कार्यस्थलों में सुरक्षा बनाए रखने के लिए ट्रैफ़िक शंकु महत्वपूर्ण हैं. इनका व्यापक रूप से निर्माण और यातायात नियंत्रण में उपयोग किया जाता है. तथापि, उनके उपयोग से संबंधित नियम पूरे अमेरिका में भिन्न-भिन्न हैं, कनाडा, और मेक्सिको. ये विविधताएं सीमा पार परियोजनाओं पर श्रमिकों की सुरक्षा पर महत्वपूर्ण प्रभाव डाल सकती हैं. मेक्सिको में, शंकु विभिन्न सेटिंग्स में नियोजित होते हैं, निर्माण सहित, पार्किंग, और आपात स्थिति, जबकि अमेरिका और कनाडा मुख्य रूप से निर्माण और यातायात उद्देश्यों के लिए शंकु का उपयोग करते हैं. सुरक्षा सुनिश्चित करने और जोखिमों को कम करने के लिए इन अंतरों को समझना आवश्यक है. प्रभावी सुरक्षा प्रबंधन और यातायात नियंत्रण के लिए OSHA ट्रैफ़िक शंकु नियमों और स्थानीय कानूनों का पालन करना महत्वपूर्ण है.

चाबी छीनना

- Traffic cones keep people safe in construction and traffic areas. Knowing the rules in the US, कनाडा, and Mexico is important for safety.

- अमेरिका में, OSHA says cones must be 18 inches tall in slow zones and 28 inches tall in fast zones. Reflective tape makes them easier to see.

- Canada’s rules, called CSA Z96-15, focus on strong materials and shiny bands. This helps cones stand out in bad weather.

- Mexico uses NOM rules, which also set cone sizes and reflectivity. Rules can change by area, so learn what applies where you work.

- Always buy cones from trusted sellers who follow safety rules. This avoids fines and keeps workers safe.

- Teach workers how to use cones and follow local rules. Training often helps prevent mistakes and keeps everyone safe.

- Labels in three languages on cones help share safety messages. This works well when people speak different languages.

- Check cones often to make sure they meet safety rules. Keep records of checks and training to pass inspections and stay safe.

OSHA Traffic Cone Rules in the US

OSHA 1926 नियम

1926 rules cover how to use traffic cones safely. These rules set basic requirements for traffic cones in work areas. Cones must be strong, नियमित, और देखने में आसान है. For low-speed areas, traffic cones need to be at least 18 इंच लंबा. हाई-स्पीड जोन में, cones must be 28 इंच लंबा. This helps cones stay visible in different places.

OSHA also says cones need reflective materials for night or dark areas. This makes them easier to see and lowers accident risks. Cones should be spaced properly to guide traffic and keep workers safe. Following OSHA rules keeps your work zone safe and legal.

ANSI Guidelines and Their Importance

The अमेरिकन राष्ट्रीय मानक संस्थान (एएनएसआई) adds extra rules to help OSHA. ANSI focuses on making cones better for work areas. They suggest using cones made from tough materials that handle bad weather and impacts.

ANSI also highlights the need for reflective sheeting. This includes basic sheeting for light traffic, stronger sheeting for busy areas, and top-grade sheeting for critical safety spots. Using ANSI rules makes cones more visible and durable, protecting workers and drivers better.

Reflective and Visibility Needs

Seeing reflective cones clearly is very important. OSHA and ANSI both require reflective materials for day and night use. The समान यातायात नियंत्रण उपकरणों पर मैनुअल (MUTCD) gives detailed rules for cone design and use. It requires reflective sheeting to make reflective cones visible in dark conditions.

Here’s a simple look at reflective options for cones:

| मानक प्रकार | विवरण |

|---|---|

| एएसटीएम मानक | Sets rules for reflective sheeting to improve visibility. |

| समान यातायात नियंत्रण उपकरणों पर मैनुअल (MUTCD) | Gives design and use rules for reflective cones to ensure visibility. |

| विभिन्न यातायात शंकुओं के लिए विशिष्टता | Lists material and inspection needs for traffic reflective cones. |

- अभियांत्रिकी ग्रेड शीटिंग: Works for light traffic areas.

- उच्च-तीव्रता वाले प्रिज्मीय शीटिंग: Best for busy traffic zones.

