सामग्री की पसंद सड़क संकेतों की सुरक्षा और दीर्घायु को बहुत प्रभावित करती है. एल्यूमीनियम मिश्रित छोटे और मध्यम एल्यूमीनियम साइन अनुप्रयोगों के लिए अच्छी तरह से अनुकूल है, हल्के और संभालने में आसान होना. ठोस एल्यूमीनियम अधिक शक्ति और स्थायित्व प्रदान करता है, इसे बड़े एल्यूमीनियम साइन आवश्यकताओं के लिए आदर्श बना रहा है. हाल के अध्ययनों से संकेत मिलता है कि प्रत्येक एल्यूमीनियम चिन्ह के लिए उच्च गुणवत्ता वाली सामग्री का चयन करने से लागत बचत होती है, कम रखरखाव, और यह सुनिश्चित करता है कि संकेत अत्यधिक दिखाई देते हैं. सड़क पेशेवर इस ज्ञान का उपयोग प्रत्येक परियोजना के लिए सबसे उपयुक्त एल्यूमीनियम संकेत का चयन करने के लिए करते हैं.

इन उद्योग मानकों के अनुरूप, Optraffic प्रीमियम की एक विस्तृत श्रृंखला प्रदान करता है एल्यूमीनियम यातायात संकेत प्रत्येक परियोजना की विशिष्ट आवश्यकताओं को पूरा करने के लिए अनुरूप. गुणवत्ता और नवाचार पर ध्यान देने के साथ, Optraffic यह सुनिश्चित करता है कि इसके साइनेज समाधान न केवल असाधारण स्थायित्व प्रदान करते हैं, बल्कि दृश्यता को भी बढ़ाते हैं, पेशेवरों की मदद करना सुरक्षित के लिए सही विकल्प बनाते हैं, लंबे समय तक चलने वाली सड़क बुनियादी ढांचा.

चाबी छीनना

- एल्यूमीनियम समग्र पैनल हल्के और उपयोग करने के लिए सरल हैं. वे छोटे या मध्यम सड़क संकेतों के लिए सबसे अच्छा काम करते हैं. ये पैनल शहरों और कस्बों के लिए अच्छे हैं.

- ठोस एल्यूमीनियम पैनल कठिन होते हैं और लंबे समय तक रहते हैं. वे बड़े या महत्वपूर्ण संकेतों के लिए सबसे अच्छे हैं. ये संकेत खराब मौसम और तेज हवाओं को संभाल सकते हैं.

- सही पैनल चुनने से पैसे बचाने में मदद मिलती है. यह संकेतों को तेजी से और आसान बनाता है. इसका मतलब कम फिक्सिंग और कम प्रतिस्थापन भी है.

- दोनों प्रकार के पैनल जंग नहीं करते हैं. वे संकेतों को उज्ज्वल और देखने में आसान रहने में मदद करते हैं. उन पर ग्राफिक्स किसी भी मौसम में स्पष्ट और चमकदार हैं.

- पुनर्नवीनीकरण सामग्री का उपयोग ग्रह के लिए अच्छा है. पैनलों को पुनर्चक्रण करने से सभी के लिए संकेत मजबूत और सुरक्षित रहते हैं.

सामग्री अवलोकन

एल्यूमीनियम मिश्रित

एल्यूमीनियम समग्र पैनल अक्सर सड़क संकेतों के लिए उपयोग किए जाते हैं. इन पैनलों में दो पतली एल्यूमीनियम चादरें होती हैं. प्रत्येक शीट लगभग 0.5 मिमी मोटी है. चादरें एक प्लास्टिक कोर से चिपक जाती हैं. कोर आमतौर पर पॉलीथीन से बनाया जाता है. यह पैनल को हल्का और सस्ता बनाता है. कुछ पैनलों में कोर में विशेष रसायन होते हैं. ये रसायन आग को रोकने में मदद करते हैं. बाहर की तरफ एल्यूमीनियम जंग और मौसम से नुकसान को रोकता है. एल्यूमीनियम समग्र सामग्री प्रकाश है. इससे चलना और ऊपर रखना आसान हो जाता है. ये पैनल स्पष्ट तस्वीरें और चमकदार फिल्में दिखा सकते हैं. यह लोगों को संकेतों को अच्छी तरह से देखने में मदद करता है. एल्यूमीनियम समग्र पैनल साइनेज कई आकार और आकारों में बनाया जा सकता है. कई कंपनियां इन पैनलों में पुनर्नवीनीकरण एल्यूमीनियम का उपयोग करती हैं. यह पर्यावरण की रक्षा करने में मदद करता है.

टिप्पणी: एल्यूमीनियम समग्र पैनल अपने रंग को बनाए रखते हैं और वर्षों से अच्छे लगते हैं, खराब मौसम में भी बाहर.

एक सामान्य एल्यूमीनियम समग्र पैनल साइनेज में कारखाने में एक मजबूत खत्म होता है. यह खत्म दरार नहीं है, चिप, या पील. पैनल मजबूत हैं लेकिन फिर भी हल्के हैं. उनका घनत्व बीच है 0.90 और 2.30 g/cm g. वे अग्नि सुरक्षा नियमों को भी पूरा करते हैं. यह उन्हें सार्वजनिक स्थानों के लिए सुरक्षित बनाता है. प्लास्टिक कोर का मतलब है कि ये पैनल ठोस एल्यूमीनियम के रूप में मजबूत नहीं हैं.

