गोदाम लोगों और फोर्कलिफ्ट चालकों के लिए खतरनाक हो सकते हैं. प्रत्येक वर्ष, इन वातावरणों में कई व्यक्ति घायल हो जाते हैं या मर जाते हैं. सर्वाधिक समय, लोग और फोर्कलिफ्ट एक दूसरे से टकराते हैं. नीचे दी गई तालिका इन दुर्घटनाओं के बारे में कुछ संख्याएँ दर्शाती है:

| सांख्यिकीय विवरण | कीमत |

|---|---|

| यू.एस. में अनुमानित वार्षिक फोर्कलिफ्ट-संबंधी चोटें. | 35,000 – 62,000 |

| गंभीर चोटें (भंग, कुचलने वाली चोटें, स्थायी क्षति) | 34,900 |

| वार्षिक विश्वव्यापी फोर्कलिफ्ट चोटें | 96,700 |

| अमेरिका में औसत वार्षिक फोर्कलिफ्ट से संबंधित मौतें. | 87 |

| पैदल यात्रियों से जुड़ी फोर्कलिफ्ट दुर्घटनाओं का प्रतिशत | 20% |

| फोर्कलिफ्ट से संबंधित मौतों का प्रतिशत जो पैदल चलने वालों की है | 36% |

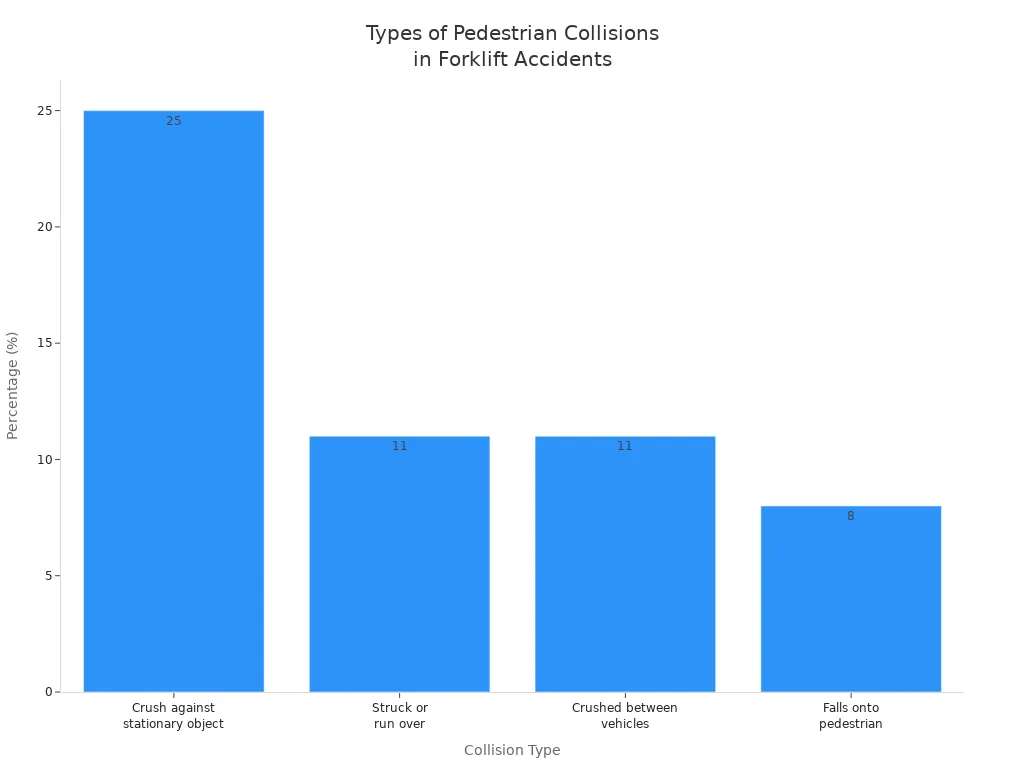

| पैदल यात्रियों की टक्कर के प्रकार: स्थिर वस्तु से कुचलना | 25% |

| पैदल यात्रियों की टक्कर के प्रकार: मारा गया या कुचल दिया गया | 11% |

| पैदल यात्रियों की टक्कर के प्रकार: गाड़ियों के बीच कुचला गया | 11% |

| पैदल यात्रियों की टक्कर के प्रकार: पैदल यात्री पर गिर जाता है | 8% |

गोदाम के वातावरण में सुरक्षा संकेत, फुटपाथ चिह्नों के साथ, इन दुर्घटनाओं को रोकने में मदद करें. वे संभावित खतरों के बारे में स्पष्ट निर्देश और चेतावनियाँ प्रदान करते हैं. ये उपकरण यह सुनिश्चित करने के लिए आवश्यक हैं कि काम के दौरान हर कोई सुरक्षित रहे.

पर ऑप्टट्रैफ़िक, हम विविध प्रकार की पेशकश करते हैं सुरक्षा संकेत विशेष रूप से गोदाम वातावरण के लिए डिज़ाइन किया गया. हमारे उत्पादों में चेतावनी संकेत और दिशात्मक संकेत शामिल हैं, सभी को सुरक्षा मानकों को पूरा करने और दृश्यता बढ़ाने के लिए तैयार किया गया है. इन संकेतों को अपने गोदाम में एकीकृत करके, आप अधिक सुरक्षित सुनिश्चित कर सकते हैं, अधिक कुशल कार्य वातावरण. आज ही गोदाम सुरक्षा संकेतों की हमारी पूरी श्रृंखला देखें!

