عندما يتعلق الأمر بتصنيع إشارات المرور, غالبًا ما يتعين عليك الاختيار بين الحفر أولا أو الترقق أولا. يفضل العديد من الخبراء التصفيح قبل الحفر, حيث تعمل هذه الطريقة على تحسين مظهر العلامة وطول عمرها. تشير إرشادات الصناعة إلى أن اختيارك يجب أن يعتمد على المواد التي تستخدمها, الظروف البيئية, وأهداف الإنتاج الخاصة بك. من الضروري مراعاة هذه العوامل لتحديد أفضل نهج لاحتياجات تصنيع إشارات المرور الخاصة بك.

الوجبات الرئيسية

- اختر طريقة الحفر الأولى للمواد الصلبة مثل الألومنيوم. فهو يتأكد من وجود الثقوب في المكان الصحيح. كما أنه يساعد على جعل العلامات أسرع.

- استخدم التصفيح المتسلسل لجعل اللافتات تدوم لفترة أطول وتبدو أفضل. بهذه الطريقة توقف الفقاعات وتحافظ على الطبقة العاكسة آمنة.

- قم دائمًا بتنظيف الألواح جيدًا قبل وضع الأغطية. يساعد التنظيف على التصاق الأغطية بشكل أفضل. كما أنه يقلل من فرصة حدوث مشاكل في العلامة النهائية.

- اختر طريقة التصنيع الخاصة بك بناءً على المواد التي تستخدمها. يساعد القيام بذلك على تجنب المشاكل ويجعل العلامات تدوم لفترة أطول.

- تحقق من أدواتك وخطواتك كثيرًا. هذا يحافظ على علاماتك جيدة ويساعدك على العمل بشكل أسرع.

