Innovation helps the traffic sign industry get better. It is important for every road user to have signs that are correct and safe. Aluminum sheet cutting now uses new technology. This makes signs last longer and stay easy to see in bad weather. OPTRAFFIC uses high-quality aluminum sheets and laser cutting technology to ensure top-notch signs and a stable production line, meeting delivery requirements. Every sign reflects their commitment to safety and excellence in production.

चाबी छीनना

- Advanced aluminum sheet cutting makes traffic signs last longer and easier to see. इससे सड़क पर चलने वाले सभी लोगों को सुरक्षित रखने में मदद मिलती है.

- Laser cutting technology makes signs faster to make. It also creates less waste and gives signs smoother edges. This makes signs easier to make and easier to read.

- CNC machines help make signs with very good accuracy. They let people create special shapes and keep the quality the same for every sign.

- Automation in making signs makes the work go faster. It also helps stop mistakes, so signs are safe and arrive on time.

- Sustainability practices, like recycling old signs and using eco-friendly materials, help protect the environment when making traffic signs.

Aluminum Sheet Cutting and Traffic Sign Quality

सड़क सुरक्षा के लिए महत्व

Aluminum sheet cutting is very important for making traffic signs. Every road needs signs that are easy to see and last a long time. These signs help keep drivers and people walking safe. When companies use advanced aluminum sheet cutting, they make reflective traffic signs that are easy to see in any weather. These signs help drivers know where to go and can stop accidents on busy roads. Reflective traffic signs have special coatings that make them brighter, यहां तक कि रात में या जब बारिश होती है. Good reflective signs help drivers see warning and guide signs from far away.

Recent research shows that how well aluminum sheet cutting is done can change road safety. नीचे दी गई तालिका कुछ महत्वपूर्ण तथ्य दिखाती है:

| साक्ष्य बिंदु | विवरण |

|---|---|

| Durability of Signs | अच्छा एल्यूमीनियम की चादरें make traffic signs last longer and stay strong in bad weather. This is important for keeping signs easy to see and useful. |

| दृश्यता | Bright colors and clear words on good aluminum signs help lower accidents by showing drivers what to do. |

| सुरक्षा मानकों का अनुपालन | Using aluminum sheets that follow safety rules makes sure traffic signs work well and help police keep roads safe. |

| लंबी उम्र | Aluminum sheets do not bend or break easily. They keep their shape and work well even when the weather is bad, जो सड़कों को सुरक्षित रखने में मदद करता है. |

| Quick Installation | Aluminum sheets are light, so workers can put up traffic signs faster. This helps keep roads safe with new signs when needed. |

Reflective traffic signs made with careful aluminum sheet cutting help keep everyone safe on the road. These signs stay bright and strong, कई वर्षों के बाद भी.

Durability and Compliance

It is important for every road sign to be strong and follow the rules. Aluminum sheet cutting helps reflective traffic signs meet safety standards. Makers pick the right aluminum alloy and thickness for each sign. The table below shows some common choices:

| एल्यूमीनियम मिश्र धातु | सामान्य मोटाई (इंच) | नोट |

|---|---|---|

| 5052-H38 | 0.040, 0.063, 0.080, 0.100, 0.125 | This alloy is strong and has less recycled material. |

| 3105-H38 | 0.040, 0.063, 0.080, 0.100, 0.125 | This alloy is also strong and uses more recycled material. |

| मानक सड़क संकेत | 0.080 | This is the usual thickness for street signs. |

| नवीनता संकेत | 0.060, के रूप में पतला 0.040 | These are used for gifts or special signs. |

Makers use these thicknesses to make sure reflective traffic signs last on busy roads. Thicker aluminum holds the reflective coating better. This makes signs easier to see and harder to damage. Signs with the right thickness cost less to fix and stay strong in bad weather.

- The right thickness makes signs strong and safe.

- Thicker aluminum keeps the reflective coating on better.

- Good thickness means less damage and lower repair costs.

Aluminum sheet cutting helps make reflective traffic signs that follow all the safety rules. ये संकेत ड्राइवरों की मदद करते हैं, खतरों के बारे में चेतावनी, और सड़कों को सुरक्षित रखें. OPTRAFFIC uses advanced aluminum sheet cutting to make guide signs and warning signs that follow every rule. Their reflective traffic signs help cities and towns keep roads safe for everyone.

