Les problèmes juridiques passent souvent inaperçus jusqu'à ce qu'un accident survienne. Mais quand ils le font, Les effets peuvent être graves. Les entreprises pourraient faire face à des poursuites, pertes d'argent, et les retards de travail. Par exemple:

- Payer des poursuites peut coûter des centaines de milliers, voire plus..

- Les accidents peuvent perturber les horaires de travail, causant une perte d'argent.

- Le bonheur des travailleurs chute après un accident, conduisant à arrêter de fumer et à moins de travail effectué.

Les panneaux de sécurité de l'OSHA sont très importants pour assurer la sécurité de votre lieu de travail. Ces panneaux de sécurité de l'OSHA suivent les règles de sécurité, Aider à éviter les amendes sur $16,000 pour de grandes erreurs. Ils arrêtent également les accidents, Protéger les travailleurs et le bon nom de votre entreprise.

OPTRAFFIC propose des panneaux de sécurité conformes à l'OSHA à vendre, Construit pour la durabilité, clarté, et haute visibilité dans des environnements de travail exigeants. Contactez-nous aujourd'hui pour trouver les bonnes solutions de signalisation de sécurité pour votre installation et assurer la protection de votre équipe.

Principaux à retenir

- Les panneaux de sécurité OSHA arrêtent les accidents et assurent la sécurité des travailleurs, réduire les risques juridiques.

- Des panneaux de sécurité clairs et corrects peuvent protéger votre entreprise contre de lourdes amendes et poursuites judiciaires..

- Vérifiez et réparez souvent les panneaux de sécurité pour qu'ils restent clairs et utiles..

- Des panneaux en différentes langues aident tous les travailleurs à comprendre les avertissements et à éviter les accidents.

- Placer des panneaux de sécurité dans les endroits dangereux rend les lieux de travail plus sûrs et respecte les règles.

Comprendre l'OSHA et l'importance juridique des panneaux de sécurité

Présentation de l'OSHA (Administration de la sécurité et de la santé au travail)

OSHA représente le Administration de la sécurité et de la santé au travail. C'est un groupe fédéral qui veille à la sécurité des lieux de travail. L'OSHA crée des règles pour réduire les risques et arrêter les accidents. Ils enseignent également aux entreprises comment suivre ces règles. En suivant les conseils de l’OSHA, vous pouvez assurer la sécurité des travailleurs et éviter les problèmes juridiques.

Le rôle de l'OSHA dans le respect de la sécurité sur le lieu de travail et de la conformité légale

L'OSHA aide à assurer la sécurité des lieux de travail et garantit le respect des règles. Ils vérifient les entreprises pour voir si les règles de sécurité sont respectées. Sinon, L'OSHA peut imposer des amendes ou arrêter le travail. Les panneaux de sécurité sont une grande partie de l’attention de l’OSHA. Ces panneaux avertissent les travailleurs des dangers tels que les sols mouillés ou la haute tension.. Ils aident les travailleurs à rester en sécurité et à éviter les blessures. L'utilisation de panneaux approuvés par l'OSHA montre que vous vous souciez de la sécurité et respectez la loi..

Exigences de signalisation de sécurité de l'OSHA sous 29 CFR 1910.145

L'OSHA a des règles pour les panneaux de sécurité dans 29 CFR 1910.145. Ces règles expliquent comment utiliser les panneaux pour indiquer les dangers. Les panneaux doivent avoir des couleurs claires, formes, et les mots. Par exemple, des panneaux d’avertissement doivent délimiter les zones interdites aux gens. L'OSHA déclare également que les panneaux doivent être dans différentes langues. Cela aide tout le monde à comprendre les avertissements, Peu importe leur langue. Le respect de ces règles assure la sécurité des travailleurs et évite les amendes.

Conseil: Installer des panneaux de sécurité avant le début des travaux. Cela aide les travailleurs et les visiteurs à être informés rapidement des dangers..

