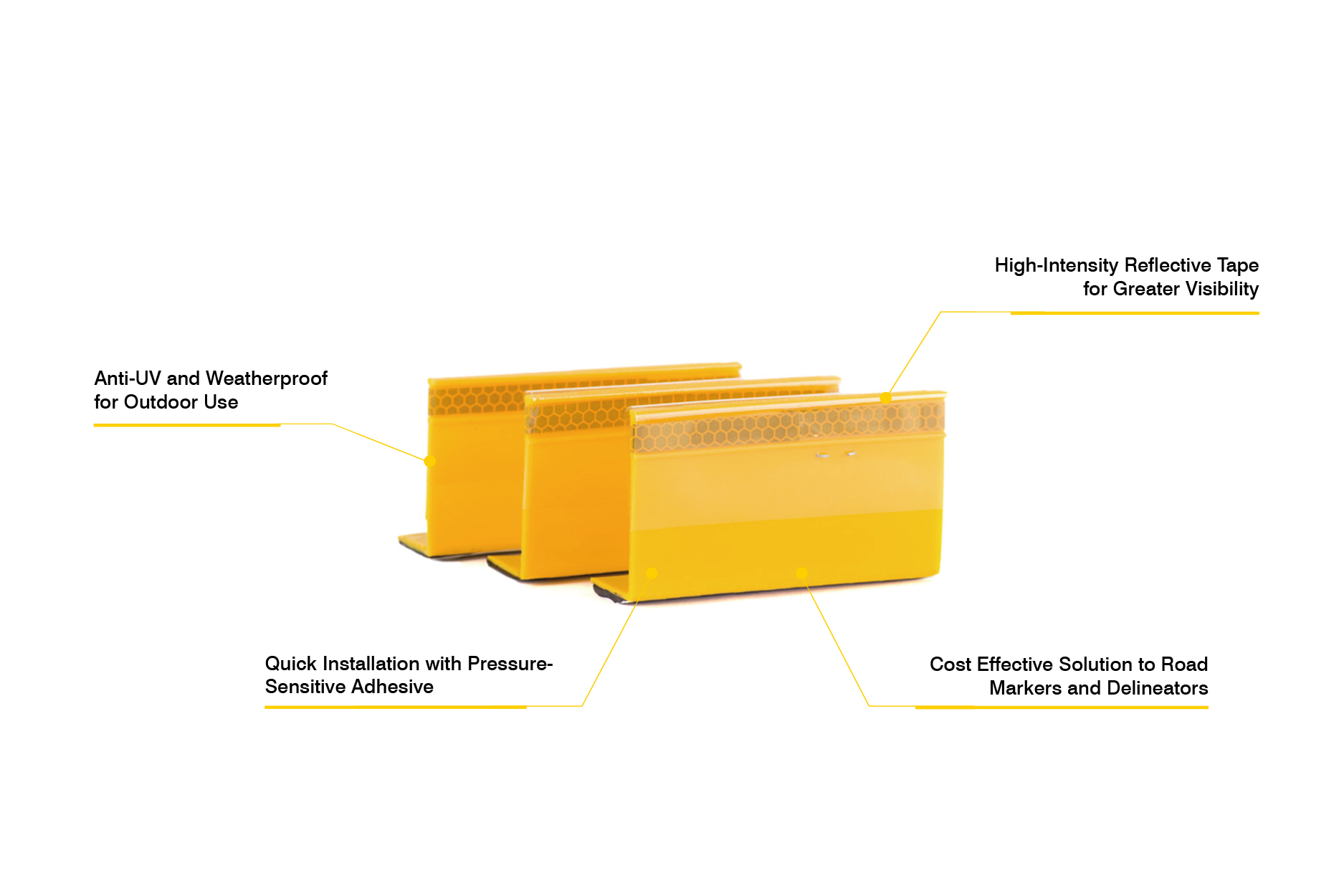

Optsigns Temporary Pavement Markers are effective and economical traffic warning devices designed to enhance road safety both day and night. These versatile Temporary Pavement Markers serve as essential lane delineators and temporary pavement indicators, making them ideal for a variety of applications, including roadworks, construction sites, and asphalt resurfacing. With their bright colors and durable materials, Temporary Pavement Markers provide clear visual guidance for drivers, ensuring safer navigation through roadway situations. Their convenient design allows for quick setup and removal, making them a practical choice for any temporary traffic management needs.

Optsigns Temporary Pavement Markers are effective and economical traffic warning devices designed to enhance road safety both day and night. These versatile Temporary Pavement Markers serve as essential lane delineators and temporary pavement indicators, making them ideal for a variety of applications, including roadworks, construction sites, and asphalt resurfacing. With their bright colors and durable materials, Temporary Pavement Markers provide clear visual guidance for drivers, ensuring safer navigation through roadway situations. Their convenient design allows for quick setup and removal, making them a practical choice for any temporary traffic management needs.

*We respect your confidentiality and all information are protected.

| Size | 100*27*55mm |

|---|---|

| Weight | 0.023kgs |

| Material | PU |

| Colour | Yellow or White |

| Reflective Sheet | Engineering Grade, Class 1, Customizable |

| Customize | Custom Logo and Colour |

Using Optsigns Temporary Pavement Markers is straightforward and effective for improving road safety. Simply position the temporary raised pavement markers along the intended lane or area to delineate boundaries and guide drivers. For optimal visibility, place temporary raised pavement markers at regular intervals, especially in high-traffic zones or areas under construction. These temporary raised pavement markers are designed to withstand various weather conditions, ensuring they remain effective both day and night. Regularly check the temporary raised pavement markers to ensure they are in place and replace any that become damaged or faded to maintain clear guidance for motorists.

A sign post sleeve is a protective casing that fits over a sign post, typically made from durable materials like galvanized steel. It enhances the stability and lifespan of the sign post while providing a cleaner aesthetic.

The weight of a socket sleeve with base plate can vary depending on its size and material. Generally, these structures are designed to be robust yet manageable for installation, often weighing between 1 and 30 pounds. The weight ensures stability while still allowing for easy handling.

The surface mount base plate serves as a sturdy foundation for mounting sign posts or sleeves on flat surfaces. It provides stability by distributing weight evenly and allows for easy installation without the need for digging holes or pouring concrete, ensuring a secure attachment.

To install sign post sleeves in the ground, first, determine the location and mark the spot. Dig a hole to accommodate the sleeve, insert it vertically, and ensure it’s level. Then secure the surface mount post sleeve plate stably on the ground.

Metal post sleeves are commonly made of galvanized steel, which provides excellent durability and corrosion resistance. This material is ideal for outdoor applications, ensuring that the sleeves can withstand harsh weather conditions while maintaining their structural integrity over time.