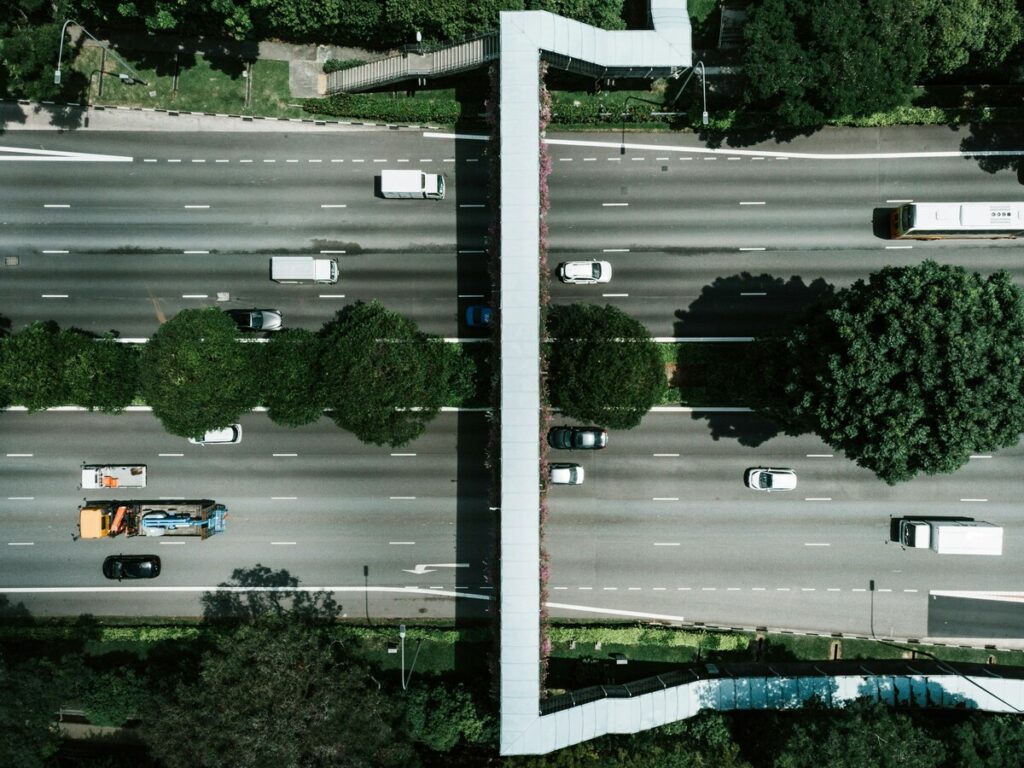

تلعب السلامة على الطرق دورًا مهمًا في ضمان النقل السلس وحماية الأرواح. تواجه المخاطر يوميا, سواء كان سائق, المشاة, أو العامل في المناطق ذات الحركة العالية. غالبًا ما تعرض الأساليب التقليدية لنشر مخروط حركة مرور كبير العمال للخطر والتسبب. يحول حل المخروط الآلي لهذه العملية عن طريق تعزيز السلامة والكفاءة. هذه الأنظمة تقلل من المشاركة البشرية في المهام الخطرة وتبسيط إدارة حركة المرور. الابتكار في هذا المجال لا يوفر الوقت فحسب ، بل يقلل أيضًا من الحوادث, جعل الطرق أكثر أمانًا للجميع.

حدود نشر مخروط المرور التقليدي

مخاطر سلامة العمال

التعرض لحركة المرور الحية أثناء النشر اليدوي

عندما يضع العمال يدويا الأقماع المرورية, غالبًا ما يخطوون إلى حارات المرور النشطة. وهذا يعرضهم للمركبات المسرعة والسائقين المشتتين. ولكم أن تتخيلوا مدى خطورة هذا الوضع, خاصة خلال ساعات الذروة أو في ظروف الرؤية المنخفضة مثل الليل أو سوء الأحوال الجوية. يزداد خطر وقوع الحوادث بشكل كبير, تعريض حياة الناس للخطر.

الإجهاد البدني ومخاطر الإصابة من المهام المتكررة

يتضمن نشر مخاريط المرور واسترجاعها يدويًا ثنيًا متكررًا, رفع, وتحمل. يمكن أن تؤدي هذه الإجراءات إلى إجهاد جسدي بمرور الوقت. قد يعاني العمال من آلام الظهر, تعب العضلات, أو حتى إصابات طويلة الأمد. هذه الطبيعة المتكررة للمهمة تجعلها تتطلب جهدًا بدنيًا وخطرة.