Conséquences d'une signalisation de sécurité manquante ou inefficace

Pénalités légales, Amendes, et ordres d'arrêt des travaux

Ne pas utiliser les panneaux de sécurité appropriés peut entraîner de gros problèmes juridiques. L'OSHA impose des amendes en cas de non-respect des règles, les plus sérieux coûtent plus cher $16,000 chaque. Si les violations se reproduisent ou sont commises intentionnellement, les amendes peuvent dépasser $165,000. Dans 2022, une entreprise a été condamnée à une amende $1,201,031 pour de nombreuses violations, y compris les mauvais avertissements de danger. Ces amendes peuvent nuire à votre entreprise et arrêter le travail avec des ordres de fermeture. Des panneaux clairs et corrects réduisent ces risques et montrent que vous vous souciez de la sécurité.

Note: L'OSHA modifie les montants des amendes chaque année. Connaître les mises à jour permet d'éviter des coûts inattendus.

Blessures au travail et poursuites civiles qui en résultent

Sans bons panneaux de sécurité, les travailleurs sont plus susceptibles de se blesser. L'OSHA affirme que les mauvais avertissements de danger constituent le deuxième problème le plus courant sur le lieu de travail et l'une des principales causes de blessures.. À propos 2.8 Des millions d’accidents du travail non mortels se produisent chaque année aux États-Unis., beaucoup évitables avec de meilleurs signes. Les travailleurs blessés pourraient poursuivre en justice, conduisant à des poursuites judiciaires coûteuses. Des études montrent que le nombre de blessures pourrait être plus élevé puisque certains incidents ne sont pas signalés. L'utilisation de panneaux appropriés assure la sécurité des travailleurs et protège votre entreprise contre les poursuites judiciaires..

Dommages à la réputation et perte de contrats

De mauvais panneaux de sécurité peuvent nuire à la réputation de votre entreprise. Les nouvelles négatives font perdre confiance aux clients et prennent du temps à être corrigées. L'OSHA affirme que les mauvais avertissements de danger constituent un problème majeur sur le lieu de travail, entraînant des contrats annulés et moins de chances d'emploi. De bons panneaux de sécurité arrêtent les accidents et rendent le travail plus sûr. Ils améliorent également la manière dont les travailleurs se comportent et se sentent en matière de sécurité.. En se concentrant sur la sécurité, vous protégez votre réputation et entretenez de solides relations avec vos clients.

Exemples concrets de violations de l'OSHA impliquant des panneaux de sécurité

Cas 1 - Non “Haute tension” Avertissement dans la salle d'équipement (Texas)

Au Texas, une usine a eu des ennuis pour avoir raté un “Haute tension” signer dans son local technique. Un travailleur est entré sans connaître le danger et a été choqué. Cela a enfreint les règles de sécurité de l'OSHA, qui sont souvent ignorés. L'erreur a entraîné une lourde amende et un arrêt de travail. Des panneaux de sécurité clairs de l'OSHA auraient pu avertir les travailleurs et arrêter l'accident.

Cas 2 – Aucun panneau de sortie pendant l’exercice d’incendie (Ohio)

Un bureau de l'Ohio a eu des problèmes lors d'un exercice d'incendie. Les travailleurs ne parvenaient pas à trouver les sorties car les panneaux manquaient. Cela a provoqué la panique et des blessures légères alors que les gens se précipitaient dehors.. L'OSHA déclare que les sorties doivent être marquées pour permettre une évacuation en toute sécurité. L'entreprise a été condamnée à une amende et a dû ajouter de nouveaux panneaux. Des panneaux de sortie clairs aident à éviter toute confusion et à sauver des vies dans de véritables situations d'urgence.

Cas 3 – Accident de chariot élévateur dans un entrepôt sans panneaux au sol (Illinois)

Dans l'Illinois, un entrepôt a eu un accident de chariot élévateur qui a blessé deux travailleurs. L'accident s'est produit parce qu'il n'y avait pas de panneaux au sol pour guider les gens.. L'OSHA souligne la nécessité de panneaux de sécurité OSHA pour prévenir de tels accidents. Sans eux, les travailleurs sont confrontés à plus de risques. L'entreprise a été condamnée à une amende et a dû arrêter ses travaux pour des contrôles. L'ajout de panneaux au sol aurait pu rendre l'entrepôt plus sûr et éviter l'accident.

