छोटी परियोजनाओं के लिए पानी से भरी बाधाएं एक अच्छा विकल्प हैं. वे लचीले हैं और बहुत महंगे नहीं हैं. उनका डिजाइन झटके को अवशोषित करके लोगों को सुरक्षित रखने में मदद करता है. ठोस बाधाएं उन नौकरियों के लिए बेहतर हैं जो लंबे समय तक चलती हैं. वे उन स्थानों के लिए भी सबसे अच्छे हैं जिन्हें मजबूत सुरक्षा की आवश्यकता है. बाधाएं श्रमिकों और लोगों को सुरक्षित रखने में मदद करती हैं. वे कारों को सुरक्षित रूप से स्थानांतरित करने में भी मदद करते हैं. सबसे अच्छा अवरोध इस बात पर निर्भर करता है कि परियोजना को क्या चाहिए. पानी से भरी बाधाओं का उपयोग अब छोटी नौकरियों के लिए अधिक किया जाता है. सरकारें और बिल्डर उन्हें पसंद करते हैं क्योंकि उन्हें स्थापित करना आसान है. वे ठोस बाधाओं की तुलना में मौतों की संख्या को कम करने में भी मदद करते हैं.

Optraffic विभिन्न प्रकार के प्रदान करता है पानी से भरी बाधाएं उपयोग में आसानी के लिए डिज़ाइन किया गया, टिकाऊपन, और अधिकतम सुरक्षा. हमारी बाधाएं अल्पकालिक परियोजनाओं और निर्माण स्थलों के लिए आदर्श हैं, त्वरित सेटअप और विश्वसनीय सुरक्षा प्रदान करना. अपनी परियोजना सुरक्षा मानकों को पूरा करने और जोखिमों को कम करने के लिए यह सुनिश्चित करने के लिए आज हमारी सीमा का अन्वेषण करें.

चाबी छीनना

- पानी से भरी बाधाएं हल्की और आसान हैं. उन्हें ज्यादा पैसा खर्च नहीं होता है. वे छोटी नौकरियों या परियोजनाओं के लिए अच्छे हैं जो अक्सर बदलते हैं.

- ठोस बाधाएं भारी और बहुत मजबूत होती हैं. वे एक लंबे समय तक चलते हैं. वे लंबी नौकरियों और तेज सड़कों के लिए सबसे अच्छा काम करते हैं जिन्हें मजबूत सुरक्षा की आवश्यकता होती है.

- पानी से भरी बाधाओं को स्थापित करना त्वरित और आसान है. वे खाली ले जाया जाता है और साइट पर पानी से भर जाता है. यह समय और पैसा बचाता है.

- ठोस बाधाओं को बड़ी मशीनों और सावधान योजना की आवश्यकता होती है. उन्हें जगह देने के लिए और समय लगता है. लेकिन वे मजबूत और स्थायी सुरक्षा देते हैं.

- सही बाधा को चुनना इस बात पर निर्भर करता है कि नौकरी कितनी लंबी है. यह इस बात पर भी निर्भर करता है कि यह कहां है, क्या सुरक्षा की जरूरत है, और आपके पास कितना पैसा है. यह श्रमिकों और ड्राइवरों को सुरक्षित रखने में मदद करता है.