عدم الكفاءة التشغيلية

العمليات المستهلكة للوقت تسبب تأخير حركة المرور

يستغرق النشر اليدوي للأقماع المرورية وقتًا. يجب على العمال وضع كل مخروط بعناية, في كثير من الأحيان المشي لمسافات طويلة على طول الطريق. يمكن أن تسبب هذه العملية البطيئة ازدحامًا مروريًا غير ضروري. ربما تكون قد شعرت بالإحباط كسائق ينتظر في طوابير طويلة بسبب مثل هذه التأخيرات.

زيادة تكاليف العمالة وتخصيص الموارد

يتطلب النشر اليدوي فريقًا من العاملين, المركبات, والمعدات. وهذا يزيد من تكاليف العمالة ويحول الموارد من المهام الحاسمة الأخرى. للشركات التي تدير مشاريع واسعة النطاق, يمكن أن تؤدي أوجه القصور هذه إلى ارتفاع النفقات التشغيلية.

المخاوف البيئية

ارتفاع استهلاك الوقود بسبب إغلاق الطرق لفترات طويلة

يؤدي إغلاق الطرق لفترات طويلة بسبب النشر اليدوي للمخروط إلى توقف المركبات عن العمل. وهذا يزيد من استهلاك الوقود ويساهم في تلوث الهواء. قد لا تدرك ذلك, لكن هذه التأخيرات لها تأثير مباشر على البيئة.

زيادة خطر وقوع الحوادث أثناء العمليات اليدوية

تتطلب العمليات اليدوية في كثير من الأحيان بقاء العمال على الطريق لفترات طويلة. وهذا يزيد من احتمالية وقوع حوادث تشمل العمال والمركبات المارة. كلما طال أمد بقاء الطريق مغلقا, كلما زاد الخطر بالنسبة لجميع المعنيين.

ظهور حلول وضع المخروط الآلي

ما هي حلول وضع المخروط الآلي؟?

نظرة عامة على تصميمها ووظائفها

تُحدث حلول وضع المخروط الآلي ثورة في كيفية إدارة السلامة على الطرق. تستخدم هذه الأنظمة آلات متقدمة لنشر واسترجاع الأقماع المرورية دون تدخل يدوي. شنت على المركبات المتخصصة, تعمل بسلاسة لوضع المخاريط على فترات زمنية محددة. وهذا يضمن تباعد ومحاذاة متسقة, مما يحسن الرؤية للسائقين. يركز التصميم على تقليل مشاركة الإنسان في المهام الخطرة مع الحفاظ على الدقة والسرعة.

OPTsigns توفر مخاريط مرورية عالية الجودة مناسبة بشكل مثالي للاستخدام مع هذه الأنظمة الآلية. OptsIsns الأقماع حركة المرور تم تصميمها من أجل المتانة والرؤية, تتميز بمواد عاكسة وقواعد متينة تضمن بقاءها ثابتة في مختلف الظروف الجوية.

المكونات والتقنيات الرئيسية المعنية

تعتمد هذه الأنظمة على عدة مكونات رئيسية. أ آلية الناقل ينقل المخاريط من التخزين إلى النشر. الأسلحة الروبوتية أو تتولى البكرات الآلية عملية التنسيب. أجهزة استشعار والكاميرات توجه النظام, ضمان وضع المخاريط بشكل صحيح. حتى أن بعض النماذج تشمل تقنية GPS لتعيين طرق النشر. تعمل هذه المكونات معًا لتقديم عمليات وضع مخروطية فعالة, تعزيز كل من السلامة والإنتاجية.

الابتكارات التكنولوجية في أنظمة النشر

السياق التاريخي والدفع نحو الأتمتة

وقد أدت الحاجة إلى إدارة حركة مرور أكثر أمانًا وسرعة إلى الابتكار في هذا المجال. وتشكل الأساليب اليدوية مخاطر وتسبب تأخيرات, حث المهندسين على استكشاف الأتمتة. على مر السنين, جعلت التطورات في مجال الروبوتات والتعلم الآلي الأنظمة الآلية أكثر موثوقية ويمكن الوصول إليها. اليوم, تعالج هذه الحلول تحديات الأساليب التقليدية مع تلبية معايير السلامة الحديثة.