À retenir: Les violations des panneaux de sécurité de l'OSHA provoquent des blessures, amendes, et les retards de travail. Des panneaux de sécurité OSHA clairs sont essentiels pour assurer la sécurité de tous et éviter les problèmes..

Comment les panneaux de sécurité OSHA réduisent les risques juridiques et de sécurité

Montrer la conformité aux règles juridiques et de sécurité

Les panneaux de sécurité OSHA sont essentiels pour suivre les règles de sécurité. Ces panneaux sont nécessaires pour réduire les risques et assurer la sécurité des personnes. Ils agissent comme des avertissements, montrer que votre lieu de travail respecte les règles de sécurité de l'OSHA. Par exemple, des panneaux indiquant des zones ou des outils dangereux montrent que vous vous souciez de la sécurité. Cela contribue à réduire les risques de problèmes juridiques.

Conseil: Vérifiez souvent vos panneaux de sécurité pour qu'ils restent clairs et utiles.. Cette simple habitude peut mettre fin aux problèmes juridiques et améliorer la sécurité au travail.

| Type de preuve | Détails |

|---|---|

| Exigences de conformité | Les règles ont besoin de panneaux de sécurité pour réduire les risques et respecter les lois. |

| Implications juridiques | Des panneaux de sécurité manquants peuvent entraîner des amendes et des problèmes juridiques. |

| Visibilité et entretien | Les employeurs doivent vérifier souvent les panneaux pour qu'ils restent clairs et utiles.. |

| Atténuation des risques | Un bon placement des panneaux réduit les risques d'accidents et de blessures. |

Aider aux inspections OSHA et éviter les amendes

De bons panneaux de sécurité OSHA aident lors des inspections et réduisent les risques. Les inspecteurs vérifient si votre lieu de travail contient des avertissements clairs. Des panneaux manquants ou peu clairs peuvent entraîner des amendes. L'OSHA affirme que l'absence de panneaux de sécurité est un problème courant au travail. En utilisant les signes appropriés, vous évitez les amendes et montrez que vous respectez les règles de sécurité.

Le respect de ces règles protège également votre entreprise des problèmes juridiques. Enfreindre les règles peut entraîner des poursuites judiciaires et nuire à la réputation de votre entreprise. Les panneaux approuvés par l'OSHA rendent votre lieu de travail plus sûr et réduisent le risque de violations.

Rendre les lieux de travail plus sûrs et prévenir les accidents

Des panneaux de sécurité clairs rendent les lieux de travail plus sûrs en stoppant les accidents. Les lieux de travail dotés de panneaux dans de nombreuses langues 25% Moins d'accidents. Cela montre à quel point des avertissements clairs sont importants. L'OSHA affirme que les mauvais signes de danger constituent un gros problème, causant plus de blessures.

Placer des panneaux de sécurité OSHA dans des endroits importants rend le travail plus sûr. Ces panneaux de sécurité OSHA rappellent aux travailleurs de suivre les règles de sécurité. Quand les travailleurs se sentent en sécurité, ils font un meilleur travail. Moins d’accidents signifie moins de problèmes pour votre entreprise.