चाबी छीनना

- फुटपाथ चिह्न और साइनेज गोदामों में दुर्घटनाओं को रोकने में मदद करते हैं. वे पैदल चलने वालों और फोर्कलिफ्ट चालकों को बताते हैं कि कहाँ जाना है. इससे दुर्घटनाओं की संभावना कम हो जाती है.

- फर्श पर निशान लगाने के लिए आसानी से दिखने वाले रंगों का उपयोग करें. पीला रास्ता दिखाता है. लाल का अर्थ है खतरे वाले क्षेत्र. हरा रंग सुरक्षा उपकरण स्थलों की ओर इंगित करता है. इससे यह स्पष्ट हो जाता है कि लोगों को कहां जाना चाहिए.

- फर्श के चिह्नों और चिह्नों की अक्सर जाँच करें. यदि वे फीके पड़ जाएं या टूट जाएं तो उन्हें ठीक कराएं. उन्हें देखना आसान रखने से कर्मचारियों को सुरक्षित रखने में मदद मिलती है और गलतियाँ रुकती हैं.

- सभी श्रमिकों को सिखाएं कि संकेतों और चिह्नों का क्या मतलब है. अच्छा प्रशिक्षण श्रमिकों को खतरों को पहचानने में मदद करता है. इससे उन्हें सुरक्षा नियमों का पालन करने में भी मदद मिलती है.

- सर्वोत्तम सुरक्षा के लिए साइनेज और फर्श चिह्नों दोनों का एक साथ उपयोग करें. एक स्मार्ट सिस्टम हर किसी को गोदाम के चारों ओर सुरक्षित और तेज़ी से घूमने में मदद करता है.

गोदाम सुरक्षा के लिए फुटपाथ चिह्न और साइनेज दोनों क्यों आवश्यक हैं?

गोदाम के वातावरण में सुरक्षा संकेत की भूमिका को समझना

गोदामों में सुरक्षा चिन्ह बहुत महत्वपूर्ण हैं. वे लोगों को ख़तरे देखने और नियमों का पालन करने में मदद करते हैं. ये संकेत यह भी बताते हैं कि आपात स्थिति में कहां जाना है. ओएसएचए का कहना है कि संकेतों में स्पष्ट रंग होने चाहिए और देखने में आसान होने चाहिए. ये तीन मुख्य प्रकार हैं: खतरा, चेतावनी, और सावधानी. प्रत्येक प्रकार का अपना रंग और आकार होता है. इससे श्रमिकों को यह जानने में मदद मिलती है कि कोई चीज़ कितनी जोखिम भरी है.