دمج الذكاء الاصطناعي وإنترنت الأشياء لإدارة حركة المرور بشكل أكثر ذكاءً

الذكاء الاصطناعي (منظمة العفو الدولية) و إنترنت الأشياء (إنترنت الأشياء) تلعب دورا حاسما في هذه الأنظمة. تقوم خوارزميات الذكاء الاصطناعي بتحليل أنماط حركة المرور لتحسين وضع المخروط. تقوم أجهزة إنترنت الأشياء بتوصيل النظام بشبكات إدارة حركة المرور المركزية, تمكين التحديثات في الوقت الحقيقي. يتيح لك هذا التكامل مراقبة عمليات النشر وضبطها عن بُعد, ضمان تدفق حركة المرور بشكل أكثر سلاسة وتحسين السلامة.

كيف تعمل الأنظمة الآلية

عملية خطوة بخطوة لنشر المخروط الآلي

تبدأ العملية بتحميل الأقماع في وحدة تخزين النظام. أثناء تحرك السيارة على طول الطريق, تقوم آلية النقل بتغذية المخاريط إلى ذراع النشر. تكتشف أجهزة الاستشعار نقاط التنسيب الصحيحة, ويضع الذراع كل مخروط بدقة. بمجرد اكتمال المهمة, يمكن للنظام أيضًا استرداد المخاريط باستخدام آلية مماثلة. تضمن هذه العملية المبسطة النشر السريع والدقيق.

التكامل مع أنظمة إدارة حركة المرور الحالية

تتكامل حلول وضع المخروط الآلي بسلاسة مع أنظمة إدارة حركة المرور الحالية. يتواصلون مع مراكز التحكم لتنسيق عمليات النشر بناءً على ظروف حركة المرور. يضمن هذا التوافق أنه يمكنك تنفيذ هذه الأنظمة دون إصلاح البنية التحتية الحالية. والنتيجة هي نهج أكثر كفاءة واستجابة لإدارة السلامة على الطرق.

فوائد أنظمة نشر مخروط المرور الآلي

تعزيز سلامة العمال

تقليل التعرض المباشر لحركة المرور

تعمل الأنظمة الآلية على إبقاء العمال بعيدًا عن ممرات المرور النشطة. لم تعد بحاجة إلى الدخول إلى المناطق الخطرة لوضع المخاريط أو استرجاعها. وهذا يقلل من فرصة وقوع الحوادث الناجمة عن المركبات المسرعة أو السائقين المشتتين. باستخدام هذه الأنظمة, أنت تخلق بيئة أكثر أمانًا لجميع المشاركين في أعمال الطرق أو مشاريع البناء.

تقليل الإجهاد البدني ومخاطر الإصابة

يمكن أن يؤدي التعامل مع الأقماع المرورية الكبيرة يدويًا إلى إجهاد جسدي. الانحناء بشكل متكرر, رفع, وحمل المخاريط يزيد من خطر الإصابة. الحلول الآلية تقضي على هذه المهام. يمكن للعمال التركيز على مراقبة العمليات بدلاً من أداء الأنشطة التي تتطلب جهداً بدنياً. وهذا يقلل من خطر الإصابة ويحسن الرضا الوظيفي بشكل عام.

تحسين الكفاءة

نشر واسترجاع أسرع للأقماع المرورية الكبيرة

تقوم الأنظمة الآلية بنشر واسترداد المخاريط بشكل أسرع بكثير من الطرق اليدوية. يمكنك إكمال المهام في جزء صغير من الوقت الذي تستغرقه الأساليب التقليدية. تضمن هذه السرعة أن يتم إعداد أعمال الطرق أو مناطق البناء بسرعة, تقليل الاضطرابات.

انخفاض تكاليف العمالة ومتطلبات الموارد

مع الأنظمة الآلية, هناك حاجة إلى عدد أقل من العمال لإدارة نشر المخروط. يمكنك توفير تكاليف العمالة وتحرير الموارد للمهام الهامة الأخرى. يعمل هذا النهج المبسط على تحسين الكفاءة مع تقليل نفقات المشروع الإجمالية.

الحد من الاضطرابات المرورية

إغلاق أقصر للطرق وتدفق مروري أكثر سلاسة

تعمل الأنظمة الآلية على تقليل الوقت اللازم لإعداد وإزالة الأقماع المرورية العاكسة. إغلاق الطرق الأقصر يعني تدفق حركة المرور بشكل أكثر سلاسة. يواجه السائقون تأخيرات أقل, وتحافظ على تحكم أفضل في ظروف حركة المرور.