ठोस एल्यूमीनियम

ठोस एल्यूमीनियम पैनल एल्यूमीनियम की एक मोटी शीट से बनाए जाते हैं. शीट आमतौर पर 2 मिमी से 4 मिमी मोटी होती है. निर्माता अक्सर AA1100 या AA3003 एल्यूमीनियम मिश्र धातुओं का उपयोग करते हैं. ठोस एल्यूमीनियम संकेत बहुत मजबूत हैं. वे तेज हवाओं के लिए खड़े हो सकते हैं. ठोस निर्माण इन पैनलों को कठोर और कठिन बनाता है. ठोस एल्यूमीनियम पैनल खराब मौसम और तेज हवाओं के माध्यम से चलते हैं. वे समुद्र के पास स्थानों के लिए अच्छे हैं. ये पैनल अधिक मूल्य के हैं क्योंकि उनके पास अधिक धातु है. ठोस एल्यूमीनियम संकेत एल्यूमीनियम समग्र पैनल साइनेज की तुलना में भारी होते हैं. यह उन्हें कठिन बना सकता है. लेकिन अतिरिक्त वजन बड़े संकेतों को जगह में रहने में मदद करता है.

ठोस एल्यूमीनियम पैनल जंग नहीं और लंबे समय तक मजबूत रहते हैं. ये पैनल सबसे अच्छे हैं जहां ताकत और लंबे जीवन की आवश्यकता होती है. कई परिषदें राजमार्ग और देश के संकेतों के लिए ठोस एल्यूमीनियम चुनती हैं. इन जगहों पर अक्सर खुरदरा मौसम होता है.

एल्यूमीनियम हस्ताक्षर अनुप्रयोग

कई प्रकार के सड़क संकेतों के लिए एल्यूमीनियम संकेतों का उपयोग किया जाता है. एल्यूमीनियम समग्र पैनल साइनेज और ठोस एल्यूमीनियम संकेतों के बीच की पसंद आकार पर निर्भर करती है, जगह, और साइन को कितना कठिन होना चाहिए. नीचे दी गई तालिका से पता चलता है कि अलग -अलग पैनल कहां है मोटाई उपयोग किया जाता है:

| एल्यूमीनियम मोटाई | सामान्य अनुप्रयोग | विशिष्ट वातावरण | हस्ताक्षर प्रकार | मुख्य लाभ |

|---|---|---|---|---|

| 1.6मिमी | छोटे से मध्यम संकेत | शहरी, उपनगरीय | नियामक, चेतावनी, पार्किंग | लाइटवेट, स्थापित करना आसान है, प्रभावी लागत |

| 2.0मिमी | बड़ा गाइड और दिशात्मक | ग्रामीण, तूफ़ानी | मार्गदर्शक, दिशात्मक पैनल | मजबूत, हवा का सामना करना पड़ता है, टिकाऊ |

| 3.0मिमी | बहुत बड़े राजमार्ग संकेत | ऊँची हवा, चक्रवात क्षेत्र | भूमि के ऊपर, गैन्ट्री संकेत | अधिकतम शक्ति, झुकने का विरोध करता है, बहुत टिकाऊ |

एल्यूमीनियम समग्र पैनल साइनेज छोटे या मध्यम एल्यूमीनियम साइन नौकरियों के लिए सबसे अच्छा है जो कस्बों और शहरों में हैं. ठोस एल्यूमीनियम संकेत बड़े के लिए बेहतर हैं, उपरि, या देश के संकेत जहां ताकत और पवन सबसे अधिक मायने रखते हैं. दोनों प्रकार के पैनलों में चमकदार कवर और विशेष चित्र हो सकते हैं. यह सुनिश्चित करता है कि सभी ड्राइवर संकेतों को स्पष्ट रूप से देख सकते हैं.

वज़न & हैंडलिंग

हल्के एल्यूमीनियम समग्र

एल्युमीनियम मिश्रित पैनल ठोस एल्युमीनियम की तुलना में बहुत हल्के होते हैं. इनमें दो पतली एल्यूमीनियम शीटों के बीच एक प्लास्टिक कोर होता है. इससे उनका वजन ठोस एल्यूमीनियम पैनलों से लगभग आधा हो जाता है. उदाहरण के लिए, एक 4 मिमी एल्यूमीनियम मिश्रित पैनल का वजन लगभग होता है 6.3 को 7.6 प्रति वर्ग मीटर किलो. एक 4 मिमी ठोस एल्यूमीनियम पैनल का वजन तक हो सकता है 15 प्रति वर्ग मीटर किलो. नीचे दी गई तालिका वजन में अंतर दर्शाती है:

| पैनल प्रकार | मोटाई | वज़न (किग्रा/वर्ग मीटर) | विवरण |

|---|---|---|---|

| एल्यूमीनियम मिश्रित पैनल | 4 मिमी | 6.3 – 7.6 | प्लास्टिक कोर वाली दो पतली एल्यूमीनियम शीट, ठोस एल्यूमीनियम की तुलना में बहुत हल्का |

| ठोस एल्यूमीनियम पैनल | 4 मिमी | 10.8 – 15 | एकल मोटी एल्यूमीनियम शीट, काफ़ी भारी |

एल्यूमिनियम कम्पोजिट पैनल साइनेज को ले जाना और ले जाना आसान है. श्रमिक इन पैनलों को बिना किसी परेशानी के उठा सकते हैं. यहां तक कि बड़े सड़क संकेत भी बहुत भारी नहीं हैं. इन्हें लगाने के लिए आपको विशेष मशीनों या भारी एंकरों की आवश्यकता नहीं है. टीमें सरल उपकरणों से इन पैनलों को काट और आकार दे सकती हैं. इससे काम तेजी से होता है. कम फिक्सिंग बिंदुओं की आवश्यकता है, इसलिए इससे समय और धन की बचत होती है. पैनल सपाट और स्थिर हैं. यह चिंतनशील फ़िल्मों और ग्राफ़िक्स के लिए अच्छा है. ये विशेषताएं एल्यूमीनियम मिश्रित पैनल साइनेज को उन सड़क संकेतों के लिए पसंदीदा बनाती हैं जो अक्सर चलते या बदलते रहते हैं.

