 0.51 | 0.60 | 0.18 | ~0 | 0.087 |

| Prism | 25 شهور | 0.83 | 0.81 | 0.8192 | 0.44 | 0.42 | 0.43 |

| Prism with Glass Covering | 485 أيام | 0.81 | 0.79 | ن/أ | 0.81 | ن/أ | ن/أ |

| Capsule | 485 أيام | 0.80 | 0.76 | ن/أ | 0.79 | ن/أ | ن/أ |

| Prism | 485 أيام | 0.69 | 0.51 | ن/أ | 0.62 | ن/أ | ن/أ |

Prism materials can be cleaned to shine again, so they do not need to be replaced as much. This means less waste and longer use. But the special materials in Class 3 signs are very hard to recycle. Most go to landfill because there are not many ways to recycle these materials.

Prism-based Class 3 signs last the longest and do not need to be replaced often, but making them uses more energy and harms the environment more.

Most and Least Sustainable Class

When we look at all three classes, each has good and bad points for the environment:

- فصل 1: Uses simple materials and less energy to make, but does not last long and is hard to recycle.

- فصل 2: يدوم لفترة أطول ويسهل إعادة تدويره قليلاً, ولكن لا يزال يستخدم البلاستيك والخرز الزجاجي.

- فصل 3: يدوم أطول ويعمل بشكل أفضل. تتيح لك تقنية المنشور تنظيف اللافتة وإعادة استخدامها, لذلك هناك نفايات أقل. لكن تصنيعها يستهلك المزيد من الطاقة ومن الصعب إعادة تدوير المواد.

باختصار, فصل 3 تدوم علامات الطريق العاكسة لفترة أطول ولا تحتاج إلى استبدالها بنفس القدر, لذلك فهي تنتج نفايات أقل بمرور الوقت. لكنها أقل استدامة لأنها تستخدم المزيد من الطاقة والمواد الخاصة التي يصعب إعادة تدويرها. فصل 1 العلامات أفضل للبيئة في البداية ولكنها تسبب المزيد من النفايات لأنها لا تدوم طويلاً. فصل 2 العلامات في المنتصف, مع التوازن بين الاستمرار لفترة أطول وعدم الإضرار بالبيئة أكثر من اللازم.

الخيارات المستدامة لإشارات الطرق العاكسة

مواد صديقة للبيئة

يختار المصنعون الآن مواد صديقة للبيئة لإشارات الطرق العاكسة. غالبًا ما يستخدمون الخرز الزجاجي المعاد تدويره من النوافذ القديمة. يتم فحص هذه الخرزات للتأكد من أنها ذات نوعية جيدة. أنها تساعد على تألق العلامات بشكل مشرق في الليل. تستخدم بعض الشركات حبات زجاجية خاصة أفضل. تدوم هذه الخرزات لفترة أطول وتعمل بشكل جيد في الأحوال الجوية السيئة. تتحلل الطلاءات الجديدة بشكل طبيعي ويمكن إعادة تدوير الأفلام. هذا يساعد على تقليل النفايات. الأغطية المنشورية تجعل العلامات أسهل في الرؤية ويسهل إعادة تدويرها. كما يتم استخدام تقنية النانو. فهو يصنع طبقات تنظف نفسها ولا تبلى بسرعة. وهذا يعني أن العلامات يمكن أن تستمر لفترة أطول. تستخدم بعض اللافتات مواد إنارة أرضية نادرة. تقوم هذه المواد بتخزين الضوء وتساعد على توفير الطاقة. وهذا يجعل الطرق أكثر أمانًا ويقلل من انبعاثات الكربون.

نصيحة: إن استخدام المواد الحيوية والمعاد تدويرها في لافتات الطرق يساعد الكوكب ويدعم الأهداف الخضراء.

الشهادات والمعايير

يتبع العديد من المصنعين قواعد صارمة لإظهار اهتمامهم بالبيئة.

- تتحقق شهادة "من المهد إلى المهد" مما إذا كانت المواد آمنة ويمكن إعادة استخدامها. كما ينظر إلى الطاقة, ماء, والعدالة. وهذا يساعد الشركات على تصميم منتجات أفضل واتباع القواعد الخضراء.

- ISO 14001 تساعد الشركات على تقليل تأثيرها على البيئة. يرشدهم لاختيار مواد أفضل, استخدام طاقة أقل, وجعل أقل النفايات.

تساعد هذه الشهادات الأشخاص على الثقة بالعلامات التجارية وفتح أسواق جديدة للمنتجات الخضراء. كما أنها تساعد الشركات على توفير المال باستخدام الموارد بشكل أفضل.

المبادرات الحكومية والصناعية

تعمل الحكومات الأسترالية ومجموعات الصناعة معًا من أجل وضع علامات طريق أكثر خضرة. إنهم يدعمون أفكارًا جديدة مثل الإشارات التي تعمل بالطاقة الشمسية وأنظمة المرور الذكية. هذه تستخدم طاقة أقل وتتسبب في تلوث أقل. تتعاون المجالس والوكالات مع المجموعات المحلية لدفع ثمن اللافتات وتحسينها. يستخدمون البيانات في الوقت الفعلي لإدارة حركة المرور وإيقاف الاختناقات. تطلب القواعد الجديدة الآن وجود علامات طريق أكثر أمانًا وخضراء. تظهر هذه الإجراءات أن أستراليا تريد طرقًا أكثر ذكاءً ونظافة.

فصل 1, فصل 2, والطبقة 3 الأغطية العاكسة لها تأثيرات بيئية مختلفة. بينما الطبقة 3 يدوم أطول, فهو يتطلب المزيد من الطاقة والمواد الخاصة. على الجانب الآخر, فصل 2 في المنتصف, موازنة عمرها وتأثيرها على الكوكب. اختيار قوي, تساعد المواد الجيدة للطقس المحلي على تقليل الهدر وتوفير المال بمرور الوقت. يقول الخبراء أنه يجب عليك استخدام الخيارات القابلة لإعادة التدوير أو القابلة للتحلل عندما تستطيع ذلك. Checking materials and ways of working often helps signs stay safe and better for the planet as technology gets better.

التعليمات

What makes a reflective road sign sustainable?

A sustainable sign is made with eco-friendly materials. It lasts a long time and can be recycled. Manufacturers use recycled glass beads and bio-based films. These choices help cut down on waste. They also lower the carbon footprint.

Can councils recycle old reflective road signs?

Most councils find it hard to recycle old signs. This is especially true for PVC-based signs. علامات PET وHDPE أسهل في إعادة التدوير. Councils often work with special recyclers to dispose of signs properly.

How do certifications help with sustainability?

الشهادات مثل ISO 14001 and Cradle to Cradle mean a manufacturer follows strict green rules. تساعد هذه الشهادات المشترين على الثقة بأن المنتجات مفيدة للبيئة.

لماذا الطبقة 3 تستمر العلامات لفترة أطول من غيرها?

فصل 3 تستخدم العلامات مواد منشورية متقدمة. هذه المواد تصمد أمام سوء الأحوال الجوية والأضرار. يبقون مشرقين لسنوات عديدة. وهذا يعني عددًا أقل من البدائل ونفايات أقل.