طريقة الحفر أولا

خطوات العملية

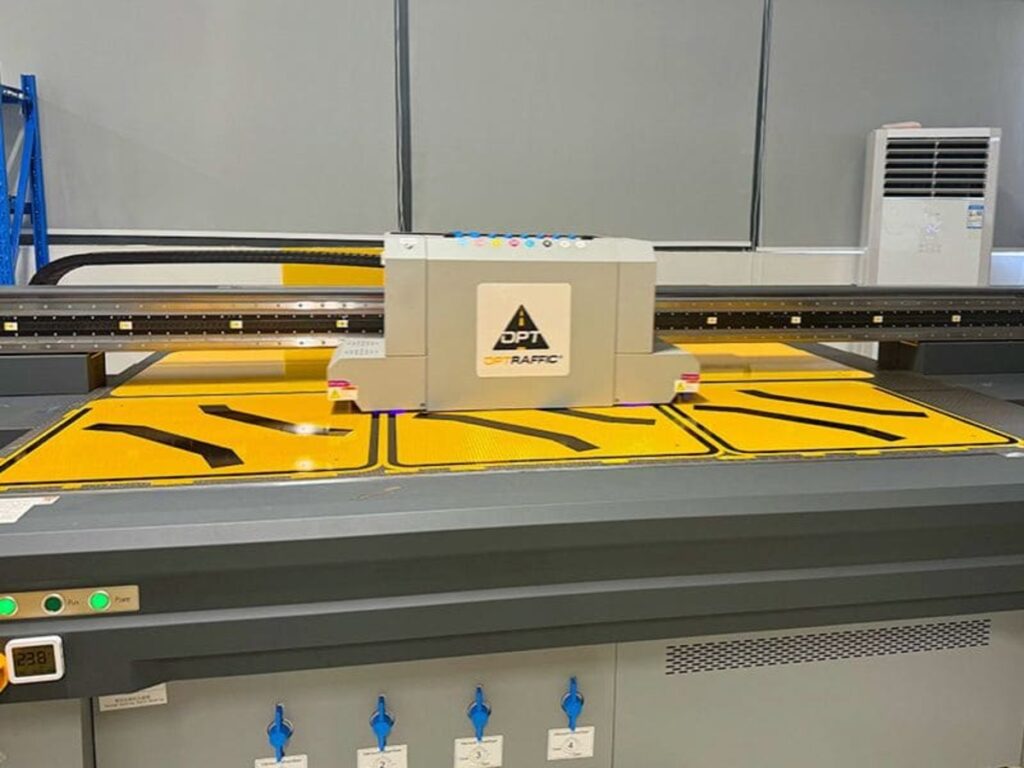

مع طريقة الحفر أولا, تقوم بعمل ثقوب في لوحة الإشارة قبل الإضافة الأغطية العاكسة. تضع الألومنيوم أو أي مادة أخرى على الطاولة. يمكنك استخدام مكبس حفر أو آلة لعمل الثقوب. بعد الحفر, تقوم بتنظيف اللوحة للتخلص من الغبار والقطع. ثم, قمت بوضع الأغطية العاكسة أو الفينيل على اللافتة. تضغط على الأغطية لأسفل لإيقاف الفقاعات وجعلها تلتصق جيدًا. من هنا, اللافتة جاهزة للأجهزة والأقواس لتثبيت لافتات الشوارع.

الفوائد والعيوب

هناك بعض الأشياء الجيدة حول الحفر أولاً. من هنا, الثقوب في المكان الصحيح, مما يساعد عند وضع اللافتة على عمود أو إطار. إنه أسرع مع المواد الصلبة مثل الألومنيوم لأن الحفر لا يؤدي إلى ثني اللوحة أو تمزقها. يؤدي الحفر أولاً أيضًا إلى منع الثقوب من التواجد في المكان الخطأ, والذي يمكن أن يحدث إذا قمت بالحفر بعد وضع الأغطية.

ولكن هناك بعض المشاكل أيضا. الحفر قبل التصفيح يمكن أن يؤذي حواف الثقوب. عند إضافة الأغطية العاكسة بعد الحفر, قد يعلق الهواء حول الثقوب. هذا يمكن أن يؤدي إلى فقاعات أو بقع لامعة, مما قد يضر بمدى عكس الإشارة للضوء. قد لا تلتصق الأغطية جيدًا بالقرب من الثقوب, خاصة إذا لم تكن اللوحة نظيفة جدًا. يمكن أن يدخل الماء بمرور الوقت ويجعل الإشارة أضعف. يجب أن تفكر في هذه الأشياء عند اختيار أفضل طريقة لعمل علاماتك.

نصيحة: قم دائمًا بتنظيف الألواح المحفورة جيدًا قبل وضع الأغطية لمساعدتها على الالتصاق بشكل أفضل وتقليل احتمالية حدوث مشكلات.

طريقة التصفيح المتتابعة

خطوات العملية

تبدأ بوضع صفائح عاكسة أو الفينيل على لوحة اللافتة قبل الحفر. يجب أن تكون اللوحة نظيفة ومسطحة. يمكنك استخدام الأسطوانة أو آلة تغليف للضغط على الأغطية لأسفل. وهذا يساعد على التصاق الأغطية جيدًا وتغطية اللوحة بأكملها. بعد الانتهاء من التصفيح, تقوم بحفر ثقوب من خلال كل من اللوحة والأغطية. هذه الطريقة تصلح للعديد من العلامات, وخاصة تلك التي تحتوي على مواد عاكسة.

مزايا وعيوب

يحتوي التصفيح المتسلسل على العديد من النقاط الجيدة لصنع اللافتات. تلتصق الأغطية بشكل أفضل لأنها تسير مباشرة على اللوحة النظيفة. هذا يساعد وقف فقاعات الهواء وبقع لامعة بالقرب من الثقوب. تبدو علاماتك سلسة وأنيقة. تبقى الطبقة العاكسة قوية, لذلك تكون العلامة مشرقة في الليل. تستمر علاماتك أيضًا لفترة أطول في الأحوال الجوية السيئة. مطر, ثلج, وأشعة الشمس لديها فرصة أقل لإيذاء حواف الأغطية.

