5052-H38 الألومنيوم هو الخيار الأفضل لعلامات مراقبة حركة المرور في أستراليا. إنها قوية للغاية ومقاومة للغاية للتآكل. كما يتوافق مع جميع المعايير الوطنية. يعد اختيار المواد المناسبة لعلامات الطرق أمرًا بالغ الأهمية لأنه يساعد في الحفاظ على سلامة الطرق ويضمن أن تظل العلامات مرئية بوضوح. هذا يعزز أيضًا الأداء الكلي للعلامات. يوضح الأبحاث التي أجريت في كوينزلاند أن الألومنيوم المستقر للأشعة فوق البنفسجية يمنع التلاشي والتآكل. هذا يبقي علامات التحكم في حركة المرور واضحة ودائمة, حتى في ظل الظروف الجوية القاسية. يمتد استخدام الألمنيوم المناسب عمر العلامات ويضمن الامتثال للوائح. بالتالي, تتطلب العلامات الأقل استبدالًا, المساهمة في الطرق الأكثر أمانًا للجميع.

إذا كنت ترغب في معرفة المزيد حول كيفية تأثير مواد علامة السلامة المرورية المناسبة على السلامة والمتانة, تحقق من مدونتنا كيف تشكل خيارات المواد مستقبل علامات المرور للبيع في أستراليا.

علامات مراقبة حركة المرور: المتطلبات الرئيسية

الرؤية والانعكاس

الرؤية مهمة للغاية لعلامات مراقبة حركة المرور. يحتاج السائقون إلى رؤية الرموز وقراءة الكلمات بسرعة. هذا صحيح حتى عندما يكون مظلمًا أو تمطر. القواعد الأسترالية, يحب AS/NZS 1906.1, يقول توقف العلامات يجب استخدام الفصل 1 أو فئة 1W أغطية عاكسة. تستخدم هذه المواد تقنية منشورية خاصة. فصل 2 الأغطية العاكسة غير مسموح بها لعلامات التوقف. يجب أن تعمل الطبقة العاكسة بشكل جيد حتى تصل إلى 10 سنين. هذا يساعد العلامات على البقاء واضحة ليل نهار. كما أنه يساعد الناس على التعرف على الرموز ويعطي أدلة قوية على الطريق. المواد العاكسة تجعل العلامات سهلة رؤيتها في الليل ومن بعيد.

- فصل 1 أو 1W أغطية عاكسة ضروري لعلامات التوقف

- يجب أن تدوم المواد العاكسة 10 سنين

- تساعد سبائك الألومنيوم القوية على البقاء مرئية لفترة طويلة

المتانة في أستراليا

يمكن أن يجعل الطقس في أستراليا علامات تلبس بشكل أسرع. يمكن لضوء الشمس أن يجعل العلامات تتلاشى وتتكسر. يمكن أن يسبب الطقس الحار والبارد تشققات أو تجعل العلامات هشة. يمكن أن يصنع رذاذ الملح بالقرب من البحر صدأ معادن غير معالجة. يمكن لسبائك الألومنيوم المصبوب والمواد المستقرة للأشعة فوق البنفسجية التعامل مع هذه الظروف الصعبة. الطلاءات الواقية تعطي حماية إضافية. غالبًا ما يساعدهم التنظيف والتحقق من العلامات على الاستمرار لفترة أطول. مواد جيدة تبقي علامات المرور تعمل بشكل جيد وآمنة, حتى في الأماكن القاسية.

- تتوقف سبائك الألومنيوم المستقرة للأشعة فوق البنفسجية عن التلاشي والتكسير

- الألومنيوم من الدرجة البحرية لا يصدأ من رذاذ الملح

- تساعد الطلاء والرعاية علامات تستمر لفترة أطول

معايير الامتثال

اتباع المعايير الأسترالية تتأكد من أن علامات المرور آمنة وتعمل بشكل جيد. مثل 1743-2001 يسرد قواعد علامات الطرق. AS/NZS 1734:1997 يشرح ما يجب أن تكون عليه سبائك الألومنيوم للعلامات. تقول هذه القواعد ما هي المواد الكيميائية والسمك الذي تحتاجه السبائك. يقولون أيضًا مدى قوة المعدن والانحناء. AS/NZS 1906.3:2017 يروي ما هي المواد العاكسة اللازمة للعلامات. باتباع هذه القواعد, يتأكد صانعو العلامات من سهلة رؤيتها, آخر طويل, والحفاظ على الناس آمنة.