अवलोकन

पानी से भरी बाधाएँ

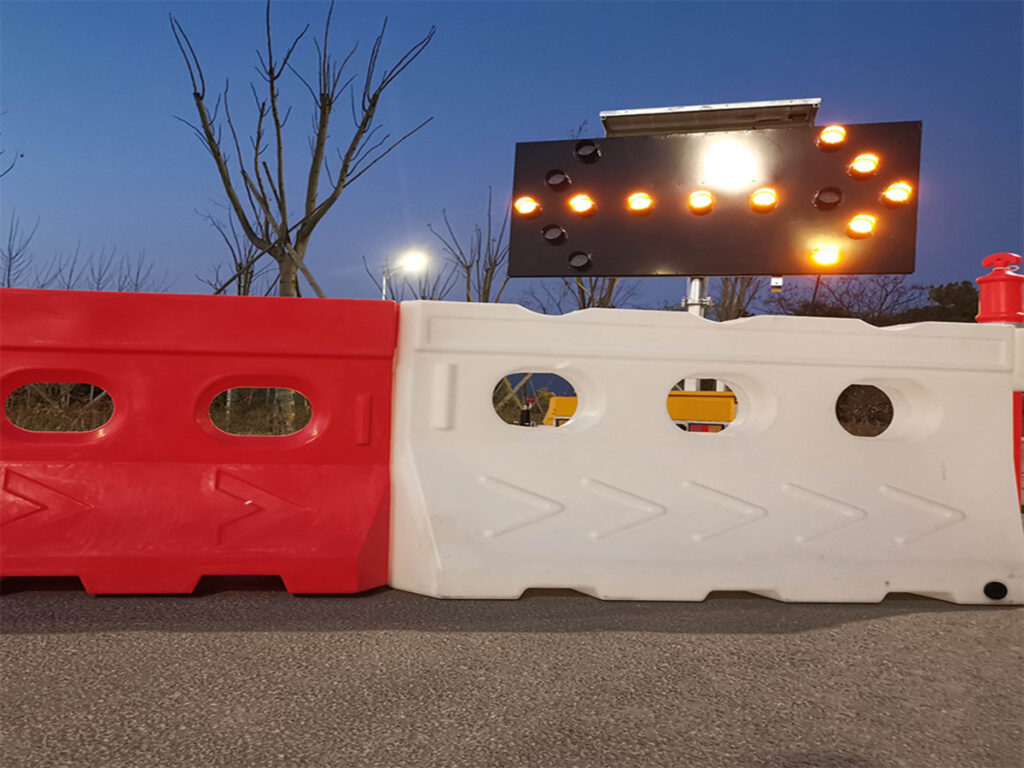

पानी से भरी बाधाओं का उपयोग अक्सर अल्पकालिक सड़क सुरक्षा और भीड़ नियंत्रण के लिए किया जाता है. वे उच्च घनत्व वाले पॉलीथीन जैसे मजबूत प्लास्टिक से बने होते हैं. साइट पर स्थानांतरित होने पर बाधाएं खाली होती हैं. एक बार आने के बाद श्रमिक उन्हें पानी से भर देते हैं. यह उन्हें भारी बाधाओं की तुलना में ले जाने और स्थापित करने में बहुत आसान हो जाता है. जब खाली हो, वे हल्के और स्टोर करने या स्थानांतरित करने में आसान हैं. जब भरा हुआ, वे जगह में रहते हैं और दुर्घटनाओं के दौरान कारों को रोकने में मदद करते हैं.

अधिक गहराई से देखने के लिए कि कैसे पानी से भरी बाधाएं सड़क सुरक्षा और कार्यस्थल दक्षता में सुधार कर सकती हैं, हमारे ब्लॉग की जाँच करें, सुरक्षित सड़कों और वर्कसाइट्स के लिए पानी से भरी बाधाओं के लिए पूरा गाइड.

टीमें पिन या टिका का उपयोग करके एक साथ कई बाधाओं में शामिल हो सकती हैं. इससे उन्हें विभिन्न परियोजनाओं के लिए सीधी रेखाएं या कोने बनाने की सुविधा मिलती है. फोर्कलिफ्ट छेद और बड़े कैप श्रमिकों को आगे बढ़ने और बाधाओं को जल्दी से भरने में मदद करते हैं. कुछ अवरोधों में रोशनी या बाड़ लगाने के लिए स्थान होते हैं. इससे लोगों को उन्हें बेहतर ढंग से देखने में मदद मिलती है और हर कोई सुरक्षित रहता है. नीचे दी गई तालिका पानी से भरे अवरोधों और कंक्रीट अवरोधों के बीच मुख्य अंतर दिखाती है:

| सुविधा/सामग्री | पानी से भरी बाधाएँ (डब्ल्यूएफबी) | कंक्रीट बाधाएँ |

|---|---|---|

| प्राथमिक सामग्री | एचडीपीई/पीई प्लास्टिक | ठोस कंक्रीट |

| निर्माण | खोखला, पानी से भरे | ठोस, कठोर |

| प्रतिरूपकता | एडजस्टेबल, कनेक्शन | निश्चित आकार |

| परिवहन सुविधाएँ | फोर्कलिफ्ट छेद, लाइटवेट | भारी मशीनरी की जरूरत |

| आघात अवशोषण | उच्च | कम |

कंक्रीट बाधाएँ

कंक्रीट अवरोधों का उपयोग दीर्घकालिक सड़क सुरक्षा और इमारतों की सुरक्षा के लिए किया जाता है. वे अंदर धातु के साथ मजबूत कंक्रीट से बने होते हैं. यह उन्हें कठोर बनाता है और खराब मौसम में भी टिकने में सक्षम बनाता है. विभिन्न प्रकार हैं, पसंद जर्सी बैरियर, जे-रेल बाधाएँ, और कदम बाधाएँ. प्रत्येक प्रकार कुछ सड़कों और क्रैश प्रकारों के लिए सबसे अच्छा काम करता है. कंक्रीट की बाधाएं कारों को अपनी गलियों में रखती हैं और उन्हें खतरनाक स्थानों पर जाने से रोकती हैं. वे दुर्घटनाओं के दौरान कारों में लोगों की रक्षा करने में भी मदद करते हैं.

छोटे स्थानों में, सुरंगों या पुलों की तरह, इंजीनियर विशेष कनेक्टर्स के साथ पतली कंक्रीट बाधाओं का उपयोग करते हैं. इन बाधाओं को लागू करने और कारों को सुरक्षित रखने के लिए जल्दी है. कंक्रीट बाधाओं को बहुत अधिक देखभाल की आवश्यकता नहीं है और बहुत लंबे समय तक रह सकते हैं. उनका मजबूत निर्माण उन्हें उन स्थानों के लिए अच्छा बनाता है जिन्हें मजबूत और स्थायी सुरक्षा की आवश्यकता होती है.

