The traffic signs regulations and general directions make rules for road signs in the UK. Regulatory signs and safety warning signs help keep people safe and make sure everyone follows the law. Every sign must stay easy to see, clear, and in good condition. The traffic signs manual gives important advice for using signs and looking after them.

At OPTRAFFIC, we ensure that our traffic signs adhere to the highest standards set by the Traffic Signs Regulations and General Directions. Our signs are designed to be durable, visible, and compliant with UK regulations. To learn more about the impact of these regulations on the traffic sign industry, check out our blog, Understanding TSRGD 2016 and What It Means for Traffic Signs for Sale.

TSRGD Overview

Legal Framework

The Traffic Signs Regulations and General Directions (TSRGD) is a law in the United Kingdom. It tells people how to design, put up, and use official road signs in Great Britain and the Isle of Man. The government made the TSRGD using the Road Traffic Regulation Act 1984 and the Road Traffic Act 1988. The newest version started on 22 April 2016. This law is very important for road safety in the UK. It says which traffic signs can be used and how they should look and work.

The Department for Transport (DfT) and local councils both help make sure people follow the traffic signs rules. The DfT gives advice for the whole country and writes the traffic signs manual. This helps everyone use the same rules. Local councils look after, check, and make sure traffic signs are followed on their roads. Since 2022, councils in England and Wales can now stop people breaking rules about TSRGD signs, like banned turns or bus lane misuse. This change lets local councils do more to keep roads safe and make sure people follow the rules.

| Government Body | Role in TSRGD Enforcement and Compliance |

|---|---|

| Department for Transport (DfT) | Gives advice and rules for the whole country, including the traffic signs manual, so everyone follows the same standards. |

| Local Authorities (Local Councils) | Look after, check, and make sure traffic signs are followed on local roads; can now stop people breaking rules about TSRGD signs because of new Road Traffic Act changes. |

Key Parts

The traffic signs rules have some very important sections. Part 3 is about regulatory signs, like speed limits, no entry, and turn bans. These signs tell drivers what they must do or not do. Part 4 is about warning signs in the TSRGD. These signs warn drivers about dangers like sharp bends, people crossing, or changes in the road. Both parts help keep roads safe and traffic moving well.

The traffic signs manual gives helpful advice for using the traffic signs rules. It helps road workers, builders, and engineers pick the right signs, materials, and places to put them. If people follow the manual, all signs will meet the law and work well in every situation.

Regulatory Signs Compliance

Key Requirements

Regulatory signs are very important for road safety. TSRGD Part 3 gives the main rules for these signs. The law uses ‘must’ and ‘shall’ to show what you have to do. Every regulatory sign has to follow these rules to be legal and work well.

- All regulatory signs must follow TSRGD rules and help enforce traffic laws.

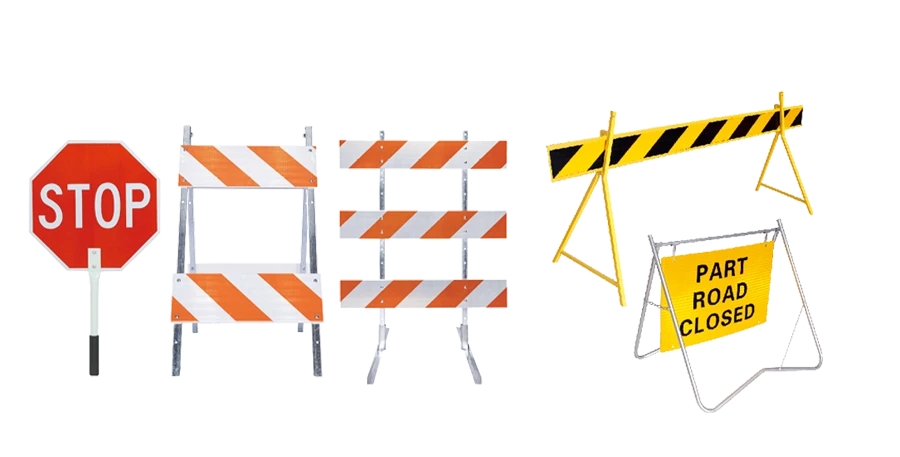

- There are two main types of signs. Some signs tell you what to do, and they are blue and round. Other signs tell you what not to do, and they are round with a red edge. STOP signs look like an octagon. GIVE WAY signs are shaped like a triangle.

- Extra plates can only go with some signs. They must use the layouts from the Department for Transport.

- The size of a sign depends on how fast cars go. Signs on fast roads need to be bigger so drivers can read them.

- Signs must be easy to see from far away. Nothing should block them. The distance depends on how fast cars go.

- Signs that start a rule or ban must be on both sides of the road. This is unless the road is narrow or the rule is only for one side.

