EN13422 प्रमाणन जर्मनी में सुरक्षा शंकु आपूर्तिकर्ताओं के लिए एक बड़ी बाधा है. निर्माताओं को यह दिखाना होगा कि वे विश्वास अर्जित करने और बाज़ार में प्रवेश करने के लिए नियमों का पालन करते हैं. तकनीकी मानकों पर सावधानीपूर्वक काम करने और मजबूत गुणवत्ता जांच की आवश्यकता है. नियम चीज़ों को कठिन बनाते हैं, और संसाधनों का अच्छी तरह से उपयोग करना हमेशा कठिन होता है. सभी सुरक्षा शंकु आपूर्तिकर्ताओं को भरोसा करने और अपने उत्पाद बेचने के लिए इन समस्याओं का सामना करना होगा.

ऑप्टट्रैफ़िक, एक उच्च गुणवत्ता वाला सुरक्षा शंकु आपूर्तिकर्ता, यह सब सुनिश्चित करता है बिक्री के लिए सुरक्षा शंकु स्थायित्व और विश्वसनीयता को ध्यान में रखकर तैयार किए गए हैं. हमारे यातायात सुरक्षा शंकु उच्चतम मानकों को पूरा करने के लिए डिज़ाइन किए गए हैं, किसी भी वातावरण में लंबे समय तक चलने वाला प्रदर्शन और अधिकतम सुरक्षा प्रदान करना.

चाबी छीनना

- जर्मनी और यूरोपीय संघ में सुरक्षा शंकु विक्रेताओं के लिए EN13422 प्रमाणीकरण आवश्यक है. यह लोगों को उत्पादों पर भरोसा करने में मदद करता है और सुनिश्चित करता है कि वे सुरक्षित हैं.

- उच्च परिशुद्धता निर्माताओं को कठिन गुणवत्ता नियमों का पालन करना चाहिए. वे बहुत अधिक भुगतान भी करते हैं और बहुत अधिक समय भी बिताते हैं. उन्हें अच्छी तकनीक और कुशल श्रमिकों की जरूरत है.

- एआई जैसे डिजिटल उपकरण, स्वचालन, और क्लाउड सिस्टम कंपनियों को बेहतर काम करने में मदद करते हैं. ये उपकरण लागत कम करते हैं और प्रमाणीकरण तेजी से करते हैं.

- नियमित जाँच और प्रशिक्षण के साथ अच्छी अनुपालन योजनाएँ कंपनियों को त्रुटियों से बचने में मदद करती हैं. इससे ग्राहकों को उन पर अधिक भरोसा करने में भी मदद मिलती है.

- साझेदारी बनाने से निर्माताओं को विचार साझा करने और जोखिम कम करने का मौका मिलता है. इससे उन्हें बाज़ार में अधिक आसानी से प्रवेश करने में भी मदद मिलती है.

जर्मनी में EU EN13422 प्रमाणन को समझना

EN13422 प्रमाणन का अवलोकन

EN13422 यूरोपीय संघ में सड़क सुरक्षा उत्पादों के लिए एक नियम है. यह प्रमाणीकरण सुरक्षा शंकु जैसी चीज़ों को कवर करता है, बाधाएं, और चेतावनी संकेत. उत्पाद कैसे दिखें, इसके लिए निर्माताओं को सख्त नियमों का पालन करना चाहिए, अंतिम, और देखा जा सकता है. प्रक्रिया यह जांचती है कि क्या उत्पाद खराब मौसम और बहुत अधिक उपयोग को संभाल सकते हैं. यह यह भी जाँचता है कि क्या वे ड्राइवरों और पैदल चल रहे लोगों को चेतावनी देते हैं.

जर्मनी में निर्माता जानते हैं कि बाज़ार में बेचने के लिए EN13422 की आवश्यकता है. इस प्रमाणीकरण के बिना, कंपनियाँ EU में नहीं बेच सकतीं. इस प्रक्रिया में सावधानीपूर्वक परीक्षण और कागजी कार्रवाई की आवश्यकता होती है. निरीक्षक उत्पाद के नमूनों की जाँच करते हैं और वे कैसे बने हैं इसकी जाँच करते हैं. वे हर बार वही अच्छी गुणवत्ता देखना चाहते हैं.