هناك بعض المشاكل مع التصفيح المتسلسل. الحفر بعد التصفيح يمكن أن يجعل من الصعب ترتيب الثقوب. إذا كنت تستخدم الأدوات الخاطئة, قد تقوم بتمزيق الأغطية أو عمل حواف خشنة. يجب أن تكون حذراً خلال كل خطوة لتجنب هذه المشاكل. للطلبات الكبيرة, قد تحتاج إلى خطوات إضافية للعمل بشكل أسرع. ما زال, يختار العديد من الخبراء التصفيح المتسلسل لأنه يجعل العلامات قوية وجميلة المظهر. هذه الطريقة هي الأفضل إذا كنت تريد أن تدوم علاماتك وتبدو بمظهر جيد في أي مكان.

ملحوظة: استخدم دائمًا لقم الثقب الحادة والأدلة الصحيحة. هذا يحافظ على ثقوبك مرتبة وأغطيةك ناعمة عند عمل اللافتات.

المواد العاكسة في صناعة إشارات المرور

الفينيل العاكس

يساعد الفينيل العاكس للضوء على تألق العلامات في الليل. هذه المادة تجعل من السهل رؤية لافتات الشوارع. يمكن للسائقين اكتشاف التفاصيل المهمة بسرعة. يمكنك الاختيار بين الحفر أولاً أو التصفيح المتسلسل. قد يؤدي الحفر أولاً إلى جعل الفينيل متصلبًا بالقرب من الثقوب. قد تلاحظ وجود فقاعات أو نقاط ضعف بالقرب من الحواف. التصفيح المتسلسل يحافظ على الأغطية مسطحة وقوية. يلتصق الفينيل بشكل أفضل باللوحة. تبقى الطبقة العاكسة مشرقة وواضحة.

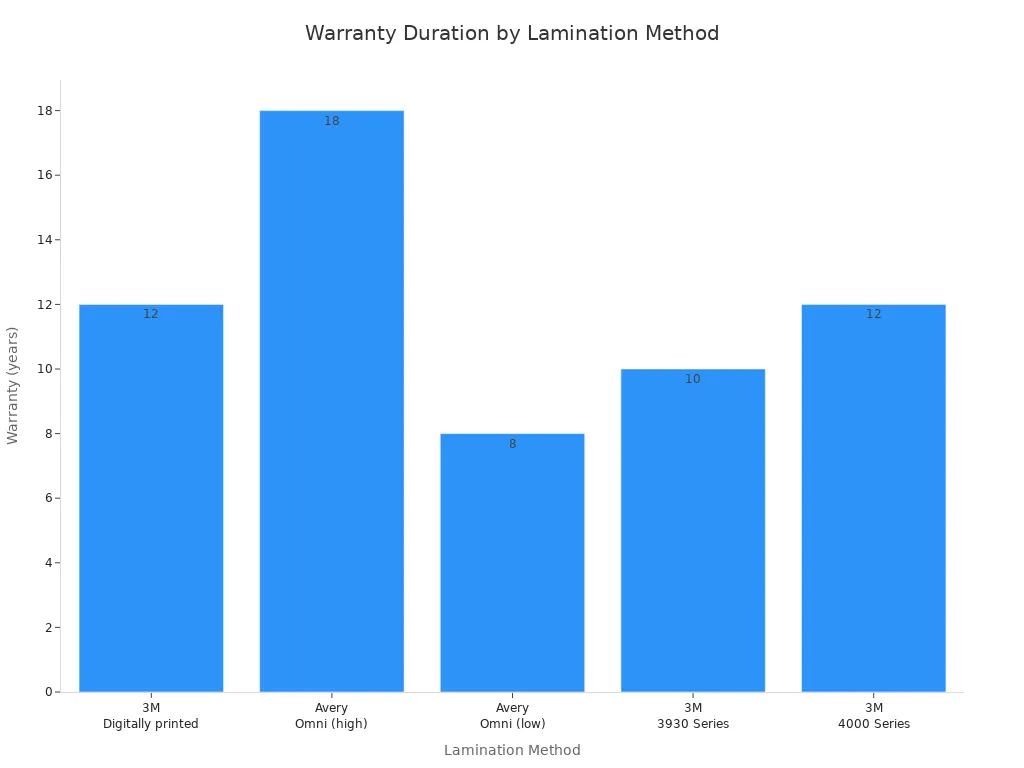

وهنا جدول يوضح كيف طريقة التصفيحيغير موثوقية وضمان الأغطية العاكسة:

