Choosing the right bollard materials is very important for success. Imported materials may have global approvals and high-quality finishes, while locally made materials are easier to obtain and better suited to the area. Consider price, strength, and environmental effects when making your decision. If you are looking for safety bollards for sale, understanding these differences will assist you in meeting your project’s needs on time and with good quality.

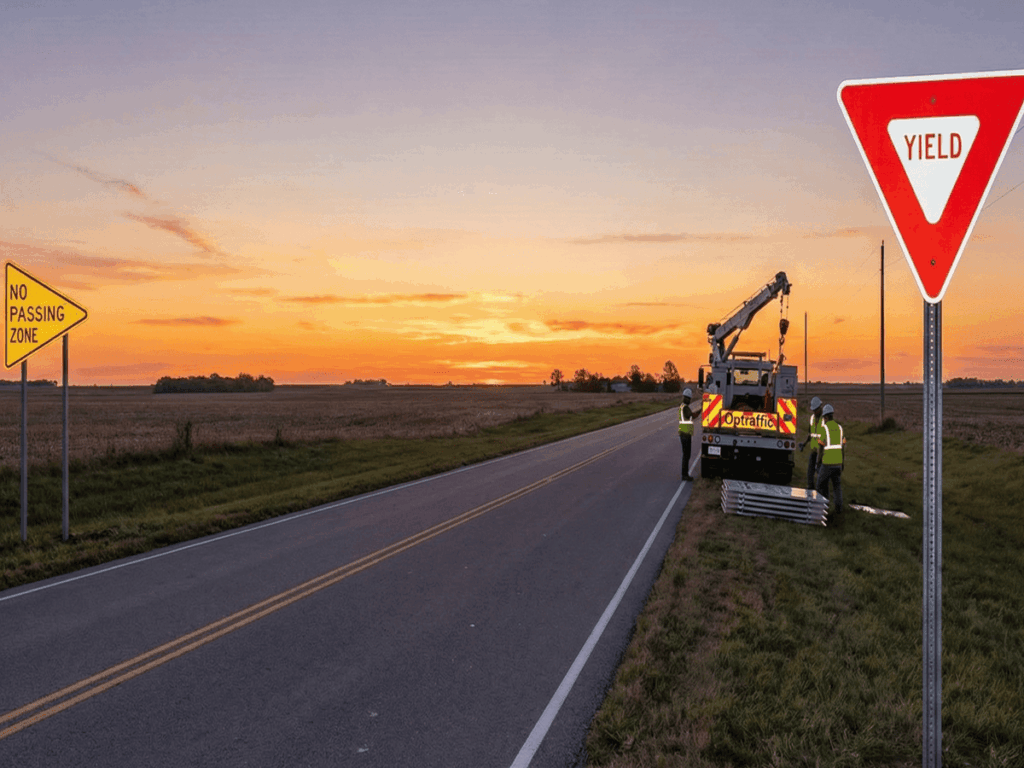

OPTRAFFIC, as a global supplier of traffic safety products, offers a wide range of safety bollards tailored to various environments and project requirements. With expertise in sourcing both imported and locally made materials, OPTRAFFIC ensures that you receive the highest quality products that meet safety standards and performance expectations, no matter where your project is located.

Key Takeaways

- Think about costs. Local materials cost less for shipping and taxes. They are good for small budgets.

- Look at quality. Imported materials meet global rules. Local ones follow regional rules for safety and reliability.

- Plan delivery times. Local suppliers are faster. They avoid delays from shipping and customs. This helps urgent projects.

- Consider the environment. Local materials travel shorter distances. This lowers pollution and helps the planet.

- Match materials to your project. Pick durable ones that need less care. Make sure they work well for your project’s needs.

Cost Comparison

Direct Material Costs

When looking at imported and locally sourced bollard materials, the cost of materials is a key factor. Imported materials, like stainless steel bollards, often cost more because of their high-quality finishes and global approvals. Locally sourced materials, such as galvanised steel, are usually cheaper since they avoid shipping fees and taxes from other countries.