बख्शीश: एल्यूमिनियम कम्पोजिट पैनल साइनेज पोस्ट और सपोर्ट पर कम दबाव डालता है, इसलिए संकेत लंबे समय तक चलते हैं.

ठोस एल्यूमीनियम वजन

ठोस एल्यूमीनियम पैनल एल्यूमीनियम मिश्रित पैनल की तुलना में बहुत भारी होते हैं. समान आकार का एक ठोस एल्यूमीनियम पैनल दोगुना वजन का हो सकता है. इन्हें उठाने और स्थापित करने के लिए श्रमिकों को अधिक ताकत की आवश्यकता होती है. ठोस एल्यूमीनियम पैनलों को चलाने के लिए मजबूत वाहनों और अधिक ईंधन की आवश्यकता होती है. टीमों को बड़े ठोस एल्यूमीनियम संकेतों के लिए विशेष मशीनों की आवश्यकता हो सकती है. भारी वजन का मतलब है कि आपको मजबूत पोस्ट और फ़्रेम की आवश्यकता है. लेकिन ठोस निर्माण इन पैनलों को बहुत मजबूत बनाता है. यह बड़े या महत्वपूर्ण सड़क संकेतों के लिए महत्वपूर्ण है. ठोस एल्यूमीनियम पैनल अभी भी उन जगहों के लिए सबसे अच्छे हैं जहां ताकत और हवा के प्रतिरोध की सबसे अधिक आवश्यकता होती है.

कठोरता & ताकत

एल्यूमीनियम समग्र का लचीलापन

एल्यूमीनियम मिश्रित पैनल दो पतली एल्यूमीनियम शीट और एक कोर है. कोर एल्यूमीनियम से नहीं बनाया गया है. यह पैनल को हल्का और मोड़ने में आसान बनाता है. श्रमिक इन पैनलों को सामान्य उपकरणों के साथ आकार दे सकते हैं. वे कई संकेत आकार और आकार बना सकते हैं. झुकने के बाद पैनल अपना आकार रखते हैं. यह विशेष संकेत बनाते समय मदद करता है.

एल्यूमीनियम समग्र पैनल हवा में मजबूत होते हैं. एक 4 मिमी पैनल बहुत तेज हवाओं को संभाल सकता है. यह एक स्तर तक खड़ा हो सकता है 17 आंधी. जब हवा है 30 मीटर प्रति सेकंड, पैनल बहुत कम झुकता है. यह GB/T17748-2016 में मानक से बेहतर है. पैनल की झुकने की ताकत कम से कम 100mpa है. पैनल के अंदर एक विशेष लहर आकार है. यह पैनल को गर्म या ठंडे मौसम में सपाट और मजबूत रहने में मदद करता है. पैनल ज्यादा झुकता नहीं है, खराब मौसम में भी.

ये पैनल हल्के लेकिन अभी भी मजबूत हैं. इससे उन्हें रखना आसान हो जाता है. उनका लचीलापन चिकनी और रचनात्मक संकेत बनाने में मदद करता है. ये विशेषताएं सड़क के संकेतों को लंबे समय तक चलने में मदद करती हैं और अच्छी लगती हैं.

ठोस एल्यूमीनियम की ताकत

ठोस एल्यूमीनियम पैनल बहुत मजबूत और कठोर होते हैं. ताकत इस बात पर निर्भर करती है कि पैनल कितना मोटा है. एल्यूमीनियम मिश्र धातु का प्रकार भी मायने रखता है. मोटे पैनलों को झुकना कठिन होता है. वाइड पैनल बीच में अधिक झुक सकते हैं. इंजीनियर बीएस 5427–1 जैसे नियमों का उपयोग करते हैं:1996 सही मोटाई लेने के लिए.

