सड़क चिन्हों में एल्युमीनियम एक महत्वपूर्ण भूमिका निभाता है इसके हल्के वजन के कारण, ताकत, और जंग के प्रति प्रतिरोध. एल्यूमीनियम चिह्नों का चयन करते समय, एल्यूमीनियम शीट धातु के वजन को प्रभावित करने वाले कई कारकों पर विचार करना महत्वपूर्ण है. इन कारकों में मोटाई शामिल है, आकार, मिश्र धातु प्रकार, कोटिंग्स, और डिजाइन. इनमें से प्रत्येक विकल्प आपके प्रोजेक्ट की समग्र लागत को प्रभावित कर सकता है, साथ ही सुरक्षा और विनियामक अनुपालन. उदाहरण के लिए, मोटा एल्युमीनियम एल्युमीनियम शीट धातु का वजन बढ़ाता है, जिसका आम तौर पर मतलब उच्च लागत लेकिन अधिक स्थायित्व होता है. कुछ मिश्रधातुएँ और कोटिंग्स भी चिन्ह की मजबूती और दीर्घायु को बढ़ाती हैं. नीचे दी गई तालिका दर्शाती है कि मोटाई और मिश्र धातु का प्रकार लागत को कैसे प्रभावित करता है, सुरक्षा, और स्थापना, आपकी आवश्यकताओं के लिए सर्वोत्तम विकल्प निर्धारित करने में आपकी सहायता करना.

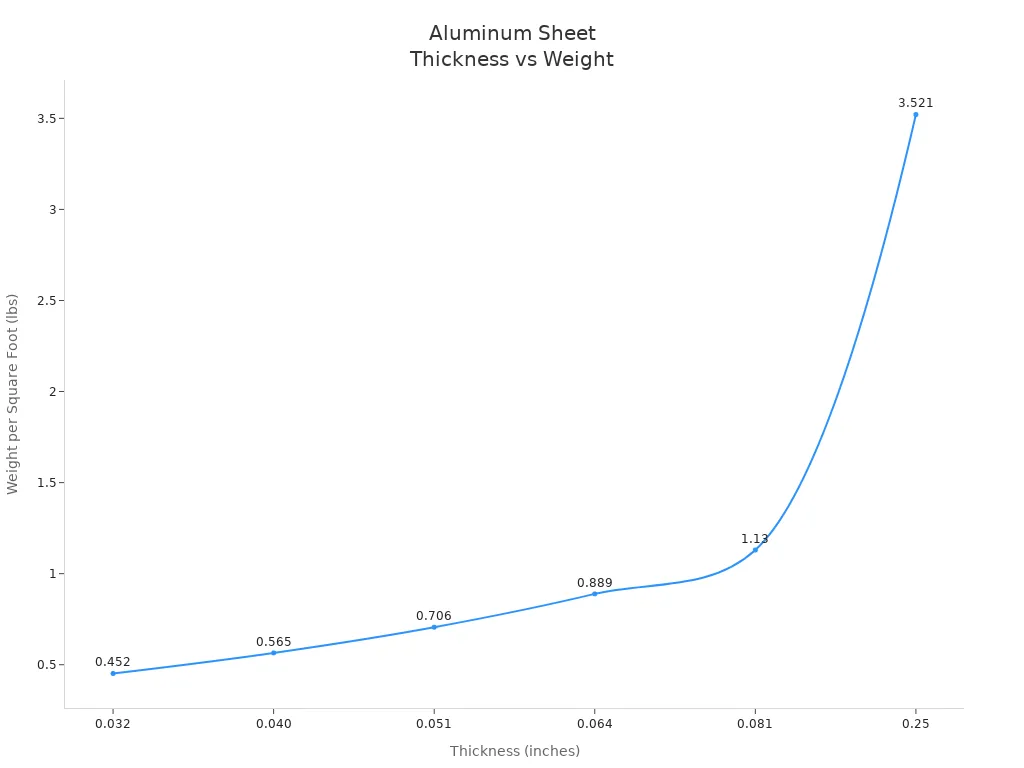

मोटाई और एल्यूमीनियम शीट धातु का वजन

मोटाई प्रभाव

मोटाई मुख्य चीज़ है जो सड़क संकेतों के लिए एल्यूमीनियम शीट धातु के वजन को बदलती है. यदि आप एल्युमिनियम शीट को मोटा बनाते हैं, यह भारी हो जाता है. ऐसा इसलिए होता है क्योंकि मोटी चादरों का आयतन अधिक होता है. मोटी चादरें मजबूत और लंबे समय तक रहती हैं. यह हवादार स्थानों या व्यस्त सड़कों पर संकेतों के लिए अच्छा है.