Think about how big your project is. For large projects, even small price differences can affect your budget a lot. Local suppliers might give discounts for buying in bulk, making them a cheaper choice if you need many bollards.

Hidden Costs (Shipping, Tariffs, and Exchange Rates)

Extra costs can add up fast when buying imported bollard materials. Shipping costs depend on the size and weight of the materials. Delays in delivery can also slow down your project. Taxes and customs fees make imported goods even more expensive, especially if your country charges high import taxes.

Currency changes can also be a problem. If your currency loses value compared to the supplier’s, you might pay more than expected. Locally sourced materials avoid these issues. By choosing local suppliers, you skip shipping and customs fees, making costs easier to predict.

Tip: Always ask suppliers for a full cost list to spot hidden fees before buying.

Long-Term Maintenance Costs

The cost of keeping safety bollards in good shape depends on how strong they are and how well they fit the environment. Imported materials, like stainless steel, often last longer in wet or coastal areas because they resist rust better than galvanised steel.

But locally sourced materials might be easier to fix or replace. Local suppliers can help faster if repairs are needed, reducing delays and keeping your project running smoothly.

Think about how long you need the bollards to last. Imported materials might last longer, but their higher price may not be worth it for short-term projects. Locally sourced materials could be a better choice if your budget is tight and the project is temporary.

Quality and Durability

Quality Standards and Certifications

When choosing bollard materials, check their safety and quality standards. These standards show the materials have been tested and are reliable.

- TÜV NORD certification: This proves bollards passed independent tests for strength and safety.

- Testing standards: UNI/TS 11886-1: This ensures bollards are tested in real-life conditions for reliability.

Imported materials often meet global standards, which is helpful for international projects. Locally sourced materials may follow local rules, making them better for regional projects.

Durability in Different Environments

Where you place safety bollards affects how long they last. Stainless steel bollards, usually imported, resist rust and work well in wet areas. Locally sourced galvanised steel is cheaper but may need extra coatings to last in similar places.

Concrete bollards are strong for cities, while recycled composites are less durable but eco-friendly. Picking the right material keeps bollards useful and looking good over time.

Longevity and Maintenance Requirements

How long traffic safety bollards last depends on their material and care. The table below shows how durable and easy to maintain common materials are:

| Material | Durability in Conditions | Maintenance Needs | Environmental Impact |

|---|---|---|---|

| Concrete | Very High | Low | Moderate |

| Steel | Very High | Low | Low |

| Recycled Composites | Medium | Medium | Low |

Steel bollards, whether imported or locally sourced, need little care and last a long time. Concrete bollards also need minimal upkeep, making them great for busy areas. If you want eco-friendly options, recycled composites balance durability and sustainability.

When buying safety bollards, think about how long they’ll last and how often they’ll need care. This helps you pick materials that fit your project’s needs and budget.

Availability and Lead Times

Inventory and Stock Levels

When getting traffic bollard materials, stock levels are very important. Imported materials often run out because of high global demand. Suppliers may find it hard to keep enough stock, especially for special items like stainless steel bollards.

Locally sourced materials have shorter supply chains, making restocking quicker. Local suppliers can provide materials faster, avoiding long waits. This is helpful for big projects or when you need quick replacements.

Tip: Check stock levels with your supplier to prevent delays.

Shipping Delays and Customs Issues

Shipping imported materials can take longer due to many problems. Weather, busy ports, or political issues can slow deliveries. Customs checks can also cause weeks of delay if there are mistakes.

Using locally sourced materials avoids these problems. Local suppliers deliver straight to your site without customs or shipping delays. This means faster delivery and fewer project interruptions.

Note: If you choose imported materials, plan for possible delays in your schedule.