| طريقة التصفيح | تفاصيل الأداء |

|---|---|

| 3M لافتات المرور المطبوعة رقميا | ضمان أعلى (12 سنين) مقارنة بالشاشة المطبوعة (8-10 سنين) |

| أفيري عاكس أومني | تم تقييمه لـ 18 سنين, تصنيف عاكس أقل لـ 7-8 سنين |

| 3م 3930 سلسلة الأفلام المنشورية عالية الكثافة | معتمد ل 10 سنوات مع ضمان 3M Traffic MCS |

| 3م 4000 سلسلة فيلم عاكس من الدرجة الماسية | معتمد ل 12 سنوات مع ضمان 3M Traffic MCS |

يمكنك أن ترى أن التصفيح المتسلسل يعطي ضمانات أطول. كما أنه يجعل العلامات أكثر موثوقية. هذه العملية تحمي الطبقة العاكسة. فهو يساعد على بقاء إنتاج اللافتة سريعًا وسلسًا.

صفائح الألمنيوم

صفائح الألمنيوم تجعل العلامات قوية ومتينة. يمكنك استخدامه لمعظم العلامات الخارجية. لا تصدأ وتبقى مسطحة. يعمل الحفر أولاً بشكل جيد مع ألواح الألمنيوم. تبقى اللوحة ثابتة, وستحصل على ثقوب أنيقة للتركيب. بعد الحفر, اضغط على الأغطية لأسفل لإيقاف الفقاعات. التصفيح المتسلسل يعمل أيضًا, لكنك تحتاج إلى أدوات حادة. يمكنك الحفر من خلال كل من الصفائح والمعادن. يبقى السطح العاكس سلسًا ومشرقًا إذا اتبعت الخطوات. إنتاجك يسير بسرعة, وعلامات تستمر لفترة أطول في الأحوال الجوية السيئة.

مواد أخرى

في بعض الأحيان تستخدم البلاستيك أو الألياف الزجاجية لعلامات خاصة. تنحني هذه المواد أكثر من الألومنيوم. قد يؤدي الحفر أولاً إلى تشقق اللوحة أو ثنيها. يساعد التصفيح المتسلسل على إبقاء الأغطية مسطحة واللافتة قوية. تحصل على التصاق أفضل ومشاكل أقل. تبقى الطبقة العاكسة واضحة, والعلامات تبدو نظيفة. يمكنك اختيار العملية بناءً على تصميمك واحتياجاتك. يمكنك الحفاظ على ثبات إنتاج اللافتات من خلال مطابقة الطريقة مع المواد.

نصيحة: قم دائمًا بمطابقة خطوات التصفيح والحفر مع نوع الصفائح ومواد اللوحة. وهذا يبقي علاماتك قوية وإنتاجك سهلاً.

المتانة والأداء البيئي

مقاومة الطقس

تريد أن تستمر علامة الشارع الخاصة بك في الطقس السيئ. مطر, ثلج, وأشعة الشمس يمكن أن تؤذي العلامات. إن الطريقة التي تصنع بها اللافتة تغير من مدى قوتها. إذا قمت بالحفر أولاً, يمكن أن يصل الماء إلى الثقوب. يحدث هذا بعد وضع الأغطية. يؤدي الماء إلى تفكك الأغطية والألواح بمرور الوقت. إذا كنت تستخدم التصفيح المتسلسل, قمت بإغلاق اللوحة أولاً. قمت بوضع أغطية عاكسة قبل الحفر. هذا يمنع الماء والأوساخ من الدخول تحت الأغطية. علاماتك تبقى قوية ومشرقة في الطقس القاسي.

حماية الطبقة العاكسة

من المهم حماية الطبقة العاكسة. وهذا يساعد الناس على رؤية اللافتة ويحافظ على سلامتهم. الحفر بعد التصفيح يمكن أن يؤذي حواف الأغطية. إذا كنت تستخدم أدوات وأدلة حادة, يمكنك الحفاظ على الأغطية ناعمة. تبقى الانعكاسات في حالة جيدة. يمكن للسائقين رؤية علاماتك في الليل. إذا قمت بالحفر أولاً, يمكن للهواء أو الماء أن يدخل تحت الأغطية. هذا يمكن أن يؤدي إلى فقاعات أو بقع لامعة. علاماتك لا تعمل كذلك. تريد أن تكون الأغطية مسطحة ومشدودة للحفاظ على الطبقة العاكسة آمنة.