Innovations in Cutting Technology

Laser Cutting vs. Traditional Methods: शुद्धता, रफ़्तार, and Waste Reduction

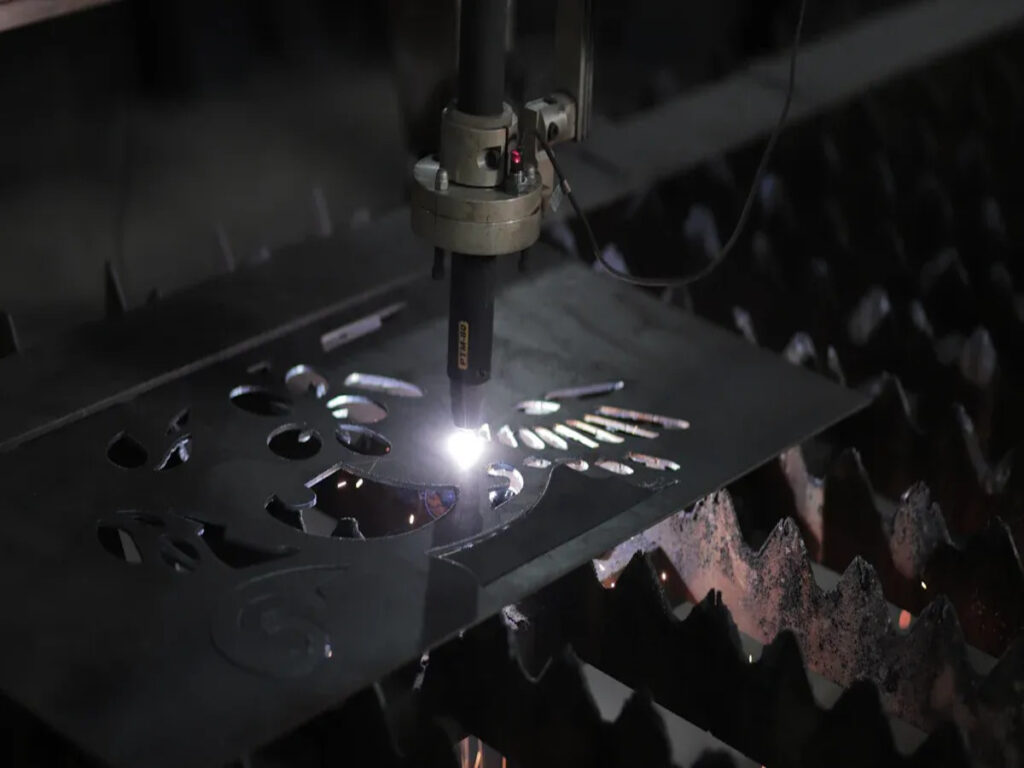

Laser cutting has changed how people make aluminum traffic signs. This method uses a strong light to cut metal very accurately. The cuts are smooth, and the metal stays strong. Laser cutting can make detailed shapes and letters. यह संकेतों को स्पष्ट और पढ़ने में आसान रहने में मदद करता है.