تحسين الإدراك العام لكفاءة أعمال الطرق

عند استخدام الأنظمة الآلية, يلاحظ الجمهور الفرق. تخلق عمليات الإعداد الأسرع والاضطرابات المنخفضة انطباعًا إيجابيًا. يقدر الناس استخدام التكنولوجيا المتقدمة لتحسين كفاءة أعمال الطرق. وهذا يعزز الثقة في قدرتك على إدارة مشاريع البناء بشكل فعال.

نصيحة: تعمل الأنظمة الآلية بسلاسة مع المخاريط البرتقالية القياسية والأقماع المرورية العاكسة, ضمان الرؤية والسلامة في جميع الظروف.

المزايا البيئية

انخفاض استهلاك الوقود والانبعاثات

تعمل أنظمة نشر مخروط المرور الآلي على تقليل استهلاك الوقود بشكل كبير. عند استخدام هذه الأنظمة, إغلاق الطرق أقصر, وتقضي المركبات وقتًا أقل في التباطؤ في حركة المرور. وهذا يقلل بشكل مباشر من استخدام الوقود, مما يساعد على تقليل الانبعاثات الضارة. قد لا تدرك ذلك, لكن كل دقيقة تقف فيها السيارة تساهم في تلوث الهواء. من خلال تقليل التأخير في مناطق البناء, تخلق الأنظمة الآلية تأثيرًا بيئيًا إيجابيًا.

تعمل هذه الأنظمة أيضًا على تحسين تدفق حركة المرور. عندما تتحرك المركبات بسلاسة, يحرقون الوقود بكفاءة أكبر. وهذا يقلل من البصمة الكربونية لأنشطة أعمال الطرق. يمكنك أن ترى كيف يمكن لهذا التغيير البسيط في إدارة حركة المرور أن يؤدي إلى تأثير كبير على جودة الهواء. لا تعمل الحلول الآلية على تحسين السلامة فحسب، بل تساهم أيضًا في توفير هواء أنظف للجميع.

المساهمة في ممارسات صيانة الطرق المستدامة

تعتبر الاستدامة أولوية متزايدة في صيانة الطرق. وتتوافق أنظمة وضع المخروط الآلي مع هذا الهدف من خلال تقليل هدر الموارد. عندما تعتمد على هذه الأنظمة, هناك حاجة إلى عدد أقل من العمال والمركبات في مناطق البناء. وهذا يقلل من استهلاك الطاقة الإجمالي لمشاريع أعمال الطرق.

بالإضافة إلى ذلك, تعمل هذه الأنظمة على إطالة عمر المعدات. غالبًا ما يؤدي النشر اليدوي إلى تآكل الأدوات والمركبات. الأنظمة الآلية تقلل من هذه السلالة, وهو ما يعني بدائل أقل تواترا. وهذا يساهم في الممارسات المستدامة من خلال الحفاظ على الموارد.

أنت أيضًا تدعم الأهداف البيئية طويلة المدى من خلال اعتماد هذه التقنيات. تُحدِث العمليات النظيفة والانبعاثات المنخفضة تأثيرًا دائمًا. تُظهر الأنظمة الآلية كيف يمكن للابتكار في إدارة حركة المرور أن يتماشى مع جهود الاستدامة. إنها تثبت أنه يمكنك تعزيز الكفاءة مع حماية البيئة.

ملحوظة: تعتبر الأنظمة الآلية خطوة للأمام في إنشاء مناطق بناء صديقة للبيئة. إنهم يوضحون كيف يمكن للتكنولوجيا أن توازن بين السلامة, كفاءة, والمسؤولية البيئية.

آثار أوسع على السلامة على الطرق وإدارة حركة المرور

اعتماد عبر الصناعات

استخدام في البناء, صيانة, والاستجابة للطوارئ

أنظمة نشر مخروط المرور الآلي لها تطبيقات في مختلف الصناعات. يمكنك رؤية تأثيرها في مناطق البناء, حيث تعمل على تعزيز سلامة إدارة حركة المرور من خلال تقليل المخاطر التي يتعرض لها العمال. تستفيد أطقم الصيانة أيضًا من هذه الأنظمة, لأنها تبسط التحكم المؤقت في حركة المرور في المناطق عالية المخاطر. تجد فرق الاستجابة للطوارئ أن هذه الأنظمة لا تقدر بثمن. إنها تسمح بالإعداد السريع لمناطق التحكم في حركة المرور أثناء المواقف الحرجة, ضمان اتخاذ تدابير السلامة دون تأخير.

