Highway sign materials are very important for road safety. These materials decide how long a sign will last. They also affect how well drivers can see the sign. Highway sign materials must handle bad weather and strong sunlight. They also need to survive lots of cars and trucks. Engineers pick highway sign materials to keep messages clear all the time. Picking the right highway sign materials saves money on repairs and new signs. Highway sign materials help people see signs during the day and night. This makes roads safer for everyone.

At OPTRAFFIC, we specialize in providing high-quality traffic signs made from durable materials. Our signs are designed to withstand harsh weather conditions and ensure maximum visibility for drivers, day and night. Whether you’re looking for long-lasting materials or customized solutions, our factory can meet your needs efficiently.

Key Highway Sign Materials

Aluminum Signs

Aluminum is the most common highway sign material in North America and Europe. This metal is very strong and does not rust easily. It is great for outdoor signs. Aluminum signs are light, so they are easy to put up. They do not make signposts bend. These signs can last from 7 to 12 years. A special film can cover them to protect from sun and rain. This film keeps the color bright and helps the sign shine at night. Aluminum works well with reflective materials and retroreflective materials. These help drivers see signs in any light. Many groups use aluminum because it can be recycled. This helps the environment.

To learn more about the benefits, durability, and applications of aluminum signs, check out our blog on The Ultimate Guide to Aluminum Signs: Durability, Applications, and Benefits.

Steel Signs

Steel signs are very strong and hard to break. They are good for busy roads or places with tough weather. Stainless steel does not rust because it has chromium. Regular steel needs a special film to stop rust. Steel signs need more care than aluminum, especially near the ocean. They are heavy, so putting them up is harder. Their weight helps them stay in place. Steel signs can use reflective technology and retroreflective properties. This makes sure people can read them day and night.

Plastic and Composite Signs

Plastic signs are made from HDPE or polycarbonate. They are cheap and light. These signs do not break easily and can handle sunlight if covered with a special film. Composite signs, like aluminum composite material, mix metal and plastic. ACM signs stay flat and do not bend. They use less aluminum, so they are better for the planet. Some plastics, like PET and HDPE, can be recycled. Other plastics can hurt the environment. Both plastic and composite signs can use reflective materials and retroreflective materials. This helps drivers see them better.

Reflective Sheeting Types

Reflective sheeting is very important for seeing highway signs. There are different types:

- Type I (Engineering Grade): This is basic and not good for every sign.

- Type III (High Intensity Prismatic): This is brighter and lasts up to 10 years.

- Diamond Grade (Type IX): This is the brightest and strongest. It uses special films to last longer.

Using better reflective materials can make roads safer and lower crash numbers. Special films help signs last longer and stay clear in rain, fog, or at night. Retroreflective materials and reflective technology help headlights light up signs from far away. This helps drivers find their way in any weather or time. To understand how retroreflective materials work and their importance in highway sign visibility, check out our blog on The Science Behind Retroreflectivity and Its Role in Highway Sign Visibility.

Durability and Weather Resistance

UV and Sunlight Exposure

Highway signs are always outside in the sun. Sunlight can make colors fade and weaken materials. Picking the right material and coating helps signs last longer. Some materials, like premium cast vinyl and uv-stabilized acrylic, do better against uv rays. Molded ABS plastic also works well in strong sunlight. Weak vinyl fades fast and gets weak. The table below shows how materials handle uv and sunlight:

| Material Type | UV Resistance | Fading Resistance | Structural Integrity |

|---|---|---|---|

| Weak Vinyl | Low | High | Low |

| Premium Cast Vinyl | High | Low | High |

| Molded ABS Plastic | High | Low | High |

| UV-Stabilized Acrylic | High | Low | High |

Special coatings and films give extra protection from uv rays. These coatings help signs stay bright and easy to read. Protective overlay films and products like Avery Dennison OL-1200/OL-1000 block sunlight and make cleaning simple. They also stop graffiti and other damage. Using uv coating on highway signs makes them last longer and look better. It works on many surfaces, like plastic and wood. Materials such as calcium carbonate and polyethylene are used in these coatings for more protection.

