Imagine a busy intersection at night when it is raining. Drivers need reflective sheeting to see traffic signs fast and stay safe. Reflective highway signs use special materials. These materials send light from headlights back to drivers, even in bad weather. Cities that used better reflective sheeting saw signs become over 50% easier to see. Accident rates went down by 30%. In Stockholm, using diamond grade reflective sheeting lowered nighttime crashes by 20%. The right class of reflective sheeting can make roads safer for city and country drivers.

Picking the best reflective sheeting helps keep everyone on the road safer and lowers accidents.

Key Takeaways

- Reflective sheeting helps keep roads safe. It makes traffic signs easy to see at night and in bad weather. This helps drivers notice signs fast and react quickly.

- Picking the right class of reflective sheeting is important. Diamond Grade is good for highways. It helps lower accident rates and makes signs easier to see.

- There are different materials and technologies for reflective sheeting. Microprismatic sheeting is one example. These give different levels of brightness and last longer. They work well for certain road conditions.

- Signs need regular care to stay bright and clear. Following safety rules keeps reflective signs working well. This helps make roads safer for everyone.

- New ways to make reflective sheeting are better for the planet. They use eco-friendly materials. This helps the environment and keeps signs safe.

What Is Reflective Sheeting for Traffic Signs?

Definition and Function

Reflective sheeting is very important for road safety. This material covers traffic signs. It sends light from car headlights back to drivers. This helps drivers see signs at night and in bad weather. Reflective sheeting makes signs easier to see. Drivers can react faster to important information. The material also keeps signs from fading or getting damaged outside. Traffic engineers use reflective sheeting to meet safety rules. It also helps lower the cost of fixing or replacing signs.

Reflective sheeting sends back almost 60% of the light to drivers. This helps all kinds of vehicles see signs better.

| Function | Description |

|---|---|

| Enhanced Nighttime Visibility | Reflective sheeting helps people see road signs at night. This is very important for safety. |

| Durability in Outdoor Environments | It protects signs from fading and weather damage. This makes signs last longer. |

| Compliance With International Standards | It makes sure traffic signs are bright enough to follow safety rules. |

| Reduced Maintenance Costs | Strong materials mean signs do not need to be replaced as often. This saves money on repairs. |

Materials and Technology

Many materials are used to make reflective sheeting. The base film gives the sign strength and shape. Some common materials are acrylic, polycarbonate, and PVC. The retroreflective layer sends light back to drivers. There are two main types: glass bead and microprismatic. Glass bead technology uses tiny beads to reflect light. It gives medium brightness. Microprismatic technology uses small prisms. It makes signs much brighter and last longer.

| Material Type | Description |

|---|---|

| Base Film (Substrate Layer) | Acrylic, polycarbonate, and PVC make signs clear, strong, and flexible. |

| Retroreflective Layer | Glass bead and microprismatic types give different levels of brightness. |

- Microprismatic materials reflect light better. They can be up to 250% brighter than other types.

- Microprismatic technology works well in rain or fog. It also sends light back from more angles.

Reflectivity Classes (RA1, RA2, RA3)

Reflective sheeting comes in different classes. These classes are based on how bright the material is. Traffic engineers pick the right class for each sign. RA1 is the most basic. It is good for slow streets or neighborhoods. RA2 is brighter and used on busy roads. RA3 is the brightest. It is best for highways and dangerous places.

| Reflectivity Class | Reflectivity Value (cd/lx/m²) |

|---|---|

| RA1 | ≥60 |

| RA2 | ≥180 |

| RA3 | ≥300 |

Traffic workers use these classes to choose the best sheeting. Higher classes help drivers see signs from farther away and in tough conditions.

Classes and Types of Reflective Sheeting

Reflective sheeting is very important for road safety. There are different types for different places and uses. The Federal Highway Administration and MUTCD make rules for how bright and strong the sheeting must be. The next parts talk about the main classes, what they do, and where they work best.

Engineer Grade

Engineer grade reflective sheeting is a common type. It uses glass bead technology to bounce light back. This kind works well for signs on slow streets or places with little traffic. Cities use engineer grade for street name signs, parking signs, and work zone signs.

| Characteristic/Application | Description |

|---|---|

| Durability | Lasts about five years |

| Adhesive Properties | Sticks with pressure |

| Weather Resistance | Stays strong in bad weather |

| Typical Applications | Used for traffic signs, stickers, and decals |

| Visibility Range | Seen from 400 to 600 feet away |

- This sheeting is tough and has tiny beads inside.

- It works for signs inside and outside.

- It sticks well and keeps its shape.