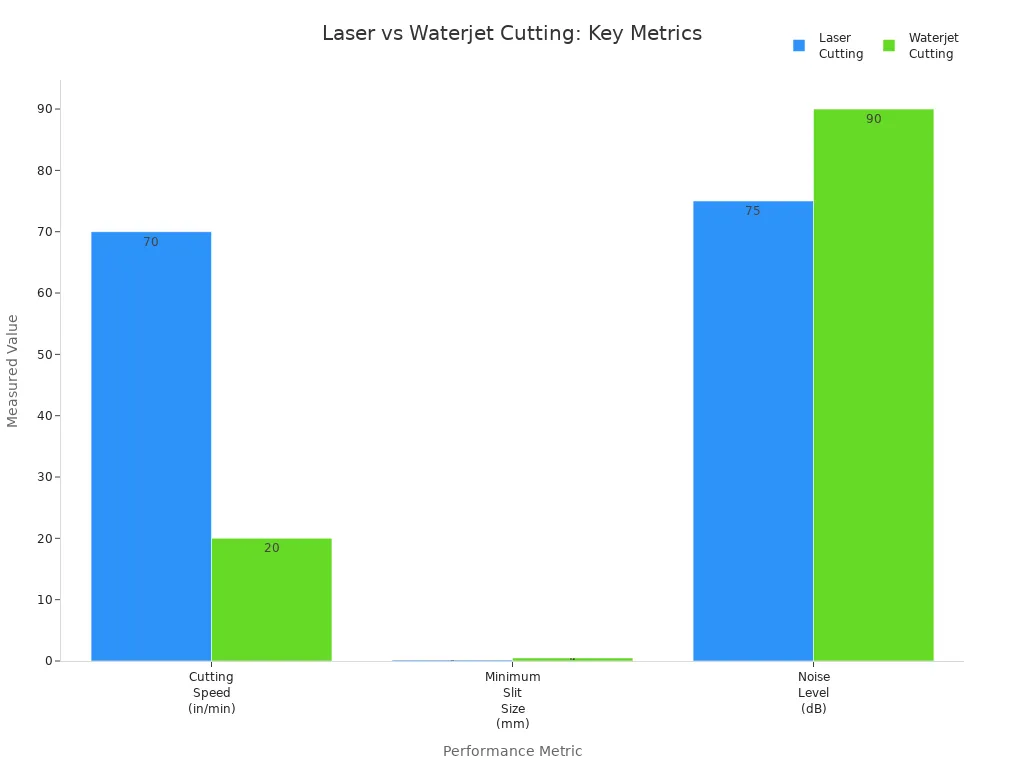

People compare laser cutting to waterjet and mechanical cutting. Laser cutting is faster and makes smoother edges. It is also quieter than waterjet cutting. The table below shows how laser cutting is different:

| फ़ायदा | Laser Cutting | Waterjet Cutting |

|---|---|---|

| Cutting Speed | 20-70 inches per minute | 1-20 inches per minute |

| Minimum Cutting Slit Size | 0.15 मिमी | 0.5 मिमी |

| Post-Processing Requirement | न्यूनतम, smooth edges | Often requires additional work |

| Material Deformation | Less due to low heat influence | More likely due to heat generation |

| Noise Level | 75 डीबी | तक 90 डीबी |

Laser cutting works faster than old ways of cutting. It helps workers finish signs more quickly. Laser cutting uses less material, इसलिए कम कचरा है. This saves money and resources. Older cutting methods make more waste and need extra work to smooth the edges.

- Laser cutting uses material well and makes little waste.

- Laser cutting is fast and saves time.

- Laser cutting is very accurate, so less material is wasted.

सीएनसी मशीनें: Enhancing Accuracy and Design Flexibility

CNC cutting lets people make complex traffic sign designs. These machines follow computer instructions to cut the metal. Every sign comes out just like the design.

CNC machines are very accurate, down to tiny measurements. They help stop mistakes and keep signs the same. With CNC, makers can try new shapes and styles. Cities can get special signs for their needs.

- CNC machines make signs faster and help workers do more.

- CNC cutting lets people make shapes that old methods cannot.

- CNC machines keep sign sizes and edges the same, which is important for quality.

- CNC technology lets companies make new designs quickly, which helps with modern signs.

OPTRAFFIC uses the best machines to make signs with smooth edges. They can make many signs or just a few special ones. Every sign is checked for quality and safety.

Automation and Efficiency: Speeding Up Production

Automation is now very important in making traffic signs. Robots and machines do the same jobs over and over. These systems help move signs from start to finish with little help from people. Automation makes work faster and helps stop mistakes.

Modern factories use robots to cut, आकार, and put together sign parts. Automated systems help make signs more quickly and with better quality. Mintech’s CNC cutting has made work faster and stopped many mistakes. OPTRAFFIC uses automation to make lots of signs at once. Their portable traffic signals work with smart systems. These systems use real-time data to help traffic move better.

- OPTRAFFIC uses portable traffic signals with smart systems, making them better with automation.

- AI helps guess traffic patterns and changes signal times, which helps stop crashes and keeps people safe.

- Quality checks make sure every part meets the rules.

- Workers use numbers like first pass yield and rejection rate to check quality and stop bad signs.

Automation helps OPTRAFFIC make good traffic signs fast. They can handle both big and small orders. Every sign is safe and helps keep roads safe.

Overcoming Industry Challenges

Meeting MUTCD and FHWA Standards

OPTRAFFIC must follow many strict rules for traffic signs. The company makes sure every aluminum sign meets MUTCD and FHWA standards. These rules help keep roads safe and help traffic move well. OPTRAFFIC works with government groups to keep signs up to date. इस तरह, every sign follows the rules and works well for everyone. Safety tests happen often to check if signs meet new rules.

OPTRAFFIC always follows the rules, so people can trust their signs.

Some big problems in the industry are:

- UV stability stops colors from fading and keeps signs bright.

- Corrosion protection helps signs last longer in tough places.

- Advanced reflective technologies, like High-Intensity Prismatic sheeting, make signs easier to see and safer by up to 50%.