यहां एक तालिका है जो दिखाती है कि मोटाई की सीमाएं सड़क चिह्न के उपयोग और वजन से कैसे मेल खाती हैं:

| मोटाई सीमा (इंच) | विशिष्ट अनुप्रयोग | वजन और उपयोग पर प्रभाव |

|---|---|---|

| .040″ | छोटे इनडोर संकेत या डिस्प्ले बोर्ड | लाइटवेट, प्रक्रिया करना आसान है, कम वजन |

| .080″ | अधिकांश आउटडोर विज्ञापन संकेत | संतुलित ताकत और मध्यम वजन |

| .125″ | बड़े या अत्यधिक टिकाऊ बाहरी संकेत | बढ़ी हुई ताकत और स्थायित्व, भारी वजन स्थापना और परिवहन को प्रभावित करता है |

जब मोटाई बढ़ जाती है, एल्यूमीनियम शीट धातु का वजन ऊपर भी जाता है. यह परिवर्तन लागत को प्रभावित करता है और आप कैसे चलते हैं और संकेत कैसे लगाते हैं.

नाप और वजन

गेज प्रणाली आपको यह जानने में मदद करती है कि एल्यूमीनियम शीट कितनी मोटी हैं. कम गेज संख्या का मतलब है कि शीट अधिक मोटी और भारी है. उदाहरण के लिए, 16 गेज एल्यूमीनियम के बारे में है 0.0508 इंच मोटा. यह मोटाई अच्छी मजबूती देती है और इसे संभालना आसान है. यह सड़क चिन्ह बनाने के लिए अच्छा काम करता है क्योंकि यह मौसम को संभाल सकता है और बहुत भारी नहीं है.

यहां एक तालिका है जो दिखाती है कि गेज मोटाई और वजन से कैसे मेल खाता है:

| गेज | मोटाई (इंच) | मोटाई (मिमी) | वज़न (प्रति वर्ग पाउंड. फुट) | मुख्य निहितार्थ |

|---|---|---|---|---|

| 14 | ~0.0641 | ~1.63 | ~0.91 | मोटी और भारी चादर, टिकाऊ साइनेज के लिए उपयुक्त |

| 16 | ~0.0508 | ~1.29 | तदनुसार हल्का | पतला और हल्का, ताकत और प्रबंधनीयता को संतुलित करना |

यदि आप निचला गेज चुनते हैं, चादर मोटी होगी और वजन भी अधिक होगा. यह विकल्प आपके सड़क चिन्हों को ले जाने और स्थापित करने के तरीके को बदल देता है.

मोटाई चयन

अपने एल्युमीनियम रोड साइन के लिए सही मोटाई चुनना चिन्ह के आकार पर निर्भर करता है, स्थापना स्थान, और हवा का जोखिम. कम यातायात वाले क्षेत्रों में छोटे संकेत पतली चादरों का उपयोग कर सकते हैं, जबकि बड़े राजमार्ग या ओवरहेड संकेतों को स्थिर और आज्ञाकारी बने रहने के लिए मोटे एल्यूमीनियम की आवश्यकता होती है.

| साइन आकार (क्षेत्र) | अनुशंसित एल्यूमीनियम शीट की मोटाई (इंच) | मुख्य विचार |

|---|---|---|

| छोटे संकेत (पार्किंग, निजी संपत्ति) | .040″ (≈1.0 मिमी) | लाइटवेट, माउंट करना आसान है; अस्थायी या गैर के लिए उपयुक्त-MUTCD अनुप्रयोग |

| मध्यम संकेत (नियामक, सड़क के संकेत) | .080″ (≈2.0 मिमी) | म्यूट-कम्प्लींट; झुकने और सामान्य हवा के भार का सामना करने के लिए पर्याप्त मजबूत |

| बड़े संकेत (राजमार्ग, मार्गदर्शक, उपरि) | .125″ (≈3.2 मिमी) | तेज़ हवा वाले क्षेत्रों के लिए आवश्यक; अधिकतम कठोरता प्रदान करता है लेकिन स्थापना के लिए भारी होता है |