Zones critiques pour la signalisation de sécurité conforme à l'OSHA

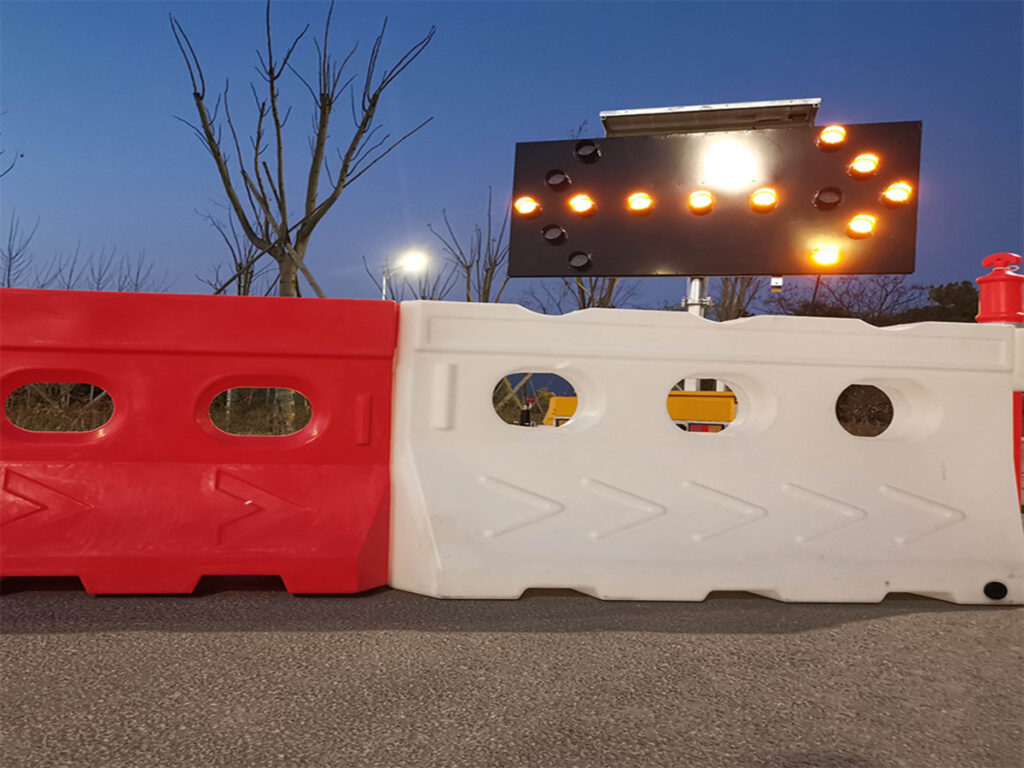

Chantiers de construction et zones de travaux routiers

Les chantiers de construction peuvent être des lieux de travail très dangereux. Les panneaux de sécurité sont importants pour réduire les risques et suivre les règles de l'OSHA. Ces panneaux de sécurité OSHA mettent en garde contre des dangers tels que la chute d'objets, grosses machines, et ouvrir des trous. Ils aident également les conducteurs et les promeneurs à proximité des travaux routiers à éviter les accidents..

- Les panneaux de sécurité aident à prévenir les blessures, avec 2.8 millions d'accidents par an aux États-Unis.

- Le respect des règles MUTCD réduit la confusion et maintient les zones de travail plus sûres.

- Le respect des règles OSHA et MUTCD protège votre entreprise des amendes.

Mettre des panneaux de sécurité OSHA clairs aux entrées, zones de danger, et les zones de circulation rendent le site plus sûr pour tous.

Entrepôts et centres logistiques

Les entrepôts ont besoin de panneaux approuvés par l'OSHA pour gérer les risques tels que les machines lourdes et les zones très fréquentées.. Des panneaux guident les travailleurs en toute sécurité, aider à éviter les accidents de chariot élévateur, glissades, et tombe. Signs in many languages are helpful for workers who don’t speak English.

| Important Area | How Signs Help |

|---|---|

| Danger Awareness | Signs remind workers of risks, keeping them careful. |

| Arrêt des accidents | Clear signs and symbols lower accidents and make work safer. |

| Règles suivantes | OSHA-approved signs build a safety culture and meet safety rules. |

Checking and updating OSHA safety signs often keeps them useful, even in dusty or dark places.