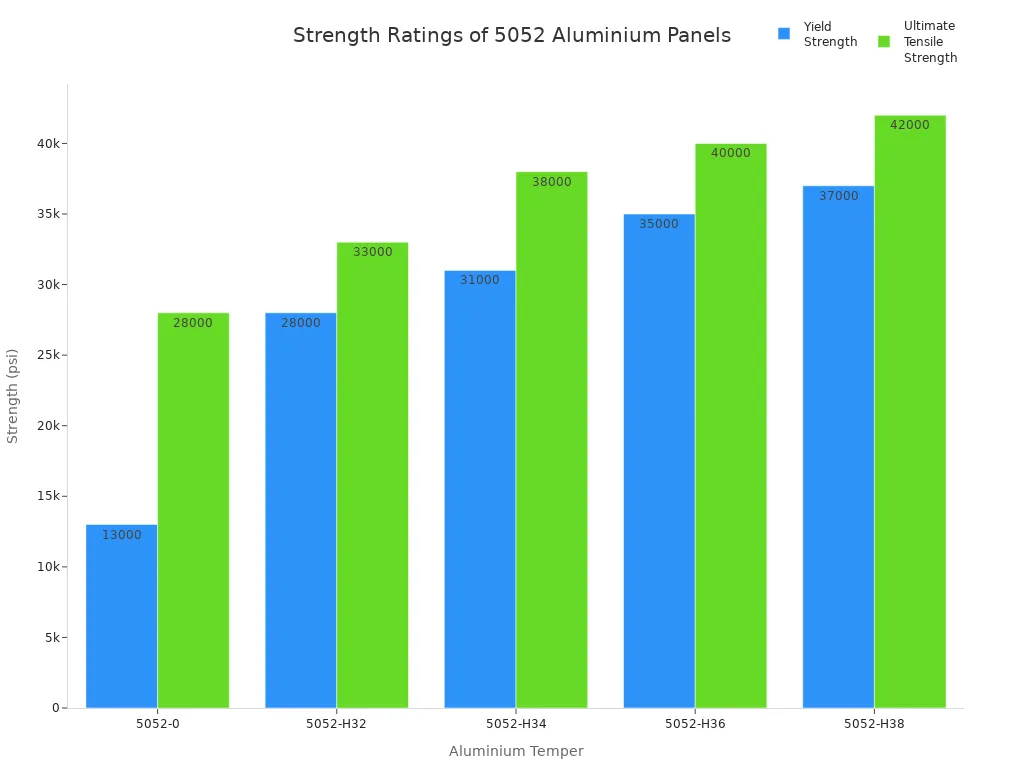

ठोस एल्यूमीनियम संकेत मिश्र धातुओं की तरह उपयोग करते हैं 5052, 1060, और 3003. The 5052 मिश्रधातु मजबूत और थोड़ी लचीली होती है. नीचे दी गई तालिका दर्शाती है कि यह कितना मजबूत है 5052 एल्यूमीनियम पैनल हैं:

| गुस्सा | नम्य होने की क्षमता (साई) | परम तन्य शक्ति (साई) |

|---|---|---|

| 5052-0 | 13,000 | 28,000 |

| 5052-H32 | 28,000 | 33,000 |

| 5052-एच34 | 31,000 | 38,000 |

| 5052-एच36 | 35,000 | 40,000 |

| 5052-H38 | 37,000 | 42,000 |

ठोस एल्युमीनियम चिन्ह तेज हवाओं में आसानी से नहीं झुकते. वे कठोर प्रहार सह सकते हैं और अपनी जगह पर बने रह सकते हैं. ठोस निर्माण चिन्ह को स्थिर रखता है. यह उन्हें बड़े या महत्वपूर्ण सड़क संकेतों के लिए सर्वोत्तम बनाता है. उनकी ताकत संकेतों को सुरक्षित और पढ़ने में आसान रखती है, उबड़-खाबड़ जगहों पर भी.

सहनशीलता & प्रतिरोध

मौसम प्रतिरोधक

एल्युमीनियम रोड साइन पैनलों को कठिन मौसम से निपटने की आवश्यकता होती है. एल्यूमीनियम मिश्रित और ठोस एल्यूमीनियम पैनल दोनों ही यह काम अच्छी तरह से करते हैं. ठोस एल्यूमीनियम पैनल एक धातु शीट से बनाए जाते हैं. यह उन्हें बारिश के खिलाफ बहुत मजबूत बनाता है, हवा, और सूर्य. वे जंग नहीं करते हैं, यहां तक कि समुद्र के पास भी जहां हवा नमकीन है. उनकी ताकत उन्हें आकार बदले बिना कई वर्षों तक जीवित रहने में मदद करती है.

एल्यूमीनियम मिश्रित पैनल में दो पतली एल्यूमीनियम शीट और एक प्लास्टिक कोर होती है. निर्माता इन पैनलों को पॉलिएस्टर या जैसी विशेष परतों से ढकते हैं पीवीडीएफ. ये परतें पैनलों को बारिश से बचाती हैं, सूरज, और गंदी हवा. पैनल लंबे समय तक अपना रंग और आकार बनाए रखते हैं. वे आसानी से टूटते या मुरझाते नहीं हैं. कई परिषदें शहरों और कस्बों में संकेतों के लिए एल्यूमीनियम मिश्रित पैनलों का उपयोग करती हैं. ये पैनल हल्के और लगाने में आसान हैं.

नीचे दी गई तालिका दिखाती है कि दोनों प्रकार के पैनल मौसम को कैसे संभालते हैं और समय के साथ कैसे टिकते हैं:

| संपत्ति/पहलू | एल्यूमीनियम मिश्रित पैनल | ठोस एल्यूमीनियम पैनल |

|---|---|---|

| मौसम प्रतिरोधक | बारिश का विरोध करने के लिए लेपित, हवा, सूरज; जंग या सड़न न हो | weatherproof, जंग मत लगाओ |

| सहनशीलता | वर्षों तक आकार और रंग बनाए रखें; लुप्त होने के प्रति प्रतिरोधी | बहुत उच्च स्थायित्व, लंबा जीवनकाल |

| पर्यावरणीय प्रतिरोध | सूरज की रोशनी का विरोध करें, पानी, गंदी हवा, समुद्र के पास नमक | सभी वातावरणों में मौसम प्रतिरोधी |

ठोस एल्यूमीनियम पैनल बाहर सबसे लंबे समय तक रहते हैं. वे खराब मौसम में कई वर्षों के बाद मजबूत और सुरक्षित रहते हैं. एल्यूमीनियम समग्र पैनल भी अच्छी तरह से काम करते हैं, लेकिन उनके प्लास्टिक कोर उन्हें बहुत कठोर स्थानों में कम सख्त बना सकते हैं.

टिप्पणी: दोनों पैनल प्रकारों को बहुत कम देखभाल की आवश्यकता है. हल्के साबुन और पानी के साथ सफाई उन्हें अच्छी लगती है.

संघात प्रतिरोध

सड़क के संकेत उड़ने वाली वस्तुओं की चपेट में आ सकते हैं, कारें, या लोग. हिट लेने में ठोस एल्यूमीनियम पैनल बहुत अच्छे हैं. मोटी धातु की चादर बल को भिगोती है और डेंट को रोकती है. परीक्षण में, ठोस एल्यूमीनियम पैनलों को केवल हार्ड हिट के बाद छोटे निशान मिलते हैं. वे दरार या टूटते नहीं हैं. यह उन्हें उन स्थानों के लिए एक स्मार्ट विकल्प बनाता है जहां संकेत क्षतिग्रस्त हो सकते हैं.