अधिकांश हम. सड़क के संकेत में उत्पादित होते हैं .080″ एल्यूमीनियम, जो MUTCD आवश्यकताओं को पूरा करते हुए स्थायित्व और हैंडलिंग को संतुलित करता है. .040″ चादरें अस्थायी या निजी संकेतों के लिए उपयोग किया जा सकता है, जबकि .125″ चादरें बड़े आकार के राजमार्ग गाइड संकेतों और तटीय वातावरण के लिए चुना जाता है जहां हवा और जंग प्रमुख कारक हैं.

आयाम और सड़क चिह्न

आकार और वजन की गणना

आपको अपने चिन्ह का वजन जानने से पहले उसका आकार अवश्य जानना चाहिए. लंबाई और चौड़ाई आपको बताती है कि आपको कितने एल्युमीनियम की आवश्यकता है. बड़े चिन्हों में अधिक एल्यूमीनियम का उपयोग होता है और उनका वजन भी अधिक होता है. वजन ज्ञात करने के लिए, लंबाई गुणा करें, चौड़ाई, और मोटाई एक साथ. उदाहरण के लिए, एक संकेत जो है 10 पैरों द्वारा 12 पैर और 1/8 इंच मोटी इन संख्याओं को गुणा करने की आवश्यकता है. इससे आपको कुल मात्रा प्राप्त होती है. तब, वजन प्राप्त करने के लिए एल्यूमीनियम के घनत्व से गुणा करें. इससे आपको यह योजना बनाने में मदद मिलती है कि साइन को कैसे स्थानांतरित और स्थापित किया जाए.

मानक बनाम. कस्टम आकार

मानक आकार साइन प्रोजेक्ट को आसान और अधिक लागत प्रभावी बनाते हैं. सामान्य प्रारूप जैसे 18″×24″, 24″×36″, और 24″×48″ मानक माउंटिंग फ्रेम में फिट होते हैं और आमतौर पर पतले एल्यूमीनियम का उपयोग करते हैं (.040″-.063″), जो वजन कम करता है और स्थापना को सरल बनाता है. कस्टम आकार ठेकेदारों को किसी भी आकार या आयाम को डिज़ाइन करने की अनुमति देते हैं, लेकिन अक्सर बड़े पैनलों की आवश्यकता होती है .080″ या .125″ एल्यूमीनियम कठोरता बनाए रखने के लिए, उन्हें स्थापित करना भारी और अधिक जटिल बना रहा है. आकार के अतिरिक्त, पैनल का प्रकार भी वजन को प्रभावित करता है. एल्यूमीनियम मिश्रित सामग्री (एसीएम) पैनल ठोस एल्यूमीनियम शीट की तुलना में हल्के होते हैं, जबकि अभी भी दीर्घकालिक आउटडोर स्थायित्व प्रदान करते हैं.

| पैनल प्रकार | मोटाई (इंच / मिमी) | वज़न (किग्रा/वर्ग मीटर) | विवरण |

|---|---|---|---|

| एल्यूमीनियम मिश्रित पैनल | 0.16″ (≈4 मिमी) | 6.3 - 7.6 | प्लास्टिक कोर वाली दो पतली एल्यूमीनियम शीट, ठोस एल्यूमीनियम की तुलना में बहुत हल्का |

| ठोस एल्यूमीनियम पैनल | 0.16″ (≈4 मिमी) | 10.8 - 15 | एकल मोटी एल्यूमीनियम शीट, काफ़ी भारी |

👉 बख्शीश: बड़े गाइड संकेतों या राजमार्ग स्थापनाओं के लिए, राज्य डीओटी अक्सर अनुमोदन करते हैं एसीएम पैनल ठोस एल्यूमीनियम के हल्के विकल्प के रूप में, बशर्ते सामग्री मिलती हो एएसटीएम बी209 और ASTM D4956 आवश्यकताएं.