टिप्पणी: EN13422 प्रमाणन ग्राहकों को कंपनी पर भरोसा करने में मदद करता है. इससे यह भी पता चलता है कि कंपनी सुरक्षा और नियमों के पालन की परवाह करती है. इस मानक वाली कंपनियां अक्सर दूसरों की तुलना में बेहतर प्रदर्शन करती हैं.

सड़क सुरक्षा उपकरण पर यूरोपीय संघ के विनियम

The यूरोपीय संघ सड़क सुरक्षा उपकरणों के लिए सख्त नियम हैं. ये नियम सुनिश्चित करते हैं कि सभी उत्पाद सुरक्षित हैं और अच्छी तरह से काम करते हैं. अधिक समय तक, EU ने बनाए कुछ अहम नियम:

- में 2007, ट्रकों को ब्लाइंड स्पॉट मिरर जोड़ने पड़े.

- में 2008, सुरक्षा प्रबंधन और दिन के समय चलने वाली रोशनी की आवश्यकता हो गई.

- में 2010, सभी देशों को वाहनों की जांच करनी पड़ी.

नियमों का पालन किया जा रहा है या नहीं यह जांचने के लिए यूरोपीय संघ विभिन्न उपकरणों का उपयोग करता है:

- CARE डेटाबेस सभी EU देशों से क्रैश डेटा एकत्र करता है.

- यूरोपीय सड़क सुरक्षा वेधशाला (ईआरएसओ) शोध और तथ्य देता है.

- सड़क सुरक्षा त्वरित संकेतक हर महीने चोटों और मौतों पर नज़र रखता है.

- वार्षिक रिपोर्ट प्रत्येक देश में सड़क सुरक्षा की तुलना करती है.

जुलाई से 7, 2024, सामान्य सुरक्षा विनियमन II (जीएसआर द्वितीय) अधिक सुरक्षा सुविधाओं के लिए नए वाहनों की आवश्यकता होगी. जर्मनी में एक सर्वेक्षण में पाया गया 64% वाहन चलाते समय लोग सुरक्षा का ध्यान रखते हैं. इससे कंपनियां नई सुरक्षा प्रणालियाँ जोड़ती हैं.

| वाहन श्रेणी | अनिवार्य सुरक्षा सुविधाएँ (जीएसआर द्वितीय) | कार्यान्वयन समयरेखा |

|---|---|---|

| एम1, एन 1 (यात्री कारें, हल्के वाणिज्यिक वाहन) | उन्नत आपातकालीन ब्रेकिंग, लेन रखना, पैदल यात्री सुरक्षा, रिवर्सिंग डिटेक्शन, गति सहायता, उनींदापन की चेतावनी, अल्कोहल इंटरलॉक, इवेंट डेटा रिकॉर्डर, आपातकालीन रोक संकेत, ध्यान भटकाने की चेतावनी, टायर दबाव की निगरानी | जुलाई से नए वाहन प्रकार 6, 2022; पूर्ण आवेदन के बाद 2 साल |

| एम2, एम3, एन 2, एन3 (बसों, ट्रक) | ब्लाइंड स्पॉट की जानकारी, पैदल यात्री/साइकिल चालक की टक्कर की चेतावनी, टायर दबाव की निगरानी | ऊपर की तरह |

ये नियम निर्माताओं को सड़क सुरक्षा उत्पाद बनाने और उनका परीक्षण करने में मदद करते हैं. EN13422 और EU नियमों का पालन सड़क उपयोगकर्ताओं को सुरक्षित रखता है और यह सुनिश्चित करता है कि उत्पाद सर्वोत्तम हों.