إمكانية التوحيد العالمي

إن الاعتماد الواسع النطاق لهذه الأنظمة يمكن أن يؤدي إلى توحيد عالمي في إدارة حركة المرور. قد تلاحظ كيف تعمل الممارسات المتسقة على تحسين السلامة على الطرق عبر المناطق. تعمل الأنظمة الموحدة على تبسيط التدريب وتضمن التوحيد في معالجة مخاطر الطرق. وهذا الاتساق يفيد كلا من العمال والسائقين, خلق بيئات أكثر أمانا في جميع أنحاء العالم.

الاتجاهات المستقبلية في أنظمة النشر

التكامل مع المركبات ذاتية القيادة والذكاء الاصطناعي

مستقبل إدارة حركة المرور يكمن في التقنيات المتقدمة. تتكامل الأنظمة الآلية بالفعل مع الذكاء الاصطناعي لتحليل أنماط حركة المرور وتحسين وضع المخروط. يمكنك أن تتوقع المزيد من التقدم, مثل التكامل مع المركبات ذاتية القيادة. يمكن لهذه المركبات نشر المخاريط دون تدخل بشري, مما يجعل أعمال الطرق أكثر أمانًا وكفاءة.

إمكانية إنشاء أنظمة أعمال الطرق المستقلة بالكامل

تخيل مستقبلًا تصبح فيه أعمال الطرق مستقلة تمامًا. يمكن أن تعمل آلات الممرات المخروطية جنبًا إلى جنب مع المعدات الآلية للتعامل مع جميع جوانب مناطق التحكم في حركة المرور. ومن شأن هذا الابتكار أن يزيل العديد من المخاطر المرتبطة بالعمليات اليدوية. تمثل الأنظمة المستقلة بالكامل الخطوة التالية في إحداث ثورة في سلامة إدارة حركة المرور.

التحديات التي تواجه التبني على نطاق أوسع

التكاليف الأولية وعوائق الاستثمار

يمكن أن تشكل التكلفة الأولية لتنفيذ الأنظمة الآلية عائقًا. قد تجد أن المؤسسات الصغيرة تكافح من أجل تحمل تكاليف هذه التقنيات. لكن, الفوائد طويلة المدى, مثل خفض تكاليف العمالة وتحسين الكفاءة, غالبا ما تفوق الاستثمار مقدما.

الحاجة إلى التدريب وتحديث البنية التحتية

ويتطلب اعتماد هذه الأنظمة تدريب العاملين على تشغيل المعدات الجديدة. قد تحتاج أيضًا إلى ترقية البنية الأساسية الحالية لدعم التقنيات المتقدمة. هذه التحديات يمكن أن تبطئ عملية التبني, ولكنها خطوات ضرورية نحو إدارة حركة المرور بشكل أكثر أمانًا وكفاءة.

ملحوظة: إن التغلب على هذه التحديات سيمهد الطريق لاعتماد الأنظمة الآلية على نطاق أوسع, ضمان طرق أكثر أمانًا للجميع.

لقد أحدثت أنظمة نشر مخروط المرور الآلي تحولًا في طريقة تعاملك مع السلامة على الطرق. تعمل هذه الأنظمة على تحسين سلامة العمال, تعزيز الكفاءة, والحد من التأثير البيئي. إن قدرتها على ضمان الرؤية العالية في مناطق المرور تجعلها لا غنى عنها للبنية التحتية الحديثة. من خلال اعتماد هذه الحلول, أنت تساهم في طرق أكثر أمانًا وتدفق مروري أكثر سلاسة. ويحمل المستقبل إمكانات أكبر, مع التطورات مثل الذكاء الاصطناعي والمركبات ذاتية القيادة. سيؤدي الاعتماد الأوسع لهذه الأنظمة إلى إحداث ثورة في إدارة حركة المرور وإنشاء بيئات أكثر أمانًا للجميع. إنكم تلعبون دورًا حيويًا في قيادة هذا التغيير وضمان مستقبل أكثر إشراقًا للسلامة على الطرق.