Local Production and Responsiveness

Local production is more flexible and responsive. You can work with local makers to adjust bollards to your needs. This helps you make changes quickly without missing deadlines.

Local suppliers also fix problems faster, like replacing faulty items. Being nearby means quicker help and better communication, keeping your project on time.

Callout: For tight deadlines, choose local production to save time and avoid risks.

Environmental Impact

Carbon Footprint of Imported Materials

Imported bollards travel far to reach your project site. This long journey adds to carbon emissions. Ships, planes, and trucks burn fuel, releasing harmful gases. Choosing imported materials increases your project’s environmental impact.

Factories abroad may use energy-heavy methods that create more pollution. Some countries have weak environmental rules, leading to harmful practices. Think about these issues to decide if imported materials fit your project’s goals.

Tip: Pick suppliers who share their carbon-cutting efforts to reduce harm.

Sustainability of Locally Sourced Materials

Locally sourced bollards are often better for the environment. Shorter transport means fewer emissions, making them a greener option. Many local makers use recycled materials or low-energy production methods.

The table below shows eco-friendly benefits of common materials:

| Material Type | Environmental Benefit |

|---|---|

| Recycled Plastics and Metals | Cuts waste while staying strong. |

| Bamboo and Composite Wood | Looks good and has a small environmental impact. |

| Low-Carbon Steel Production | Lowers emissions but keeps bollards durable. |

| Corrosion-Resistant Coatings | Makes bollards last longer, reducing replacements. |

Using local materials supports sustainability and meets local environmental rules.

Supporting Local Industries and Communities

Buying local bollards helps nearby businesses and workers. This boosts your area’s economy and supports community growth. Local suppliers often reinvest money into jobs and infrastructure.

Choosing local materials also promotes green practices in your region. Many local makers focus on eco-friendly methods to meet demand. Supporting them helps create a sustainable future for everyone.

If you need safety bollards, choosing local suppliers supports both the planet and your community.

Suitability for Specific Projects

Urban Security Projects with Tight Deadlines

Urban security projects need bollards installed fast to protect areas. These include public spaces, pedestrian zones, or busy streets. Locally sourced materials are often the best choice for quick delivery. Local suppliers respond faster to urgent needs and avoid shipping delays.

For example, securing a city square before an event needs reliable timing. Imported materials might cause delays due to customs or transport issues. Local production ensures you get bollards on time, keeping your project safe and on schedule.

Tip: For urgent projects, check lead times with suppliers early to avoid delays.

High-End Architectural Projects Requiring Premium Finishes

Luxury architectural projects focus on looks and high-quality finishes. Imported materials often provide more design choices and better finishes. Stainless steel bollards are popular for their stylish look and strength. These materials meet global standards, making them ideal for famous landmarks or upscale buildings.

However, importing materials can bring challenges like shipping delays or damage. Work closely with suppliers to ensure safe packaging and delivery. Consider if the extra cost and time for imported materials match your project’s goals.

Locally sourced options may offer custom designs without shipping problems. This lets you create unique looks while avoiding delays.

Projects with Specific Regulatory or Customisation Needs

Some projects need bollards to follow strict rules or special designs. Locally sourced materials are great for these situations. Local suppliers know regional building codes and ensure compliance with local laws.

Customisation is easier with local production. You can request specific colours, sizes, or designs quickly. This is helpful for heritage sites where bollards must match the area’s style.

Imported materials may meet international standards but are harder to change after shipping. Last-minute changes with imported bollards can cause delays or extra costs.

Callout: For projects needing strict rules or custom designs, choose local suppliers for flexibility and compliance.

Decision Framework for Professionals

Budget Flexibility

Your budget is key when picking bollard materials. Imported materials cost more because of their fancy finishes and global approvals. Locally sourced materials are usually cheaper and have steady prices.

To decide wisely, think about these points:

- Initial Costs: Compare the price of imported and local materials.

- Bulk Discounts: See if local suppliers give deals for big orders.