उच्च परिशुद्धता निर्माताओं के लिए प्रवेश बाधाएँ

उच्च परिशुद्धता विनिर्माण मानकों को पूरा करने की चुनौतियाँ

जर्मनी में उच्च परिशुद्धता निर्माताओं को सख्त नियमों का पालन करना होगा. उन्हें यह सुनिश्चित करना होगा कि उनके उत्पाद सटीक हों, मज़बूत, और सुरक्षित. ये नियम EN13422 और अन्य वैश्विक मानकों से आते हैं आईएसओ 9001 और आईएटीएफ 16949. कंपनियों को हर कदम पर नजर रखनी होगी और अपने काम की जांच करनी होगी. उन्हें जोखिमों को देखने और उन्हें ठीक करने की भी आवश्यकता है. कई लोग गलतियाँ खोजने और प्रक्रिया को नियंत्रित करने के लिए कृत्रिम बुद्धिमत्ता का उपयोग करते हैं. से 2012 को 2024, ऊपर 32,000 मेडिकल डिवाइस रिकॉल हुआ. इससे पता चलता है कि गुणवत्ता को उच्च बनाए रखना कितना कठिन है. एक साथ कई अच्छे उत्पाद बनाना अभी भी कठिन है. कठोर सामग्रियों के साथ कार्य करना, सुपरअलॉय की तरह, उपकरण तेजी से खराब हो जाते हैं और काम धीमा हो जाता है. सही फिनिश चुनना, जैसे कि एनोडाइजिंग या निकल चढ़ाना, उत्पादों को लंबे समय तक चलने में मदद करता है. समापन पर जल्दी निर्णय लेने से चीजें कैसे फिट होंगी या कैसे काम करेंगी, इसकी समस्याएं बंद हो जाती हैं.

- निर्माताओं को चाहिए:

- सभी उत्पादों की गुणवत्ता समान रखें

- उत्पादों को ख़त्म करने के लिए विशेष तरीकों का उपयोग करें

- हर चरण को ट्रैक करें और जांचें

लागत और समय निवेश

EN13422 प्रमाणन प्राप्त करने में बहुत समय और पैसा लगता है. कंपनियां नई टेक्नोलॉजी पर खर्च करती हैं, कुशल श्रमिक, और नियमों का पालन करने के लिए उपकरण. में 2024, तकनीकी खर्च था 30% बजट का, से लेकर 23% पिछले साल. कंपनियाँ क्लाउड सिस्टम का उपयोग करती हैं, ऐ, और 5G बेहतर ढंग से काम करेगा. उच्च सामग्री और श्रमिक लागत, साथ ही पर्याप्त कुशल लोग भी नहीं, चीजों को और अधिक महंगा बनाओ. कई लोग जल्द ही डिजिटल टूल पर और भी अधिक खर्च करने की योजना बना रहे हैं.

| पहलू | 2024 डेटा/रुझान | प्रभाव |

|---|---|---|

| टेक बजट | 30% परिचालन बजट का | उच्च वित्तीय प्रतिबद्धता |

| प्रमुख प्रौद्योगिकियाँ | बादल, ऐ, 5जी | अनुपालन और दक्षता को बढ़ाता है |

| निवेश चालक | सामग्री/श्रम लागत, कौशल अंतराल | अनुकूलन और अधिक निवेश को बल देता है |

| नियोजित निवेश | 34% 5जी में, 40%+ एआई/एमएल में | निरंतर समय और वित्तीय प्रतिबद्धता |

डिजिटल टूल का उपयोग न करने से नियमों का पालन करना धीमा और कठिन हो जाता है. जब ऑर्डर तेजी से ऊपर या नीचे जाते हैं तो योजनाओं को बदलना कठिन होता है. स्वचालन और कनेक्टेड सिस्टम पैसे बचाने और तेजी से प्रमाणित होने में मदद करते हैं.