Sustainability and Cost-Effectiveness

Sustainability is very important when making traffic signs today. OPTRAFFIC uses new cutting methods to waste less and save resources. The hydrostripping process takes off old laminates without using chemicals. This keeps the aluminum strong and its coatings safe.

Automation in aluminum extrusion helps too. It makes signs faster and cuts down on waste and CO2. These steps save money and help the planet. OPTRAFFIC cares about the environment and makes sure their signs are good for it.

गुणवत्ता नियंत्रण प्रक्रियाएँ

Quality control starts with picking the best aluminum. Each sheet does not bend or warp, so signs stay strong. Careful engineering keeps signs flat and easy to read. Special materials protect signs from rain, सूरज, और धूल.

| गुणवत्ता नियंत्रण उपाय | Impact on Performance and Reliability |

|---|---|

| उच्च गुणवत्ता वाली सामग्री | Stop warping and bending, so signs stay strong |

| Precise engineering | Keeps signs flat and words clear |

| मौसम प्रतिरोधी सामग्री | Protect signs from damage and help them last |

Other important steps are:

- Anti-reflective coatings help people see signs by stopping glare.

- Good ways to put up signs, like the right angle and height, make them easy to read.

Engineers make signs to handle bad weather. Coatings and covers keep water and dust out. These steps help signs work well for a long time. OPTRAFFIC checks every sign to make sure it is safe and works right.

Future of Aluminum Sheet Cutting in Traffic Signs

Smart Sign Innovations

Smart technology is changing how people see traffic signs. Cities use sensors and digital screens to make roads safer. These smart signs can change messages when traffic changes. उदाहरण के लिए, a sign can warn about ice or show a new speed limit in bad weather. Aluminum helps these signs last longer and stay strong in all kinds of weather. Engineers use aluminum traffic sign blanks to build smart signs with cameras and sensors. These signs help drivers make better choices and keep everyone safe.

Smart signs also help with new road designs. They can connect to traffic lights and send updates to drivers’ phones. This helps people follow rules and avoid accidents. Aluminum signs with smart features help cities manage busy roads and keep traffic moving. Safety gets better when drivers get clear, real-time information.

Trends in Materials and Technology

The future of aluminum sheet cutting brings new trends to the industry. Companies now try to make aluminum signs in ways that help the planet. They use less energy and recycle more materials. This lowers the carbon footprint of making traffic signs. Factories use CNC and laser cutting to make aluminum traffic sign blanks with great precision. These tools help workers cut aluminum faster and waste less material.

Automation and digital tools are important for making traffic directional signs. उद्योग 4.0 technology lets machines talk to each other and check quality at every step. This means every sign meets safety rules and lasts longer on the road.

Here are some key trends:

| रुझान | विवरण |

|---|---|

| वहनीयता | More eco-friendly practices and lower carbon footprint in aluminum production. |

| तकनीकी नवाचार | CNC and laser cutting improve precision and efficiency in aluminum sheet cutting. |

| Automation and Digitalization | उद्योग 4.0 tools optimize processes and boost product quality for aluminum signs. |

Aluminum will stay important for traffic safety. New technology will help cities use better signs that last longer and keep roads safe for everyone.

New ways to cut aluminum sheets, like laser and CNC, make traffic signs tougher and brighter. These signs also last much longer than before. Makers add smart things like anti-graffiti layers and UV-cured inks. These help signs stay strong and easy to see. OPTRAFFIC uses green designs and smart machines to lead the way. Their signs help cities spend less and keep roads safe.

- मज़बूत, clear signs help stop crashes and can be seen in any weather.

- Smart signs use solar power and can be recycled, which helps cities grow in the future.

Cities get signs they can trust. These signs follow the rules and fit new city needs.

अक्सर पूछे जाने वाले प्रश्न

What makes laser cutting better for aluminum traffic signs?

Laser cutting makes edges smooth and shapes sharp. Workers finish signs faster and waste less material. इस तरह, signs last longer and stay clear in any weather.

How do CNC machines improve sign quality?

CNC machines use computer plans to cut aluminum. They are very accurate and make each sign match the plan. Signs meet safety rules and can have special shapes or designs.

Why does OPTRAFFIC use automation in production?

Automation helps make signs faster and with fewer mistakes. Machines do the same job again and again. OPTRAFFIC can finish big orders quickly. Automation keeps costs down and quality high.

Are OPTRAFFIC’s signs compliant with safety standards?

OPTRAFFIC checks every sign to meet MUTCD and FHWA rules. Tests look at how easy signs are to see and how long they last. Cities trust OPTRAFFIC because their signs follow the rules.