- Signs must always be clear and easy to see. This is true even for road works or temporary signs.

Note: Using regulatory signs the right way helps drivers know what to do. This stops confusion and accidents.

Design and Placement

Regulatory signs have strict rules for how they look and where they go. Each sign must be put at the place where the rule starts. This helps drivers know when and where the rule begins.

- Signs must be big enough for drivers to read at their speed.

- All regulatory signs must shine in car lights or be lit up. This helps people see them at night and during the day.

- Most regulatory signs are rectangles. STOP and GIVE WAY signs have special shapes.

- Parking signs with arrows should point between 30 and 45 degrees to the road. This makes them easier to see.

- At junctions, engineers must think about how many cars use the road, how fast they go, how far drivers can see, and if there have been crashes.

- If a sign is put at a right angle to the kerb, there must be two signs back-to-back with extra plates where zones change.

| Sign Type | Shape | Colour Scheme | Placement Rule |

|---|---|---|---|

| Speed Limit | Circular | Red border, white | Both sides at start of zone, clear visibility |

| No Entry | Circular | Red border, white | At entry point, both sides if possible |

| STOP | Octagonal | Red with white text | At junction, clear line of sight |

| GIVE WAY | Triangular | Red border, white | At junction, visible from approach |

Common Pitfalls

Many groups have problems when they do not follow the rules for regulatory signs. Some common mistakes are:

- Using signs that are too small for fast roads. This makes them hard to read.

- Putting signs where trees, cars, or buildings block them.

- Using the wrong shape or colour, which can confuse drivers.

- Not putting signs on both sides of the road when needed.

- Using old or broken signs that do not shine at night.

- Adding too much writing or unclear words, which makes the sign less helpful.

Not following the rules for regulatory signs can cause big problems:

- Road councils may give fines for signs that are the wrong size or in the wrong place.

- Accidents from unclear or missing signs can lead to court cases.

- Projects might lose their permissions or be delayed after checks fail.

- Insurance might not pay if a bad sign caused a crash.

- Companies could lose their good name and future jobs.

- People may stop trusting the signs if they are confusing or not legal.

Tip: Checking and fixing signs often helps avoid these problems. It keeps all regulatory signs following the law.

Safety Warning Signs

Design Standards

Safety warning signs help drivers know about dangers ahead. TSRGD Part 4 gives strict rules for how these signs look. Each sign must have a shape and symbol that people know. Most safety warning signs are triangles with a red border, white inside, and a black symbol. This makes it easy for drivers to see danger and react fast.

Sometimes, warning signs need to be even easier to see. In these cases, signs can have a yellow background. Yellow backgrounds are used in places like roadworks or accident spots. All safety warning signs must use reflective materials. These help drivers see the signs at night or when the weather is bad. The British Standard BS EN 12899-1 says how bright and strong the signs must be. Signs also need to last a long time and not fade or break in bad weather.

Note: Good reflective and strong materials help safety warning signs stay bright and last longer.

Placement Rules

Putting safety warning signs in the right place is very important. TSRGD Part 4 gives clear rules for where to put each sign. Signs must be far enough from the danger so drivers have time to slow down or turn. The distance depends on how fast cars go and what the danger is.

In places like roadworks or sharp bends, signs must be even easier to see. Signs must use special materials that shine in car lights and do not get ruined by rain. Drivers must be able to see the sign even if it is dark or raining. Workers sometimes use signs that light up, reflective tape, or glowing markers to help. Signs should never be hidden by trees, parked cars, or anything else.

- Extra warning signs and traffic control are needed in work zones.

- Workers must wear bright clothes to stay safe.

- Signs must be put at the best distance so drivers can react.

- Flashing lights or electronic boards may be used in dangerous places.

A good Traffic Control Plan helps make sure all safety warning signs are in the right spot and follow the law.

Compliance Issues

Following TSRGD Part 4 is very important for road safety. Bad or wrongly placed safety warning signs can cause crashes and legal trouble. Signs that are not bright or strong enough can be hard to see at night or in bad weather. This makes crashes more likely, especially in risky or temporary places.

Checking safety warning signs often helps find ones that are broken or faded. Councils and workers must change any sign that does not meet the rules. Using the same colours, symbols, and words stops drivers from getting confused. Checking and fixing signs often keeps all safety warning signs working well and following the law.

| Compliance Issue | Impact on Safety and Legal Status |

|---|---|

| Poor reflectivity | Harder to see at night |

| Wrong placement | Drivers miss danger, more crashes |

| Non-standard symbols or colours | Drivers get confused, breaks the law |

| Damaged or faded signs | Signs do not work, may get a penalty |

Tip: Always use the traffic signs manual and check safety warning signs often to follow the rules and keep people safe.