गुणवत्ता नियंत्रण और परीक्षण

उच्च परिशुद्धता कार्य के लिए गुणवत्ता नियंत्रण और परीक्षण बहुत महत्वपूर्ण हैं. कंपनियाँ ग़लतियों पर नज़र रखती हैं, बर्बाद हुए हिस्से, और वे कितनी अच्छी वस्तुएँ बनाते हैं. वे गणित उपकरणों का उपयोग करते हैं, ची-स्क्वायर परीक्षण की तरह, गलतियों को खत्म करने के लिए 20% कभी-कभी. वे यह भी जांचते हैं कि चीजें कितनी तेजी से चलती हैं, नौकरियों में कितना समय लगता है, और जब मशीनें बंद हो जाती हैं. अच्छा कच्चा माल मायने रखता है क्योंकि ख़राब कच्चा माल बाद में अधिक समस्याएँ पैदा करता है. गुणवत्ता की कीमत का मतलब गलतियों को रोकना और उन्हें ठीक करना दोनों है. मजबूत गुणवत्ता जांच से बेहतर उत्पाद बनते हैं, कम स्मरण, और ग्राहक खुश. एक सुरक्षा शंकु आपूर्तिकर्ता के लिए, ये चरण EN13422 नियमों को पूरा करने में मदद करते हैं और सुनिश्चित करते हैं कि उत्पाद अच्छी तरह से काम करें.

जर्मन बाज़ार में उच्च परिशुद्धता विनिर्माण की भूमिका

जर्मन विनिर्माण उत्कृष्टता और बाजार प्रतिष्ठा

चीजें बनाने के मामले में जर्मनी शीर्ष देश है. में 2023, कारखाने बने $844.93 अरबों का माल. ये था 12.25% पिछले वर्ष से अधिक. के बारे में 5.5 इन फ़ैक्टरियों में लाखों लोग काम करते हैं. यह प्रत्येक पाँच श्रमिकों में से एक से अधिक है. सामान बनाने के मामले में जर्मनी विश्व में तीसरे स्थान पर है. केवल चीन और संयुक्त राज्य अमेरिका ही अधिक कमाते हैं. में 2020, यूएनआईडीओ ने कहा कि जर्मनी मजबूत कारखानों और नई तकनीक के मामले में नंबर एक है.

जर्मनी बहुत सारी कारें और मशीनें बनाता है. ये उद्योग अधिकांश देशों की तुलना में बहुत बड़े हैं. जर्मनी जैसे देश में कार उद्योग विश्व औसत से तीन गुना बड़ा है. मशीन उद्योग है 2.5 विश्व औसत से कई गुना बड़ा. इससे जर्मनी को गुणवत्ता और सटीकता के लिए अपना अच्छा नाम बनाए रखने में मदद मिलती है.

| सूचक | जर्मनी का डेटा | प्रसंग |

|---|---|---|

| विनिर्माण आउटपुट (2023) | $844.93 अरब | 3वैश्विक स्तर पर तीसरा उच्चतम |

| विनिर्माण में कार्यबल | 5.5 लाख लोग | 20.8% कार्यबल का |

| यूनिडो सीआईपी सूचकांक (2020) | प्रथम स्थान प्राप्त हुआ | उच्च तकनीक क्षमता और आर्थिक प्रभाव |

उच्च परिशुद्धता वाले सुरक्षा उत्पादों की बाज़ार में माँग

जर्मनी में लोग अधिक उच्च परिशुद्धता वाले सुरक्षा उत्पाद चाहते हैं. उदाहरण के लिए, सुरक्षा चश्मे का बाज़ार USD के आसपास था 242 में मिलियन 2024. यह लगभग दोगुना हो सकता है 2035. भवन निर्माण कार्य जोखिम भरा है, इसलिए इसे अधिक सुरक्षा गियर की आवश्यकता है. कंपनियाँ विशेष सुरक्षा उत्पाद चाहती हैं जो अच्छी तरह फिट हों. कुछ में सेंसर या स्क्रीन भी हैं. जैसे-जैसे नियम सख्त होते जाते हैं और नई तकनीक आती जाती है, लोगों को बेहतर और अधिक सटीक उपकरणों की आवश्यकता है.

जर्मनी भी बहुत सारे औद्योगिक सेंसर बेचता है. में 2022, इस बाज़ार ने EUR बनाया 35 अरब. यह बढ़ता गया 7% के शुरू में 2023. ये सेंसर स्मार्ट कारखानों और उद्योग की मदद करते हैं 4.0. उन्हें बहुत सटीक होने और तेजी से अपडेट देने की जरूरत है.