- डायमंड ग्रेड शीटिंग: Gives the best visibility for critical safety spots.

Choosing the right reflective material helps meet OSHA rules. It also improves safety in work zones. Good visibility lowers accidents and follows federal rules.

For more insights on OSHA traffic cone regulations, don’t hesitate to check out “OSHA ट्रैफिक कोन नियमों और अनुपालन के लिए पूरा गाइड” and stay informed to keep your work environment safer!

Work Zone Applications

Traffic cones are important for keeping work zones safe. वे यातायात को नियंत्रित करने में मदद करते हैं, श्रमिकों की रक्षा करें, and guide people walking by. OSHA wants work cones used correctly to lower risks and keep things organized. OSHA नियमों का पालन करके, work zones can be safer for everyone.

राजमार्गों पर, highway cones guide cars around roadwork safely. This helps prevent traffic jams and accidents. सड़क की मरम्मत के लिए, road cones show closed lanes, helping drivers move easily. शहरों में, traffic safety cones create safe paths for walkers while keeping traffic smooth. Utility work areas use work cones to block off dangerous spots and stop injuries.

Cones are not just for construction. घटनाओं पर, safety cones direct cars, reducing traffic and making things safer. Emergency teams use safety cones to mark safe zones around accidents, protecting everyone nearby. On job sites, safety cones show vehicle paths, दुर्घटना के जोखिम को कम करना.

To make safety cones work better, use them with work zone signs. Signs give extra details so drivers and walkers know what cones mean. परावर्तक शंकु रात में या कम रोशनी में देखना आसान होता है. OSHA says safety cones must meet certain height and reflectivity rules based on traffic speed and type.

New ideas also make work zones safer. Virtual reality training, like C2 SMART, teaches workers how to use safety cones well. Smart systems mix technology with safety tools to fix work zone problems. These updates help follow OSHA rules and improve safety.

Using safety cones the right way keeps work zones neat and safe. Following OSHA rules ensures safety cones are visible and strong. चाहे निर्माण के लिए, मार्ग, या घटनाओं, safety cones are key to safety and order.

Traffic Cone Standards in Canada

CSA Z96-15 Overview

कनाडा में, traffic cone rules come from the CSA Z96-15 standard. This standard helps keep workers safe and traffic organized. It explains how cones should be made, उनका आकार, और सामग्री. These rules make cones stronger and easier to see, खराब मौसम में भी.

The CSA Z96-15 also focuses on reflective materials. These materials make cones visible during both day and night. Following this standard ensures your cones are safe for Canadian work areas.

Reflective Material and Visibility Standards

Seeing traffic cones clearly is very important for safety. The CSA Z96-15 says cones must have good reflective materials. These materials help cones stand out in the dark or rain. Choose cones with reflective bands that meet these rules for better safety.

Reflective bands must cover a certain part of the cone. This helps drivers and walkers notice cones from far away. Bright colors like orange or red also make cones easier to see in daylight. Using cones that follow these rules lowers accidents and keeps everyone safer.

Broader Applications Beyond Work Zones

कनाडा में, work cones are used for more than construction. They are helpful at events, पार्किंग स्थल, और आपात स्थिति. Their many uses make them important for safety in different places.

घटनाओं पर, cones guide cars and create safe paths for people. पार्किंग में, they show reserved spots or direct cars to park. Emergency teams use cones to block off danger zones and protect people.

The CSA Z96-15 makes sure work cones in these situations are safe and visible. Using cones that follow these rules keeps things organized and protects everyone in various settings.

Enforcement Mechanisms in Canada

Canada uses federal and provincial rules to enforce cone standards. Knowing these rules is key for working safely in Canada. The Canadian Standards Association (सीएसए) creates safety rules like the CSA Z96-15 for cones. Provinces and territories may add their own rules to these.

Each province has its own safety laws for workplaces. These laws match CSA rules but may have extra steps. ओंटारियो में, the Ministry of Labour checks if cones meet size and reflectivity rules. Breaking these rules can cause fines or slow down projects.

क्यूबेक में, CNESST ensures workplace safety rules are followed. Cones in Quebec must meet the CSA Z96-15 standard. यदि नहीं, you could face penalties or work stoppages. British Columbia and Alberta also have groups that check safety practices.