बड़े संकेत संबंधी विचार

बड़े संकेतों के लिए अतिरिक्त योजना की आवश्यकता होती है. आपको उन्हें स्थानांतरित करने और स्थापित करने के बारे में अवश्य सोचना चाहिए. यदि आप कई संकेत या बहुत बड़ी शीट ऑर्डर करते हैं, आपको अधिक समस्याओं का सामना करना पड़ता है. आपको परमिट की आवश्यकता हो सकती है, विशेष ट्रेलर, और एस्कॉर्ट वाहन. एल्युमीनियम को सुरक्षित रखने के लिए आपको चेन और कवर का उपयोग करना चाहिए. आपको संकेतों को संग्रहीत करने और उन्हें क्षति से बचाने के लिए भी जगह की आवश्यकता है. एल्यूमीनियम मिश्रित पैनल बड़े संकेतों को संभालना आसान बनाते हैं क्योंकि उनका वजन कम होता है. ठोस एल्यूमीनियम पैनलों को स्थापित करने के लिए अधिक लोगों या मशीनों की आवश्यकता होती है, लेकिन वे कठिन स्थानों पर अधिक समय तक टिके रहते हैं. हमेशा अपने मार्ग की योजना बनाएं और बड़े संकेतों को हटाने से पहले स्थानीय नियमों की जांच करें. इससे आपका प्रोजेक्ट सुरक्षित और समय पर रहता है.

ओप्ट्राफिक पर, हम एएसटीएम और एमयूटीसीडी मानकों के अनुसार निर्मित ठोस एल्यूमीनियम और एल्यूमीनियम मिश्रित पैनल प्रदान करते हैं, ठेकेदारों को राजमार्ग के लिए सही विकल्प चुनने की छूट देना, शहर, या कस्टम साइन प्रोजेक्ट. हमारे एल्यूमीनियम पैनल समाधानों का अन्वेषण करें.

बख्शीश: यदि आप आसान संचालन और तेज़ स्थापना चाहते हैं तो बड़े संकेतों के लिए एल्यूमीनियम मिश्रित पैनल चुनें. जब आपको अधिक मजबूती और स्थायित्व की आवश्यकता हो तो ठोस एल्यूमीनियम का उपयोग करें.

एल्यूमीनियम मिश्र धातु और घनत्व

मिश्र धातु के प्रकार

जब आप सड़क चिन्हों के लिए सामग्री चुनते हैं, आप कई देखते हैं एल्यूमीनियम मिश्र धातु. प्रत्येक मिश्र धातु की विशेष ताकत और उपयोग होते हैं. राज्य डीओटी और साइन निर्माता आमतौर पर निर्दिष्ट करते हैं 5052-एच 38 एल्यूमीनियम राजमार्ग और तटीय अनुप्रयोगों के लिए, क्योंकि यह नमक स्प्रे और औद्योगिक प्रदूषण के खिलाफ बेहतर संक्षारण प्रतिरोध प्रदान करता है. 6061-T6 का उपयोग तब किया जाता है जब संकेतों को अतिरिक्त संरचनात्मक मजबूती की आवश्यकता होती है, जैसे ओवरहेड गैन्ट्री संकेत, यद्यपि यह कम गठन योग्य है. नगरपालिका और सड़क संकेतों के लिए, 3003 और 3105 मिश्र धातुएँ अपनी लागत-प्रभावशीलता और निर्माण में आसानी के कारण लोकप्रिय बनी हुई हैं. ये मिश्र धातु विकल्प परिवहन बुनियादी ढांचे में उपयोग की जाने वाली एल्यूमीनियम शीट के लिए एएसटीएम बी209 विनिर्देशों के अनुरूप हैं.

यहां एक तालिका है जो सड़क संकेतों के लिए लोकप्रिय एल्यूमीनियम मिश्र धातुओं की तुलना करती है:

| एल्यूमीनियम मिश्र धातु | घनत्व (g/cm g) | ताकत और गुण सारांश |

|---|---|---|

| 6061 (6000 शृंखला) | 2.7 | अच्छी ताकत, संक्षारण प्रतिरोध, आकार में आसान, प्रभावी लागत, अधिकांश सड़क संकेतों के लिए व्यापक रूप से उपयोग किया जाता है |

| 7075 (7000 शृंखला) | 2.81 | उच्च शक्ति, भारी, अधिक महंगा, साथ काम करना कठिन, विशेष टिकाऊ अनुप्रयोगों के लिए उपयोग किया जाता है |

आप देख सकते हैं 6061 हल्का और उपयोग में आसान है. 7075 भारी और मजबूत है लेकिन लागत अधिक है. अधिकांश सड़क चिन्हों का उपयोग करते हैं 6061 या 5052 क्योंकि ये वजन को संतुलित करते हैं, ताकत, और कीमत.