ملحوظة: يعد استخدام سبائك الألمنيوم المناسبة والمواد العاكسة أمرًا مهمًا للغاية للسلامة والقانون. إذا كانت العلامات لا تتبع القواعد, قد يفشلون ويكلفون أكثر لاستبداله. تريد أن تعرف ما هي المواد التي تناسب احتياجاتك? اقرأ مدونتنا أي مادة مناسبة لك? مقارنة علامات السلامة للبيع: الألومنيوم مقابل البلاستيك مقابل المغناطيسي لاستكشاف جميع الخيارات.

5052-H38 الألومنيوم: الخصائص والفوائد

مقاومة التآكل

5052-H38 الألومنيوم لا يصدأ بسهولة. هذا يجعلها رائعة لعلامات المرور في الهواء الطلق في أستراليا. ليس له نحاس, لذلك لا يتآكل في الأماكن المالحة أو البحرية. العلامات المصنوعة من هذه السبائك لا تحصل على الحفر أو الصدأ, حتى بالقرب من البحر أو في أمطار غزيرة. يساعد المغنيسيوم المرتفع في 5052-H38 على مقاومة الأضرار في الطقس القاسي. معايير الصناعة تعطي هذه السبائك "أ’ لمقاومة التآكل. هذا يعني أنه يعمل بشكل جيد في المصانع وبالقرب من البحر بدون طلاء إضافي. تختار المجالس والبناة 5052-H38 الألمنيوم لأن العلامات تظل جديدة وسهلة القراءة لفترة طويلة. مقاومتها القوية للتآكل تعني أن العلامات لا تحتاج إلى استبدالها في كثير من الأحيان. هذا يساعد البيئة ويوفر المال.

- 5052-H38 الألومنيوم جيد جدًا في مقاومة التآكل في الأماكن المالحة والكيميائية.

- يحافظ على علامات واضحة وسهلة القراءة, حتى بعد سنوات عديدة.

- تدوم السبائك وقتًا طويلاً, لذلك فهو يساعد البيئة من خلال صنع مضيعة أقل.

القوة والصلابة

5052-H38 الألومنيوم قوي ولكن ليس ثقيل. هذا مهم لعلامات المرور. إن قوتها العالية الشد تبقي العلامات قاسية وتمنعها من الانحناء في الريح القوية. هذه القوة تساعد العلامات على الحفاظ على شكلها, حتى في الأماكن المفتوحة. المعامل المرن من 5052-H38 هو 70.3 GPA. هذا يعني أنه لا ينحني بسهولة مقارنة بالسبائك الأخرى. قوة العائد أقل من بعض السبائك الأخرى, لكنها لا تزال قوية بما يكفي لمعظم العلامات. يتيح مزيج القوة والتشكيل السهل لصناعه بناء علامات صعبة سهلة التقدم. علامات مصنوعة من هذه السبائك تقف وسهلة رؤيتها, حتى في الطقس السيئ.

| ملكية | 5052-H38 سبيكة الألومنيوم | 6061 سبيكة الألومنيوم |

|---|---|---|

| معامل مرن | 70.3 GPA | 68.9 GPA |

| قوة العائد | 193 MPA | 276 MPA |

5052-يعطي الألمنيوم H38 مزيجًا مناسبًا من القوة والمرونة من أجل الآمنة, علامات طويلة الأمد.

السطح وقابلية العمل

5052-H38 الألومنيوم لديه سطح أملس. هذا جيد لوضع الطلاء العاكس وعلامات الطباعة. يستخدم صناع هذه السبائك لجعل الفراغات اللامعة والسلسة. هذه النهاية تجعل من السهل إضافة أوراق عاكسة, ملصقات, والطباعة. يمكن التعامل مع السبائك بعدة طرق, مثل أنوود, تلوين, أو بالفرشاة. هذه العلاجات تجعل العلامات تدوم لفترة أطول وتبدو أفضل. سطحه اللامع يجعل العلامات مشرقة وسهلة رؤيتها, ليلا أو نهارا. يساعد السطح العاكس على السائقين لافتات من بعيد أو في الظلام.