Rain, Snow, and Moisture

Rain, snow, and moisture can hurt highway signs if the wrong materials are used. Aluminum, galvanized steel, and stainless steel protect well against rust. Aluminum is good in wet places, especially with powder coating. Galvanized steel is often used for sign posts and does not rust easily. Stainless steel is best for places near the ocean or factories. The table below compares these materials:

| Material | Corrosion Resistance | Recommended Use |

|---|---|---|

| Galvanized Steel | High | Common for sign posts, protects against rust |

| Stainless Steel | Very High | Ideal for coastal and industrial areas |

| Aluminum | High | Good for high-moisture environments, especially when powder-coated |

Plastic signs made from HDPE or polycarbonate also resist water and do not rust. These materials help signs last longer in rainy or snowy places. Good coatings and treatments make signs even stronger and help them last.

Impact and Vandalism Resistance

Highway signs need to handle hits from cars, debris, and vandalism. Aluminum is very tough in these cases. It bends instead of breaking, so the sign stays up and can be read. This means fewer repairs and saves money for towns. Aluminum also stands up to rain, snow, and sun. Anti-graffiti laminations can be added to stop paint and markers.

Plastic and composite signs are also strong against impacts. They do not break easily and can take rough use. These materials help signs last in busy or risky places.

Tip: Using protective coatings on signs stops graffiti and makes cleaning easier.

Maintenance and Traffic Sign Durability

Taking care of highway signs keeps them safe and easy to see. Using strong materials like high-grade aluminum and reflective sheeting helps signs last longer. Good installation keeps signs in place during storms or strong winds. Cleaning with gentle soap and soft brushes keeps signs clear.

The table below lists ways to keep signs working longer:

| Maintenance Practice | Description |

|---|---|

| Regular Inspections | Check signs often for fading, damage, or things blocking them. |

| Quality Materials | Use strong materials like high-grade aluminum and reflective sheeting. |

| Proper Installation | Make sure signs are put up well to handle bad weather. |

| Cleaning and Upkeep | Clean signs with gentle soap and soft brushes to keep them visible. |

| Protection from Vandalism | Use coatings and teach people to help stop vandalism. |

Checking signs often helps find fading or damage early. Fixing rust and corrosion quickly stops bigger problems. Making sure signs are mounted right keeps them steady. All these steps help signs last longer and work better.

Visibility and Road Safety

Reflective Coatings and Night Visibility

Being able to see signs is very important for road safety. Drivers need to see signs clearly, especially when it is dark. Highway signs often have reflective coatings. These coatings use retroreflective materials. Retroreflective materials send light from headlights back to the driver. This makes signs easier to see at night. Drivers can react faster when they see signs clearly. Signs without reflective coatings spread light in many ways. This makes them hard to see at night. Drivers might miss warnings if they cannot see the signs.

- Reflective coatings use retroreflective materials to send light back, making signs easier to see.

- Signs without reflective coatings are harder to see at night.

- Reflective road signs help drivers see better and stay safe.

Transportation authorities have rules for how bright highway signs must be. For example, some signs must have a retroreflectivity level of at least 50 cd/lx/m². If a sign does not meet this rule, it must be replaced. This helps keep roads safe, especially at night or when it is hard to see.

Diamond grade reflectors are the brightest. They use special films to keep signs bright for a long time. These reflectors help drivers see signs even when it is dark or foggy.

Material Thickness and Sign Clarity

How thick a sign is can change how easy it is to see. Thicker signs stay flat and do not bend. This keeps the words clear and easy to read. Thick signs do not curl at the edges. The table below shows how thickness helps signs work better:

| Factor | Impact of Thickness |

|---|---|

| Adhesion | Thicker materials stick better because they have more pull. |

| Wind Resistance | Thick signs stay up better in strong winds. |

| Mechanical Deformation | Thicker signs do not bend as much, so they last longer. |

| Outdoor Durability | Thick sheeting does not curl, so signs last longer outside. |

Permanent traffic signs often use thick aluminum or composite panels. This helps the sign stay easy to read in any weather. Flat signs also work well with reflective coatings. To dive deeper into how different thicknesses impact the durability and performance of traffic signs, check out our blog on Is Thicker Always Better? The Pros and Cons of Different Thicknesses in Aluminum Traffic Signs.