लागत

पानी से भरी बाधाएँ

अधिकांश परियोजनाओं के लिए पानी से भरी बाधाएं ज्यादा खर्च नहीं करती हैं. वे हल्के प्लास्टिक से बने होते हैं, इसलिए उन्हें स्थानांतरित करना सस्ता है. टीमें उन्हें बड़ी मशीनों के बिना ले जा सकती हैं. यह श्रमिकों पर पैसे बचाने में मदद करता है. जब खाली हो, बाधाएं आसानी से ढेर हो जाती हैं. यह स्थान बचाता है और भंडारण लागत में कटौती करता है. साइट पर, कार्यकर्ता उनमें पानी भरते हैं. पानी आसानी से मिल जाता है और ज्यादा खर्च भी नहीं होता.

टिप्पणी: आप अन्य कार्यों के लिए पानी से भरे अवरोधों का दोबारा उपयोग कर सकते हैं. इससे कंपनियों को समय के साथ कम पैसा खर्च करने में मदद मिलती है.

पानी से भरे अवरोधों को ख़रीदने में आमतौर पर कंक्रीट अवरोधों की तुलना में कम लागत आती है. प्लास्टिक में जंग नहीं लगती या वह टूटता नहीं है, इसलिए उन्हें ठीक करना सस्ता है. अगर कोई टूट जाता है, टीमें केवल उस टुकड़े की अदला-बदली कर सकती हैं. इसमें ज्यादा खर्चा नहीं आता. छोटी नौकरियों या बदलने वाली नौकरियों के लिए, पानी से भरी बाधाएं खर्च कम रखने में मदद करती हैं.

कंक्रीट बाधाएँ

कंक्रीट अवरोधों की शुरुआत में लागत अधिक होती है. कंक्रीट सामग्री प्लास्टिक की तुलना में अधिक महंगी है. इन बाधाओं को हटाने के लिए विशेष ट्रकों और उठाने वाले उपकरणों की आवश्यकता होती है. इससे डिलीवरी और सेटअप की लागत अधिक हो जाती है. एक बार सेट अप, कंक्रीट की बाधाएँ यथावत बनी रहती हैं. यह उन नौकरियों के लिए अच्छा है जो लंबे समय तक चलती हैं.

नीचे दी गई तालिका दर्शाती है कि प्रत्येक प्रकार की लागत कितनी है:

| बाधा प्रकार | प्रारंभिक लागत | परिवहन लागत | स्थापना लागत | मेंटेनेन्स कोस्ट |

|---|---|---|---|---|

| पानी से भरी बाधाएँ | कम | कम | कम | कम |

| कंक्रीट बाधाएँ | उच्च | उच्च | उच्च | कम |

ठोस बाधाएं बहुत लंबे समय तक चलती हैं. वे मजबूत हैं, इसलिए आपको उन्हें अक्सर बदलने की आवश्यकता नहीं है. उन नौकरियों के लिए जो आगे नहीं बढ़ेंगी, उच्च कीमत इसके लायक है. ये बाधाएं उन स्थानों के लिए सबसे अच्छी हैं जिन्हें मजबूत और स्थायी सुरक्षा की आवश्यकता है.

बख्शीश: प्रोजेक्ट मैनेजर्स को बाधाओं को चुनते समय अल्पकालिक और दीर्घकालिक लागत दोनों के बारे में सोचना चाहिए.

इंस्टालेशन

पानी से भरी बाधाएँ

पानी से भरी बाधाएं स्थापित करने के लिए सरल हैं. टीमें उन्हें खाली ले जाती हैं, तो वे प्रकाश हैं. श्रमिक फोर्कलिफ्ट का उपयोग करते हैं या उन्हें हाथ से ले जाते हैं. उन्होंने ट्रैफ़िक बाधाओं को रखा जहां उन्हें जरूरत है. इसके बाद, श्रमिक उन्हें पास से पानी से भरते हैं. यह बाधाओं को स्थिर बनाता है और उन्हें जगह में रखता है.

टिप्पणी: खाली बाधाओं को स्थानांतरित करना और बाद में उन्हें भरने से पैसे बचाते हैं. यह टीमों को तेजी से काम करने देता है, विशेष रूप से शहरों या आसानी से पहुंचने वाले स्थानों में.

दूर स्थानों में, सेटिंग कठिन हो सकती है. टीमों को विशेष मिश्रण मशीनों और मजबूत पंपों की आवश्यकता हो सकती है. ये बाधाओं को पानी से भरने में मदद करते हैं. मॉड्यूलर उपकरण और स्किड-माउंटेड गियर विभिन्न स्थानों में मदद करते हैं. कुछ टीमें ऐसी मशीनों का उपयोग करती हैं जो पानी मिलाती हैं और दूर से प्रक्रिया की जांच करती हैं. खराब मौसम या पर्याप्त पानी न होने से काम धीमा हो सकता है. यह बाधाओं को भी कमजोर बना सकता है. पोर्टेबल डिज़ाइन और स्मार्ट सेंसर टीमों को बाधाओं पर नजर रखने और उनकी देखभाल करने में मदद करते हैं.