5052-H38 الألمنيوم سهل العمل مع. يمكن للعمال قطع, لكمة, وتشكيله بسرعة. هذا يجعل علامات البناء أسرع ويحافظ على جودة عالية. تساعد قوتها على علامات على الوقوف على الطقس السيئ والأشخاص الذين يحاولون إلحاق الضرر بهم. لأنه من السهل شكله, يمكن تقديم علامات بأحجام وأشكال كثيرة للطرق المختلفة.

- تستخدم الفراغات اللافتة 5052-H38 الألومنيوم لأنها لامعة وقوية.

- من السهل العمل مع السبائك, لذا فإن العلامات مصنوعة بشكل أسرع وأفضل.

- تساعد النهاية اللامعة على السائقين على رؤية العلامات والبقاء آمنين.

اختيار 5052-H38 الألمنيوم يعني أن علامات المرور ستبقى قوية, واضح, وجيد للبيئة لسنوات عديدة.

مقارنة سبائك الألومنيوم

5052-H38 مقابل 3003

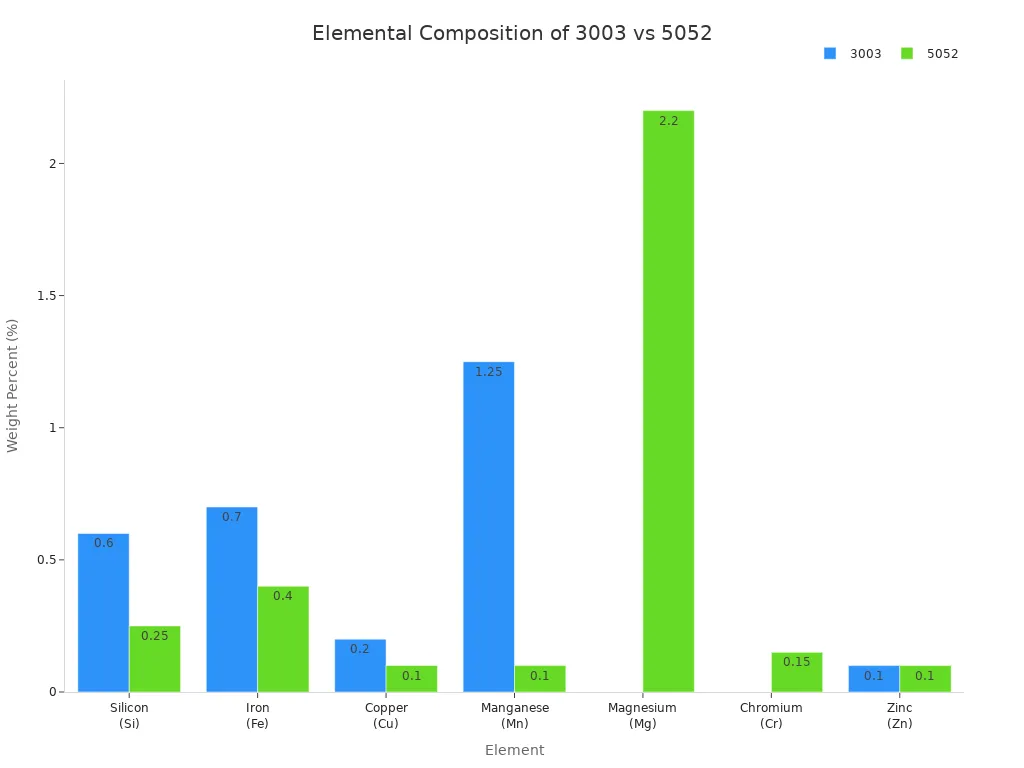

غالبًا ما ينظر المهندسون إلى كلا 5052-H38 و 3003 عند اختيار المواد لعلامات المرور. هاتان السبائك شائعة, لكنها ليست هي نفسها. 5052-H38 لديه المغنيسيوم والكروم. هذه تجعلها أقوى وأفضل في محاربة الصدأ. 3003 لديه المنجنيز بدلا من ذلك. هذا يجعلها أكثر ليونة وليست صعبة في الطقس السيئ.

