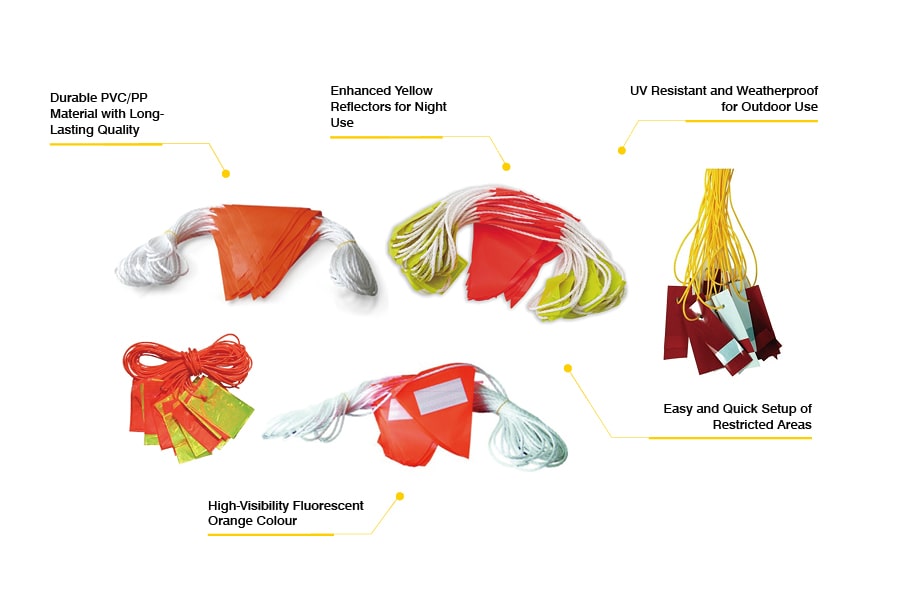

OPTsigns Australia Day Night Bunting Safety Line is engineered for high visibility and durability, featuring fluorescent orange PVC triangle flags on rope combined with a high-strength PP flag line. Its bright color ensures visibility in various conditions, and the reflective flag design with enhanced yellow reflectors provides extra safety during nighttime use. The bunting flag is crafted from durable materials, making it UV resistant and weatherproof, ideal for outdoor settings.

This flagging solution allows for quick and easy setup of restricted areas, making it suitable for temporary work zones, pedestrian sidewalks, parking lots, and construction sites. It’s also widely used in the mining industry and demolition worksites for marking hazardous zones. The flags on line not only improve crowd control but also enhance traffic management, providing a low-cost and long-lasting solution.

*We respect your confidentiality and all information are protected.

| Flag Size | 190*190*165mm, 45pcs |

|---|---|

| Length | 30m, Customizable |

| Colour | Fluorescent Orange, Yellow, Green, Blue |

| Material | PVC Plastic Flags with a PP Rope |

| Reflector | 13.5*7mm, Yellow, 44pcs |

| Reflective Film | None, Commercial Grade, Class 1, Customizable |

| Customize | Logo and Marking |

| Option | Roller |

Plastic Road Studs are designed to serve as lane delineators and raised pavement markers. Plastic Road Studs are commonly used in car parks, school zones, traffic islands, and gas stations to enhance visibility and guide vehicles safely.

The high-visibility reflectors in reflective road stud significantly enhance nighttime visibility, making it easier for drivers to navigate and understand lane boundaries. Reflective road stud helps reduce accidents and improve overall traffic management.

Yes, Optsigns reflective road studs are constructed from robust materials designed to withstand the wear and tear of daily traffic. Their durable structure ensures they remain effective in various roadway conditions.

Absolutely! Plastic reflective road studs are designed for outdoor use and can perform well in various weather conditions, including rain and snow. Their reflective properties ensure visibility regardless of the environment.

It’s recommended to inspect Plastic Road Studs regularly to ensure they are properly positioned and in good condition. This maintenance helps to maintain optimal visibility and effectiveness in guiding drivers.

Yes, Plastic Road Studs are effective for both daytime and nighttime use. Their reflective design enhances visibility in low-light conditions, ensuring they provide guidance to drivers at any time of day.