When you choose aluminum for road signs, you get a metal that is both lightweight and strong. Most traffic signs use aluminum sheets because they resist rust and withstand harsh weather conditions. Understanding aluminum sheet metal weight is essential for selecting the right material. For example, a 4×8 foot sheet of 0.063 inch aluminum weighs about 40 pounds, a 0.080 inch sheet weighs around 50 pounds, and a 0.125 inch sheet weighs approximately 80 pounds. The table below shows the typical aluminum sheet metal weight for these sizes:

| Thickness (inch) | Weight per Square Foot (lb/ft²) | Weight of 4×8 ft Sheet (lbs) |

|---|---|---|

| 0.063 | ~1.26 | ~40.3 |

| 0.080 | ~1.56 | ~50 |

| 0.125 | ~2.5 | ~80 |

Knowing the aluminum sheet metal weight helps you plan proper placement and ensures compliance with safety regulations. Use this chart to select the right aluminum sheet metal weight for your road signs.

At OPTRAFFIC, we supply high-quality aluminum sheets in a range of weights and thicknesses, perfect for traffic and road signage. Our durable materials help you meet safety standards while keeping your projects cost-effective and reliable.

Key Takeaways

- Aluminum sheets have different weights. The weight depends on thickness and size. Thicker sheets weigh more. Bigger sheets also weigh more. Thicker and bigger sheets are stronger.

- Picking the right thickness and alloy is important. This makes your traffic sign strong. It helps the sign last longer. It also meets safety rules in your area.

- Knowing the weight of aluminum sheets is helpful. It helps you plan safe installation. It helps with moving the sheets. It also helps you follow the rules.

- Aluminum signs are lighter than steel signs. They do not rust. They are easier to move and use. This makes them good for permanent signs. They are also good for temporary signs.

- Always check your sign’s weight before you order. Look at the specifications too. This helps keep things safe. It makes sure your sign lasts. It helps you install it the right way.

Aluminum Sheet Metal Weight

Common Thicknesses and Sizes

When you select aluminum for traffic signs, you need to consider both the thickness and the size of the sheet. Aluminum sheet metal weight changes based on these factors. Most roadwork signs use aluminum because this metal is light, strong, and resists rust. You often see aluminum sheets measured in gauge, where a lower gauge means a thicker sheet. For traffic signs, common thicknesses include 0.080 inch, 0.125 inch, and sometimes 3/16 inch for larger signs. These thicknesses help balance strength and flexibility.

You might use a 1/8 inch thickness for a sturdy sign that can handle wind and weather. Thicker aluminum, like 3/16 inch or even 1/4 inch, works best for bigger signs or those placed in high wind zones. The size of the sign also matters. Standard aluminum sign sizes include 30″x30″, 36″x36″, and 48″x48″. Custom signs often use sheets ranging from 2’x4′ to 4’x8′. The recommended thickness for each sign depends on its size and where you install it. For example, a small sign in a low wind area may only need 1.6 mm aluminum, while a large sign in a cyclonic zone could require up to 3.0 mm thickness.

Tip: Always check the recommended thickness for your sign based on its location and size. This helps you choose the right aluminum sign material thickness for safety and durability.

Weight Reference Table

You can use a weight reference table to quickly find the aluminum sheet metal weight for different thicknesses and sizes. This table helps you plan for installation and transportation. The weight increases as the thickness and size of the aluminum sheet grow. For example, a 4×8 foot sheet of 0.080 inch aluminum weighs about 50 pounds, while a 0.125 inch sheet weighs around 80 pounds.