- टीमें तेजी से पानी से भरे अवरोध स्थापित कर सकती हैं, भले ही चीजें बदल जाएं.

- मॉड्यूलर बाधाओं को हटाना या हटाना आसान है.

- पर्यावरण के बारे में नियम बदल सकते हैं कि टीमें पानी से कैसे छुटकारा पाती हैं या लीक को ठीक करती हैं.

कंक्रीट बाधाएँ

कंक्रीट अवरोधों को स्थापित करना कठिन है. वे बहुत भारी हैं और बड़े ट्रकों और क्रेनों की आवश्यकता है. कार्यकर्ताओं को प्रत्येक बाधा को एक साथ फिट करने के लिए अच्छी योजना बनानी चाहिए. वजन उन्हें तुरंत स्थिर रखता है. यह उन्हें उन नौकरियों के लिए अच्छा बनाता है जो लंबे समय तक चलती हैं या मजबूत सुरक्षा की आवश्यकता होती है.

पानी से भरे लोगों की तुलना में ठोस बाधाओं में डालने में अधिक समय लगता है. टीमों को बड़ी मशीनों और कुशल श्रमिकों का उपयोग करने की आवश्यकता है. एक बार जगह में, ठोस बाधाओं को स्थानांतरित करना मुश्किल है. यह उन्हें उन नौकरियों के लिए सबसे अच्छा बनाता है जो जल्द ही नहीं बदलेंगे या आगे बढ़ेंगे.

- ठोस बाधाएं मजबूत और स्थायी सुरक्षा देती हैं.

- उन्हें स्थापित करने की आवश्यकता है सावधानीपूर्वक योजना और विशेष उपकरण.

- टीमें एक जगह पर रहने वाली नौकरियों के लिए इन बाधाओं का उपयोग करती हैं.

FLEXIBILITY

पानी से भरी बाधाएँ

पानी से भरी बाधाएं उन परियोजनाओं के लिए महान हैं जो बहुत कुछ बदलती हैं. टीमें उन्हें आसानी से स्थानांतरित कर सकती हैं क्योंकि वे खाली होने पर हल्के होते हैं. श्रमिकों को उन्हें ले जाने के लिए बड़ी मशीनों की आवश्यकता नहीं है. यह उन जगहों के लिए अच्छा है जहां लेआउट अक्सर बदलता है. अगर ट्रैफ़िक को स्थानांतरित करने की आवश्यकता है, टीमें बाधाओं को जल्दी से स्थानांतरित कर सकती हैं. मॉड्यूलर डिज़ाइन श्रमिकों को लाइनों या घटता में बाधाओं में शामिल होने देता है. यह उन्हें किसी भी सड़क या घटना के आकार को फिट करने में मदद करता है.

यदि किसी परियोजना को एक नए सेटअप की आवश्यकता है, टीमें ट्रैफिक बाधाओं को अलग कर सकती हैं. वे स्थानांतरित कर सकते हैं और उन्हें थोड़ा प्रयास के साथ फिर से स्थापित कर सकते हैं. यह समय बचाता है और काम में देरी से काम बंद कर देता है. उदाहरण के लिए, रोडवर्क या घटनाओं के दौरान, टीमें नए रास्ते तेजी से बना सकती हैं. बाधाओं को स्टैक किया जा सकता है और जरूरत नहीं होने पर एक छोटी सी जगह में संग्रहीत किया जा सकता है.

टिप्पणी: टीमों को प्रत्येक उपयोग के बाद लीक के लिए नाली और जांच करनी चाहिए. कभी-कभी, उन्हें फिर से बाधाओं का उपयोग करने से पहले लीक को ठीक करने की आवश्यकता है. ये कदम अतिरिक्त समय लेते हैं, लेकिन पानी से भरी बाधाएं अभी भी नौकरियों के लिए सबसे अच्छी हैं जो बहुत कुछ बदलती हैं.

| विशेषता | पानी से भरी बाधाएँ |

|---|---|

| वज़न (खाली) | लाइटवेट |

| इंस्टालेशन | त्वरित और आसान |

| पुनर्विन्यासन | सरल और तेज |

| भंडारण | खाली होने पर कॉम्पैक्ट |

| रखरखाव | ड्रेनिंग और लीक टेस्टिंग |

कंक्रीट बाधाएँ

ठोस बाधाएं पानी से भरी बाधाओं के रूप में लचीली नहीं हैं. वे बहुत भारी हैं, इसलिए टीमों को उन्हें स्थानांतरित करने के लिए क्रेन या ट्रक की आवश्यकता होती है. एक बार जगह पर रख दें, वे आमतौर पर काम पूरा होने तक वहीं रहते हैं. यह उन्हें लंबी नौकरियों या उन जगहों के लिए उपयुक्त बनाता है जहां मजबूत सुरक्षा की आवश्यकता होती है, लेकिन उन साइटों के लिए नहीं जो अक्सर बदलती रहती हैं.