गोदाम सुरक्षा संकेत दुर्घटनाओं को रोकने और चीज़ों को साफ-सुथरा रखने में मदद करते हैं. जब श्रमिक लक्षण देखते हैं तो वे सुरक्षित महसूस करते हैं. वे जानते हैं कि गोदाम के प्रत्येक भाग में क्या करना है.

नीचे दी गई तालिका विभिन्न संकेतों और वे क्या करते हैं, को सूचीबद्ध करती है:

| संकेत का प्रकार | समारोह |

|---|---|

| ख़तरे की चेतावनी के संकेत | गीले फर्श या बिजली के तार जैसे खतरे दिखाएं. |

| सामग्री प्रबंधन संकेत | बताएं कि चीज़ों को सुरक्षित रूप से कैसे ले जाएं और संग्रहीत करें. |

| अग्नि सुरक्षा संकेत | दिखाएँ कि अग्नि निकास और अग्नि उपकरण कहाँ हैं. |

| पीपीई संकेत | श्रमिकों को सुरक्षा गियर पहनने की याद दिलाएँ. |

| यातायात संकेत | दुर्घटनाओं को रोकने के लिए पैदल पथ और ड्राइविंग लेन चिह्नित करें. |

| सुरक्षा अनुस्मारक संकेत | श्रमिकों को सुरक्षा नियमों के बारे में याद दिलाएँ. |

| सुरक्षा प्रोटोकॉल संकेत | कर्मचारियों को कंपनी के सुरक्षा नियमों के बारे में बताएं. |

पूरे गोदाम में सावधानी के संकेत लगे हुए हैं. वे खतरे वाले स्थानों के बारे में चेतावनी देते हैं और श्रमिकों को सावधान रहने की याद दिलाते हैं.

सुरक्षित संचालन के लिए फ़्लोर मार्किंग का महत्व

फ़्लोर मार्किंग से लोगों को गोदाम में सुरक्षित रूप से चलने और गाड़ी चलाने में मदद मिलती है. यह दिखाने के लिए कि कहाँ जाना है, यह चमकीले रंगों और रेखाओं का उपयोग करता है. पीला रंग पथों और गलियारों को चिह्नित करता है. लाल खतरे वाले क्षेत्रों को दर्शाता है. हरा दिखाता है कि सुरक्षा उपकरण कहाँ हैं. उपकरण लगाने के स्थान पर नीले निशान. नारंगी और सफेद रंग सूची को क्रमबद्ध करने और दिशा-निर्देश देने में मदद करते हैं. काली और पीली धारियों का मतलब है कि आपको अतिरिक्त सावधान रहने की जरूरत है.

| रंग अंकित करना | उद्देश्य | विवरण |

|---|---|---|

| पीला | गलियारे और रास्ते | दिखाता है कि कहाँ चलना है या गाड़ी चलानी है, ताकि लोग दुर्घटनाग्रस्त न हों. |

| लाल | खतरनाक क्षेत्र | ख़तरे वाले स्थानों को चिह्नित करता है और कर्मचारियों को सावधान रहने को कहता है. |

| हरा | सुरक्षा उपकरण | दिखाता है कि आपात्कालीन स्थिति के लिए सुरक्षा उपकरण कहाँ हैं. |

| नीला | उपकरण भंडारण | उपकरण कहाँ रखना है यह चिन्हित करता है, ताकि चीजें साफ-सुथरी रहें. |

| नारंगी | इन्वेंटरी भंडारण | दिखाता है कि इन्वेंट्री कहां रखनी है, इसे ढूंढना आसान हो गया है. |

| सफ़ेद | सामान्य अनुदेश | कार्य क्षेत्रों को चिह्नित करना और कार्यों के लिए निर्देश देना. |

| काला पीला | सावधानी क्षेत्र | उन स्थानों को दिखाता है जहां आपको अतिरिक्त सावधानी बरतनी चाहिए. |