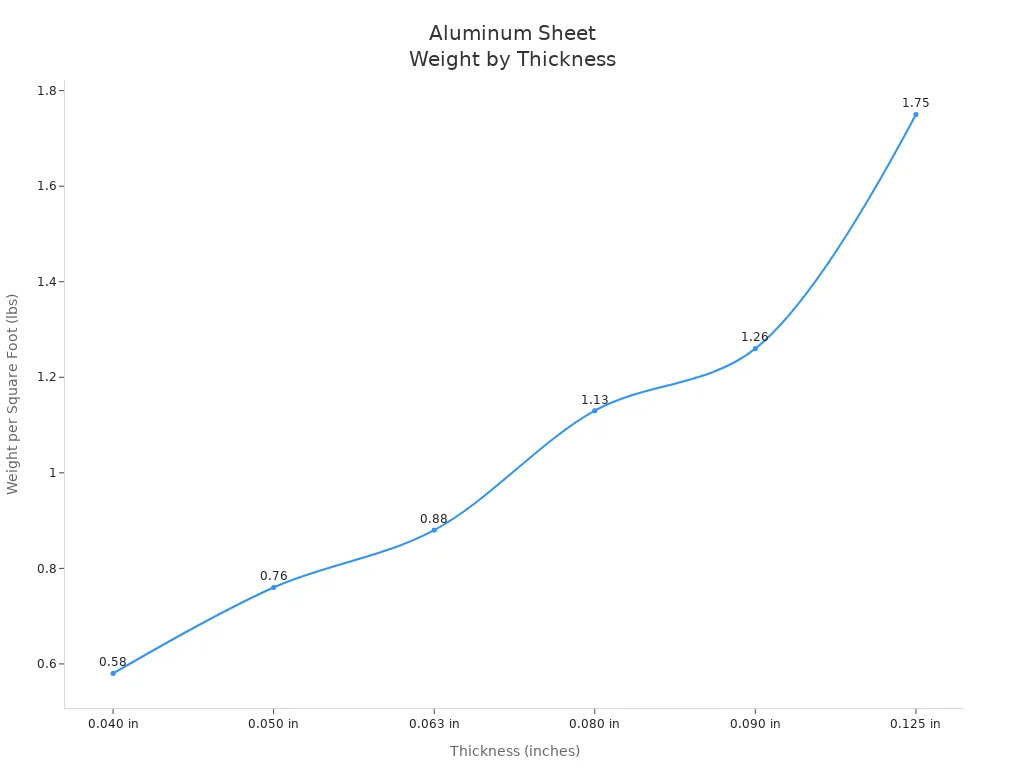

Here is a helpful table showing how aluminum sheet metal weight changes with thickness:

| Thickness (inches) | Width (inches) | Length (inches) | Weight per Square Foot (lbs) |

|---|---|---|---|

| 0.040 | 48 | 96, 120, 144 | ~0.58 |

| 0.050 | 48 | 96, 120, 144 | ~0.76 |

| 0.063 | 48 | 96, 120, 144 | ~0.88 |

| 0.080 | 48 | 96, 120, 144 | ~1.13 |

| 0.090 | 48 | 96, 120, 144 | ~1.26 |

| 0.125 | 48 | 96, 120, 144 | ~1.75 |

As you can see, thicker aluminum means more metal and a heavier sign. You should always use the recommended thickness for your project to make sure your sign stays safe and secure.

Factors Affecting Weight

Thickness and Dimensions

When picking aluminum for signs, you need to look at thickness and size. These two things change how heavy your sign will be. Thicker aluminum sheets are heavier and stronger than thin ones. For example, a 0.080-inch sheet is lighter than a 0.125-inch sheet if they are the same size. Bigger sheets also weigh more because they use more metal.

- Aluminum sheets for signs come in thicknesses like 0.032″, 0.040″, 0.050″, and 0.080″. Thicker sheets do not bend or warp easily, so they are good for flat surfaces.

- Common sheet sizes are 4×8 feet, 4×10 feet, and 5×10 feet. Larger sheets mean more aluminum and more weight.

- Composite materials, like DiBond or Alumalite, have a plastic core between aluminum layers. These sheets are about as thick as solid aluminum but weigh less, so they are easier to move and put up.

Tip: Pick the right thickness and size for where your sign will go. Bigger and thicker signs are better for windy or busy places.

Aluminum Alloys

The kind of aluminum alloy you pick also changes the weight and how well your sign works. Different alloys have their own mix of strength, resistance, and how long they last. For traffic signs, people often use alloys like 1100, 3003, 5052, 5454, 5754, and 6061. Each alloy has its own density and special features.

| Aluminum Alloy | Typical Use in Traffic Signage | Density (g/cm³) | Notes |

|---|---|---|---|

| 5754 | Sign substrate (plates) | ~2.7 | High strength, corrosion resistant, lightweight |

| 6061 | Road sign brackets | 2.7 | Good strength, corrosion resistance, lighter than 7000 series |

| 7075 | High-stress applications | 2.81 | Stronger but heavier and more expensive |

You should pick an alloy that gives you the right mix of strength, resistance, and weight. For example, 5754 is strong and does not rust easily, so it is great for big or outdoor signs. Alloys like 5052 and 5454 are tough and do not rust, which is good for signs near the ocean or in stormy places. Special coatings and reflective layers add a little weight but help your sign last longer and be easier to see.