Performance in Poor Weather

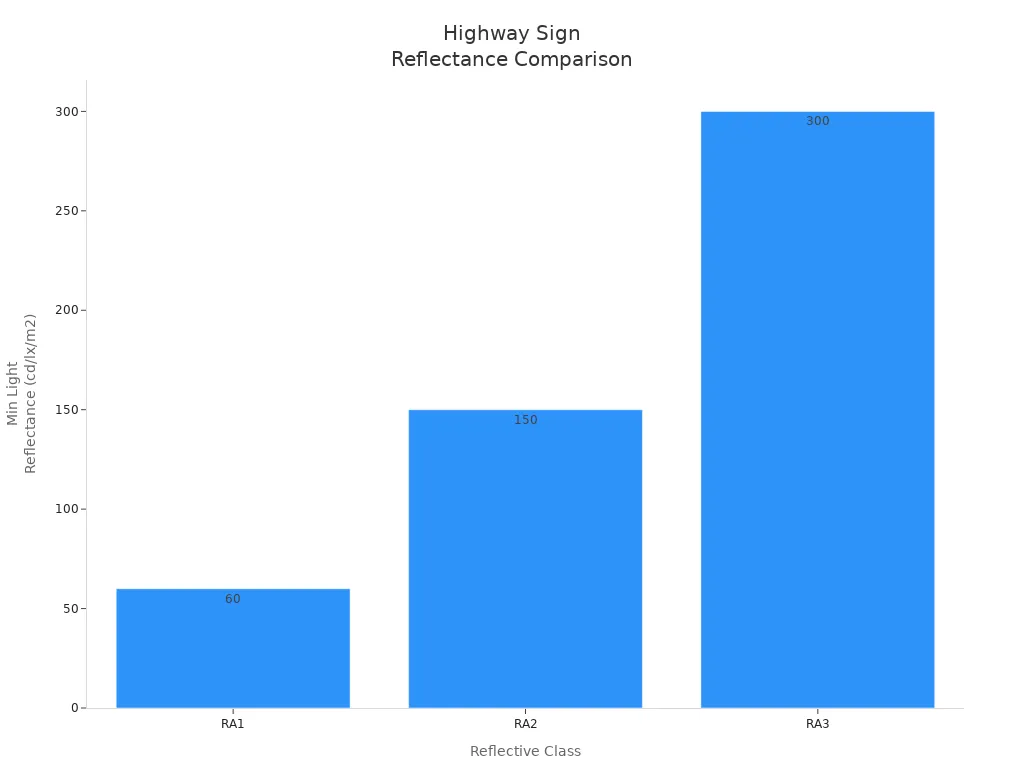

Bad weather makes it hard to see highway signs. Rain, fog, and snow can block a driver’s view. Good materials and coatings help solve this problem. Reflective sheeting comes in different types. The table below shows how well each type works:

| Reflective Class | Minimum Light Reflectance (cd/lx/m2) | Visibility in Bad Weather |

|---|---|---|

| RA1 | < 60 | Limited visibility |

| RA2 | 150 | Moderate visibility |

| RA3 | 300 | High visibility, ideal for fog, rain, and snow |

RA3 sheeting is best for fog, rain, and snow. These signs help drivers see in all kinds of weather. They last longer and do not get damaged by water or wind. In Mendocino County, California, better sign sheeting made crashes go down by 42%. Injuries dropped by 42% and deaths dropped by 61% in three years. This shows that better visibility saves lives and keeps roads safe.

Other new ideas also help people see signs better. Glass beads in coatings make signs brighter at night and in bad weather. Special computer programs can change brightness and contrast right away. Some filters cut down glare and make signs stand out. These upgrades help drivers see signs and act quickly.

- Better nighttime visibility helps drivers see signs and road lines.

- Good visibility in bad weather helps people drive safely.

- Glass beads are safe for the environment and can be recycled.