Temporary Traffic Signs

Requirements

Temporary traffic signs are very important for safety during street works. The traffic signs manual and chapter 8 have strict rules for these signs. All temporary traffic signs must use reflective materials. This helps drivers see them at night or when it is foggy or raining. On dual carriageways, workers must put signs on both sides of the road. This makes sure every driver can see the signs. Temporary traffic management must follow the same rules as permanent signs. But workers must be extra careful so signs are easy to see and last longer.

Temporary traffic signs must be clear and easy to read. They should be put at the right distance before the work zone. Signs need to warn drivers early about changes like lane closures or new speed limits. Signs must not block footpaths or cycle lanes. Extra signs are often needed to help drivers go around dangers. Chapter 8 compliant barriers keep workers safe and guide cars away from danger. Workers must check signs often to keep them in good shape and make sure they follow the rules.

Best Practice

The traffic signs manual gives good advice for using temporary traffic signs. Workers should always follow chapter 8 to keep everyone safe. Here are some best ways to manage temporary traffic:

- Put trailer signals at least 150 feet before the work zone. Do the same on the other side.

- Use simple and clear words on all temporary traffic signs.

- Make sure signs are high enough and use bright, reflective materials. This helps people see them day and night.

- Check batteries, clean the lights, and look at the wires often.

- Tell emergency services and the public before starting street works.

- Use flaggers or extra workers to help guide traffic if needed.

- Follow all safety rules for street works and change signs if things change.

Good planning and checking signs often keeps temporary traffic signs working well. The right design and using chapter 8 barriers helps protect workers and drivers.

Materials and Dimensions

Material Choices

Picking the right material for traffic signs is very important. It helps signs last longer and follow the rules. In the UK, most signs use aluminium, steel, or polycarbonate. Each one has good points and bad points.

| Material | Strengths | Weaknesses |

|---|---|---|

| Aluminium | Lightweight, corrosion-resistant, cost-effective | Less durable than steel |

| Steel | Strong, stable, suitable for large signs | Heavier, prone to corrosion |

| Polycarbonate | Impact-resistant, flexible, weather-resistant | Less durable than metal |

Aluminium is popular because it is light and does not rust. This makes it a cheap choice for many road signs. Steel is stronger and steadier, so it is used for big or heavy signs. But steel can rust, so it needs a special cover. Polycarbonate is good for temporary signs. It bends easily and does not get ruined by rain, but it does not last as long as metal.

All sign materials get a shiny layer to meet UK rules like TSRGD and BS EN 12899-1. Special covers, like ones that stop sun damage or graffiti, help signs stay bright and last longer. New ways of making signs, like CNC cutting and special printing, make sure every sign is made well and fits its job.

Standard Sizes

TSRGD gives clear rules for how big signs must be. The right size helps drivers see and understand signs fast. This makes roads safer. Regulatory signs, like speed limits or no entry, come in set sizes: 450 mm, 600 mm, 750 mm, and 900 mm. Small signs are for slow or city roads. Big signs are for fast roads and motorways.

Warning signs also have strict size rules. The table below shows the smallest sizes for different roads:

| Road Environment | Speed Limit Range | Recommended Minimum Warning Sign Size |

|---|---|---|

| Urban Streets | 20–30 mph | 600 mm |

| Rural B-Roads | 40–50 mph | 750 mm |

| Rural Highways | 60 mph and above | 900 mm |

Motorways sometimes need warning signs up to 1200 mm or even 1800 mm in special places. Bigger signs on fast roads give drivers more time to see and react. This helps stop confusion and lowers the chance of crashes.

Environmental Considerations

The weather is important when picking sign materials. Engineers pick materials and covers that can handle rain, sun, and UV rays. Special finishes stop signs from fading or getting damaged. Local weather, like lots of rain or strong sun, helps decide which material to use. Tough, weather-proof signs do not need to be replaced as often. This helps the environment by making less waste. Some signs are made to deal with special weather problems. This helps keep roads safe for a long time.

Reflective Materials

Reflectivity Standards

Reflective materials are very important for road safety. They help drivers see safety warning signs at night and in bad weather. The UK uses British Standard BS EN 12899-1 for these materials. This standard says how bright and strong the materials must be. Signs that follow this rule stay easy to see for many years. This helps stop accidents from happening.

There are different types of reflective sheeting used on UK traffic signs:

| Reflective Sheeting Type | Performance Characteristics | Typical Applications | Durability / Lifespan |

|---|---|---|---|

| Engineer Grade (Glass Bead) | Basic retroreflectivity, moderate light return (ASTM D4956 Type I) | Non-critical signs, low traffic areas | 5-7 years |

| High Intensity Prismatic (HIP) | Uses prismatic technology, ~16% light return, UV and weather resistant | Traffic signs, construction zones | Up to 10 years |

| Diamond Grade (Microprismatic) | Advanced microprismatic cube-corner optics, up to 60% light return, very bright and durable | High visibility needs, busy roads, highways | Superior durability, 7+ years warranty |

Signs with better reflective materials, like diamond grade, are much easier to see. These signs are very important on busy roads and in dangerous places.