सफल जर्मन निर्माताओं के मामले का अध्ययन

कुछ जर्मन कंपनियाँ उच्च परिशुद्धता वाले कार्यों में अग्रणी हैं. शेफ़लर और जुंगहेनरिच अपने उत्पादों की जाँच के लिए विशेष उपकरणों का उपयोग करते हैं. इससे उन्हें सख्त नियमों का पालन करने में मदद मिलती है. जेडएफ समूह, एक बड़ी कार पार्ट्स कंपनी, ट्रांसमिशन बनाने के लिए मशीनों का उपयोग करता है. इससे उन्हें निर्माण करना पड़ा 40% और उत्पाद. उन्होंने बर्बाद कर दिया 65% कम सामग्री और उपयोग किया गया 28% कम ऊर्जा. ये कहानियाँ दिखाती हैं कि कैसे जर्मन कंपनियाँ बढ़िया काम करने और गुणवत्ता की आवश्यकता को पूरा करने के लिए नई तकनीक और मशीनों का उपयोग करती हैं.

| कंपनी | उद्योग | स्वचालन कार्यान्वयन | आउटपुट में वृद्धि | सामग्री अपशिष्ट में कमी | ऊर्जा की खपत में कमी |

|---|---|---|---|---|---|

| जेडएफ समूह | ऑटोमोटिव | स्वचालित ट्रांसमिशन विनिर्माण लाइन | 40% | 65% | 28% |

| शेफ़लर | औद्योगिक | स्वचालित कोड सत्यापन | एन/ए | एन/ए | एन/ए |

| जंगहेनरिच | औद्योगिक | स्वचालित कोड सत्यापन | एन/ए | एन/ए | एन/ए |

निर्माता प्रवेश बाधाओं को कैसे दूर कर सकते हैं

प्रौद्योगिकी और नवाचार का लाभ उठाना

उत्पाद बनाने में सहायता के लिए निर्माता रोबोटिक्स और स्वचालन का उपयोग करते हैं. ये मशीनें कारखानों को दिन-रात काम करने देती हैं. रोबोट बहुत सावधानी से काम करते हैं, इसलिए उत्पाद बेहतर हैं और लागत कम है. स्मार्ट फ़ैक्टरियाँ समस्याओं को तेज़ी से ठीक करने के लिए वास्तविक समय डेटा का उपयोग करती हैं. इससे सब कुछ ठीक से काम करता रहता है. कई कंपनियाँ नए विचार प्राप्त करने और स्मार्ट विकल्प चुनने के लिए कृत्रिम बुद्धिमत्ता का उपयोग करती हैं. का एक अध्ययन 125 हाई-टेक फर्मों ने पाया कि एआई टीमों को रचनात्मक बनने और बेहतर निर्णय लेने में मदद करता है. उच्च परिशुद्धता विनिर्माण में डिजिटल उपकरणों का बहुत उपयोग किया जाता है. लेकिन केवल कुछ ही कंपनियाँ जाँचती हैं कि ये उपकरण कितनी मदद करते हैं. इसका मतलब है कि कंपनियों को नई तकनीक का मूल्य देखने के लिए बेहतर तरीकों की आवश्यकता है.