- कंक्रीट की बाधाओं को हटाना कठिन और महंगा है.

- जो परियोजनाएं अक्सर लेआउट बदलती हैं उनमें देरी और लागत अधिक होगी.

- शहरों में, स्थायी बाधाएँ रास्ते में आ सकती हैं या पीछे रह जाने पर ख़राब दिख सकती हैं.

ठोस बाधाएं मजबूत और स्थायी सुरक्षा देती हैं. लेकिन वे उन जगहों के लिए अच्छे नहीं हैं जहां त्वरित बदलाव की आवश्यकता है. टीमों को उन नौकरियों की योजना बनाते समय इस बारे में सोचना चाहिए जिनमें बार-बार बदलाव की आवश्यकता हो सकती है.

सुरक्षा

पानी से भरी बाधाएँ

पानी से भरी बाधाएं लोगों को अल्पकालिक नौकरियों और शहरों में सुरक्षित रखती हैं. उनके पास एक खोखला बीच वाला एक कठोर प्लास्टिक खोल होता है. टीमें साइट पर खोखले हिस्से को पानी से भरती हैं. यह डिज़ाइन हिट को सोखने में मदद करता है और श्रमिकों और ड्राइवरों को सुरक्षित रखता है. यदि एक कार बाधा में टकरा जाती है, अंदर का पानी झटका नरम करता है. यह उन्हें उन जगहों के लिए अच्छा बनाता है जहां कारें धीरे -धीरे चलती हैं.

- ये बाधाएं आसानी से दरार नहीं करती हैं या टूटती नहीं हैं, खराब मौसम में भी.

- प्लास्टिक धूप में फीका नहीं होता है, इसलिए वे उज्ज्वल रहते हैं.

- नारंगी जैसे चमकीले रंग ड्राइवरों को दिन या रात में मदद करते हैं.

यातायात और भीड़ के प्रबंधन के लिए पानी से भरी बाधाएं सबसे अच्छी हैं. उन्हें स्थानांतरित करना आसान है और ज्यादा खर्च नहीं होता है. लेकिन वे बड़े या तेज वाहनों से टकराने पर उतने मजबूत नहीं हैं. कभी-कभी, तेज हवा या भारी कारें उन्हें धक्का दे सकती हैं. उन नौकरियों के लिए जिन्हें अधिक क्रैश प्रोटेक्शन की आवश्यकता है, अंदर एक स्टील फ्रेम की जरूरत है. टीमों को हर किसी को सुरक्षित रखने के लिए प्रत्येक बाधा को सही तरीके से स्थापित करना होगा और शामिल होना चाहिए.

टिप्पणी: नियमों का कहना है कि बाधाओं में स्पष्ट लेबल होना चाहिए. यह लोगों को यह जानने में मदद करता है कि क्या वे यातायात का मार्गदर्शन करने या क्रैश को रोकने के लिए हैं.

कंक्रीट बाधाएँ

कारों को रोकने और लंबे समय तक लोगों को सुरक्षित रखने के लिए ठोस बाधाएं सबसे अच्छी हैं. वे भारी और ठोस हैं, इसलिए वे जोखिम भरे या तेज स्थानों में अच्छी तरह से रक्षा करते हैं. ये सड़क बाधाएं कारों को एक दुर्घटना में दूर धकेलती हैं और श्रमिकों और ड्राइवरों को सुरक्षित रखते हैं. वे ज्यादा नहीं चलते हैं, यहां तक कि अगर मुश्किल से या खराब मौसम में मारा जाता है.

- ठोस बाधाएं कई वर्षों तक रहती हैं और थोड़ी देखभाल की आवश्यकता होती है.

- वे कई हिट ले सकते हैं और तेजी से बाहर नहीं पहन सकते हैं.

- उनका कठिन निर्माण सुरक्षित क्षेत्रों में कारों को रखता है.

परीक्षण दिखाते हैं कि ठोस बाधाएं तेजी से दुर्घटनाओं में सबसे अच्छी रक्षा करती हैं. वे ज्यादा नहीं झुकते हैं और अधिक सुरक्षा के लिए जमीन पर तय किए जा सकते हैं. इसका मतलब है कि वे दुर्घटना में नहीं चलते हैं, जो कम बीमा लागत में मदद कर सकता है. सड़कों के लिए ठोस बाधाएं महान हैं, राजमार्ग, और उन स्थानों को जिनकी सबसे अधिक सुरक्षा की आवश्यकता है.

| पहलू | पानी से भरी बाधाएँ (एचडीपीई) | कंक्रीट बाधाएँ |

|---|---|---|

| प्रभाव प्रदर्शन | हिट्स को सोखता है, लोगों के लिए सुरक्षित | कारों को दूर धकेलता है, दुर्घटनाओं में मजबूत |

| मौसम प्रतिरोधक | फीका नहीं है, मजबूत रहता है | सतह बाहर पहन सकती है, पेंट कैन चिप |

| स्थिरता | तेज हवा या बड़ी हिट में गिर सकते हैं | भारी, जगह में रहता है |

| जीवनकाल | अक्सर स्थानांतरित करने के लिए बनाया गया, सख्त प्लास्टिक | तक चलता है, ज्यादा फिक्सिंग की जरूरत नहीं है |