एल्यूमीनियम समग्र पैनल भी हिट के खिलाफ मजबूत हैं. एल्यूमीनियम परतें और प्लास्टिक कोर झटके में मदद करते हैं. ये पैनल कस्बों और शहरों में अधिकांश हिट संभाल सकते हैं. लेकिन अगर हिट बहुत कठिन है, शीर्ष एल्यूमीनियम परत सेंध लगा सकती है. नीचे की परत दरार कर सकती है, और परतें अलग हो सकती हैं. कभी-कभी, अगर हिट बहुत मजबूत है तो कोर टूट सकता है.

यहां कुछ सामान्य तरीके दिए गए हैं जो प्रत्येक पैनल प्रकार विफल हो सकते हैं:

- एल्यूमीनियम मिश्रित पैनल:

- शीर्ष परत पर डेंट

- नीचे की परत में दरारें

- परतें अलग आ रही हैं

- बहुत कठिन हिट के साथ कोर ब्रेकिंग

- ठोस एल्यूमीनियम पैनल:

- डेंट लेकिन कोई दरार या छेद नहीं

ठोस एल्यूमीनियम पैनल उन स्थानों के लिए सबसे अच्छे हैं जहां संकेतों को बहुत कठिन होने की आवश्यकता है. एल्यूमीनियम समग्र पैनल मजबूत और हल्के होते हैं, इसलिए वे अधिकांश सड़क संकेतों के लिए अच्छी तरह से काम करते हैं जहां बड़ी हिट की संभावना नहीं है.

बख्शीश: बहुत सारी हिट वाले स्थानों के लिए, राजमार्गों या कारखानों की तरह, ठोस एल्यूमीनियम पैनल अधिक सुरक्षा देते हैं और लंबे समय तक रहते हैं.

उपयुक्तता & इंस्टालेशन

साइन आकार & बढ़ते

आप जिस सामग्री को लेते हैं, वह बदलती है कि ट्रैफ़िक के संकेत कैसे लगाए जाते हैं. अलग -अलग साइन साइज़ और वेट उन्हें पकड़ने के लिए अलग -अलग तरीकों की जरूरत है. एल्यूमीनियम समग्र जैसे लाइटर पैनल छोटे और मध्यम संकेतों के लिए अच्छी तरह से काम करते हैं. श्रमिक इन संकेतों के लिए सरल तह पैरों का उपयोग कर सकते हैं. मध्यम संकेतों को कभी-कभी अधिक समर्थन के लिए द्वि-पॉड तह पैरों की आवश्यकता होती है. भारी या स्थायी संकेत, जैसे कि ठोस एल्यूमीनियम, स्थिर रखने के लिए मजबूत वाई-स्टैंड्स की आवश्यकता है.

मौसम भी मायने रखता है. सूरज, बारिश, कोहरा, और अंधेरा देखने के लिए संकेत कठिन बना सकता है. चिंतनशील सामग्री और चमकीले रंग ड्राइवरों को किसी भी मौसम में स्पॉट संकेतों में मदद करते हैं. नीचे दी गई तालिका से पता चलता है कि सामग्री कैसे आकार का आकार बदलती है, वज़न, और इसे कैसे रखा जाता है:

| सामग्री प्रकार | साइन आकार और आकार के लिए उपयुक्तता | भार प्रभाव | बढ़ते निहितार्थ |

|---|---|---|---|

| मानक ठोस एल्यूमीनियम | छोटे के लिए सबसे अच्छा, मानक संकेत | कंपोजिट की तुलना में भारी | पूर्व-निर्मित छेद, मानक आकार, मजबूत समर्थन |

| मैक्समेटल एल्यूमीनियम समग्र | बड़े के लिए अच्छा है, कस्टम आकार के संकेत | हल्का, संभालना आसान है | सरल स्थापना, बड़े या दो तरफा संकेतों के लिए अच्छा है |

सही ट्रैफ़िक साइन सामग्री चुनना साइन को सुरक्षित और देखने में आसान रखता है. चिन्ह लगाने का सही तरीका यह स्थिर रहता है, यहां तक कि तेज हवा या व्यस्त स्थानों में.

परिषद की प्राथमिकताएँ

ऑस्ट्रेलिया में स्थानीय परिषदों के पास सड़क हस्ताक्षर सामग्री के लिए स्पष्ट पसंदीदा है. शहरों और कस्बों में, काउंसिल अक्सर छोटे और मध्यम संकेतों के लिए एल्यूमीनियम समग्र पैनल चुनते हैं. ये पैनल हल्के हैं, सरल, और पैसे बचाओ. श्रमिक जल्दी से कई संकेत स्थापित कर सकते हैं, जो व्यस्त शहर की नौकरियों में मदद करता है.

बड़े या अधिक महत्वपूर्ण संकेतों के लिए, जैसे राजमार्गों पर या देश में, परिषदें ठोस एल्यूमीनियम संकेत चुनती हैं. ये एल्यूमीनियम संकेत मजबूत होते हैं और कठिन मौसम में लंबे समय तक रहते हैं. परिषदें ऐसे संकेत चाहते हैं जो रहते हैं और कई वर्षों तक पढ़ना आसान है. वे ऐसी सामग्री भी चाहते हैं जिन्हें बहुत अधिक देखभाल की आवश्यकता नहीं है.