Manufacturing and Industrial Facilities

Factories have special dangers like chemicals, chaleur, and moving machines. OSHA safety signs teach workers about safety and warn of risks. Par exemple, OSHA safety signs near chemical storage or tight spaces tell workers about specific dangers.

| Type de preuve | Détails |

|---|---|

| Stopping Injuries | Signs cut down injuries, avec 2.8 million accidents yearly in workplaces. |

| Following OSHA Rules | Correct signs meet OSHA rules and avoid fines. |

| Worker Education | Des panneaux enseignent aux travailleurs les mesures de sécurité, rendre le lieu de travail plus sûr. |

Placer des panneaux de sécurité OSHA à des endroits clés comme les zones des machines et les sorties de secours améliore la sécurité et montre que vous vous souciez des travailleurs.’ bien-être.

Sorties de secours, Espaces confinés, et zones dangereuses

Sorties de secours, espaces confinés, et les zones de danger sont très importantes. Les panneaux de sécurité OSHA à ces endroits assurent la sécurité des travailleurs et respectent les règles..

Sorties de secours

Les sorties de secours doivent toujours être faciles à trouver et à utiliser. L'OSHA affirme que les panneaux de sortie doivent être clairs et faciles à voir. Ces panneaux aident les travailleurs à s'échapper en cas d'incendie ou de déversement de produits chimiques. Sans signes clair, les travailleurs pourraient paniquer ou perdre du temps à trouver des sorties.

Conseil: Placez les panneaux de sortie à la hauteur des yeux et gardez-les dégagés. Vérifiez souvent les lumières et les flèches pour vous assurer qu'elles fonctionnent..

Espaces confinés

Espaces confinés, comme des tanks ou des tunnels, peut être très dangereux. Ces zones ont souvent peu d'air, les rendre dangereux. L'OSHA exige des panneaux d'avertissement pour indiquer les espaces confinés et avertir des dangers tels que le mauvais air ou le manque d'oxygène..

- Exemples de panneaux requis:

- “Espace confiné requis par un permis”

- “Danger: N'entrez pas sans autorisation”

Des panneaux empêchent les gens d'entrer sans autorisation et rappellent aux travailleurs de rester en sécurité.

Zones à risque

Les zones de danger comportent des risques tels que des chutes d'objets, produits chimiques, ou chauffer. Les panneaux OSHA avertissent les travailleurs de rester prudents et de porter des équipements de sécurité. Par exemple, un “Prudence: Zone des casques de sécurité” un panneau indique aux travailleurs de se protéger la tête dans les zones à risque.

| Type de danger | Exemple de signalisation |

|---|---|

| Exposition chimique | “Danger: Matériaux corrosifs” |

| Objets qui tombent | “Prudence: Objets qui tombent” |

| Températures élevées | “Avertissement: Surface chaude” |

À retenir: Des panneaux de sécurité clairs de l'OSHA dans ces zones sauvent des vies et mettent fin aux accidents. Vérifiez et mettez à jour les panneaux souvent pour assurer la sécurité des travailleurs et respecter les règles..

Meilleures pratiques pour une signalisation de sécurité efficace

Utiliser des couleurs standard, Formes, et les mots comme le suggère l'OSHA

Utiliser des couleurs standards, formes, et les mots rendent les panneaux de sécurité OSHA faciles à comprendre. OSHA et ANSI suggèrent certaines couleurs pour différents dangers. Par exemple:

- Rouge signifie DANGER ou STOP, montrant les zones ou les outils à haut risque.

- Orange est pour AVERTISSEMENT, souvent utilisé à proximité de travaux routiers ou de dangers.

- Jaune signifie ATTENTION, avertissement sur les risques tels que les sols glissants.

Ces règles aident les travailleurs à repérer rapidement les dangers et à rester en sécurité. Suivre ces conseils rend les panneaux clairs et réduit la confusion au travail.

Conseil: Gardez le libellé des panneaux simple et clair. Cela aide tout le monde à comprendre, Peu importe leur niveau de lecture.

Placez des panneaux là où tout le monde peut les voir clairement

Il est très important de placer les panneaux de sécurité OSHA aux bons endroits. Placez-les au niveau des yeux, là où les travailleurs peuvent facilement les voir. Pensez à la façon dont les gens se déplacent sur votre site. Par exemple, mettre “Prudence: Sol mouillé” panneaux à proximité des zones très fréquentées ou des entrées.