Federal agencies also check safety on federal lands or highways. The Canada Labour Code includes CSA rules for safety. Federal inspectors may visit to ensure your project follows these rules.

समस्याओं से बचने के लिए, check your safety gear often. Work with suppliers who sell CSA-approved cones. Teach your team about local safety rules to stay compliant. Using work cones that meet both CSA and OSHA rules helps with cross-border projects.

Canada’s enforcement focuses on keeping workers and the public safe. इन नियमों का पालन करके, your project can stay safe and run smoothly.

Traffic Cone Standards in Mexico

Overview of NOM Standards

मेक्सिको में, traffic cone rules follow NOM (Normas Oficiales Mexicanas). These rules make sure cones are safe and easy to see. NOM focuses on work cone materials, डिज़ाइन, and reflectivity for different uses. These rules apply to construction sites, सड़कें, और आपात स्थिति.

NOM standards require strong materials that handle bad weather. Cones must be bright colors like orange or red for daytime visibility. Reflective bands are needed to make work cones visible at night or in dim light. Following these rules helps keep work areas safe and lowers risks.

Size and Reflectivity Requirements

Traffic cones in Mexico must meet size and reflectivity rules. Cone height depends on where they are used. धीमी गति वाले क्षेत्रों में, traffic cones must be at least 18 इंच लंबा. For fast-speed zones, traffic cones need to be 28 inches or taller to stay visible.

Reflectivity is key for safety, खासकर रात में. NOM says reflective cones must have reflective bands covering much of their surface. These bands help drivers and walkers see reflective cones from far away. Using reflective cones with good reflective materials meets rules and keeps everyone safer.

Regional Variations in Enforcement

Different regions in Mexico enforce cone rules differently. Some areas check NOM rules strictly, while others are more relaxed. Learn the rules for your project’s location to avoid problems.

Local officials inspect cones for size, रंग, और परावर्तकता. Breaking rules can lead to fines or delays. नियमों का पालन करने के लिए, buy cones that meet NOM standards. Check cones often to ensure they are in good shape and visible. Knowing local enforcement helps you stay safe and avoid penalties.

Challenges in Sourcing Compliant Cones

Getting traffic cones that follow नियामक मानकों can be tricky. This is especially true for cross-border projects. मेक्सिको में, the problem is even harder due to local issues. Knowing these problems is important to keep your project safe.

One big problem is finding the right materials. Things like polyvinyl and thermosets are needed to make strong cones. These materials are often hard to find in Mexico. This makes cones more expensive to produce and harder to get. Some suppliers use cheaper, weaker materials instead. These cones don’t meet safety rules and can be dangerous. They might cost less at first but can cause accidents or fines later.

Another issue is the number of cones that don’t meet NOM standards. These cones are often too small, not reflective, या आसानी से तोड़ो. They are cheaper, so people buy them, लेकिन वे जोखिम भरे हैं. Using these cones can lead to penalties, देरी, या दुर्घटनाएँ. Always check carefully when buying cones to avoid these problems.

बख्शीश: Check if your supplier’s cones are certified. Make sure they meet NOM standards आकार के लिए, परावर्तन, और सामग्री की गुणवत्ता.

Different areas in Mexico enforce rules differently. Some places are strict about NOM regulations, while others are not. This makes it confusing to know which cones are okay to use. Learn the rules for your project’s location. Talk to local officials or experts to stay on track.

Making work cones that meet all safety rules is also tough for manufacturers. They need better materials and advanced tools, जिसकी लागत अधिक है. This makes good work cones harder to afford for small projects or companies with tight budgets.

इन समस्याओं को हल करने के लिए, work with trusted suppliers who focus on compliant cones. Check your work cones often to make sure they are still safe and visible. ऐसा करने से, you can avoid risks and keep your work zones safe.

Key Differences and Comparisons Between the US, कनाडा, और मेक्सिको

Size and Height Requirements

The traffic cone size is important for keeping work zones safe. अमेरिका में, traffic cone height depends on traffic speed. For slower traffic, traffic cones must be at least 18 इंच लंबा. तेज क्षेत्रों में, शंकु होना आवश्यक है 28 इंच या उससे अधिक लंबा. These rules help traffic cones stay visible to drivers and walkers.