बख्शीश: काउंसिल आमतौर पर एल्यूमीनियम संकेतों के लिए निर्धारित नियमों का पालन करते हैं ताकि सभी सड़क उपयोगकर्ता स्पष्ट और सुरक्षित संदेश देखें.

लागत तुलना

माल की लागत

एल्यूमीनियम समग्र और ठोस एल्यूमीनियम पैनलों की लागत अक्सर बदल सकती है. कई चीजें इन कीमतों को ऊपर या नीचे कर देती हैं. एल्यूमीनियम और पॉलीथीन की कीमत बहुत बदल जाती है. तेल की कीमतें और धन मूल्य भी लागतों को प्रभावित करते हैं. एल्यूमीनियम समग्र पैनलों को बनाने की जरूरत है बड़े कारखानों और मशीनों को. नए नियम और बेहतर पैनल, आग-सुरक्षित या हरे रंग की तरह, प्रत्येक पैनल और कीमत में जो कुछ भी है उसे बदल सकते हैं. अधिक लोग निर्माण और परिवहन के लिए हल्के और मजबूत सामग्री चाहते हैं, तो कीमतें बढ़ सकती हैं.

एल्यूमीनियम समग्र पैनलों के लिए विश्व बाजार जल्दी से बढ़ रहा है. कंपनियां नए विचारों और उत्पादों पर पैसा खर्च करती हैं, जिससे कीमतें अधिक बदल सकती हैं. ठोस एल्यूमीनियम पैनल आमतौर पर समग्र पैनलों की तुलना में अधिक खर्च होते हैं क्योंकि वे अधिक धातु का उपयोग करते हैं. लेकिन अगर कच्चे माल की कीमत बढ़ जाती है, दोनों प्रकार अधिक महंगे हो सकते हैं.

| पैनल प्रकार | विशिष्ट लागत सीमा (प्रति वर्ग) | मुख्य लागत चालक |

|---|---|---|

| एल्यूमीनियम मिश्रित पैनल | कम से कम | कच्चे माल की कीमतें, उत्पादन, माँग |

| ठोस एल्यूमीनियम पैनल | मध्यम से अधिक | एल्यूमीनियम कीमत, मोटाई, प्रसंस्करण |

टिप्पणी: जब लागत के बारे में सोच रहा था, देखें कि पैनल कितने समय तक रहता है और यह कितना अच्छा काम करता है, सिर्फ कीमत नहीं.

इंस्टालेशन & रखरखाव

एक पैनल लगाने के लिए कितना खर्च होता है, इसके वजन और आकार पर निर्भर करता है. एल्यूमीनियम समग्र पैनल हल्के होते हैं, इसलिए श्रमिक उन्हें तेजी से और कम गियर के साथ रख सकते हैं. यह काम पर पैसा बचाता है और पैनलों को स्थानांतरित करता है. ठोस एल्यूमीनियम पैनल भारी होते हैं और स्थापित करने के लिए अधिक लोगों या मशीनों की आवश्यकता हो सकती है, जो अधिक खर्च कर सकता है.

पैनलों की देखभाल करना भी पैसे बचाने के लिए महत्वपूर्ण है. दोनों प्रकारों को ज्यादा देखभाल की आवश्यकता नहीं है. उन्हें साबुन और पानी से साफ करना उन्हें अच्छा लग रहा है. ठोस एल्यूमीनियम पैनल अक्सर लंबे समय तक रहते हैं, खराब मौसम में भी, इसलिए आपको उन्हें अक्सर बदलने की आवश्यकता नहीं हो सकती है. एल्यूमीनियम समग्र पैनल भी अच्छी तरह से पिछले तक रहते हैं, लेकिन बहुत मोटे स्थानों में, उन्हें जल्द ही बदलने की आवश्यकता हो सकती है.

बख्शीश: नौकरी के लिए सही पैनल चुनने से परिषदों और कंपनियों को समय के साथ पैसे बचाने में मदद मिलती है.

उपस्थिति & .Customization

सतह खत्म

एल्यूमीनियम समग्र पैनल साइनेज कई फिनिश में आता है. निर्माता मजबूत मिश्र धातुओं का उपयोग करते हैं जो जंग नहीं करते हैं, समुद्र के पास भी. इन पैनलों में अक्सर कारखाने से विशेष कोटिंग्स होते हैं, पीवीडीएफ या पॉलिएस्टर की तरह. पीवीडीएफ कोटिंग्स बाहरी उपयोग के लिए महान हैं. वे यूवी किरणों को रोकते हैं, स्क्रैच, और लुप्त होती. रंग लंबे समय तक उज्ज्वल रहता है. पॉलिएस्टर कोटिंग्स इनडोर या कवर किए गए संकेतों के लिए अच्छे हैं. वे ठोस रंग देते हैं और लागत कम होती है. कुछ पैनलों में उन्हें कठिन बनाने के लिए ऑक्साइड फिल्में हैं. अन्य एक चमकदार लुक के लिए एक चमकदार लैमिनेटिंग फिनिश का उपयोग करते हैं.

| सतह समापन प्रकार | स्थायित्व सुविधाएँ | उपस्थिति विकल्प |

|---|---|---|

| पीवीडीएफ कोटिंग | यूवी, मौसम, प्रतिरोधी खरोंच; लंबे समय तक चलने वाला रंग | धातु का, मैट, ग्लोस |

| पॉलिएस्टर कोटिंग | मध्यम स्थायित्व | ठोस रंग |

| ऑक्साइड फिल्म | बहुत कठिन, जंग प्रतिरोधी | सीमित विकल्प |

| टुकड़े टुकड़े करना | प्रतिरोधी खरोंच, चमकदार | चमकदार उपस्थिति |

एल्यूमीनियम समग्र पैनल साइनेज का उपयोग करने के लिए तैयार है जब यह आता है. इंस्टॉलर को इसे डालने के बाद इसे पेंट करने की आवश्यकता नहीं है. यह समय बचाता है और सभी संकेत समान दिखता है. पैनल अच्छे दिखते रहते हैं और कई सालों तक मजबूत रहते हैं.