Note: The best alloy helps your sign stay strong in bad weather, keeps it from rusting, and makes it last a long time.

Weight Calculation

Formula and Method

You can easily figure out how much an aluminum sheet weighs if you know its size and thickness. The standard formula for calculating the weight of aluminum sheet metal is:

Weight = Length × Width × Thickness × Density

You must use the same unit for all measurements. For example, if you measure the length, width, and thickness in inches, you should use the density in pounds per cubic inch (lb/in³). The density of aluminum is usually about 2.7 g/cm³ or 0.0975 lb/in³. Most aluminum alloys used for signage, like 3003 or 1100, have a density very close to pure aluminum. This makes your calculations accurate and reliable.

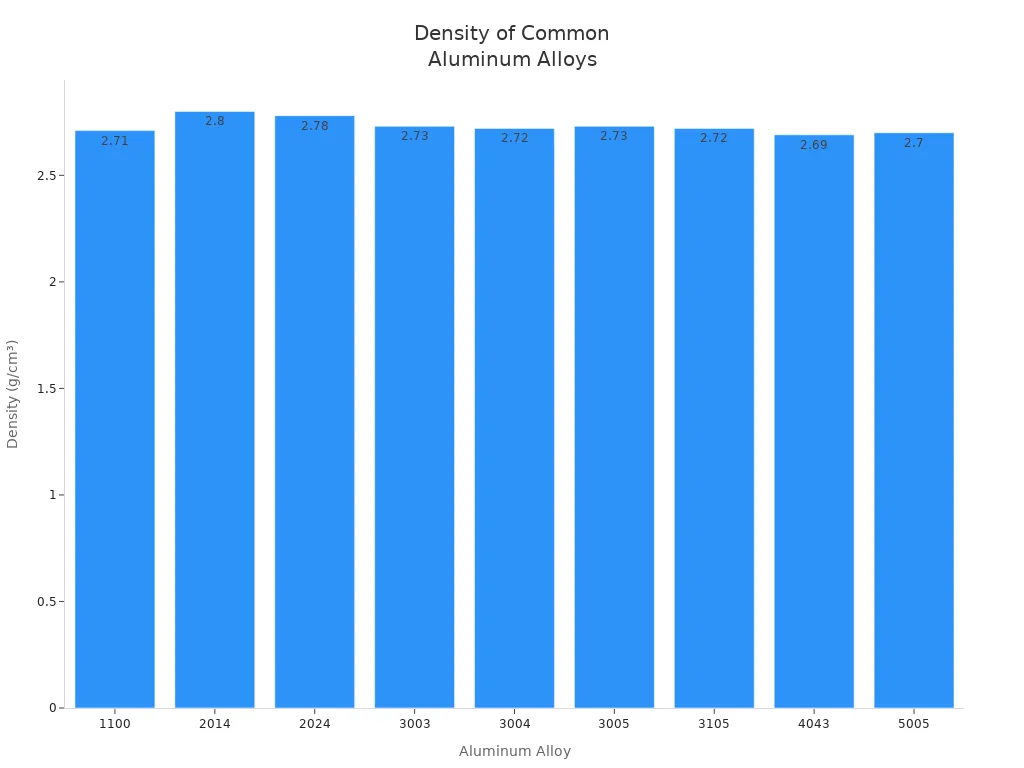

Here is a table showing the density of common aluminum alloys used in signage:

| Aluminum Alloy | Density (g/cm³) | Density (lb/in³) |

|---|---|---|

| 1100 | 2.71 | 0.098 |

| 2014 | 2.80 | 0.101 |

| 2024 | 2.78 | 0.100 |

| 3003 | 2.73 | 0.099 |

| 3004 | 2.72 | 0.098 |

| 3005 | 2.73 | 0.098 |

| 3105 | 2.72 | 0.098 |

| 4043 | 2.69 | 0.097 |

| 5005 | 2.70 | 0.098 |

You can see that the density does not change much between different aluminum alloys. This helps you estimate the weight of your aluminum sign with confidence.