Les matériaux des panneaux de sécurité OSHA sont également importants. Utilisez des matériaux réfléchissants ou résistants pour que les panneaux de sécurité soient visibles dans la pénombre ou par mauvais temps.. Ceci est particulièrement utile pour les espaces extérieurs ou les entrepôts sombres. De bons panneaux préviennent les accidents et rappellent aux travailleurs de rester vigilants.

Note: Vérifiez souvent pour vous assurer que les panneaux de sécurité OSHA ne sont pas bloqués par des éléments tels que des outils ou des déchets.. Des panneaux clairs sont essentiels pour la sécurité.

Vérifiez et remplacez souvent les panneaux anciens ou cassés

Les panneaux anciens ou cassés ne fonctionnent pas bien. Vérifiez souvent vos panneaux pour trouver ceux qui doivent être réparés.. Chercher des fissures, peeling, ou des mots fanés et difficiles à lire. Remplacez immédiatement les mauvais panneaux pour assurer la sécurité de tous.

Des contrôles réguliers montrent que vous vous souciez de la sécurité. Les travailleurs remarquent que vous prenez la sécurité au sérieux, ce qui les rend plus susceptibles de suivre les règles. De bons panneaux de sécurité ne se limitent pas à l'endroit où ils se trouvent : ils doivent également être en bon état..

À retenir: Un bon panneau de sécurité ne fonctionne que s’il est en bon état. Vérifiez vos panneaux de sécurité OSHA chaque mois pour les garder utiles et respecter les règles de l'OSHA..