कनाडा में, the CSA Z96-15 standard has similar height rules. Canadian cones often have wider bases for better stability. This helps them stay in place during bad weather. The design also improves safety for workers and traffic control.

Mexico uses NOM standards, which also set height rules. Cones in slow areas must be at least 18 इंच लंबा. तेजी से क्षेत्रों में, cones need to be taller. लेकिन, enforcement can vary by region. Always check local rules to make sure you follow them.

परावर्तन और दृश्यता मानकों

Good visibility is key for safety in work zones. अमेरिका में, OSHA and ANSI require cones to have reflective materials. These materials make cones easier to see in low light. The MUTCD gives detailed rules for reflective sheeting. Options like engineering-grade, उच्च-तीव्रता, and diamond-grade sheeting improve visibility based on traffic needs.

Canada’s CSA Z96-15 standard requires reflective bands on cones. These bands cover a large part of the cone for better visibility. Bright colors like orange or red also help cones stand out in different lighting.

मेक्सिको में, NOM standards require cones to have reflective bands for night use. But finding cones with good reflective materials can be hard. Work with reliable suppliers to get cones that meet visibility rules.

Scope of Application

Traffic cone uses differ across the three countries. अमेरिका में, cones are mostly used for construction and roadwork. वे यातायात का मार्गदर्शन करते हैं, श्रमिकों की रक्षा करें, and work with signs to improve safety.

Canada uses cones for more than just construction. They are also used in parking lots, इवेंट्स, और आपात स्थिति. This makes them useful for many safety needs.

मेक्सिको में, cones are used for construction, पार्किंग, और आपात स्थिति. But regional enforcement can vary, causing challenges. Knowing local rules helps you use cones correctly and stay compliant.

बख्शीश: Always check the rules for your project’s location. This ensures your cones meet size, दृश्यता, and usage standards.

प्रवर्तन और दंड

Knowing how rules are enforced is very important. अमेरिका, कनाडा, and Mexico each have their own ways to check if traffic cone rules are followed. Breaking these rules can cause big problems.

अमेरिका में, OSHA checks traffic cones during inspections. They look at cone size, परावर्तन, and placement in work zones. If traffic cones don’t meet OSHA 1926 नियम, you could face fines or delays. उदाहरण के लिए, cones without reflective bands in dark areas can lead to penalties. इससे बचने के लिए, check your traffic cones often and make sure they follow OSHA rules.

Canada also inspects cones but adds extra checks by provinces. The CSA Z96-15 standard is the main rule, but places like Ontario and Quebec have more rules. Inspectors visit sites to see if cones meet these standards. यदि नहीं, आप पर जुर्माना लग सकता है, have to stop work, or retrain workers. सुरक्षित रहने के लिए, use cones that meet CSA rules and teach your team about local laws.

मेक्सिको में, enforcement depends on the region. Some areas are strict with NOM rules, while others are not. Officials check cones for size, रंग, और परावर्तकता. If cones don’t meet NOM standards, you could face fines or delays. Finding good cones can be hard because many don’t meet the rules. Work with trusted suppliers to get cones that follow NOM standards.

Breaking traffic cone rules in any country can slow down your project and make it unsafe. Check local rules and inspect cones often to avoid problems. Using the right cones keeps workers safe and projects running smoothly.

बख्शीश: Keep records of cone checks and supplier details. This helps prove you are following the rules if someone asks.

Practical Tips for Cross-Border Compliance

Reviewing Traffic Cone Standards

Start by checking the traffic cone rules for each country. This helps you follow local laws and avoid fines. उदाहरण के लिए, अमेरिका. का उपयोग करता है MUTCD, which lists rules for materials and reflectivity. Canada follows the CSA Z96-15, while Mexico uses NOM standards. ये नियम शंकु की ऊंचाई को कवर करते हैं, चिंतनशील बैंड, और ताकत.

Compare the rules to find gaps in your cones. Use a chart to organize the key points:

| क्षेत्र | मानक/विनियमन | Key Focus Areas |

|---|---|---|

| हम. | MUTCD | Specifications for materials, परावर्तन, वगैरह. |

| ऑस्ट्रेलिया/न्यूजीलैंड | के रूप में/nzs 1906.1:2017 | Safety standards for public use |

| यूरोप | सीई प्रमाणीकरण | Compliance with European safety standards |

Reviewing these rules often ensures your cones meet safety needs. This step is important for keeping workers safe and projects running smoothly.