الاستخدام الخارجي طويل الأمد

يجب أن تستمر العلامات لسنوات في الخارج. أنت لا تريدهم أن يتلاشى أو يتقشروا. يساعد التصفيح المتسلسل على بقاء اللافتات لفترة أطول في الهواء الطلق. تلتصق الأغطية جيدًا باللوحة. تبقى الثقوب مغلقة. يعمل هذا مع العديد من المواد مثل الألومنيوم والفينيل. عملك يسير بسرعة, وستحصل على أخطاء أقل. إذا قمت بمطابقة عمليتك مع المواد والتصميم الخاص بك, علاماتك تعمل بشكل أفضل. يمكنك توفير الوقت والمال لأنك تقوم بإصلاح واستبدال العلامات بشكل أقل.

نصيحة: تحقق دائمًا من الأغطية والألواح الخاصة بك قبل البدء. يساعدك هذا على اختيار أفضل طريقة لتصبح قويًا, علامات طويلة الأمد.

كفاءة التكلفة في الإنتاج

العمل والوقت

تريد الخاص بك تصنيع إشارات المرور للعمل بسلاسة وسرعة. عندما تختار العملية الصحيحة, يمكنك توفير الوقت وخفض تكاليف العمالة. غالبًا ما يؤدي الحفر أولاً إلى تسريع عملية إنتاج المواد الصلبة مثل الألومنيوم. يمكن للعمال حفر عدة ألواح في وقت واحد, مما يساعد عند عمل علامات كثيرة. التصفيح المتسلسل يأخذ المزيد من الرعاية. يجب عليك الضغط على الأغطية على كل لوحة قبل الحفر. هذه الخطوة تضيف الوقت, ولكنه يساعد على التصاق الأغطية بشكل أفضل ويحافظ على مظهر العلامات نظيفًا. إذا كنت تستخدم الأغطية العاكسة, تحتاج إلى التأكد من أن السطح مسطح وخالي من الغبار. تحمي هذه الخطوة الطبقة العاكسة وتبقي لافتة الشارع الخاصة بك مشرقة.

تكاليف المعدات

أنت بحاجة إلى الأدوات المناسبة لكل عملية تصنيع. يستخدم الحفر أولاً مكابس أو آلات الحفر الأساسية. تعمل هذه الأدوات بشكل جيد مع المواد الصلبة وتبقي تكاليفك منخفضة. يحتاج التصفيح المتسلسل إلى جهاز تغليف أو بكرة للضغط على الصفائح على اللوحة. تحتاج أيضًا إلى لقم ثقب حادة لقطع الأغطية واللوحة. المعدات الإضافية يمكن أن ترفع تكاليفك, ولكنه يساعدك على الحصول على نتائج أفضل من خلال الانعكاسات الرجعية والأغطية العاكسة. إذا كنت تخطط لإنتاج واسع النطاق, يجب عليك الاستثمار في الآلات التي تتعامل مع التصفيح والحفر. يحافظ هذا الإعداد على تحرك خط الإنتاج الخاص بك ويساعدك على تحقيق أهداف التصميم الخاصة بك.

إعادة العمل والعيوب

تريد أن تستمر علاماتك وتبدو جيدة. يمكن أن يؤدي الحفر أولاً إلى مشاكل مثل الفقاعات أو الفضة بالقرب من الثقوب. تقلل هذه العيوب من موثوقية إشاراتك وقد تضر بسلامة الإشارة. قد تحتاج إلى إعادة بعض اللوحات, مما يبطئ إنتاجك ويرفع التكاليف. التصفيح المتسلسل يقلل من مخاطر هذه المشاكل. تبقى الأغطية مسطحة, وتبقى الثقوب مغلقة. تحصل على عيوب أقل وإعادة صياغة أقل. تعمل هذه الطريقة بشكل جيد مع العديد من المواد وتساعدك على الحفاظ على كفاءة عملية التصنيع. عندما تقوم بمطابقة عمليتك مع المواد والأغطية الخاصة بك, يمكنك حماية علاماتك وتوفير المال.