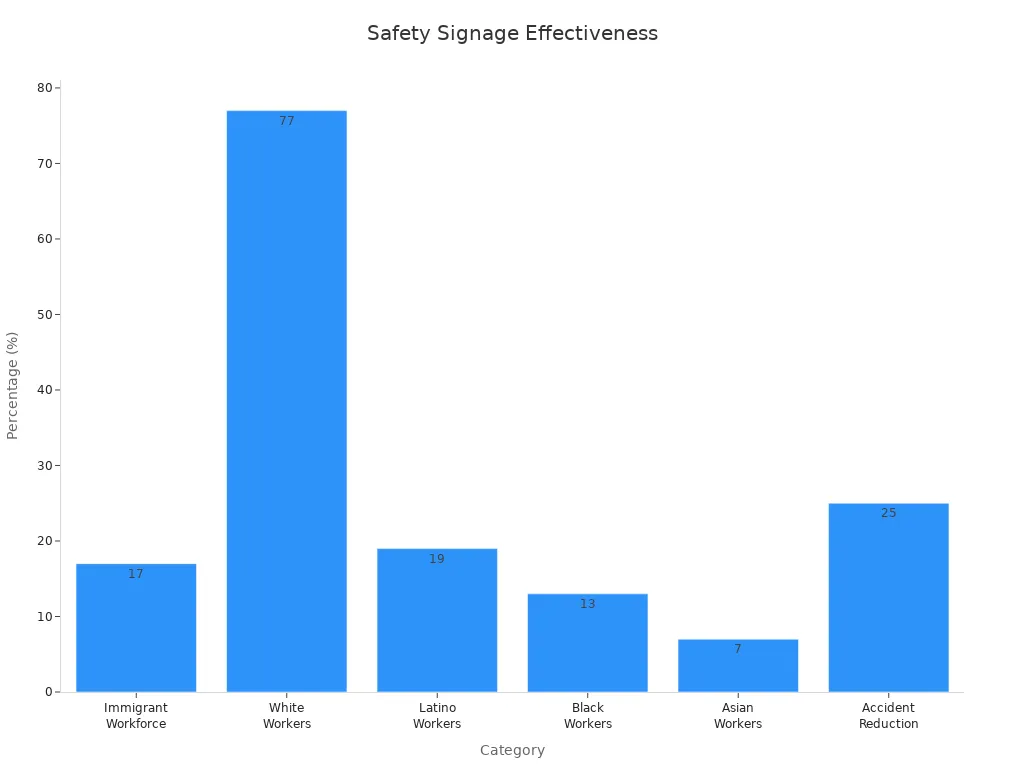

Utilisez du texte et des symboles multilingues pour des effectifs diversifiés

Aujourd’hui, les lieux de travail comptent des personnes issues de divers horizons. Aux États-Unis, 17% des travailleurs sont nés dans d’autres pays. Cela signifie que les panneaux de sécurité doivent être faciles à comprendre pour tout le monde.. Des panneaux en plusieurs langues et des symboles clairs rendent les lieux de travail plus sûrs.

L'utilisation de différentes langues sur les panneaux aide tous les travailleurs à comprendre les avertissements. Par exemple, un “Prudence: Sol mouillé” un signe en anglais et en espagnol aide les deux groupes à éviter de glisser. Ajouter une image, comme si quelqu'un tombait, rend le message encore plus clair. Les images fonctionnent pour les personnes qui ne savent pas lire ou ne connaissent pas la langue.

Une meilleure communication réduit les accidents. Des études montrent que les lieux de travail dotés de panneaux multilingues ont 25% Moins de blessures. Cela aide les travailleurs à rester en sécurité et protège les entreprises des problèmes juridiques.. Quand les travailleurs se sentent en sécurité, ils travaillent mieux et font davantage confiance à leur employeur.

Voici comment la diversité de la main-d’œuvre est liée aux panneaux multilingues:

| Statistique | Valeur |

|---|---|

| Travailleurs nés hors des États-Unis. | 17% |

| Travailleurs blancs | 77% |

| Travailleurs latinos | 19% |

| Travailleurs noirs ou afro-américains | 13% |

| Travailleurs asiatiques | 7% |

| Moins d'accidents avec des panneaux multilingues | 25% |

L'ajout de langues et de symboles montre que vous vous souciez de vos travailleurs. Il crée un lieu de travail sûr et accueillant. Les travailleurs se sentent valorisés lorsque les panneaux sont faciles à comprendre. Vérifiez souvent vos panneaux pour répondre aux besoins de votre équipe. L'ajout d'une langue ou d'un symbole peut faire une grande différence.

Conseil: Gardez les mots simples et utilisez des symboles que tout le monde connaît pour les panneaux de sécurité OSHA clairs..

Choisir des panneaux de sécurité OSHA qui répondent aux normes

Suivez ANSI Z535 et ISO 7010 Règles

Choisissez les panneaux de sécurité qui suivent ANSI Z535 et ISO 7010 règles. Ces règles garantissent que les panneaux indiquent clairement les dangers et expliquent les risques.. L'OSHA déclare que les panneaux de sécurité de l'OSHA doivent avertir de dangers spécifiques et de leur gravité. L'utilisation de ces panneaux de sécurité OSHA montre que vous vous souciez de la sécurité et aide à éviter les problèmes juridiques..

Les panneaux qui respectent ces règles réduisent les risques juridiques. Par exemple, les entreprises portant ces panneaux ne signalent aucune poursuite en justice pour dangers sur le lieu de travail. Cela prouve à quel point il est important d'utiliser des panneaux de sécurité appropriés.. Que votre site comporte de grosses machines ou des matières dangereuses, ces panneaux assurent la sécurité des travailleurs et des visiteurs.

Utilisez des matériaux solides pour des panneaux durables

Choisissez des matériaux solides pour des panneaux de sécurité qui durent longtemps. Les panneaux de sécurité OSHA à l'extérieur ou à proximité de machines lourdes doivent résister à des conditions difficiles. Des matériaux comme l'aluminium ou les revêtements réfléchissants prolongent la durée de vie des panneaux et les rendent plus faciles à voir.. Les panneaux réfléchissants sont parfaits pour les zones sombres ou extérieures.

Vérifiez souvent vos panneaux et remplacez rapidement ceux endommagés.. Les panneaux brisés ou décolorés n’avertissent pas bien les travailleurs et peuvent provoquer des accidents. Des matériaux solides permettent d'économiser de l'argent sur les remplacements et assurent la sécurité du lieu de travail.