Tip: Always double-check your units before you start your calculation. If you use inches for length, width, and thickness, use the density in lb/in³. If you use centimeters, use the density in g/cm³.

Example Calculations

Let’s walk through a real example. Suppose you want to know the weight of a 4×8 foot aluminum sheet that is 0.080 inches thick. Here’s how you do it step by step:

- Convert all dimensions to inches.

- 4 feet = 48 inches

- 8 feet = 96 inches

- Thickness = 0.080 inches

- Calculate the volume.

- Volume = Length × Width × Thickness

- Volume = 48 in × 96 in × 0.080 in = 368.64 cubic inches

- Multiply by the density of aluminum.

- Density = 0.0975 lb/in³ (for most aluminum alloys)

- Weight = Volume × Density

- Weight = 368.64 in³ × 0.0975 lb/in³ ≈ 35.94 pounds

- Check your answer.

- This matches closely with standard weight charts for aluminum sheets.

If you use a different alloy, like 2014, with a density of 0.101 lb/in³, the weight would be: Weight = 368.64 in³ × 0.101 lb/in³ ≈ 37.23 pounds

You can use this same method for any aluminum sheet size or thickness. Just remember to keep your units consistent.

Conversion Tip: If you want to convert your result to kilograms, divide the weight in pounds by 2.205. Online calculators can also help you switch between inches, feet, millimeters, and centimeters. This makes it easy to work with aluminum sheets no matter what measurement system you use.

Here is a quick reference table for gauge and thickness, which helps you pick the right aluminum sheet for your project:

| Gauge | Thickness (inches) | Thickness (mm) |

|---|---|---|

| 12 | 0.081 | 2.05 |

| 14 | 0.064 | 1.63 |

| 16 | 0.051 | 1.29 |

| 18 | 0.040 | 1.02 |

| 20 | 0.032 | 0.81 |

You can see how the thickness changes with the gauge number. Thicker aluminum sheets weigh more and are stronger, which is important for large or outdoor signs.

Note: Online metal weight calculators let you enter dimensions in different units and give you the weight in pounds or kilograms. This saves time and helps you avoid mistakes.

By following these steps, you can quickly and accurately calculate the weight of any aluminum sheet. This helps you plan for installation, shipping, and safety in your signage projects.

Why Weight Matters in Signage

Installation and Handling

Aluminum signs are light, so they are easy to put up. You can carry and hang them without much trouble. The weight changes if the sign is thicker or thinner. Most aluminum signs weigh between 0.56 and 1.13 pounds for each square foot. If your sign is light, you can use simple ways to hang it, like command strips on smooth walls. Heavy or thick aluminum signs need stronger ways to mount them, such as standoffs.

Signs with holes already drilled and rounded corners are safer to install. These features help you avoid getting hurt and make the job easier. If the sign is big, you might need help from another person to lift and place it. Working together keeps everyone safe and protects the sign from damage.

- Aluminum signs are simple to move and hang.

- Light signs work with easy mounting tools.

- Heavy signs need strong supports.

- Holes and rounded corners make handling safer.

- Big signs often need two people for safe setup.

Compliance and Safety

You should always think about safety rules when putting up aluminum signs. The weight of the sign tells you how to handle it and what support is needed. Die-cast aluminum signs are heavier, so they are stronger and last longer in bad weather. These signs can be harder to install, especially if you need to put them high up. Profile aluminum signs are lighter but might need extra parts to keep water out and make them stronger.

All road signs must follow MUTCD rules for size, shine, and where they go. Aluminum helps you meet these rules because it is light and tough. You can add special reflective sheeting to make the sign easier to see and follow the rules. When you put up aluminum signs, use the right pole height and make sure the sign is anchored well. This keeps the sign safe and easy to read, which helps keep roads safe.

- Aluminum signs must meet MUTCD rules for size and placement.

- Light signs make setup and care safer.

- Reflective sheeting helps signs be seen and follow rules.

- Good installation keeps signs safe and helps road safety.

- Cities pick sign materials by looking at cost, weight, and how long they last.

Tip: Always check your aluminum sign’s weight before you install it. This helps you plan for safe handling and makes sure your sign follows all safety and rule standards.