GRAPHICS & चिंतनशील फिल्में

सड़क के संकेतों को देखने में आसान बनाने के लिए ग्राफिक्स महत्वपूर्ण हैं. एल्यूमीनियम कम्पोजिट पैनल साइनेज में कई प्रकार के ग्राफिक्स हो सकते हैं. पैनल मैट में आते हैं, ग्लोस, ब्रश, और दर्पण खत्म हो जाता है. ये अलग -अलग ग्राफिक जरूरतों के लिए काम करते हैं. सतह यूवी और लेटेक्स प्रिंटिंग के लिए अच्छी है. यह उज्ज्वल और लंबे समय तक चलने वाले ग्राफिक्स देता है. इंस्टॉलर पैनलों पर चिंतनशील विनाइल फिल्में डाल सकते हैं. यह ड्राइवरों को रात में संकेत देखने में मदद करता है. कई प्रकार की विनाइल फिल्में हैं, उच्च प्रदर्शन वाले कलाकारों की तरह, पारदर्शी, और विशेष.

- पैनल प्रत्यक्ष मुद्रण और आसान विनाइल उपयोग के लिए अच्छे हैं.

- चिंतनशील फिल्में ड्राइवरों को अंधेरा होने पर संकेत देखने में मदद करती हैं.

- विभिन्न आवश्यकताओं के लिए कई आकार और आकारों में संकेत बनाए जा सकते हैं.

ठोस एल्यूमीनियम पैनल में ग्राफिक्स और विनाइल फिल्में भी हो सकती हैं. लेकिन एल्यूमीनियम कम्पोजिट पैनल साइनेज में अधिक फिनिश विकल्प हैं और इसे कस्टमाइज़ करना आसान है. यह उन संकेतों को बनाने में मदद करता है जो बाहर खड़े हैं और पढ़ने में आसान हैं.

पर्यावरणीय प्रभाव

एल्यूमीनियम समग्र की स्थिरता

एल्यूमीनियम समग्र पैनल पर्यावरण के लिए अच्छे हैं. वे प्रकाश हैं, तो कम एल्यूमीनियम की जरूरत है. इसका मतलब है कि उन्हें कम ऊर्जा का उपयोग करना और कम प्रदूषण करना है. पैनल अक्सर अधिक से अधिक होते हैं 30% पुनर्निर्मित एल्यूमीनियम. दोनों एल्यूमीनियम शीट और प्लास्टिक कोर को पुनर्नवीनीकरण किया जा सकता है जब साइन पुराना हो. यह लैंडफिल में जाने से बकवास को रोकने में मदद करता है और सामग्री का पुन: उपयोग करने में मदद करता है.

ये पैनल बाहर लंबे समय तक चलते हैं, के बारे में 10 को 20 साल. क्योंकि वे इतने लंबे समय तक चलते हैं, आपको उन्हें अक्सर बदलने की आवश्यकता नहीं है. यह संसाधनों को बचाता है और कम अपशिष्ट बनाता है. उनके चमकदार कोटिंग्स गर्मी को प्रतिबिंबित करने में मदद करते हैं, इसलिए वे बाहरी संकेतों के लिए अच्छे हैं. यह पास की इमारतों को कम ऊर्जा का उपयोग करने में भी मदद कर सकता है.

लेकिन इन पैनलों को पुनर्चक्रण करना हमेशा आसान नहीं होता है. प्लास्टिक कोर और परतों को विशेष रीसाइक्लिंग मशीनों की आवश्यकता होती है. कुछ रीसाइक्लिंग केंद्र पैनलों को अलग कर सकते हैं और एल्यूमीनियम वापस ले सकते हैं. सभी स्थान अभी तक ऐसा नहीं कर सकते. उद्योग और सरकार में समूह रीसाइक्लिंग को बेहतर बनाना चाहते हैं. वे लोगों को पुराने पैनलों को इकट्ठा करने में मदद कर रहे हैं और उन आपूर्तिकर्ताओं को चुनते हैं जो पर्यावरण की परवाह करते हैं.

| पर्यावरणीय पहलू | एल्यूमीनियम मिश्रित सामग्री (एसीएम) स्थिरता अंतर्दृष्टि |

|---|---|

| पुनरावृत्ति | एल्यूमीनियम शीट को पुनर्नवीनीकरण किया जा सकता है; प्लास्टिक कोर को विशेष मशीनों की आवश्यकता होती है |

| सहनशीलता | 10-20 साल के बाहर रहता है, इतना कम बेकार |

| उत्पादन ऊर्जा उपयोग | यदि पुनर्नवीनीकरण एल्यूमीनियम का उपयोग किया जाता है तो कम ऊर्जा का उपयोग करता है |

| समग्र पुनरावर्तन | रीसायकल करने के लिए कठिन, विशेष केंद्रों की जरूरत है |

| परिपत्र अर्थव्यवस्था | पुनर्नवीनीकरण सामग्री का उपयोग करता है, लैंडफिल से बाहर बकवास रखने में मदद करता है |

ठोस एल्यूमीनियम पदचिह्न

ठोस एल्यूमीनियम पैनल पर्यावरण को एक अलग तरीके से प्रभावित करते हैं. नया एल्युमीनियम बनाने में बहुत अधिक ऊर्जा खर्च होती है और मिश्रित पैनल बनाने की तुलना में अधिक प्रदूषण होता है. ये पैनल भारी हैं, इसलिए उन्हें हिलाने और ऊपर रखने में अधिक ऊर्जा खर्च होती है, खासकर बड़े संकेतों के लिए.