फ़्लोर मार्किंग ट्रैफ़िक लेन और केवल पैदल चलने वाले क्षेत्रों को दिखाती है. यह खतरे वाले स्थानों को भी चिन्हित करता है. सावधानी के संकेत और फर्श के निशान सभी का मार्गदर्शन करने के लिए मिलकर काम करते हैं. एक गोदाम में मजबूत फर्श चिह्नों का उपयोग किया गया और कम दुर्घटनाएँ देखी गईं. गोदाम सुरक्षा संकेत और फर्श चिह्न दोनों ही लोगों को सुरक्षित रखने और काम को अच्छी तरह से चलाने में मदद करते हैं.

गोदाम में फोर्कलिफ्ट सुरक्षा

पैदल चलने वालों को फोर्कलिफ्ट आंदोलन से बचाना

व्यस्त गोदामों में फोर्कलिफ्ट सुरक्षा बहुत महत्वपूर्ण है. जब फोर्कलिफ्ट लोगों के करीब आ जाती है तो कई दुर्घटनाएँ होती हैं. गोदाम लोगों को सुरक्षित रखने के लिए विभिन्न तरीकों का उपयोग करते हैं. चमकीले फर्श के निशान और संकेत दिखाते हैं कि फोर्कलिफ्ट कहाँ जाते हैं. वे यह भी दिखाते हैं कि केवल लोग कहाँ चल सकते हैं. ये निशान हर किसी को यह जानने में मदद करते हैं कि कहाँ चलना है और कहाँ दूर रहना है. Warehouses put up flashing lights and alarms in busy areas. These signals warn both drivers and people about danger.

वास्तविक बाधाएं like guardrails and bollards keep forklifts away from people. This helps protect people from moving machines. Some warehouses use gates that slow people down before they cross busy paths. Technology helps make forklift safety better too. Proximity sensors and special devices warn workers if they enter forklift zones. Automatic brakes can stop forklifts if a person is close. All these tools work together to keep everyone safe.

बख्शीश: Warehouses with both barriers and technology have fewer accidents between forklifts and people.

Preventing Forklift and Pedestrian Collisions

Forklifts and people sometimes crash because of bad warehouse design or unsafe actions. नीचे दी गई तालिका फोर्कलिफ्ट दुर्घटनाओं के सामान्य कारणों को सूचीबद्ध करती है:

| दुर्घटना का कारण | विवरण |

|---|---|

| टिप-ओवर | बहुत अधिक भार वाली लिफ्टें गिर सकती हैं और लोगों को चोट पहुँचा सकती हैं. |

| दुर्घटनाओं से त्रस्त | फोर्कलिफ्ट चीज़ों से टकरा सकते हैं या सामान गिरा सकते हैं, चोट पहुँचाना. |

| ऊंचाई से गिरता है | श्रमिक ऊंचे स्थानों तक पहुंचने और गिरने के लिए लिफ्ट का उपयोग कर सकते हैं. |

| पैदल यात्री दुर्घटनाएँ | फोर्कलिफ्ट लोगों को मार सकती है और बुरी तरह घायल कर सकती है. |

सुरक्षा कदमों का पालन करके गोदाम इन दुर्घटनाओं को रोक सकते हैं:

- सभी फोर्कलिफ्ट ड्राइवरों को प्रशिक्षित करें और प्रमाणित करें.

- समस्याओं का शीघ्र पता लगाने के लिए प्रतिदिन उपकरण की जाँच करें.

- फोर्कलिफ्टों को स्थिर रखने के लिए सुरक्षित रूप से लोड और अनलोड करें.