परियोजना प्रकार

शहरी परियोजनाएं

शहरी बिल्डिंग साइटों को उन बाधाओं की आवश्यकता होती है जो उपयोग करने में आसान और सुरक्षित हों. शहरों में पानी से भरी बाधाएं अच्छी तरह से काम करती हैं. आप उन्हें रोडवर्क में देखते हैं, उचीं इमारतें, और धीमी या कम यातायात के साथ स्थान. ये बाधाएं प्रकाश हैं, इसलिए टीमें उन्हें तेजी से आगे बढ़ा सकती हैं. कार्य क्षेत्र बदलने पर श्रमिक उन्हें स्थानांतरित कर सकते हैं. वे हिट्स को भिगोते हैं, जो श्रमिकों को रखने में मदद करता है, वॉकर, और ड्राइवर सुरक्षित.

- पानी से भरी बाधाएं कारों और लोगों को दिखाती हैं जहां इमारत या घटनाओं के दौरान जाना है.

- उनका डिजाइन टीमों को कई आकार और आकार बनाने देता है.

- चमकीले रंग सभी को व्यस्त सड़कों पर उन्हें देखने में मदद करते हैं.

- टीमें सुरक्षित रास्ते बनाने और खतरे को रोकने के लिए बाड़ लगाने को जोड़ सकती हैं.

पानी से भरे बैरियर शहर के सुरक्षा नियमों का पालन करते हैं. इनकी कीमत ज्यादा नहीं है और ये ग्रह के लिए अच्छे हैं. वे शहरी नौकरियों के लिए बहुत अच्छे हैं जो बहुत कुछ बदलती हैं. कई बिल्डर इन कारणों से उनका उपयोग करना पसंद करते हैं.

राजमार्ग प्रोजेक्ट्स

राजमार्गों को अवरोधों की आवश्यकता है जो मजबूत होते हैं और लंबे समय तक चलते हैं. तेज़ सड़कों पर कंक्रीट अवरोधकों का उपयोग किया जाता है. वे कई वर्षों तक रक्षा करते हैं और कई मार झेल सकते हैं. टीमें उन्हें चुनती हैं क्योंकि वे कारों को सुरक्षित लेन में रखते हैं और उन्हें वहां जाने से रोकते हैं जहां उन्हें नहीं जाना चाहिए.

राजमार्गों की योजना बनाते समय, टीमें सोचती हैं:

- कितनी गाड़ियाँ सड़क का उपयोग करती हैं और कितनी तेज़ चलती हैं.

- यह सुनिश्चित करना कि बैरियर सुरक्षा नियमों का पालन करें.

- अवरोधों को सही स्थान पर लगाना और उन्हें स्थिर बनाना.

- ऐसी सामग्री चुनना जिसमें जंग न लगे या खराब मौसम में टूट न जाए.

टीमें अच्छी तरह से काम करने के लिए बाधाओं की जाँच करती हैं और उन्हें ठीक करती हैं. समान भागों का उपयोग करना फिक्सिंग आसान बनाता है. कंक्रीट रोड बैरियर उन सड़कों के लिए सबसे अच्छा है जिन्हें लंबे समय तक सुरक्षित रहने की जरूरत है. कभी-कभी, यदि टीमों को अधिक विकल्पों की आवश्यकता होती है, तो स्टील की बाधाओं का भी उपयोग किया जाता है.

आपात क्षेत्र

आपातकालीन क्षेत्रों को बाधाओं की आवश्यकता होती है यह त्वरित और उपयोग करने में आसान है. इन नौकरियों के लिए पानी से भरी बाधाएं सबसे अच्छी हैं. टीमें उन्हें तेजी से ला सकती हैं और उन्हें साइट पर पानी से भर सकती हैं. क्योंकि वे प्रकाश हैं, छोटे समूह उन्हें सड़क ब्लॉकों या भीड़ नियंत्रण के लिए स्थापित कर सकते हैं.

उसके बाद, टीमों ने पानी को खाली कर दिया और अगली बार बाधाओं को संग्रहीत किया. यह उन्हें उन नौकरियों के लिए अच्छा बनाता है जो लंबे समय तक नहीं रहती हैं. ठोस बाधाओं को बड़ी मशीनों की आवश्यकता होती है और उन्हें डालने में अधिक समय लगता है. वे उन नौकरियों के लिए बेहतर हैं जो स्थानांतरित नहीं करते हैं या बदलते हैं.

बख्शीश: अगर चीजें आपात स्थिति में तेजी से बदलती हैं, पानी से भरी बाधाएं गति के लिए सबसे अच्छे हैं, आसान उपयोग, और सुरक्षा.