Working with Trusted Suppliers

चुनना traffic cones suppliers who know international traffic cone rules. They should provide cones that meet OSHA, सीएसए, या NOM standards. Ask for proof that their cones follow these rules. This makes sure your cones match local safety laws.

Good traffic cone suppliers can also help you choose the right cones. उदाहरण के लिए, cones with bright reflective bands work better in busy areas. Reliable suppliers prevent you from buying unsafe cones that could cause fines or delays.

Building strong ties with suppliers ensures you always get safe cones. This teamwork lowers risks and keeps your project on schedule.

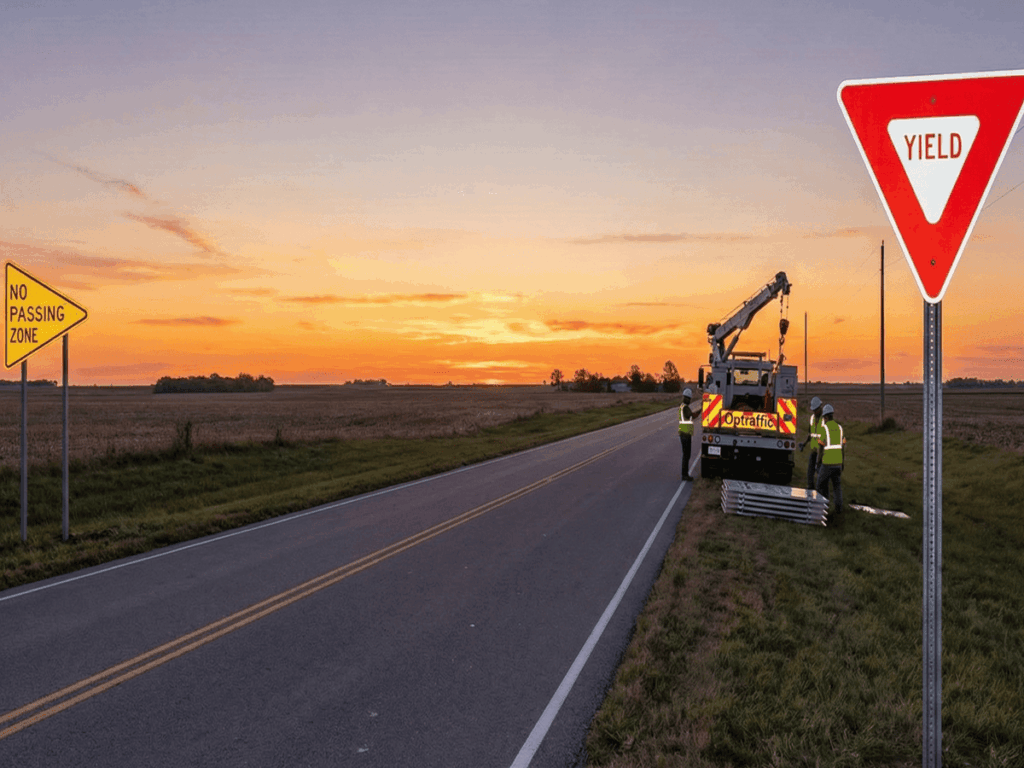

ऑप्टट्रैफ़िक, as a reliable traffic cone supplier, understands the importance of meeting international standards and providing high-quality, अनुपालन बिक्री के लिए यातायात शंकु to enhance safety and ensure your project runs smoothly.

Teaching Workers About Standards

Training workers is key to following the rules. Teach them how to use cones properly and why the rules matter. Explain the differences between U.S., कनाडा, and Mexico standards. Show how these rules protect workers and improve safety.

Use hands-on lessons to show proper cone placement. उदाहरण के लिए, taller cones are needed in fast zones, and spacing must be wider. Pictures and videos can make learning easier.

Hold regular training sessions to update workers on new rules. इससे गलतियाँ कम होती हैं और सुरक्षा में सुधार होता है. Trained workers help keep your site safe and compliant.

बख्शीश: Offer training in multiple languages so everyone understands the rules, कोई फर्क नहीं पड़ता उनकी भाषा.