- धीरे-धीरे गाड़ी चलाएँ और हमेशा लोगों को पहले जाने दें.

- हर दिन सुरक्षा नियमों का अभ्यास करें.

केवल चलने योग्य क्षेत्रों को स्पष्ट बनाना और एआई विज़न या सेंसर जैसी तकनीक का उपयोग करने से दुर्घटनाओं को रोकने में मदद मिलती है. ये सिस्टम ड्राइवरों और लोगों को खतरे के बारे में चेतावनी देते हैं, यहां तक कि देखने में मुश्किल जगहों पर भी. अच्छा गोदाम डिजाइन, नियमित प्रशिक्षण, और मजबूत सुरक्षा नियम काम पर सभी को सुरक्षित रखने में मदद करते हैं.

गोदाम सुरक्षा के लिए प्रभावी फ़्लोर मार्किंग रणनीतियाँ

सुरक्षित आवाजाही पथों के लिए कलर कोडिंग का उपयोग करना

फ्लोर मार्किंग के लिए कलर कोडिंग बहुत महत्वपूर्ण है. कहाँ जाना है यह जानने के लिए श्रमिक और फोर्कलिफ्ट चालक चमकीले रंगों का उपयोग करते हैं. पीला रंग यातायात मार्गों और गलियारों को दर्शाता है. लाल का अर्थ है खतरा या खतरनाक मशीनों के पास रुकना. हरा रंग सुरक्षित स्थानों या आपातकालीन निकास को दर्शाता है. लोगों और सुरक्षा उपकरणों के लिए नीले निशान वाले रास्ते. काली और पीली धारियाँ खतरों की चेतावनी देती हैं. सफ़ेद रंग सामान्य नियम देता है और सीमाएँ चिह्नित करता है. ये रंग सभी को सुरक्षा नियमों का पालन करने और दुर्घटनाओं से बचने में मदद करते हैं.

| रंग कोड | महत्व |

|---|---|

| पीला | गलियारे के रास्ते के लिए उपयोग किया जाता है, कार्य कोशिकाएं, और यातायात लेन. |

| सफ़ेद | ऐसे उपकरण और फिक्स्चर को चिह्नित करना जो अन्यथा रंग कोडित न हों. |

| लाल | दोषपूर्ण उपकरण को इंगित करता है, स्क्रैप, पुनः कार्य करना, और अधिक. |

| नारंगी | निरीक्षण के लिए रखी जाने वाली सामग्रियों या उत्पादों को दर्शाता है. |

| नीला, हरा, काला | कच्चे माल सहित सामग्रियों का प्रतिनिधित्व करता है, कार्य प्रगति पर है, या तैयार माल. |

| लाल और सफेद धारियाँ | उन क्षेत्रों को चिह्नित करता है जो सुरक्षा और अनुपालन के लिए स्पष्ट रहना चाहिए. |

| काली और सफ़ेद धारियाँ | परिचालन उद्देश्यों के लिए एक क्षेत्र को साफ़ रखता है. |

| काली और पीली धारियाँ | श्रमिकों के लिए शारीरिक या स्वास्थ्य खतरे या खतरे का संकेत देता है. |

अच्छा फ़्लोर मार्किंग लोगों का मार्गदर्शन करने के लिए इन रंगों का उपयोग करता है. यह ट्रैफिक लेन को खुला और देखने में आसान रखता है. यह प्रणाली भ्रम को रोकने में मदद करती है और सभी को सुरक्षित रखती है.

उचित फ़्लोर मार्किंग प्लेसमेंट के लिए सर्वोत्तम अभ्यास

फर्श पर निशान सही स्थानों पर लगाने से चीज़ें सुरक्षित हो जाती हैं. प्रबंधक गोदाम के लेआउट और लोगों की आवाजाही के तरीके को देखते हैं. वे योजना बनाते हैं कि कहां लेन बनाई जाए, रास्तों, और डेंजर ज़ोन. कार्यकर्ता और अन्य कर्मचारी योजना को बेहतर बनाने में मदद करते हैं. मजबूत सामग्रियों का उपयोग करने से निशान लंबे समय तक टिके रहते हैं. निर्देशों का पालन करते हुए कार्यकर्ता निशान लगाते हैं. प्रशिक्षण हर किसी को सिखाता है कि चिह्नों का क्या मतलब है.