Note: The right reflective materials help drivers see signs clearly, even when it is dark or raining.

Technological Advances

New reflective materials have made UK roads safer. Microprismatic and diamond-grade films use special prism shapes. These films send more light back to drivers. This makes signs easier to see from far away and from the side. They work well at night and in bad weather.

Now, makers use strong acrylic and PMMA with UV protection. These films can last up to 10 years and stay bright. Some products, like 3M’s Diamond Grade™ DG³ Series, use new technology to be brighter and stronger. These films also let councils and workers print custom signs quickly.

Reflective materials have helped lower accidents by making signs and road lines easier to see. Flexible reflective road studs and markers help guide drivers, especially on highways and near roadworks. These new materials help everyone travel more safely and with more confidence.

Ensuring Compliance

Compliance Checklist

A simple checklist helps councils and workers follow TSRGD Part 3 and Part 4. Checking safety signs often makes sure they meet the law and keep people safe at road works. Use this easy checklist:

- Look at all regulatory and warning signs for the right size, shape, and colour.

- Make sure signs use approved reflective materials so drivers can see them in any weather.

- Check that temporary traffic signs follow the same rules as permanent ones.

- Put signs at the right height and angle so everyone can see them.

- Make sure all symbols and words match the traffic signs manual.

- Take away or swap any broken, faded, or wrong signs.

- Check that temporary signs are on both sides of dual carriageways.

- Look at where temporary signs are before, during, and after road works.

- Train staff often on the latest traffic sign rules.

- Plan regular checks for both permanent and temporary traffic signs.

Tip: Using a good checklist helps stop mistakes and keeps roads safer.

Maintenance

Looking after signs keeps them working well and following the rules. Teams should clean signs with gentle cleaners to get rid of dirt. Cut back plants so they do not hide any sign. Special fasteners help stop people from stealing signs. Workers must check that sign posts are straight and steady. Crashworthy supports help protect drivers if a car hits a sign. Move safety signs away from places where cars often hit them. Watch for soil washing away or trees growing near sign posts to keep signs steady. Temporary signs need extra care, especially for long jobs or when roads change. Check these signs often to make sure they are easy to see and not broken.

Common Mistakes

Many councils and workers make the same mistakes with traffic signs. These mistakes can make roads unsafe and break the law. Some common mistakes are:

- Picking the wrong sign size, which makes them hard to see.

- Putting signs at the wrong height or angle.

- Not using reflective materials, so signs are hard to see at night.

- Forgetting to check and replace broken or faded signs.

- Using symbols or colours that are not standard, which confuses drivers.

- Not making good plans for temporary traffic signs.

- Not giving staff enough training on the latest rules.

- Missing regular checks of temporary traffic signs.

- Not working well with local councils, which causes problems with local rules.

- Not using the right advice for temporary signs, so setups are not the same.

Note: Stopping these mistakes helps both permanent and temporary traffic signs keep roads safe and legal.

To follow the Traffic Signs Regulations and General Directions, each authority should do these main things:

- Only use signs that are allowed or approved.

- Put warning signs in the right places and do not use too many.

- Make sure signs are the right size and shape.

- Signs must have lights or shine in car headlights.

- Pick materials that last long and do not rust.

- Put signs at the right height and angle so people can see them.

- Check and fix signs often to keep them in good shape.

- Change any sign that is broken or faded as soon as possible.

Looking at the Traffic Signs Manual often helps everyone follow the law and avoid problems. If a project is tricky, getting help from experts makes sure all signs are safe and follow the rules. You can share your stories or ask questions below.

FAQ

What does TSRGD stand for?

TSRGD means Traffic Signs Regulations and General Directions. This law tells people how to make, put up, and look after road signs in the United Kingdom.

Why must road signs use reflective materials?

Reflective materials help drivers see signs at night or in bad weather. These materials make signs easier to spot from far away, which is very important on busy or fast roads.

How often should councils check road signs?

Councils need to check road signs often. Most experts say signs should be checked at least once every year. If a road is very busy or the weather is rough, checks should happen more often.

What happens if a sign does not meet TSRGD standards?

If a sign does not follow TSRGD rules, there could be fines or legal trouble. It can also make accidents more likely. Councils must fix or change any sign that does not meet the rules as soon as they can.

Can temporary signs use different materials from permanent signs?

Temporary signs are usually made from lighter materials like polycarbonate. But they still have to follow the same rules for being bright and easy to see, just like the TSRGD and the traffic signs manual say.