Rendre les messages clairs et ajouter plusieurs langues

Les panneaux de sécurité OSHA doivent être faciles à lire et à comprendre. Utilisez des mots et des symboles simples que tout le monde connaît. Pour les travailleurs qui parlent des langues différentes, ajouter des traductions. Par exemple, un “Prudence: Sol mouillé” signer en anglais et en espagnol, avec une silhouette glissante, aide tout le monde à comprendre.

Les chantiers de construction emploient souvent des travailleurs provenant de nombreux endroits. Les panneaux multilingues mettent fin à la confusion et rendent le travail plus sûr. Les études montrent que les lieux de travail avec ces signes ont 25% Moins d'accidents. Ce petit changement protège les travailleurs et montre que vous vous souciez de leur sécurité.

Conseil: Travailler avec des experts qui connaissent les règles de sécurité. Ils peuvent vous aider à choisir des panneaux adaptés aux besoins de votre site.

Les panneaux de sécurité de l'OSHA sont importants pour garder les lieux de travail en sécurité. Ils aident à respecter les règles de sécurité, réduire les risques d'amendes ou de poursuites. Ces panneaux de sécurité OSHA arrêtent également les accidents, Protéger les travailleurs et le bon nom de votre entreprise.

| Type de preuve | Description |

|---|---|

| Règles suivantes | Les panneaux OSHA aident à respecter les règles de sécurité et à éviter les amendes. |

| Problèmes d'argent | Enfreindre les règles peut entraîner de lourdes amendes et des coûts d'accident. |

| Arrêt des accidents | Des panneaux clairs préviennent les accidents et protègent les entreprises des poursuites judiciaires. |

Utiliser le bien, les panneaux qui respectent les règles montrent que vous vous souciez de la sécurité. Consultez nos panneaux de sécurité approuvés par l'OSHA pour rendre votre lieu de travail plus sûr dès aujourd'hui.!

Vous voulez savoir comment les réglementations de l'OSHA affectent d'autres équipements de sécurité routière comme les cônes de signalisation?

Visitez notre blog: “Guide complet des réglementations et de la conformité du cône de la circulation OSHA“ pour explorer les principales normes de conformité, règles de placement, et des conseils de sécurité pour garantir que votre zone de travail répond aux exigences de l'OSHA.

FAQ

Que sont les panneaux de sécurité OSHA?

Les panneaux de sécurité OSHA sont des images ou des mots qui mettent en garde contre les dangers. Ils suivent des règles pour être clairs et faciles à comprendre. Ces panneaux assurent la sécurité des lieux de travail et respectent les lois sur la sécurité..

Pourquoi les panneaux de sécurité OSHA sont-ils importants pour votre entreprise?

Ces panneaux aident à arrêter les accidents et vous montrent que vous respectez les lois en matière de sécurité.. Ils protègent également votre entreprise contre les amendes ou les poursuites en montrant que vous vous souciez de la sécurité des travailleurs..

À quelle fréquence devez-vous inspecter les panneaux de sécurité?

Vérifiez les panneaux de sécurité chaque mois pour vous assurer qu'ils sont clairs. Remplacez les panneaux de sécurité OSHA qui sont fanés, cassé, ou disparu tout de suite. Des contrôles réguliers permettent de prévenir les accidents et de respecter les règles de sécurité.

Les panneaux de sécurité OSHA peuvent-ils être multilingues?

Oui, L'OSHA prend en charge les panneaux dans différentes langues pour tous les travailleurs. L'ajout de traductions et d'images aide tout le monde à comprendre les avertissements et à rester en sécurité.

Où devriez-vous placer les panneaux de sécurité OSHA?

Placez les panneaux de sécurité OSHA dans les zones dangereuses comme les chantiers de construction ou à proximité des sorties. Assurez-vous qu'ils sont faciles à voir, même dans des endroits faiblement éclairés ou poussiéreux.