نصيحة: تحقق دائمًا من المعدات والمواد الخاصة بك قبل البدء. تساعدك هذه الخطوة على تجنب الأخطاء المكلفة وتبقي إنتاجك على المسار الصحيح.

اختيار الطريقة الصحيحة

متى يتم الحفر أولاً

يعمل الحفر أولاً بشكل جيد مع المواد الصلبة. إنه جيد لألواح الألمنيوم والطبقات المكدسة مثل CFRP والألمنيوم. يمكنك رؤية أين تتغير المواد وتغيير طريقة الحفر. إذا كنت تستخدم آلة ناقلات الدعم (SVM), يمكنك مشاهدة العملية والتغيير لكل مادة. للألمنيوم, لا تقم بالحفر ببطء شديد لفترة طويلة. هذا يمكن أن يجعل المثقاب ساخنًا ويسبب مشاكل.

قد ترغب في الحفر أولاً في هذه الحالات:

- يمكنك إنشاء العديد من لوحات لافتات الشوارع التي تحتاج إلى ثقوب في نفس المكان.

- أنت تستخدم مواد مكدسة وتحتاج إلى مراقبة التغييرات بين الطبقات.

- تريد منع الثقوب من التواجد في المكان الخطأ في الألواح الصلبة.

- تحتاج علامتك إلى أجهزة يجب وضعها في المكان الصحيح.

نصيحة: تنظيف الألواح بعد الحفر. وهذا يساعد على التصاق الأغطية العاكسة بشكل أفضل وتدوم لفترة أطول.

متى صفح أولا

يساعد التصفيح أولاً على استمرار علاماتك لفترة أطول وتبدو أفضل. هذه الطريقة هي الأفضل للمواد الناعمة مثل الفينيل أو البلاستيك. كما أنه يعمل مع أي علامة ذات أغطية عاكسة للضوء. عندما صفح أولا, تقوم بإغلاق اللوحة والحفاظ على الطبقة العاكسة آمنة. تبقى علاماتك مشرقة وسهلة رؤيتها, حتى بعد سنوات من الخارج.

اختر التصفيح المتسلسل في هذه الأوقات:

- تقوم بعمل علامات يجب أن تستمر في الطقس السيئ وفي الخارج لفترة طويلة.

- يمكنك استخدام عاكسات رجعية أو أغطية عاكسة يجب أن تظل مسطحة ولا تحتوي على فقاعات.

- تريد منع الماء أو الهواء من الدخول تحت الأغطية, مما قد يضر بكيفية عمل العلامة.

- يمكنك استخدام مواد بلاستيكية أو ألياف زجاجية قد تتشقق إذا قمت بالثقب قبل الترقق.

ملحوظة: استخدم لقم الثقب الحادة والأدلة الصحيحة. يؤدي هذا إلى إبقاء الأغطية مسطحة ويمنعها من التمزق عند الحفر.

التوصيات النهائية

يجب عليك اختيار طريقتك بناءً على المواد الخاصة بك, ما تريد القيام به, والقواعد التي يجب عليك اتباعها. يوضح الجدول أدناه أهم الأشياء التي يجب التفكير فيها:

| عامل | وصف |

|---|---|

| الرؤية | صفائح عاكسة جيدة, مثل 3M™ Diamond™ Grade DG3, يجعل الإشارات أكثر سطوعًا ويساعد السائقين على الرؤية بشكل أسرع. |

| متانة | اختر الأجزاء التي تدوم لفترة طويلة, مثل منتجات 3M التي تعمل لمدة تصل إلى 12 سنين. |

| التصنيع | إن صنع اللافتات بالطريقة الصحيحة يساعدها على عكس الضوء من جميع الجهات. |

تحتاج أيضًا إلى التفكير في البيئة. إن استخدام أشياء مثل الألومنيوم التي يمكنك إعادة تدويرها يساعد في تقليل النفايات. تساعدك آلات CNC على استخدام مواد أقل. يساعد اختيار المواد البلاستيكية القابلة لإعادة التدوير على تحسين عملك من أجل الكوكب.