एक मजबूत अनुपालन रणनीति का निर्माण

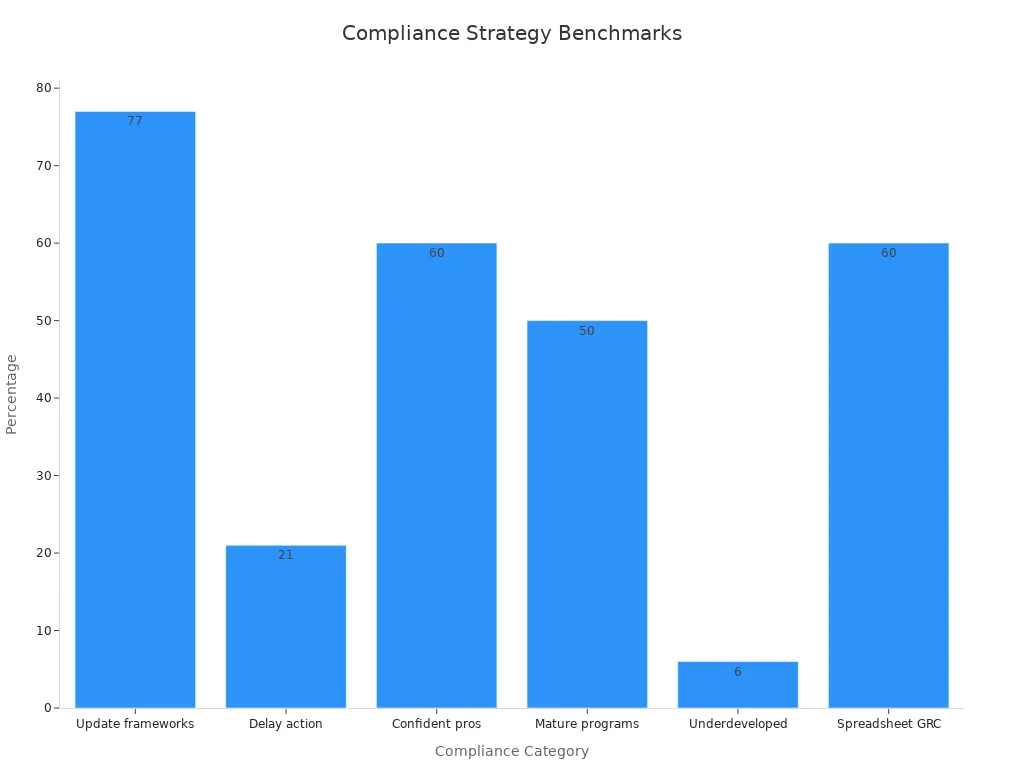

एक मजबूत अनुपालन योजना कंपनियों को EN13422 प्रमाणन नियमों को पूरा करने में मदद करती है. अधिकांश कंपनियां अपनी अनुपालन योजनाओं को जल्द ही अपडेट करना चाहती हैं. कुछ लोग तब तक प्रतीक्षा करते हैं जब तक कि ऑडिट उन्हें कार्रवाई के लिए बाध्य न कर दे. नीचे दी गई तालिका अनुपालन कार्यक्रमों के बारे में महत्वपूर्ण तथ्य दिखाती है:

| बेंचमार्क मेट्रिक | सांख्यिकीय | स्रोत |

|---|---|---|

| संगठन अनुपालन ढाँचे को अद्यतन करने की योजना बना रहे हैं | 77% | कोयला अग्नि अनुपालन रिपोर्ट 2023 |

| संगठन ऑडिट या बाहरी निष्कर्ष तक कार्रवाई में देरी कर रहे हैं | 21% | कोयला अग्नि अनुपालन रिपोर्ट 2023 |

| गैर-अनुपालन से जुड़े उल्लंघनों की औसत अतिरिक्त लागत | $220,000 अधिक | डेटा उल्लंघन रिपोर्ट की आईबीएम लागत 2023 |

| जोखिम और अनुपालन पेशेवर जोखिमों से निपटने में आश्वस्त हैं | 60% | थॉमसन रॉयटर्स जोखिम & अनुपालन सर्वेक्षण 2023 |

कंपनियों को अपनी अनुपालन योजनाओं को आईएसओ जैसे मानकों के साथ मिलाना चाहिए. उन्हें स्पष्ट नियमों की आवश्यकता है, नियमित जाँच, और श्रमिकों के लिए प्रशिक्षण. सिस्टम पर हर समय नजर रखना और त्वरित बदलाव करना इसे मजबूत बनाए रखता है. एक अच्छी अनुपालन योजना वाला सुरक्षा शंकु आपूर्तिकर्ता बड़ी गलतियों से बच सकता है और ग्राहकों से विश्वास अर्जित कर सकता है.