घनत्व अंतर

जब विभिन्न तत्वों को मिलाया जाता है तो एल्यूमीनियम मिश्र धातुओं का घनत्व बदल जाता है. तांबा या जस्ता मिलाने से मिश्रधातु भारी हो जाती है. मैग्नीशियम और सिलिकॉन इसे हल्का बनाते हैं. ये परिवर्तन एल्यूमीनियम शीट धातु के वजन को प्रभावित करते हैं. यदि आप कम घनत्व वाला मिश्र धातु चुनते हैं, आपके चिन्ह का वज़न कम है. यह आपको बड़े या ऊंचे संकेतों को स्थानांतरित करने और स्थापित करने में मदद करता है.

सड़क चिन्हों के लिए अधिकांश एल्युमीनियम मिश्रधातुओं का घनत्व चारों ओर होता है 2.7 g/cm g. यह स्टील से काफी हल्का है, जिसके बारे में है 7.87 g/cm g. एल्युमीनियम चिन्हों को ले जाना और स्थापित करना आसान होता है. भले ही वे प्रकाश हैं, ये मिश्रधातुएँ अभी भी सड़क चिन्हों के लिए पर्याप्त मजबूत हैं. उदाहरण के लिए, 6061 मिश्रधातु का घनत्व लगभग होता है 2.7 g/cm g. 7075 पर थोड़ा भारी है 2.81 g/cm g. The 5052 मिश्रधातु में मैग्नीशियम होता है, इसलिए यह हल्का है और मजबूत लोगों के लिए अच्छा है, प्रकाश संकेत.

बख्शीश: कम घनत्व वाला मिश्रधातु चुनने से आपको हल्के सड़क चिन्ह बनाने में मदद मिलती है. आप ताकत या स्थायित्व नहीं खोते.

प्रदर्शन कारक

आपके द्वारा चुनी गई मिश्र धातु आपके रोड साइन के मौसम को संभालने के तरीके को बदल देती है, एचआईटीएस, और समय. कुछ मिश्रधातुएँ जंग का बेहतर प्रतिरोध करती हैं, जो आपके संकेतों को बारिश का सामना करने पर मदद करता है, बर्फ, या नमकीन हवा. दूसरे मजबूत हैं, ताकि वे हवा या उन पर पड़ने वाली चीजों को संभाल सकें.

यहां एक तालिका है जो दिखाती है कि विभिन्न एल्यूमीनियम मिश्र धातुएं सड़क संकेतों के लिए कैसे काम करती हैं:

| एल्यूमीनियम मिश्र धातु | मुख्य गुण | स्थायित्व और मौसम प्रतिरोध पर प्रभाव |

|---|---|---|

| 3003-H18 | असाधारण रूपात्मकता, संक्षारण प्रतिरोध, टिकाऊपन | सड़क चिन्हों के लिए आदर्श; स्पष्टता और दीर्घायु बनाए रखते हुए विभिन्न मौसम स्थितियों का सामना करता है |

| 5052-H38 | उच्च तन्यता शक्ति, बेहतर संक्षारण प्रतिरोध | उच्च गति यातायात और कठोर वातावरण के संपर्क में आने वाले राजमार्ग संकेतों के लिए उपयुक्त; दीर्घायु और दृश्यता सुनिश्चित करता है |

| 6061-टी 6 | असाधारण ताकत और स्थायित्व | पर्यावरणीय तनावों और प्रभावों के विरुद्ध मजबूती की आवश्यकता वाले नियामक संकेतों के लिए उपयोग किया जाता है; संरचनात्मक अखंडता और दृश्यता बनाए रखता है |

| 3004-H38 | अच्छी फॉर्मैबिलिटी और संक्षारण प्रतिरोध | बाहरी सेटिंग में उच्च दृश्यता और स्थायित्व की आवश्यकता वाले चेतावनी संकेतों के लिए पसंदीदा; स्पष्टता बनाए रखता है और पर्यावरणीय परिस्थितियों का सामना करता है |

आपको अपने प्रोजेक्ट की आवश्यकताओं के अनुरूप मिश्रधातु का मिलान करना चाहिए. के लिए व्यस्त राजमार्ग या तटीय क्षेत्र, 5052-H38 एक स्मार्ट पिक है. यदि आप ऐसा चिन्ह चाहते हैं जो आसानी से आकार दे और स्थापित हो जाए, 6061-T6 एक अच्छा विकल्प है. 3003-H18 और 3004-H38 जैसे मिश्र धातु सड़क और चेतावनी संकेतों के लिए बहुत अच्छे हैं. ये हर तरह के मौसम में अपना रंग और आकार बनाए रखते हैं.