बख्शीश: चौड़ी रेखाओं का प्रयोग करें, लगभग 50 मिमी से 100 मिमी, ताकि लोग व्यस्त इलाकों में उन्हें देख सकें.

प्रबंधक OSHA जैसे नियमों का पालन करते हैं 29 सीएफआर 1910.22. यह नियम कहता है कि गलियारे स्पष्ट और देखने में आसान होने चाहिए. पीली रेखाएं बताती हैं कि खतरा कहां है. चिह्नों की जाँच करने से सिस्टम अक्सर अच्छी तरह से काम करता रहता है. एक अच्छी फ़्लोर मार्किंग प्रणाली यह सुनिश्चित करती है कि सुरक्षा क्षेत्र और लेन हमेशा देखने में आसान हों.

फर्श चिह्नों का निरंतर रखरखाव सुनिश्चित करना

गोदाम के फर्श के संकेतों का ध्यान रखने से गोदाम सुरक्षित रहता है. कार्यकर्ता अक्सर चिह्नों की जांच करते हैं और फीके धब्बों को तेजी से ठीक करते हैं. नियमित 5एस जांच से समस्याओं का शीघ्र पता लगाने में मदद मिलती है. निशानों को साफ करने से उन्हें चमकदार बने रहने और देखने में आसान रहने में मदद मिलती है. व्यस्त क्षेत्रों में, कर्मचारी लाइनों को दोबारा रंगते हैं ताकि वे फीकी न पड़ें. विशेष कोटिंग से निशान लंबे समय तक टिके रहते हैं.

अगर आप मार्किंग का ध्यान नहीं रखते हैं, वे फीके पड़ जाते हैं और भ्रम पैदा करते हैं. लोगों को यह नहीं पता होगा कि कहां चलना है या गाड़ी चलानी है, जो दुर्घटनाओं का कारण बन सकता है. स्पष्ट निशान बताते हैं कि कहां जाना है और चीजों को अच्छी तरह से चलाना है. जब कार्यकर्ता निशानों को स्पष्ट रखने में मदद करते हैं, सुरक्षा और दृश्यता हर दिन बेहतर होती जा रही है.

टिप्पणी: फर्श के चिह्नों को अद्यतन करने से अक्सर चोटों को रोकने में मदद मिलती है और काम में तेजी आती है.

गोदाम सुरक्षा के लिए सर्वोत्तम अभ्यास

सुरक्षा को अधिकतम करने के लिए साइनेज और फर्श चिह्नों को एकीकृत करना

वेयरहाउस प्रबंधक साइनेज और फर्श चिह्नों दोनों का उपयोग करके फोर्कलिफ्ट सुरक्षा को बेहतर बना सकते हैं. इससे हर किसी को यह जानने में मदद मिलती है कि कहां चलना है, गाड़ी चलाना, या रुकें. एक अच्छी योजना खतरों का पता लगाने और यह देखने से शुरू होती है कि काम कैसे किया जाता है. प्रबंधकों को चाहिए:

- पहले से योजना बनाएं और व्यस्त क्षेत्रों में जोखिमों पर ध्यान दें.

- ऐसी मजबूत सामग्रियाँ चुनें जो चमकदार रहें और देखने में आसान हों.

- सतहें तैयार करें और कर्मचारियों को नई प्रणाली के बारे में सिखाएं.

- नियमित जांच के साथ चीजों को साफ-सुथरा रखें.

ओएसएचए का कहना है कि गलियारे और पैदल मार्ग स्पष्ट और चिह्नित होने चाहिए. आपातकालीन निकासों के लिए संकेत और रोशनी की आवश्यकता होती है.