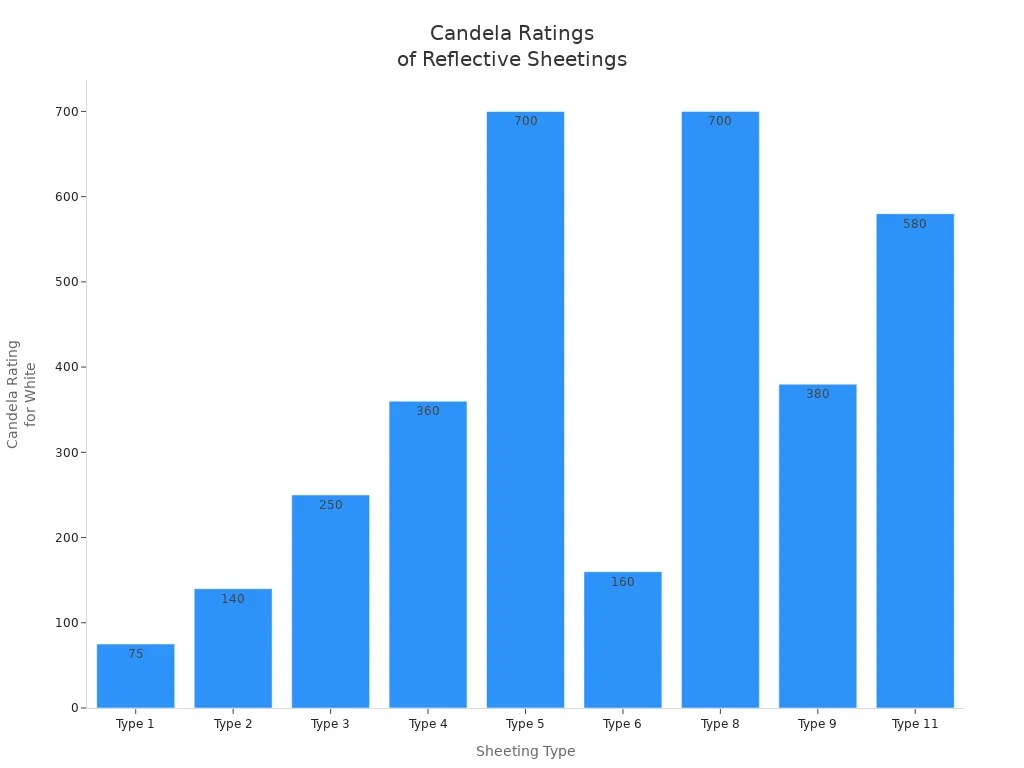

Engineer grade meets DOT Type 1 rules. It has a candela rating of 75 for white.

High Intensity Prismatic

High intensity prismatic reflective sheeting uses microprism technology. This makes signs brighter and last longer. It is good for busy roads, construction zones, and places where safety is very important.

- It is very bright and easy to see.

- It can last up to 10 years.

- It is better for the environment than engineer grade.

- It is better than ASTM D4956 Types 3 and 4.

- It is great for work zones, cones, and barricades.

This sheeting meets DOT Type 4 rules. It has a candela rating of 360 for white.

High intensity prismatic helps drivers see signs in rain, fog, and at night. It keeps people safer in busy places.

Diamond Grade

Diamond grade reflective sheeting is the brightest kind. It uses special microprisms to send more light back to drivers. This sheeting is needed for highways, big intersections, and dangerous spots.

| Sheeting Type | Initial Reflectivity (cd/lx/m²) | Expected Service Life |

|---|---|---|

| High-Intensity Prismatic | 50–75 | 10–12 years |

| Diamond Grade | 100–150 | 12–18+ years |

- It helps people see signs day and night.

- It is made for new car headlights.

- It can last 18 years or more.

Diamond grade meets DOT Type 8 and Type 11 rules. It has a candela rating up to 700 for white.

Diamond grade is best for important traffic signs. It lets drivers see signs from far away.

Commercial Grade

Commercial grade reflective sheeting is cheaper and not as bright. It is good for signs that are not on highways or for short-term use. This type does not meet DOT or ASTM rules for highways.

| Features | Applications |

|---|---|

| Cheaper with basic reflectivity | Used for non-official and short-term signs |

- It is used for signs that do not need to follow strict rules.

- It is good for marking places and emergency vehicles.

Commercial grade is not for real traffic signs. It works best in private areas or for short jobs.

Specialized Types (Fluorescent, Retroreflective Tapes)

Some reflective sheeting is special, like fluorescent films and retroreflective tapes. These help people see better in special places, like construction zones, school crossings, and emergencies.

| Type of Reflective Sheeting | Unique Benefits |

|---|---|

| Retroreflective (Glass Beads) | Sends light back to where it came from, good for simple uses. |

| Retroreflective (Microprisms) | Very bright from far away, good for safety. |

| Engineering Grade | Works with digital printing, lasts up to 7 years, for less important signs. |

| High-Intensity Prismatic Grade | Brighter than normal, lasts up to 10 years, good for safety. |

| Prismatic (Diamond) Grade | Very bright day and night, lasts up to 10 years, made for new headlights. |

- Fluorescent sheeting is easy to see during the day.