टिप्पणी: सही एल्यूमीनियम मिश्र धातु चुनने से आपके संकेत लंबे समय तक बने रहते हैं और देखने में आसान रहते हैं. आप उन्हें ठीक करने में कम समय और पैसा खर्च करेंगे.

भूतल उपचार और एल्यूमिनियम कम्पोजिट साइन विकल्प

कोटिंग्स और फिल्में

कोटिंग और फिल्म के कारण सड़क के संकेत अक्सर चमकीले और चमकदार दिखते हैं. इन परतों में पेंट भी शामिल है, चिंतनशील फिल्में, और सुरक्षात्मक कोटिंग्स. वे संकेतों को अलग दिखने और लंबे समय तक टिके रहने में मदद करते हैं. जब आप इन परतों को जोड़ते हैं, संकेत थोड़ा भारी हो जाता है. प्रत्येक परत पतली है, लेकिन साथ में वे वजन बढ़ाते हैं, खासकर बड़े संकेतों पर. परावर्तक फिल्में ड्राइवरों को रात में संकेत देखने में मदद करती हैं. सुरक्षात्मक कोटिंग्स जंग और खरोंच को दूर रखती हैं. जब आप अपने एल्युमीनियम मिश्रित चिन्ह के अंतिम वजन का पता लगाते हैं तो इन परतों को गिनना हमेशा याद रखें.

एल्यूमीनियम मिश्रित

एल्यूमीनियम मिश्रित संकेतों का एक विशेष डिज़ाइन होता है. वे बीच में एक प्लास्टिक कोर के साथ दो पतली एल्यूमीनियम शीट का उपयोग करते हैं. सैंडविच का यह आकार उन्हें ठोस एल्यूमीनियम शीट की तुलना में बहुत हल्का बनाता है. आप एल्युमीनियम मिश्रित चिह्नों को अधिक आसानी से स्थानांतरित और लगा सकते हैं. इंस्टॉल करते समय हल्का वजन आपको समय और पैसा बचाने में मदद करता है. भले ही वे हल्के हों, अधिकांश उपयोगों के लिए एल्यूमीनियम मिश्रित संकेत अभी भी मजबूत हैं. आप इन्हें बाहरी संकेतों के लिए उपयोग कर सकते हैं, प्रदर्शित करता है, और विज्ञापन. ठोस एल्यूमीनियम शीट मजबूत होती हैं और आग का बेहतर प्रतिरोध करती हैं, लेकिन वे भारी हैं. एल्युमीनियम मिश्रित चिन्हों में जंग नहीं लगती और वे खराब मौसम को भी संभाल सकते हैं. यदि आप जानना चाहते हैं कि वे कितने समय तक चलते हैं, यह आमतौर पर है 10 को 20 साल, कोटिंग पर निर्भर करता है. बहुत से लोग एल्युमीनियम कंपोजिट चुनते हैं क्योंकि इसका उपयोग करना आसान है और यह लंबे समय तक चलता है.

बख्शीश: बड़े या ऊंचे संकेतों के लिए एल्युमीनियम कंपोजिट चुनें. यह इंस्टॉलेशन को आसान और सुरक्षित बनाता है.

विनियामक आवश्यकताएँ

सड़क संकेतों पर कोटिंग और फिल्म का उपयोग करने के नियम हैं. कई जगहें कहती हैं कि आपको रात में यातायात संकेतों के लिए परावर्तक फिल्मों का उपयोग करना चाहिए. आपके एल्यूमीनियम मिश्रित चिन्ह पर कोटिंग को स्थानीय और राष्ट्रीय नियमों का पालन करना चाहिए. ये नियम आपके चिन्ह को सुरक्षित रहने में मदद करते हैं, मज़बूत, और किसी भी मौसम में देखना आसान है. एल्युमीनियम कम्पोजिट साइन खरीदने या लगाने से पहले हमेशा नवीनतम नियमों की जांच करें. यह सुनिश्चित करता है कि आपका प्रोजेक्ट सुरक्षित है और सभी मानकों को पूरा करता है.