Aluminium Traffic Signs Standards

Industry Specifications

You should know the main rules before picking aluminium traffic signs. These rules help you choose signs that are safe and last a long time. Here are some key things to remember:

- Many countries have laws like BS EN 12899-1 for permanent signs and BS 8442 for temporary ones. These laws tell you what aluminium traffic signs must have.

- In the United States, the MUTCD gives rules for sign materials and how easy they are to see. It says you should use reflective materials so signs are bright at night.

- Aluminium sheets for traffic signs need to be at least 2mm thick to meet ASTM rules. This keeps your signs strong and helps them last.

- Reflective sheeting comes in many types. You pick the type based on how bright you want your sign.

- Most companies give a 7-year warranty for highway and expressway signs. This means you can trust the signs to last a long time.

- Common aluminium alloys for traffic signs are 1100, 3003, 5052, 5454, and 5754. Each alloy works best in different places. For example, 5052 H38 is strong and does not bend easily, so it is good for windy areas. In Europe, 5454 and 5754 are used near the coast because they do not rust.

- Aluminium sheet thickness can be from 0.48mm to 3.175mm. Some rules say you need at least 2mm for certain signs.

- Aluminium traffic signs weigh about 2.70 kg per square meter. They are lighter than other metals, so they are easier to put up and move.

- Aluminium signs do not rust and can handle bad weather. You can cut or punch them to fit your needs.

Tip: Always check the alloy and thickness before you buy aluminium traffic signs. This helps you pick the right sign for your weather and traffic.

Regulatory Requirements

You must follow strict rules when putting up aluminium traffic signs. In the USA, rules focus on crash safety and how signs work with cars. For example, there are limits on the size and thickness of sign supports, like fiberglass ribs, to make sure they are safe in a crash. Signs on trailers must be tested so they do not become dangerous in a crash. Some states do not allow certain signs if they fail safety tests. Aluminium and plywood sign panels have been tested for crash safety. Sometimes, these panels can come off and cause problems. Plastic and composite panels, like aluminium/plastic sandwich types, are also being tested for safety. These rules help keep drivers and workers safe by making sure aluminium traffic signs, guide signs, and warning signs are strong and safe in crashes.

Applications in Roadwork and Custom Aluminum Signs

Permanent vs Temporary Signage

Aluminum is used for both permanent and temporary traffic signs. Each type has its own good points. Permanent aluminum signs stay in one spot for many years. These signs use strong materials and tough coatings. You need experts to install them with a solid base. They stand up to bad weather and last a long time. Temporary aluminum signs are lighter and easy to move. You can set them up fast for roadwork or events. These signs do not need a base. They are great for short-term traffic control and can be used again for other jobs.

Here is a table that shows the main differences:

| Aspect | Temporary Aluminum Signs | Permanent Aluminum Signs |

|---|---|---|

| Installation | Light, easy to carry, quick to set up | Strong, needs experts to install |

| Durability | Not as tough, needs more care | Handles weather, lasts many years |

| Compliance | Good for short-term rules | Meets strict rules for long-term use |

| Flexibility | Simple to move or change | Stays in one place |

| Cost | Costs less at first, but needs more care | Costs more at first, but needs less care |

Pick the sign that fits your project best. Aluminum works for both types because it does not rust and can be recycled.

Custom Aluminum Signs

Custom aluminum signs let you choose what you want for your road projects. You can pick the size, shape, color, and reflective coating. These signs last from 7 to 12 years with little care. You can add logos or special pictures to make them easy to see and show your brand. Custom aluminum signs work in many places like highways, building sites, schools, parking lots, and work zones. You can put these signs up easily with holes already drilled and different ways to mount them.

- Custom aluminum signs do not rust and can handle rain, sun, and saltwater.

- You can use special printing for clear pictures and bright colors.

- Reflective coatings help drivers see the signs day and night.

- Custom aluminum signs are light but strong, so they do not bend or break.

- You can use them for many traffic and road jobs, like warning signs or event signs.

When you look at aluminum, steel, and plastic, you see big differences. Aluminum weighs about one-third as much as steel. This makes aluminum signs much easier to carry and put up. Steel signs are stronger but much heavier and harder to use. Aluminum gives you better strength for its weight, which helps for signs above roads or ones that move. Aluminum does not rust as easily as steel and costs less to make. For most traffic signs, aluminum is the best choice because it lasts long, is light, and easy to use.