- Retroreflective tapes are used on barriers, cones, and cars.

- These materials help drivers spot dangers fast.

The MUTCD and DOT say signs must stay bright enough. Each class of reflective sheeting helps with different safety needs and costs.

Applications of Reflective Sheeting in Highway Signs

Reflective highway signs help keep roads safe. The right reflective sheeting makes signs easier to see. This helps drivers make quick choices. Each class of reflective sheeting works best for certain uses. The next parts show how engineers pick materials for different signs. Choosing the right sheeting is important for safety.

Regulatory Signs

Regulatory signs tell drivers what to do. Some examples are Stop, Yield, and speed limit signs. These signs must be easy to see all the time. This is extra important when it is dark or foggy. Diamond Grade reflective sheeting is used for these signs. It reflects almost 60% of light. Drivers can see it from up to 1500 feet away. It works well for new cars and older drivers. Cities and states use Diamond Grade for important traffic signs. It gives the best visibility. Most highways and busy streets use Diamond Grade for these signs.

Diamond Grade reflective sheeting on Stop signs helps drivers see better. This helps them react faster and lowers the chance of accidents.

Warning Signs

Warning signs tell drivers about dangers ahead. These signs include curve warnings, crosswalks, and slippery road signs. High Intensity Prismatic and Diamond Grade are used for these signs. In cities with lots of people, reflective panels at crosswalks cut accidents by 40%. Highways with reflective warning signs had fewer crashes at night. Studies show reflective delineators lower accidents by 67%. They also lower deaths by 62% and injuries by 78%. Using good reflective sheeting for warning signs is very important.

- High Intensity Prismatic is good for most warning signs.

- Diamond Grade is best for fast roads or risky places.

Guide and Directional Signs

Guide and directional signs help drivers find exits and streets. These signs must be clear, especially at night or on highways. The type of reflective sheeting depends on the road and traffic speed.

- Diamond Grade is the brightest and can be seen from far away.

- High Intensity Prismatic works well for city streets and medium traffic.

- Engineer Grade is used for slow roads with little traffic.

Using brighter reflective sheeting helps guide signs stay visible in the dark. This is important on highways where drivers need to read signs quickly. Diamond Grade lasts longer. It saves money for big roads and highway markers.

High-Risk and Construction Zones

High-risk and construction zones need bright signs to keep workers and drivers safe. The type of reflective sheeting matters a lot in these places. The table below shows how each class works:

| Reflective Sheeting Class | Impact on Visibility and Safety |

|---|---|

| Class 1 (High-Intensity) | Good for busy streets; helps drivers see better in traffic |

| Class 3 (Diamond Grade) | Best for fast roads; gives the most brightness and visibility |

| Class 2 (Engineer Grade) | Not as bright; not good for risky or dark areas |

Using the wrong sheeting can cause accidents, especially near schools or intersections. Good reflective signs in construction zones help drivers see changes and react quickly. The type of sheeting should match the traffic and area.

Tip: Always use Diamond Grade or High Intensity Prismatic for construction and risky areas. This keeps everyone safer.

Reflective sheeting is used in many ways on highway signs. Engineers pick the right class based on speed, road type, and safety needs. These uses show how reflective materials help drivers and make roads safer every day.

Choosing Reflective Sheeting for Traffic Signs

Traffic Volume and Speed

Picking reflective sheeting starts with knowing the road. Engineers check if it is a highway, parking lot, or walkway. They look at how fast cars go and how many use the road. Fast roads need signs that are easy to see from far away. Busy places need signs that stay bright and clear. The way cars approach and how much light hits the sign matter too. Premium sheeting helps drivers see better and react faster in busy or fast areas.

- Highways need brighter materials than parking lots.

- Fast traffic means drivers must see signs sooner.

- Signs must be seen from far away on fast roads.

Environmental and Weather Factors

Weather and the environment change how well signs can be seen. Some materials work better in rain, fog, or snow. The table below shows how each type works in different weather:

| Reflective Sheeting Type | Visibility Distance | Recommended Material | Environmental Considerations |

|---|---|---|---|

| Highway Grade Reflective (Type VIII) | Up to 1,500 feet | Aluminum, HDPE | Stays strong in bad weather |

| Engineer Grade Reflective | Up to 500 feet | Aluminum | Good for mild weather |

| High Intensity Prismatic | Higher reflectivity | Aluminum | Works well in low light |

| Diamond Grade | Up to 1,500 feet | Aluminum | Best for fast highways |

Diamond Grade and High Intensity Prismatic work best in tough weather. Engineer Grade is fine for places with less traffic and mild weather.