डिज़ाइन सुविधाएँ और स्थापना

वेध और कटआउट

आप छेद जोड़कर एल्युमीनियम सड़क चिन्हों को हल्का बना सकते हैं, कटआउट, या विशेष आकार. जब आप सर्कल कट जैसे डिज़ाइन का उपयोग करते हैं, अंडाकार कटौती, या ड्रिल किए गए छेद, आप कुछ धातु हटा दें. इससे चिन्ह का कुल भार कम हो जाता है. कम सामग्री के साथ भी, चिन्ह अभी भी मजबूत रह सकता है और अपना आकार बनाए रख सकता है. कस्टम आकार और छिद्रण आपको संकेत को उसके उद्देश्य से मिलाने देते हैं और साथ ही इसे संभालना आसान बनाते हैं. उदाहरण के लिए, बढ़ते छेद या अद्वितीय रूपरेखा वाले संकेतों का वजन कम होता है और उन्हें स्थापित करना आसान होता है, विशेष रूप से ऊंचे पदों पर या दुर्गम स्थानों पर.

बख्शीश: स्थायित्व खोए बिना बड़े संकेतों का वजन कम करने के लिए कटआउट और वेध का उपयोग करें.

स्थापना सुरक्षा

आपके एल्युमीनियम चिन्ह का वजन प्रभावित करता है कि आप इसे कैसे स्थापित करते हैं और आपको किस उपकरण की आवश्यकता है. हल्के चिन्ह ले जाना आसान होता है, उठाना, और माउंट. आप अक्सर सरल उपकरणों और कम लोगों का उपयोग कर सकते हैं. भारी संकेतों के लिए विशेष उपकरण की आवश्यकता हो सकती है, जैसे लिफ्ट या क्रेन, और सुरक्षित स्थापना के लिए अधिक कर्मचारी. अपने प्रोजेक्ट को सुरक्षित रखने और स्थानीय नियमों का पालन करने के लिए, तुम्हे करना चाहिए:

- इंस्टालेशन शुरू करने से पहले सही परमिट प्राप्त करें.

- सड़क से ऊंचाई और दूरी के लिए प्लेसमेंट नियमों का पालन करें.

- अनुमोदित सामग्री और माउंटिंग हार्डवेयर का उपयोग करें.

- सुनिश्चित करें कि चिन्ह स्थिर और दृश्यमान है.

- हल्के एल्यूमीनियम संकेत आपको फोल्डेबल स्टैंड या बेसिक माउंटिंग ब्रैकेट का उपयोग करने देते हैं.

- आप उन्हें जल्दी से स्थापित कर सकते हैं, जिससे समय की बचत होती है और श्रम लागत कम होती है.

सड़क चिन्हों में स्थायित्व

अपने चिन्ह के लिए सही वजन चुनने से इसे लंबे समय तक चलने में मदद मिलती है और सड़कें सुरक्षित रहती हैं. एल्युमीनियम जंग का प्रतिरोध करता है और हवा का सामना करता है, बारिश, और सूर्य. यदि आप कोई ऐसा चिन्ह चुनते हैं जो बहुत हल्का है, तेज़ मौसम में यह मुड़ सकता है या टूट सकता है. अगर यह बहुत भारी है, इसे स्थापित करना कठिन हो सकता है और अतिरिक्त सहायता की आवश्यकता हो सकती है. उचित वजन चयन का मतलब है कि आपका चिन्ह वर्षों तक दृश्यमान और मजबूत रहेगा. इससे ड्राइवरों को महत्वपूर्ण जानकारी देखने में मदद मिलती है और यातायात सुरक्षित रूप से चलता रहता है.

टिप्पणी: टिकाऊ, अच्छी तरह से लगाए गए संकेत मरम्मत या प्रतिस्थापन की आवश्यकता को कम करके ड्राइवरों और आपके निवेश दोनों की रक्षा करते हैं.