| عنصر | 3003 | 5052 |

|---|---|---|

| الألومنيوم (آل) | 97.0-98.0 ٪ | الباقي |

| المغنيسيوم (ملغ) | 0.0% | 2.2-2.8 ٪ |

| الكروم (كر) | 0.0% | 0.15-0.35 ٪ |

| المنغنيز (MN) | 1.0-1.5 ٪ | ≤0.10 ٪ |

| نحاس (النحاس) | 0.05-0.20 ٪ | ≤0.10 ٪ |

5052-H38 الألمنيوم أقوى بكثير من 3003. يمكن أن تتعامل مع المزيد من القوة قبل الانحناء أو كسر. هذا أمر جيد للعلامات في الأماكن العاصفة أو الساحلية. يوضح الجدول أدناه مدى قوة كل سبيكة:

| حِدّة | قوة الشد (MPA) | قوة العائد (MPA) | برينيل صلابة (HB) |

|---|---|---|---|

| 3003-H14 | 155 | 150 | 40 |

| 5052-H38 | 295 | 260 | 77 |

5052-H38 الألمنيوم هو أفضل اختيار للعلامات الخارجية في أستراليا. المغنيسيوم يبقيه في مأمن من الملح والمطر. 3003 سهل الشكل, لكنه لا يدوم طويلًا أو يظل قويًا مثل 5052-H38.

التكلفة والعمر

5052-يكلف الألمنيوم H38 أكثر من البداية من 3003. لكنه يوفر المال لاحقًا لأنه يستمر لفترة أطول. المجالس والبنائين مثل 5052-H38 لأنها تحتاج إلى إصلاح أقل. لا تزال العلامات المصنوعة منها قوية وسهلة القراءة لسنوات عديدة. 3003 قد تحتاج العلامات إلى التغيير عاجلاً, خاصة بالقرب من البحر أو في أماكن عاصفة.

تطلب العديد من الوظائف الحكومية 5052-H38 الألومنيوم لعلامات الطرق. هذا يتأكد من أن العلامات تتبع القواعد وتستمر لفترة طويلة.

5052-H38 الألومنيوم مميز لأنه قوي, لا يصدأ, وموثوق جدا. صانعي يستخدمونه لعلامات الطرق المهمة. إنهم يعلمون أنه سيعمل بشكل جيد ويساعدون في توفير المال على علامات جديدة.

دليل التثبيت والسمك

-1024x768.jpg)

اختيار السماكة

من المهم اختيار السماكة المناسبة لعلامات المرور. يساعد في الحفاظ على علامات آمنة وقوية. يختار المهندسون الألومنيوم 1.6 ملم للعلامات الصغيرة. هذه أشياء مثل وقوف السيارات أو علامات الحد من السرعة. هذا السماكة جيدة إذا كانت العلامة لها دعم أو في مكان آمن. علامات متوسطة, مثل لوحات التحذير, استخدام 2.0mm الألومنيوم. هذه العلامات تحتاج إلى مزيد من القوة بسبب الرياح. علامات كبيرة على الطرق السريعة تستخدم الألمنيوم 3.0 مم. هذا يمنعهم من الانحناء في ريح قوية. يعتمد أفضل سماكة على حجم العلامة وأين تذهب. يعتمد أيضًا على مقدار الرياح التي ستحصل عليها. إن استخدام السمك المناسب يجعل العلامات تدوم لفترة أطول وسهلة القراءة.

نصيحة: انظر دائمًا إلى القواعد المحلية قبل اختيار السماكة. تساعد المعايير الأسترالية على علامات اتباع قوانين السلامة.

طرق التثبيت

التثبيت الجيد يبقي العلامات آمنة وسهلة رؤيتها. استخدام المثبتات توقيع قوسين, توقيع المشاركات, أو توقيع إطارات مصنوع من الألومنيوم. هذه الأجزاء لا تصدأ وتتناسب مع العلامة. يقوم العمال بإصلاح العلامة بمسامير الفولاذ المقاوم للصدأ أو المسامير. هذا يوقف الصدأ ويحافظ على الإشارة ضيقة. للحصول على علامات فوق الطرق, يستخدم المهندسون إطارات قوية وألومنيوم سميك. الألومنيوم الناعم 5052-H38 مفيد للأوراق العاكسة. تساعد هذه الطبقة السائقين على رؤية علامات في الليل أو في المطر. العمل الدقيق يوقف الخدوش ويحافظ على الانتهاء اللامع بشكل جيد.