Compliance and Standards

Traffic signs must follow safety rules. The MUTCD sets rules for how bright and what color signs should be. Laws say which sheeting types must be used for each sign. The table below shows the lowest brightness for common signs:

| Sign Type | Minimum Reflectivity (cd/lx/m²) |

|---|---|

| Overhead guide signs | White ≥ 250, Green ≥ 25 |

| Warning signs | Sheeting ≥ 50 |

| Stop signs | White ≥ 35, Red ≥ 7 |

Using the right reflective sheeting keeps roads safe and meets the rules.

Cost and Durability

Cities and agencies must think about cost and how long signs last. Engineer Grade costs less but needs to be replaced more often. Diamond Grade costs more but lasts longer and needs less fixing. The table below compares price and how long each type lasts:

| Sheeting Type | Upfront Cost (24″×24″ sign) | Expected Lifespan (years) | Annualized Cost |

|---|---|---|---|

| Engineer Grade | $80 | 7 | $11.43 |

| Diamond Grade | $140 | 15 | $9.33 |

Choosing reflective sheeting means thinking about the road, traffic, weather, and money. Good materials save money over time and keep signs easy to see.

Tip: Pick the right grade for each road. Use better materials for fast or risky places to help drivers see signs and stay safe.

Future Trends in Reflective Highway Signs

Advancements in Reflective Technology

Highway signs are getting better every year. New materials and smart features help keep roads safer. Makers now use microprismatic layers to make signs brighter. These layers also help signs last longer, even in strong sunlight. They stop signs from fading and keep them easy to see for many years.

Nanostructured coatings are a big new idea. These coatings work well with LED lights. This makes signs easier to see in any weather. Some smart reflective materials can change how bright they are. For example, a sign can get brighter in fog or rain. This helps drivers see important signs faster.

- High-grade reflective sheets help drivers see signs up to 3 seconds faster than old signs.

- New materials meet tough ASTM and EN rules for being bright and strong.

- The Manual on Uniform Traffic Control Devices (MUTCD) says how bright signs must be.

Many new reflective materials also help smart city projects. They work with sensors and systems to give updates right away. These new ideas help cities react fast to changes on the road.

Sustainability and Eco-Friendly Materials

Sustainability is very important for the future of reflective sheeting. About 35% of new ideas use eco-friendly materials and ways to make them. Makers now create reflective films that use less energy and make less pollution. These materials follow green rules and give people safer, cleaner products.

- Microprismatic and retroreflective solutions are bright and last long. They are also better for the environment.

- Many reflective materials can be recycled. Cities can join recycling programs to get rid of old signs the right way.

- These programs help cut down on waste and protect nature.

| Sustainability Feature | Benefit |

|---|---|

| Eco-conscious materials | Lower environmental impact |

| Recycling programs | Less landfill waste |

| Energy-efficient production | Reduced carbon footprint |

In the future, highway signs will focus on safety and caring for the planet. New technology and green ideas will help keep roads safe and protect the earth.

Reflective sheeting classes are not all the same. They have different levels of visibility and last for different times. They are also used in different ways. The table below shows how RA1 and RA2 are different:

| Reflective Sheeting Type | Visibility Distance at Night | Average Lifespan (Years) | Durability Characteristics |

|---|---|---|---|

| RA1 (Engineering Grade) | Up to 150 meters | 7 | Good for low-traffic areas |

| RA2 (High-Intensity Prismatic) | Up to 250 meters | 10–12 | Withstands weather, stays bright |

Picking the right reflective sheeting helps people stay safe. It makes signs easier to see and helps them last longer. Agencies must make sure signs are bright enough. They should check signs often to keep safety high and follow the rules. Sign designers and safety workers should:

- Use MUTCD standards so signs can be seen at night.

- Look at signs often to make sure they are safe.

- Check state DOT rules before picking materials.

- Choose sheeting that fits all the rules.

Looking at all the choices and rules helps keep roads safe for everyone.

FAQ

What is the main purpose of reflective sheeting on highway signs?

Reflective sheeting helps drivers see signs at night or in bad weather. It bounces light from headlights back to drivers. This keeps people safer and helps stop accidents.

How long does reflective sheeting last on traffic signs?

Engineer grade sheeting usually lasts about 7 years. High intensity prismatic can last up to 12 years. Diamond grade can last 15 years or even longer if cared for well.

Can reflective sheeting be recycled?

Many new reflective materials can be recycled. Cities and agencies join recycling programs to make less trash and help the environment.

Why do some signs look brighter than others at night?

Signs use different classes of reflective sheeting. Diamond grade and high intensity prismatic reflect more light. This makes those signs look brighter and easier to see from far away.