रणनीतिक साझेदारी और सहयोग

रणनीतिक साझेदारी निर्माताओं को नए बाजारों में प्रवेश करने और अधिक खरीदार ढूंढने में मदद करती है. सौदे हैं 53% जब साझेदार एक साथ काम करते हैं तो बंद होने की अधिक संभावना होती है. साझेदारी से अनुसंधान लागत भी कम होती है और नए विचारों को तेजी से बढ़ने में मदद मिलती है. कई व्यापारिक नेता सोचते हैं कि एक साथ काम करने से कंपनियों के बढ़ने का तरीका बदल जाएगा. कुशल साझेदारों के साथ मिलकर, निर्माता जो जानते हैं उसे साझा कर सकते हैं और जोखिम कम कर सकते हैं. लेकिन समस्याओं को रोकने के लिए कंपनियों को इन साझेदारियों पर बारीकी से नजर रखनी चाहिए. एक मजबूत साझेदार नेटवर्क कंपनियों को लंबे समय तक उच्च परिशुद्धता बाजार में अच्छा प्रदर्शन करने में मदद करता है.

जर्मनी में उच्च परिशुद्धता निर्माताओं को सख्त नियमों का पालन करना पड़ता है. सुरक्षा शंकु आपूर्तिकर्ताओं को उत्पाद बेचने के लिए EN13422 प्रमाणीकरण की आवश्यकता है. जो कंपनियाँ नियमों का पालन करने पर पैसा खर्च करती हैं, नई टेक्नोलॉजी, और अच्छे साथी बेहतर कार्य करते हैं. वे विश्वास अर्जित करते हैं और उच्च सुरक्षा आवश्यकताओं को पूरा करते हैं. जो निर्माता नए नियमों का ध्यान रखते हैं और स्मार्ट विचारों का उपयोग करते हैं वे लंबे समय तक अच्छा प्रदर्शन कर सकते हैं.

बख्शीश: एक सुरक्षा शंकु आपूर्तिकर्ता को अक्सर अपनी अनुपालन योजनाओं की जांच करनी चाहिए और आगे रहने के लिए विशेषज्ञों से मदद मांगनी चाहिए.

अक्सर पूछे जाने वाले प्रश्न

EN13422 प्रमाणन क्या है??

EN13422 प्रमाणन का मतलब है कि कोई उत्पाद सख्त यूरोपीय सुरक्षा नियमों का पालन करता है. सड़क सुरक्षा उपकरणों के लिए इसकी आवश्यकता है. जर्मनी और यूरोपीय संघ में सुरक्षा शंकु बेचने के लिए निर्माताओं के पास यह होना चाहिए.

उच्च परिशुद्धता निर्माताओं को जर्मनी में प्रवेश बाधाओं का सामना क्यों करना पड़ता है??

उच्च परिशुद्धता निर्माता कठिन नियमों और उच्च लागतों से निपटते हैं. उन्हें गुणवत्ता पर कड़ी जांच का भी सामना करना पड़ता है. उन्हें जर्मन और यूरोपीय संघ के मानकों को पूरा करने के लिए उन्नत तकनीक और कुशल श्रमिकों की आवश्यकता है.

EN13422 प्रमाणन प्राप्त करने में कितना समय लगता है??

EN13422 प्रमाणन प्राप्त करने में कई महीने लग जाते हैं. कंपनियों को दस्तावेज़ तैयार रखने होंगे, उनके उत्पादों का परीक्षण करें, और चेक पास करें. यदि उत्पाद सभी नियमों को पूरा नहीं करते हैं, देरी हो सकती है.

EN13422 प्रमाणन के मुख्य लाभ क्या हैं??

EN13422 प्रमाणन ग्राहकों और नियामकों को किसी कंपनी पर भरोसा करने में मदद करता है. यह कंपनियों को नई जगहों पर बेचने की सुविधा देता है. इससे यह भी पता चलता है कि वे सुरक्षा और गुणवत्ता की परवाह करते हैं.

क्या साझेदारी EN13422 अनुपालन में मदद कर सकती है??

हाँ. विशेषज्ञों या तकनीकी साझेदारों के साथ काम करने से चीज़ें आसान हो सकती हैं. ये साझेदारियाँ कंपनियों को विचार साझा करने में मदद करती हैं, कम जोखिम, और तेजी से प्रमाणित हो जाएं.