तुलना

सही सड़क अवरोध को चुनने का मतलब है कि हर एक कैसे काम करता है. नीचे दी गई तालिका में पानी से भरी बाधाओं और ठोस बाधाओं को दिखाया गया है:

| पहलू | पानी से भरी बाधाएँ | कंक्रीट बाधाएँ |

|---|---|---|

| लागत | सस्ता, पैसे बचाता है, लंबे समय तक रहता है | अधिक लागत, सेट अप करने और ठीक करने के लिए अधिक पैसे की जरूरत है |

| स्थापना काल | तेज और सरल में डालने के लिए, खाली होने पर प्रकाश | अधिक समय लगता है, अधिक लोगों और बड़ी मशीनों की जरूरत है |

| FLEXIBILITY | स्थानांतरित करने के लिए बहुत आसान है, परिवर्तन, और स्टोर | भारी, स्थानांतरित करना या स्टोर करना मुश्किल है, आकार नहीं बदल सकता |

| सुरक्षा | हिट्स को सोखता है, चोटों और मौतों को रोकने में मदद करता है | कठोर और मजबूत, झुकता नहीं है, कम झटका अवशोषण |

| पर्यावरण | कठिन, फिर से उपयोग कर सकते हैं, रीसायकल कर सकते हैं, प्रकृति के लिए अच्छा है | समय के साथ कमजोर हो जाता है, रीसायकल नहीं कर सकते |

पानी से भरी बाधाएं हल्की और सरल हैं जो स्थापित करने के लिए सरल हैं. टीमें उन्हें खाली ले जा सकती हैं और उन्हें साइट पर पानी से भर सकती हैं. यह समय बचाता है और इसका मतलब है कि कम श्रमिकों की आवश्यकता होती है. इन बाधाओं को स्थानांतरित करना और बदलना आसान है, इसलिए वे नौकरियों के लिए अच्छे हैं जो बहुत कुछ बदलते हैं. वे हिट्स को भिगोते हैं, जो लोगों को सुरक्षित रखने में मदद करता है. निर्माताओं ने उन्हें हिट लेने में मजबूत और बेहतर बनाया है, इसलिए वे छोटी नौकरियों के लिए अच्छा काम करते हैं.

ठोस बाधाएं बहुत मजबूत होती हैं और लंबे समय तक रहती हैं. वे राजमार्गों जैसी जगहों के लिए सबसे अच्छे हैं जिन्हें मजबूत सुरक्षा की आवश्यकता है. उन्हें बड़ी मशीनों और कुशल श्रमिकों की जरूरतों में डाल दिया, इसलिए इसमें अधिक समय और पैसा लगता है. एक बार सेट अप, वे मजबूत सुरक्षा देते हैं और अक्सर बदलने की आवश्यकता नहीं होती है. लेकिन वे कठिन हैं और अच्छी तरह से हिट नहीं सोखते हैं, इसलिए ड्राइवरों के लिए दुर्घटनाएं बदतर हो सकती हैं.

छोटी नौकरियों के लिए, इवेंट्स, या जो स्थान बदलते हैं, पानी से भरी बाधाओं को स्थानांतरित करने और सुरक्षित होने के लिए सबसे अच्छा है. उन नौकरियों के लिए जो लंबे समय तक या तेज सड़कों पर चलती हैं, ठोस बाधाएं मजबूत सुरक्षा की आवश्यकता देती हैं.

मामले का अध्ययन

सिडनी रोडवर्क्स

सिडनी का बड़ा रोडवर्क अक्सर यातायात के प्रबंधन के लिए तेज और सुरक्षित तरीकों की आवश्यकता होती है. परियोजना प्रबंधकों ने पानी से भरी बाधाओं को उठाया क्योंकि उन्हें स्थानांतरित करना और सेट करना आसान है. टीमों ने बाधाओं को साइट पर लाया और उन्हें पानी से भर दिया. इसने इसे शुरू करने के लिए जल्दी कर दिया. परियोजनाओं को कुछ समस्याएं थीं:

- आपूर्ति श्रृंखला की समस्याओं ने सामग्री प्राप्त करना कठिन बना दिया.

- शिपिंग में अधिक समय लगता है और अधिक पैसा खर्च होता है.

- कई आपूर्तिकर्ता नौकरी चाहते थे, इसलिए कीमतें बढ़ गईं.

- सुरक्षा और पर्यावरणीय नियमों का मतलब था कि अधिक योजना की आवश्यकता थी.

- जब ज्यादा पानी नहीं था, टीमों ने कभी -कभी रेत या जेल का इस्तेमाल किया.

इन समस्याओं के साथ भी, बाधाओं ने श्रमिकों और ड्राइवरों को सुरक्षित रखा. मॉड्यूलर डिज़ाइन टीमों को लेआउट को बदलने देता है जब परियोजना बदल जाती है.