Using Trilingual Warning Labels

Trilingual warning labels are important for safety on cross-border projects. These labels share key information with workers who speak different languages. का उपयोग करते हुए अंग्रेज़ी, स्पैनिश, और फ़्रेंच helps everyone understand instructions better.

Adding these labels to traffic cones makes them more useful. Workers can quickly see dangers and follow directions without confusion. उदाहरण के लिए, a trilingual label might say:

- अंग्रेज़ी: “सावधानी: Construction Zone Ahead.”

- स्पैनिश: “Precaución: Zona de Construcción Adelante.”

- फ़्रेंच: “Attention : Zone de Construction Devant.”

इस तरह, all workers, कोई फर्क नहीं पड़ता उनकी भाषा, understand the warning.

When creating trilingual labels, focus on making them clear and easy to see. Use bright colors like yellow with black text for contrast. Reflective materials help workers see the labels in the dark. Simple pictures, like arrows or hazard signs, make the message even clearer. These choices make the labels safer and easier to read.

Make sure your labels follow local rules. कनाडा में, they must meet CSA Z96-15 मानकों. मेक्सिको में, they should match NOM requirements. Following these rules avoids fines and keeps your project safe.

बख्शीश: Check your labels often for damage. Replace any faded or torn labels to keep them working well.

Avoiding Common Compliance Risks

Compliance problems can slow down your project and make it unsafe. Knowing these risks helps you prevent them.

One big problem is using traffic cones for sale that don’t meet local rules. उदाहरण के लिए, traffic cones for sale without reflective bands may not be visible at night. This can cause accidents and fines. Always check that your cones meet size, रंग, और परावर्तन नियम.

Another issue is uneven enforcement of rules in different areas. मेक्सिको में, some places strictly follow NOM rules, while others don’t. यह भ्रमित करने वाला हो सकता है. इसे ठीक करने के लिए, learn the rules for your project’s location. Talk to local experts or officials to stay updated.

Not training workers properly is another risk. Workers who don’t know local cone rules might use them wrong, creating unsafe conditions. Train your team regularly about the rules and how to use cones correctly. Hands-on practice helps them learn better.

Buying traffic cones for sale from unreliable suppliers is also risky. Weak traffic cones for sale may break easily and fail to keep workers safe. Work with trusted traffic cone suppliers like ऑप्टट्रैफ़िक who sell certified traffic cones that meet safety standards.

टिप्पणी: Keep records of your efforts, like supplier details and training logs. These can help during inspections.

इन समस्याओं को हल करके, you can keep workers safe and your project running smoothly.

Traffic cone rules are not the same in the US, कनाडा, और मेक्सिको. Differences in size, परावर्तन, and enforcement affect worker safety. Always check local rules to stay compliant. Work with trusted suppliers to get traffic cones that follow the rules. Teach workers about these rules to improve safety on-site. Following these steps helps avoid fines and keeps projects running smoothly. Focusing on safety and traffic control creates a safer place for everyone.

अक्सर पूछे जाने वाले प्रश्न

What are traffic cone standards for?

Traffic cone rules keep people safe. They control size, परावर्तन, और सामग्री. These rules make traffic cones strong and easy to see. This lowers accidents and helps manage traffic better.

Why do countries have different traffic cone rules?

Each country has its own safety needs and traffic issues. Rules depend on local traffic, मौसम, and safety goals.

How can you follow local traffic cone rules?

Learn the rules for your project’s area. Buy traffic cones from trusted sellers who meet the rules. Teach workers about these rules so they use cones correctly.

What happens if traffic cones don’t follow the rules?

Using bad traffic cones can cause accidents, जुर्माना, या देरी. They might not be visible or safe enough, लोगों को ख़तरे में डाल रहे हैं.

Do all traffic cones need reflective materials?

हाँ, most rules say traffic cones must have reflective bands. This helps people see them at night or in low light.

How do you pick the right cone for your project?

Think about traffic speed, प्रकाश, और स्थानीय नियम. Taller traffic cones with bright reflective bands are best for fast traffic.

Why is it important to train workers about cone rules?

Training helps workers use traffic cones safely and follow the rules. It prevents mistakes and keeps everyone safe.

Can one cone type work in the US, कनाडा, और मेक्सिको?

It’s hard but possible. Each country has different rules. Pick traffic cones for sale that meet the strictest rules to make things easier.