في أوبترافيك, نحن نقدم حلول توقف لكليهما علامات المرور للبيع وملحقات التثبيت الخاصة بهم, التأكد من أن مشاريعك متوافقة, آمن, وبنيت لتستمر.

احتياجات الصيانة

5052-H38 الألومنيوم يساعد المجالس والعمال على توفير المال. لا يصدأ, لذا تدوم العلامات لفترة أطول. علامات نظيفة مع صابون معتدل لإبقائها مشرقة. يفحص المفتشون علامات المرور كل عام للتلف أو التلاشي. إذا كانت الطبقة اللامعة تقشير أو تنحني الإشارة, تم تغيير هذا الجزء فقط. هذا يوفر المال ويبقي الطرق آمنة. تدوم علامات الألومنيوم لفترة طويلة, لذلك هناك قدر أقل من القمامة. تصميمات جيدة ومواد قوية تساعد العلامات على ما يرام لسنوات عديدة.

5052-H38 الألمنيوم هو الخيار الأفضل لعلامات المرور في أستراليا. إنه قاس, لا يصدأ, ويلبي جميع القواعد. هذا يعني أن العلامات تعمل بشكل جيد وتستمر لفترة طويلة. إن اختيار السمك المناسب والشراء من الموردين الجيدين يبقي الناس آمنين. كما أنه يساعد على تجنب مشاكل القانون.

- إذا كنت تستخدم سمك خاطئ أو نوع خاطئ من الألمنيوم, يمكن:

- كسر قواعد علامات الطرق

- اجعل العلامات يصعب رؤيتها, خاصة في الليل

- جعل الحوادث أكثر احتمالا وتسبب مشكلة قانونية

يختار المهندسون 5052-H38 عندما يريدون علامات تدوم وتعمل بشكل جيد.

التعليمات

ما الذي يجعل الألمنيوم 5052-H38 مناسبًا لعلامات المرور الأسترالية?

5052-H38 الألومنيوم قوي ولا يصدأ بسهولة. إنه يعمل بشكل جيد في الطقس القاسي. تستخدم المجالس هذه السبائك لعلامات الطرق التي تستمر لفترة طويلة. تبقى علامات التحكم في حركة المرور هذه مشرقة وسهلة رؤيتها على الطرق والطرق السريعة. كما أنه يستخدم لعلامات القمامة.

كيف يعالج 5052-H38 الألومنيوم البيئات الساحلية?

هذه السبائك تقف على رذاذ الملح والهواء الرطب. يتوقف الصدأ ويتوقف بالقرب من البحر. يختار المهندسون 5052-H38 للحصول على علامات وحواجز من الساحل. العلامات لا تزال تبدو جيدة وتبقى قوية لسنوات عديدة.

أي سمك يجب أن يختار المهندسون لعلامات كبيرة?

غالبًا ما يختار المهندسون سمك 3.0 مم للعلامات العامة الكبيرة. هذا السماكة تجعل العلامات قاسية وتمنعها من الانحناء في الريح. كما أنه يحمل وزن الأوراق والأجهزة العاكسة.

هل يتطلب 5052-H38 الألومنيوم صيانة خاصة?

5052-H38 الألومنيوم لا يحتاج إلى الكثير من العناية. التنظيف مع الصابون المعتدل يحافظ على علامات التحكم في حركة المرور لامعة. المفتشون يبحثون عن تلف أو يتلاشى كل عام. معظم العلامات تعمل بشكل جيد لسنوات عديدة دون الكثير من الإصلاحات.

يمكن استخدام 5052-H38 الألومنيوم لأشكال العلامات المخصصة?

يمكن للمصنعين قطع, لكمة, وشكل 5052-H38 الألومنيوم بسهولة. هذا يجعل من السهل إنشاء علامات مخصصة. من السهل إجراء أشكال فريدة من نوعها لعلامات القمامة أو الحواجز الخاصة.