لماذا 4 القدمين هو الارتفاع المثالي لمرحلات المرور

A 4-foot height for a traffic delineator offers the perfect balance of visibility and functionality. This height ensures drivers can spot it easily, even from a distance. Pedestrians and cyclists also benefit, as it aligns with their eye level, making it noticeable in busy areas. You’ll find that this height complies with traffic safety standards, ensuring consistency across roadways. By choosing this standard, أنت تساعد في إنشاء طرق أكثر أمانًا للجميع.

كيفية تحديد التباعد الصحيح لترسيط حركة المرور

Traffic delineators play a vital role in keeping roads safe and organized. Their reflective properties improve visibility, especially at night or on high-speed roads. Drivers can anticipate sharp turns or obstacles earlier, reducing accidents. Proper spacing ensures that delineators provide continuous guidance along the roadway. This helps drivers interpret road conditions and stay on course. Effective delineator application also influences driver behavior, جعل الطرق أكثر أمانًا للجميع. By understanding the factors that affect spacing, you can optimize lane delineators for maximum safety and efficiency.

الصيانة والتفتيش على المدى الطويل من مراسلة المرور

Traffic delineators play a vital role in keeping roads safe and organized. You see them on highways, مناطق البناء, and other areas where clear guidance is essential. Flexible traffic delineators enhance safety by absorbing vehicle impacts and reducing injuries. Their reflective surfaces improve visibility in low light, ensuring drivers stay on track. لكن, exposure to harsh weather can degrade their performance over time. Regular inspection helps maintain their stability and effectiveness, ensuring they meet safety standards. By prioritizing maintenance, you can extend their lifespan and keep roads safer for everyone.

دليل لأنواع مختلفة من المراسلة البلاستيكية

Have you ever wondered how roads stay organized and safe, even in chaotic traffic? Plastic delineator plays a huge role in making that happen. These simple yet effective tools guide vehicles, reduce confusion, and improve overall safety. In fact, studies show that plastic delineators can cut accidents by up to 40%. They also help maintain lane discipline and keep traffic flowing smoothly, especially in high-risk areas.

اختيار قاعدة حاجز المرور المناسبة مع التركيز على خيارات قاعدة المخروط لتحقيق أقصى سلامة وكفاءة

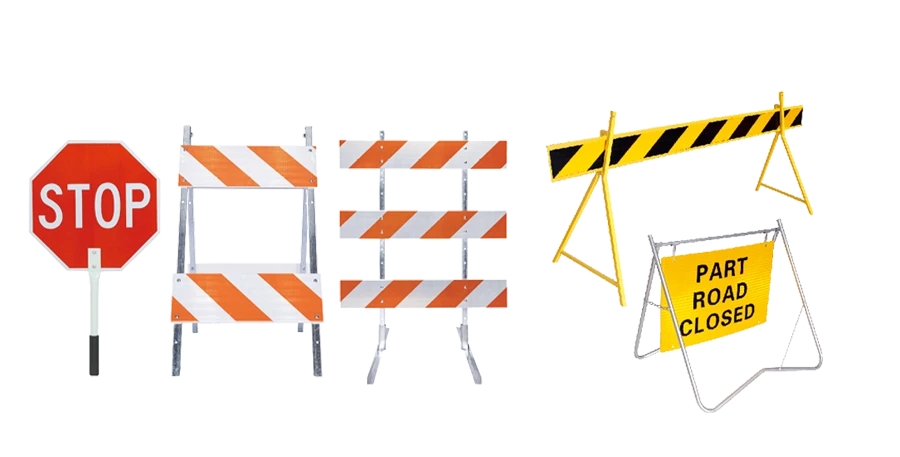

Choosing the right traffic barrier base plays a vital role in ensuring safety and efficiency in traffic management. Among the many options available, the cone base stands out as a cost-effective solution for various scenarios. You can rely on traffic cones with sturdy bases to redirect traffic during peak hours, mark hazardous areas, or create temporary lanes. These barriers also guide vehicles around obstacles and establish contraflow lanes during emergencies like hurricane evacuations. Their versatility makes them an essential part of any traffic control system. Understanding their features and applications helps you make informed decisions for maximum safety.

The Evolution of Reflective Delineators and Advancements in Road Safety Technology

Road safety remains a critical concern as traffic volumes increase worldwide. Poor visibility contributes significantly to accidents, especially during nighttime or adverse weather conditions. Reflective delineators play a vital role in addressing this issue by enhancing visibility and guiding drivers effectively. These devices reflect headlights, improving navigation in low-light environments and reducing accidents by up to 40%, according to the Federal Highway Administration.