- Hidden Expenses: Add shipping, taxes, and currency changes for imported items.

Tip: If money is tight, go for local materials to avoid surprises. For fancy projects, save extra for premium imported finishes.

Lead Time Constraints

Projects with tight schedules need good planning. Imported materials may take longer due to shipping or customs delays. Locally sourced materials arrive faster and are more reliable.

Ask yourself these questions:

- How urgent is the project? Quick deadlines suit local suppliers better.

- Are delays likely? Imported materials often take more time to arrive.

- Can suppliers handle changes? Local makers adjust faster to last-minute needs.

Callout: For fast projects, pick local suppliers to avoid delays and finish on time.

Regulatory Requirements

Following rules is important for your project’s success. Imported materials meet global standards like ISO or ASTM. Locally sourced materials match local building codes better.

Think about these points:

- Project Location: Check if local rules prefer local materials.

- Customisation Needs: Local suppliers can make bollards fit specific needs.

- Documentation: Ensure imported materials have proper certificates.

Note: For strict local rules, local materials make it easier to follow laws and avoid problems.

Expected Lifespan and Usage Conditions

How long bollards last depends on their material and location. Think about how they’ll be used and the conditions they’ll face. This helps you pick materials that last longer and work better.

Material Lifespan Comparison

Different materials last for different amounts of time. The table below shows how long common bollard materials can last and where they work best:

| Material | Expected Lifespan | Best Usage Conditions |

|---|---|---|

| Stainless Steel | 20–30 years | Wet areas, busy streets |

| Galvanised Steel | 10–20 years | Cities, normal weather |

| Concrete | 25–50 years | Tough jobs, factories |

| Recycled Composites | 10–15 years | Green projects, light-use areas |

Stainless steel doesn’t rust easily, so it’s great for wet places. Galvanised steel is good for cities but might need extra protection in bad weather. Concrete is super strong and perfect for heavy-duty areas. Recycled composites are eco-friendly but better for places with less damage.

Factors Affecting Lifespan

Many things affect how long bollards last:

- Weather Conditions: Rain, snow, and salt can cause rust or damage.

- Impact Resistance: Bollards in busy areas get hit more often.

- Maintenance: Cleaning and fixing them regularly makes them last longer.

Tip: Use materials with coatings or rust-proof features for tough weather.

Matching Materials to Usage

Think about what the bollards will do. For example, car park bollards need to handle car bumps. Decorative bollards in walking areas focus more on looks than strength. Picking the right material saves money and keeps them working longer.

By checking lifespan and usage, you can choose bollards that fit your project and budget.

There isn’t a single best choice for bollard materials. The right option depends on your project’s specific needs. Think about cost, quality, delivery time, and environmental effects. For instance, cities like New York use crash-rated bollards to protect public areas. This shows how important it is to match materials with safety needs.

Planning early helps you make better choices for your project. It ensures materials fit your schedule, budget, and rules. Whether buying safety bollards or designing a fancy building, picking the right materials is key to success.

To learn more about selecting the best bollard material for your specific needs, check out the blog How to Choose the Best Traffic Bollard Material for Your Project. It provides valuable guidance on how to choose materials that meet both practical and aesthetic requirements while staying within budget and timeline.

FAQ

What are the benefits of using local bollard materials?

Local materials arrive quicker, cost less, and follow local rules. They also help nearby businesses and cut pollution from transport.

Are imported bollard materials always better in quality?

Not always. Imported materials meet global standards, but local ones can be just as good, especially for local needs.

How do I pick the best bollard material for my project?

Think about your budget, timeline, weather, and rules. Choose a material that lasts long and looks right for your project.

Can local bollards be customised easily?

Yes, local suppliers can change designs, colours, or sizes faster. This helps meet special project needs.

Do imported materials harm the environment more?

Yes, imported materials cause more pollution due to long shipping and energy-heavy production. Local materials are greener.