يجب عليك اتباع القواعد الخاصة بمنطقتك. تخبرك هذه القواعد بالمواد التي يجب استخدامها وكيفية صنع علاماتك. ويتحدثون أيضًا عن كيفية الحفاظ على العلامات آمنة وجيدة للبيئة. يمكن أن تغير القواعد كيفية اختيار المواد الخاصة بك وما إذا كنت تقوم بالحفر أو التصفيح أولاً.

نصيحة: تحقق من العملية الخاصة بك في كثير من الأحيان. انظر إلى المواد الخاصة بك, أغطية, وأدوات للتأكد من اتباع القواعد وتعزيزها, علامات جيدة.

عندما تعرف المواد الخاصة بك, ما تحتاج إلى القيام به, والقواعد, يمكنك اختيار أفضل طريقة لعمل إشارات المرور. يساعدك هذا على ظهور علامات تدوم, من السهل رؤيتها, والحفاظ على أمان الطرق.

عليك أن تختار أفضل طريقة لعمل إشارات المرور. فكر في المدة التي ستستمر فيها العلامات, مدى السرعة التي يمكنك جعلها, وكم يكلف. تأكد من أن طريقتك تناسب المواد الخاصة بك وما تريد القيام به. للحفاظ على علاماتك قوية وليست باهظة الثمن, تقول الشركات الكبرى أنه يجب عليك ذلك:

- تتبع التكاليف مثل الحبر, قوة, وتدريب العاملين.

- جرب مطبوعات الاختبار للتحقق من اللون, مدى جودة الأمور, ومدى سطوع العلامة.

- اعمل مع الموردين الذين يساعدونك في دعم وإصلاح الآلات.

- تأكد من أن برنامجك يعمل وخطط للتحديثات لاحقًا.

يمكنك الحصول على نتائج أفضل إذا نظرت إلى عمليتك كثيرًا واستخدمت أدوات وأفكارًا جديدة.

التعليمات

ما هي الفائدة الرئيسية من الترقق قبل الحفر?

يحافظ التصفيح أولاً على سلامة الطبقة العاكسة. يجعل اللافتة تدوم لفترة أطول في الخارج. بهذه الطريقة توقف الفقاعات وتساعد على ظهور اللافتة بشكل سلس. يتم إغلاق اللوحة, لذلك تبقى الإشارة قوية.

هل يمكن استخدام الحفر أولا مع جميع مواد الإشارة?

يعمل الحفر أولاً بشكل أفضل مع المواد الصلبة مثل الألومنيوم. المواد الناعمة مثل الفينيل أو البلاستيك يمكن أن تتشقق أو تنحني. اختر دائمًا الطريقة الصحيحة للمواد الخاصة بك.

كيف يمكنك منع الفقاعات عند تطبيق الأغطية العاكسة؟?

نصيحة: قم بتنظيف اللوحة قبل وضع الأغطية. استخدم أسطوانة أو جهاز تغليف للضغط عليه بشكل مسطح. هذا يوقف الجيوب الهوائية ويحافظ على سلاسة الطبقة.

هل يؤثر ترتيب الحفر والتصفيح على ضمانات التوقيع؟?

| طريقة | مدة الضمان النموذجية |

|---|---|

| الترقق أولا | حتى 12 سنين |

| الحفر أولا | 8- 10 سنوات |

غالبًا ما تتمتع اللافتات المصنوعة بالتصفيح المتسلسل بضمانات أطول. معظم الشركات المصنعة تحب هذه الطريقة للأقوياء, علامات عالية الجودة.

ما هي الأدوات التي تساعدك على الحفر من خلال الألواح المصفحة دون ضرر?

استخدم لقم الثقب الحادة والأدلة الجيدة. تساعدك هذه الأدوات على عمل ثقوب أنيقة والحفاظ على سلامة الأغطية. تحقق دائمًا من أدواتك قبل البدء في عمل اللافتات.