LED and Enhanced Visibility Options

LED signs are a new way to make signs easier to see. These signs make their own light. They do not need headlights or streetlights to be seen. LED traffic signs can flash or blink to get attention. This is helpful in fog, rain, or at night. Signs with lights are easier to see than regular signs. When drivers see signs better, roads are safer.

- LED signs shine on their own, unlike regular signs.

- They can blink or flash, so drivers notice them in bad weather.

- Lighted signs are easier to see, which helps keep people safe.

- LED traffic signs use less energy than old lights. LEDs turn over 60% of electricity into light. This makes them save energy and money.

LED signs cost more to put up, but they save energy later. Regular signs last about 20 years. Their posts can last up to 40 years, but may need paint. LED signs last a long time and help people see better.

Note: LED technology is getting better every year. Many cities now use LED traffic signs and LED signs for important warnings and school zones. These signs help drivers see at night and in bad weather, making roads safer for everyone.

Choosing Materials for Different Applications

Urban vs. Rural Sign Needs

Highway sign materials should fit where they are used. Cities have busy roads and lots of signs. There are many drivers, people on bikes, and people walking. Country roads are long and face tough weather. The table below shows how sign needs are different in each place:

| Factor | Urban Environment | Rural Environment |

|---|---|---|

| Traffic Flow Management | Needs many signs because there are lots of cars and people. | Tells drivers about safe speeds, curves, and animals. |

| Wayfinding | Needs clear signs for many places and landmarks. | Signs show how far towns and services are, so drivers know ahead of time. |

| Maintenance and Visibility | Signs must handle pollution and people trying to damage them. They need to be checked often. | Signs need to be bright and strong for bad weather. It is hard to fix them often. |

| Diverse User Needs | Signs must help people on bikes and people walking. | Most signs are for cars, but some help people not in cars stay safe. |

| Emergency Information | Signs help people find help fast in crowded places. | Signs show where to get help in faraway places. |

City signs use aluminum or composite panels. These are easy to put up and hard to damage. Reflective sheeting makes city signs easy to see at night. In the country, thicker aluminum or steel signs are used. These signs are strong against wind and snow. Bright coatings help drivers see signs in fog or at night.

Heavy-Duty and High-Impact Areas

Some places need very strong signs. Construction zones and highways with big trucks need signs that do not bend or break. Steel signs are good here because they can take hard hits. Aluminum signs with strong edges also work well. Plastic composites bend but do not break. In these places, engineers use thicker panels and special coatings. These choices help signs stay clear after storms or crashes.

Tip: In places where people damage signs a lot, use anti-graffiti coatings and special bolts to keep signs safe.

Eco-Friendly and Regulatory Considerations

Many cities and states want signs that are better for the planet. Recycled aluminum, plastics that can be used again, and water-based coatings make less waste. But picking green materials is not always easy. Each place has its own rules for road signs. This can make it hard for companies to follow every rule. New green products can take a long time to get approved. Agencies want to make sure they are safe for a long time. Meeting all the safety rules can cost more money. This is hard for small companies.

- Different places have their own rules for road signs, which can cost more.

- Agencies may wait to approve new green materials until they know they are safe.

- Following all the safety rules can be expensive, especially for small companies.

Picking the best material means thinking about safety, how long it lasts, and the planet. Planners need to check local rules and pick materials that keep roads safe and help the environment.

Picking the best highway sign materials helps signs last longer and be seen better. The material you pick changes how often you need to fix signs and how much they cost. Good materials make signs last a long time and help keep roads safe for all people.

Planners must think about local weather, traffic, and rules before picking materials for traffic signs.

FAQ

What material lasts the longest for highway signs?

Aluminum is the material that lasts the longest. It does not rust and stands up to bad weather. Many groups pick aluminum because it is strong and lasts many years.

How do reflective coatings improve sign visibility?

Reflective coatings send light from headlights back to drivers. This helps people see signs better at night or when it is foggy.

Are eco-friendly highway sign materials available?

Yes, there are eco-friendly choices. Some signs use recycled aluminum or plastic. Certain coatings use water instead of harsh chemicals. These choices help protect the environment.

Why do some signs use LED lights?

LED lights help people see signs in the dark or when it is stormy. They make important warnings stand out and use less power than old lights.