केस अध्ययनों से पता चलता है कि योजना बनाने और संकेत और लेबल लगाने से काम तेजी से आगे बढ़ने में मदद मिलती है. उदाहरण के लिए, लास वेगास के एक गोदाम ने अपना साइन प्रोजेक्ट जल्दी पूरा कर लिया. इससे श्रमिकों को तेजी से स्थान ढूंढने में मदद मिली और गलतियाँ कम हुईं. एक अन्य केंद्र ने फर्श के चिह्नों को अद्यतन किया और देखा कि काम बेहतर हो गया है. संकेत और रेखाएं मिलकर एक मजबूत सुरक्षा प्रणाली बनाते हैं. फ़्लोर स्ट्रिपिंग से यातायात व्यवस्थित रहता है. संकेत नियम और अतिरिक्त सहायता देते हैं. यह टीम वर्क भ्रम को रोकता है और कर्मचारियों की मदद करता है, इसलिए जोखिम कम हैं.

साइनेज और फ़्लोर मार्किंग अनुपालन के लिए स्टाफ प्रशिक्षण का महत्व

फोर्कलिफ्ट सुरक्षा और नियमों के पालन के लिए सुरक्षा प्रशिक्षण बहुत महत्वपूर्ण है. प्रशिक्षण से लोगों और फोर्कलिफ्टों को अलग रखने में मदद मिलनी चाहिए. इसे गलियारों को चिह्नित करना चाहिए और स्पष्ट दिशा-निर्देश देना चाहिए. समान रंगों का उपयोग करने से सभी को नियमों को जानने में मदद मिलती है.

| सिफारिश | विवरण |

|---|---|

| कर्मचारी को काम पर लगाना | सभी कर्मियों को फर्श के चिह्नों को अच्छी स्थिति में रखने में मदद करनी चाहिए. |

| मानक स्थापित करें | रंग कोड का उपयोग करें ताकि कर्मचारी जल्दी से सुरक्षा कदम सीख सकें. |

| प्रशिक्षण प्रदान | कर्मचारियों को अक्सर फर्श चिह्नों और संकेतों के बारे में सिखाएं. |

- टीमों को सुरक्षा कदमों का पालन करना सिखाएं.

- चिह्नों को स्पष्ट रखने के लिए उन्हें उपकरण दें.

- एक ही रंग का प्रयोग करें ताकि हर कोई समझ सके.

संकेतों के बारे में पढ़ाना नए कार्यकर्ता प्रशिक्षण का हिस्सा होना चाहिए. श्रमिकों को सीखना चाहिए कि संकेतों का क्या मतलब है और वे कहाँ हैं. कार्यकर्ताओं को अक्सर याद दिलाना महत्वपूर्ण है, खासकर बदलाव के बाद.

सुरक्षा प्रथाओं में निरंतर सुधार लागू करना

सुरक्षा को हर समय बेहतर बनाने से गोदाम सुरक्षित रहता है. प्रबंधकों को चाहिए:

- सुरक्षा नियमों को अक्सर जांचें और अद्यतन करें.

- सुधार के तरीके खोजने के लिए सुरक्षा जांच करें.

- सुरक्षा को बेहतर बनाने के लिए कार्यकर्ताओं से विचार पूछें.

- कौशल को ताज़ा रखने के लिए अधिक प्रशिक्षण दें.

- नए सुरक्षा उपकरणों और काम करने के सर्वोत्तम तरीकों के बारे में जानें.

- कारण जानने के लिए दुर्घटनाओं या करीबी कॉलों पर गौर करें.

- कानून का पालन करने के लिए अन्य कंपनियों से तुलना करें.

5S विधि चीजों को सुरक्षित रखने में मदद करती है:

- क्रम से लगाना: जिन चीज़ों की आपको आवश्यकता नहीं है उन्हें हटा दें.