जब आप सड़क चिन्हों के लिए एल्युमीनियम शीट चुनते हैं, मोटाई के बारे में सोचो, आकार, मिश्र धातु, कोटिंग्स, और डिजाइन. ये चीजें कितनी भारी बदल जाती हैं, मज़बूत, और चादर सख्त है. चुनने में सहायता के लिए इस चेकलिस्ट का उपयोग करें:

- ऐसा एल्युमीनियम ग्रेड चुनें जिसमें जंग न लगे.

- सुनिश्चित करें कि आपूर्तिकर्ता सुरक्षा नियमों का पालन करता है.

- जांचें कि क्या मोटाई और परावर्तन की अनुमति है.

- स्थापित करने में आसान सुविधाओं की तलाश करें जैसे कि पहले से ही छिद्रित छेद.

- देखें कि क्या आपूर्तिकर्ता विश्वसनीय है और वारंटी प्रदान करता है.

आप अपने प्रोजेक्ट के लिए सर्वोत्तम सामग्री ढूंढने के लिए विशेषज्ञों से मदद मांग सकते हैं, मौसम, और बजट. यह सुनिश्चित करता है कि आपके संकेत सुरक्षित हैं और हर समय नियमों का पालन करें. ओप्ट्राफिक पर, हमारी टीम प्रदान करती है एल्यूमीनियम शीट और यातायात साइनेज समाधान जो MUTCD और ASTM मानकों का अनुपालन करते हैं, ठेकेदारों और नगर पालिकाओं को परियोजनाओं को सुरक्षित रूप से पूरा करने में मदद करना, समय पर, और बजट के भीतर.

अक्सर पूछे जाने वाले प्रश्न

एल्यूमीनियम सड़क संकेतों के लिए सबसे अच्छी मोटाई क्या है??

यू.एस. में MUTCD-संगत सड़क संकेतों के लिए, 0.080-इंच एल्यूमीनियम शीट उद्योग मानक हैं, जैसा कि संघीय राजमार्ग प्रशासन द्वारा अनुशंसित है (एफएचडब्ल्यूए). कुछ राज्यों, जैसे कि टेक्सास डॉट और फ्लोरिडा डॉट, उच्च पवन भार आवश्यकताओं को पूरा करने के लिए बड़े राजमार्ग गाइड संकेतों के लिए .125-इंच पैनल भी स्वीकार करते हैं. छोटी पार्किंग या निजी संपत्ति के संकेतों के लिए, .040-इंच एल्यूमीनियम पर्याप्त हो सकता है, लेकिन ये सार्वजनिक सड़क मार्गों के लिए MUTCD को पूरा नहीं करते हैं.

मैं अपने साइन के लिए एल्यूमीनियम शीट के वजन की गणना कैसे करूं??

लंबाई गुणा करें, चौड़ाई, और वॉल्यूम पाने के लिए मोटाई. तब, एल्युमीनियम के घनत्व से आयतन को गुणा करें (2.7 g/cm g). इससे आपको कुल वजन मिलता है.

बख्शीश: त्वरित परिणामों के लिए ऑनलाइन कैलकुलेटर का उपयोग करें.

क्या कोटिंग्स और फ़िल्में एल्युमीनियम चिन्हों पर अधिक भार डालती हैं?

कोटिंग्स और फिल्में केवल थोड़ी मात्रा में वजन बढ़ाती हैं. अधिकांश संकेतों के लिए, यह अतिरिक्त वजन हैंडलिंग या स्थापना को प्रभावित नहीं करता है. आपको अब भी बेहतर दृश्यता और सुरक्षा मिलती है.

क्या एल्यूमीनियम मिश्रित पैनल ठोस एल्यूमीनियम शीट की तुलना में हल्के होते हैं??

हाँ, एल्यूमीनियम मिश्रित पैनलों का वजन कम होता है. वे दो पतली एल्यूमीनियम शीटों के बीच एक प्लास्टिक कोर का उपयोग करते हैं. यह डिज़ाइन उन्हें उठाना और स्थापित करना आसान बनाता है.

सड़क चिह्न भार के लिए मिश्रधातु का प्रकार क्यों मायने रखता है??

विभिन्न मिश्रधातुओं का घनत्व और शक्ति अलग-अलग होती है. कुछ मिश्र धातुएँ आपके चिन्ह को हल्का और जंग के प्रति अधिक प्रतिरोधी बनाती हैं. सही मिश्र धातु का चयन आपके चिन्ह को लंबे समय तक चलने और सुरक्षित रहने में मदद करता है.