मेलबोर्न मैराथन

मेलबर्न मैराथन हर साल कई धावक और लोगों को देखने के लिए लाता है. आयोजकों को उन बाधाओं की आवश्यकता थी जिन्हें तेजी से स्थापित किया जा सके और आसानी से स्थानांतरित किया जा सके. इस कार्यक्रम के लिए पानी से भरी बाधाओं ने अच्छा काम किया. टीमों ने धावकों को कारों और भीड़ से दूर रखने के लिए दौड़ के रास्ते पर बाधाओं को रखा. चमकीले रंगों ने उन्हें देखने में आसान बना दिया, जिसने सभी को सुरक्षित रखने में मदद की.

दौड़ के बाद, टीमों ने बाधाओं को खाली कर दिया और अगली बार उन्हें दूर कर दिया. इसने समय और पैसा बचाया. बाधाओं ने चलने वाले लोगों के लिए सुरक्षित रास्ते भी बनाए और कर्मचारियों को जल्दी से आपात स्थिति में पहुंचने दिया.

तटीय राजमार्ग

क्वींसलैंड में तट के पास एक राजमार्ग परियोजना खराब मौसम और नमकीन हवा थी. प्रोजेक्ट लीडर्स ने पानी से भरी बाधाओं को चुना क्योंकि वे जंग नहीं लगाते हैं और उन्हें स्थानांतरित करना आसान है. बदलते मौसम में यातायात बाधाओं ने अच्छा काम किया. जरूरत पड़ने पर टीमों ने लेआउट बदल दिया, इसलिए ट्रैफ़िक आगे बढ़ता रहा और श्रमिक सुरक्षित रहे.

टिप्पणी: पानी से भरी बाधाएं उन परियोजनाओं के लिए एक अच्छा विकल्प थीं जिन्हें अक्सर बदलने की आवश्यकता होती थी और कठिन मौसम में स्पष्ट रूप से देखा जा सकता था.

नीचे दी गई तालिका दर्शाती है कि प्रत्येक अवरोध प्रकार किसमें अच्छा और बुरा है:

| पहलू | पानी से भरी बाधाएँ | कंक्रीट बाधाएँ |

|---|---|---|

| लाभ | लाइटवेट, पोर्टेबल, प्रभावी लागत | मज़बूत, टिकाऊ, स्थिर |

| नुकसान | कम प्रभाव प्रतिरोध, कम स्थिर | भारी, उच्च लागत, परिवहन चुनौतियाँ |

परियोजना प्रबंधकों को यह सोचने की ज़रूरत है कि कितनी कारें सड़क का उपयोग करती हैं. उन्हें यह भी देखना चाहिए कि नौकरी कितने समय तक चलेगी. अवरोध चुनते समय मौसम और क्षेत्र भी मायने रखते हैं. बाधाओं की जाँच करने से अक्सर सभी को सुरक्षित रखने में मदद मिलती है. यदि आवश्यक हो तो टीमों को बाधाओं को ठीक करना चाहिए या हटाना चाहिए. अगर काम पेचीदा है, किसी आपूर्तिकर्ता या विशेषज्ञ से मदद माँगना समझदारी है. यह सुनिश्चित करता है कि परियोजना अच्छी तरह से चले.

अक्सर पूछे जाने वाले प्रश्न

पानी से भरे और कंक्रीट अवरोधों के बीच मुख्य अंतर क्या है??

पानी से भरे अवरोध प्लास्टिक से बनाए जाते हैं और पानी से भरे होते हैं. कंक्रीट अवरोध ठोस कंक्रीट से बनाए जाते हैं. पानी से भरी बाधाएं छोटी नौकरियों के लिए या जब चीजें बदलती हैं. कंक्रीट की बाधाएं लंबी नौकरियों या उन स्थानों के लिए बेहतर हैं जिन्हें मजबूत सुरक्षा की आवश्यकता है.

क्या टीमें विभिन्न परियोजनाओं के लिए पानी से भरी बाधाओं का पुन: उपयोग कर सकती हैं?

हाँ, टीमें फिर से पानी से भरी बाधाओं का उपयोग कर सकती हैं. वे पानी को खाली करते हैं और बाधाओं को एक नई जगह पर ले जाते हैं. तब, वे उन्हें फिर से भरते हैं. यह भंडारण के लिए पैसे और स्थान बचाने में मदद करता है.

उच्च गति वाली सड़कों के लिए पानी से भरी बाधाएं सुरक्षित हैं?

पानी से भरी बाधाएं धीमी सड़कों या छोटी नौकरियों के लिए अच्छी हैं. वे इन स्थानों पर लोगों को सुरक्षित रखने में मदद करते हैं. तेजी से सड़कों पर, ठोस बाधाएं सुरक्षित और मजबूत होती हैं. वे बेहतर रक्षा करते हैं अगर कारें उनमें दुर्घटनाग्रस्त हो जाती हैं.

टीमें पानी से भरी बाधाओं को कैसे स्थापित करती हैं?

टीम खाली होने पर साइट पर पानी से भरी बाधाओं को लाती है. उन्होंने उन्हें वहां रखा जहां उन्हें जरूरत है. तब, वे उन्हें पानी से भरते हैं. यह तेज और सरल स्थापित करता है.