- क्रम में सेट करें: उपकरण और आपूर्तियाँ सही स्थान पर रखें.

- चमक: सब कुछ साफ़ रखें.

- मानकीकरण: सभी के लिए स्पष्ट नियम बनाएं.

- बनाए रखना: जांचें और नियमों को बेहतर बनाएं.

दुर्घटना दर और पिछली दुर्घटना के बाद के दिनों जैसी संख्याओं को देखने से यह देखने में मदद मिलती है कि चीजें काम कर रही हैं या नहीं. ये कदम सुरक्षा नियमों का पालन करने और गोदाम को सभी के लिए सुरक्षित बनाने में मदद करते हैं.

एक गोदाम जो फुटपाथ चिह्नों और साइनेज का उपयोग करता है वह अधिक सुरक्षित है. ये उपकरण दुर्घटनाओं को रोकने और लोगों को चोट लगने से बचाने में मदद करते हैं. श्रमिक सुरक्षित महसूस करते हैं और बेहतर काम करते हैं. प्रबंधकों को कम दुर्घटनाएँ और बेहतर परिणाम नज़र आते हैं.

- एक मजबूत सुरक्षा योजना में स्पष्ट गलियाँ और चिह्नित खतरे वाले स्थान होते हैं. यह बाहर निकलने के सुरक्षित रास्ते भी बताता है.

- विशेषज्ञों का कहना है कि फोर्कलिफ्ट पार्किंग को चिह्नित करें और ब्लाइंड स्पॉट के बारे में चेतावनी दें. वे यह भी कहते हैं कि दिखाओ कि खतरनाक सामग्रियाँ कहाँ रखी हैं.

जब सुरक्षा महत्वपूर्ण है, चोटें कम होती हैं. कार्यस्थल अधिक सुरक्षित है और लोग अधिक काम करते हैं.

अक्सर पूछे जाने वाले प्रश्न

गोदाम में फुटपाथ चिह्नों का मुख्य उद्देश्य क्या है??

फुटपाथ चिह्न लोगों और वाहनों को सुरक्षित रूप से चलने में मदद करते हैं. वे दिखाते हैं कि कहाँ चलना या गाड़ी चलाना सुरक्षित है. ये निशान ख़तरे वाले क्षेत्रों की ओर भी इशारा करते हैं. कार्यकर्ता देख सकते हैं कि किन रास्तों का उपयोग करना है और किन स्थानों से बचना है.

गोदाम प्रबंधकों को कितनी बार फर्श चिह्नों और साइनेज की जांच करनी चाहिए?

विशेषज्ञों का कहना है कि महीने में एक बार निशानों और संकेतों की जांच करें. प्रबंधकों को ऐसी लाइनें तलाशने की ज़रूरत है जिन्हें देखना मुश्किल हो या जो चिन्ह टूटे हुए हों. इन समस्याओं को शीघ्रता से ठीक करने से सभी को सुरक्षित रखने में मदद मिलती है.

क्या कलर कोडिंग से दुर्घटनाओं को रोकने में मदद मिल सकती है??

हाँ, कलर कोडिंग से सुरक्षा नियमों को समझना आसान हो जाता है. उदाहरण के लिए:

| रंग | अर्थ |

|---|---|

| पीला | रास्तों, गलियारों |

| लाल | ख़तरे वाले क्षेत्र |

| हरा | सुरक्षा उपकरण |

गोदाम सुरक्षा के लिए कर्मचारियों का प्रशिक्षण क्यों महत्वपूर्ण है??

स्टाफ प्रशिक्षण श्रमिकों को दिखाता है कि चिह्नों और संकेतों का क्या मतलब है. प्रशिक्षण से सभी को सुरक्षा नियमों का पालन करने में मदद मिलती है. श्रमिक सीखते हैं कि खतरों को कैसे पहचाना जाए और खुद को सुरक्षित कैसे रखा जाए.