Note: Aluminum traffic signs are used for rules, warnings, and guides on roads and highways. You can count on aluminum for both permanent and temporary sign needs.

Choosing the Right Aluminum

Project Assessment

Before you pick aluminum for your sign, think about a few things. First, look at where you will put the sign. Will it be in strong sun, heavy rain, snow, or salty air? These things change how long your sign will last. You also need to check if your sign must follow rules like MUTCD or ASTM. These rules tell you which aluminum alloys and coatings you should use.

- Pick the right aluminum sheet type. Use standard for simple jobs, reflective for signs that need to be seen easily, or composite for big, windy places.

- Think about your sign’s size and shape. Bigger signs need thicker aluminum to stay strong.

- Make sure people can see your sign during the day and at night.

- See if you need extra things like UV protection or anti-graffiti coatings.

- Ask about the company’s experience making and installing signs. Companies with more experience usually do a better job.

Tip: Always ask for a sample or a test sign before you order a lot. This helps you check the look and quality of the aluminum.

Cost and Durability

Aluminum sheet prices change with thickness, alloy, and coatings. Thicker sheets and special alloys cost more, but they last longer and need less fixing. Reflective aluminum sheets cost more, but they help drivers see signs at night or in bad weather.

| Aluminum Sheet Type | Thickness Range | Typical Price Range (USD) | Outdoor Lifespan | Notes |

|---|---|---|---|---|

| Budget-Friendly Alloys | 0.48 mm to 3.175 mm | $7 to $40 per sheet | Up to 10 years | Good for mild weather and short-term use |

| Premium Reflective Aluminum | 0.040 to 0.080 inches | $20 to $60+ per sheet | 12 to 18+ years | Best for highways, high visibility, and tough weather |

| Composite Aluminum | 5 to 10 years | Moderate | 5 to 10 years | Strong and light, good for large or windy locations |

If you buy a lot of sheets, the price for each one goes down. If you choose high-quality aluminum, you pay more at first, but you save money later because you do not need to replace signs as often. Premium reflective aluminum is best for busy roads because it lasts longer and keeps people safe.

Note: Picking the right aluminum helps your signs last longer, look good, and keep everyone safe.

You need to understand how aluminum sheet metal weight affects every sign you install. Aluminum weighs about one-third as much as steel, so you can move and set up each sign with less effort. Aluminum signs resist rust, which means you spend less time on maintenance. You should always check the thickness and size of each aluminum sign before you order. Aluminum signs work well for both permanent and temporary projects. You can use aluminum for signs in wet, coastal, or city areas. Aluminum signs last longer and cost less to maintain. You should keep a quick reference chart for aluminum sign weights.

- Aluminum signs are lighter than steel signs.

- Aluminum signs resist rust and last longer.

- Aluminum signs cost more at first but save money over time.

- Aluminum signs work best for long-term, low-maintenance projects.

- Aluminum signs are easy to install and move.

For best results, always check your aluminum sign chart before you start a project. You should talk to your supplier to make sure your aluminum sign meets all rules. You can use extra tools like alloy guides to help you pick the right aluminum sign for your needs.

- Pick the right aluminum thickness for your sign.

- Use your chart to match the aluminum sign gauge.

- Double-check your aluminum sign measurements.

- Think about where you will use the aluminum sign.

- Ask your supplier about the aluminum sign specs.

- Use extra guides for your aluminum sign choices.

- Keep contact info for aluminum sign questions.

FAQ

How do you calculate the weight of an aluminum sheet for a road sign?

You multiply the length, width, and thickness of the sheet to get the volume. Then, multiply the volume by the density of aluminum. Most aluminum used for signs has a density of about 0.0975 lb/in³.

What thickness of aluminum works best for outdoor traffic signs?

Most outdoor traffic signs use 0.080-inch or 0.125-inch thick aluminum. Thicker sheets give more strength and last longer in harsh weather. Always check local rules before you choose.

Can you use the same aluminum sheet for both permanent and temporary signs?

You can use aluminum for both types. Permanent signs need thicker, stronger sheets. Temporary signs work well with lighter, thinner sheets. Choose the right thickness for your project.

Why does the weight of the sign matter for installation?

Heavier signs need stronger supports and may require more people or equipment to install. Lighter signs are easier to handle and set up. Knowing the weight helps you plan for safe and easy installation.