एल्युमीनियम के पुनर्चक्रण से काफी ऊर्जा की बचत होती है, तक 95% नए एल्युमीनियम बनाने की तुलना में. अधिकांश ठोस एल्यूमीनियम पैनलों को पूरी तरह से पुनर्नवीनीकरण किया जा सकता है, जो ग्रह के लिए अच्छा है. वे बहुत मजबूत हैं और कई वर्षों तक बाहर रहते हैं. इसका मतलब है कि आपको उन्हें बार-बार बदलने की ज़रूरत नहीं है. इससे अपशिष्ट कम करने में मदद मिलती है और पर्यावरण की देखभाल में मदद मिलती है.

ठोस एल्यूमीनियम पैनल कठिन बाहरी स्थानों के लिए अच्छे होते हैं और लंबे समय तक चलते हैं. काउंसिल और बिल्डर अक्सर पर्यावरण की मदद के लिए पुनर्नवीनीकरण एल्यूमीनियम से बने पैनल चुनते हैं. जैसे-जैसे रीसाइक्लिंग बेहतर होती जाती है, दोनों प्रकार के पैनल ग्रह के लिए और भी बेहतर हो जाएंगे.

जब आप एसीएम और ठोस एल्यूमीनियम की तुलना करते हैं, आप बड़े अंतर देखते हैं. नीचे दी गई तालिका मुख्य बिंदुओं को दिखाती है:

| गुण | एल्यूमीनियम मिश्रित पैनल | ठोस एल्यूमीनियम |

|---|---|---|

| सहनशीलता | अच्छा, रहता है 10+ साल | उत्कृष्ट, बहुत लंबा |

| वज़न | रोशनी, संभालना आसान है | भारी, समर्थन की आवश्यकता है |

| लागत | कम प्रारंभिक लागत | उच्चतर लागत |

| साइन आकार | बड़ा, कस्टम आकार | छोटे, मजबूत संकेत |

विशेषज्ञों का कहना है कि एल्यूमीनियम कम्पोजिट बड़े या विशेष आकार के संकेतों के लिए सबसे अच्छा है. इसे रखना आसान है और पहली बार में ज्यादा खर्च नहीं होता है. ठोस एल्यूमीनियम कठिन आउटडोर संकेतों के लिए बेहतर है जो लंबे समय तक चलना चाहिए. कई परिषदें पुनर्नवीनी सामग्री का उपयोग करने के लिए हर एल्यूमीनियम साइन चाहते हैं. भविष्य में, अधिक संकेत पुनर्नवीनीकरण भागों का उपयोग करेंगे. परिषदें ऐसे संकेतों का चयन करना शुरू कर रही हैं जो पर्यावरण के लिए बेहतर हैं.

इस बारे में अधिक जानने के लिए कि कैसे सामग्री विकल्प ऑस्ट्रेलिया में यातायात संकेतों के विकास को प्रभावित कर रहे हैं, हमारे नवीनतम ब्लॉग पढ़ें, कैसे सामग्री विकल्प ऑस्ट्रेलिया में बिक्री के लिए यातायात संकेतों के भविष्य को आकार देते हैं.

अक्सर पूछे जाने वाले प्रश्न

एसीएम और ठोस एल्यूमीनियम पैनलों के बीच मुख्य अंतर क्या है?

एसीएम पैनलों में दो पतली एल्यूमीनियम शीट के बीच एक प्लास्टिक कोर होता है. ठोस एल्यूमीनियम पैनल धातु की एक मोटी शीट का उपयोग करते हैं. एसीएम पैनल कम वजन. ठोस एल्यूमीनियम पैनल अधिक ताकत प्रदान करते हैं और कठोर मौसम में लंबे समय तक रहते हैं.

किस पैनल प्रकार को स्थापित करना आसान है?

एसीएम पैनल हल्के होते हैं. श्रमिक उन्हें जल्दी से उठा सकते हैं और फिट कर सकते हैं. इन पैनलों को कम उपकरण और कम समर्थन की आवश्यकता होती है. ठोस एल्यूमीनियम पैनल अधिक वजन करते हैं. टीमों को स्थापना के लिए अतिरिक्त सहायता या मशीनों की आवश्यकता हो सकती है.

दोनों पैनल प्रकार जंग का विरोध करते हैं?

हाँ, एसीएम और ठोस एल्यूमीनियम पैनल दोनों जंग का विरोध करते हैं. एल्यूमीनियम की सतह पानी और हवा से बचाती है. यह पैनलों को मजबूत रखता है और कई वर्षों से अच्छा दिखता है.

क्या दोनों पैनल चिंतनशील ग्राफिक्स का समर्थन कर सकते हैं?

दोनों एसीएम और ठोस एल्यूमीनियम पैनल चिंतनशील फिल्मों और ग्राफिक्स का समर्थन करते हैं. चिकनी सतह ग्राफ़िक्स को अच्छी तरह चिपकाने में मदद करती है. इससे सड़क चिन्हों को देखना आसान हो जाता है, रात को भी.

बड़े राजमार्ग चिन्हों के लिए कौन सा पैनल बेहतर है??

ठोस एल्यूमीनियम पैनल बड़े राजमार्ग संकेतों के लिए सबसे उपयुक्त होते हैं. उनकी ताकत और कठोरता उन्हें तेज़ हवाओं में मजबूती से खड़े रहने में मदद करती है. परिषदें अक्सर बड़े या महत्वपूर्ण संकेतों के लिए ठोस एल्यूमीनियम का चयन करती हैं.