When choosing heavy-duty safety bollards for protection, understanding material strength is crucial. Ductile iron is exceptionally strong and can bend without breaking, effectively handling force and making it ideal for strong impacts. In contrast, gray cast iron performs adequately when stationary but tends to break under pressure. Its brittleness renders it unsuitable for crash scenarios. For tough safety bollards, ductile iron is the superior choice for managing accidents and high-speed impacts.

To learn more about the benefits of cast iron traffic bollards and how they combine aesthetics with durability, check out the blog Cast Iron Bollards: Classic Look, Heavy Protection. It provides a detailed look at how cast iron bollards can offer both style and robust protection for various urban environments.

Key Takeaways

- Ductile iron bollards can bend and take in energy. This makes them great for places with heavy impacts.

- Gray cast iron works better for looks but breaks easily under pressure.

- Pick ductile iron for safety in crowded spots. It lasts longer and stays strong over time.

- Think about costs; ductile iron costs more at first but needs fewer repairs later.

- Use gray cast iron in quiet areas where looks are more important than strength.

Overview of Ductile Iron Bollards

Material Properties of Ductile Iron

Ductile iron is special because of how it’s made. It has nodular graphite, unlike gray cast iron. This gives it strength and flexibility. Instead of breaking, it bends under pressure. This makes it great for safety uses. It can handle heavy loads without cracking. Ductile iron also absorbs energy well. This helps it work in tough situations. These features make it a strong choice for bollards in demanding areas.

Strength and Flexibility Under Impact

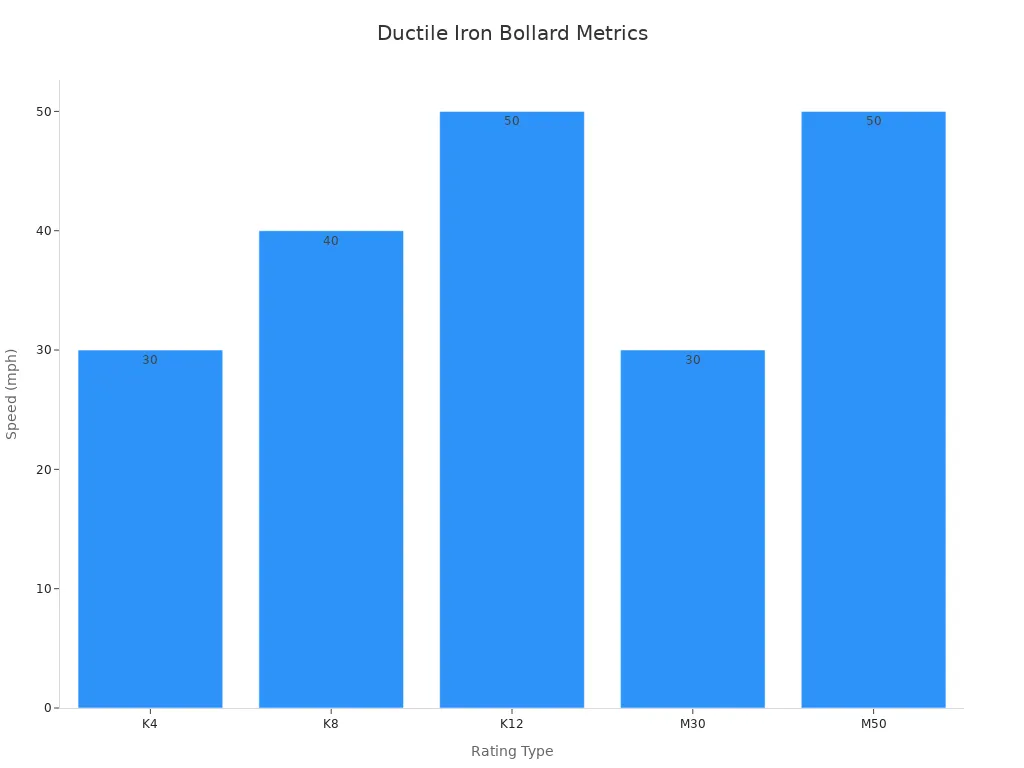

Ductile iron is very good at handling impacts. It absorbs energy without breaking, even in crashes. For example, it can stop vehicles weighing 15,000 pounds at different speeds. Below is a table showing how it performs:

| Rating Type | Description | Vehicle Weight | Speed |

|---|---|---|---|

| K4 | Stops a 15,000 lb vehicle | 15,000 lbs | 30 mph |

| K8 | Stops a 15,000 lb vehicle | 15,000 lbs | 40 mph |

| K12 | Stops a 15,000 lb vehicle | 15,000 lbs | 50 mph |

| M30 | Stops a medium-duty truck | Medium-duty truck | 30 mph |

| M50 | Stops a medium-duty truck | Medium-duty truck | 50 mph |

This shows why ductile iron is used in risky areas. Its flexibility lets it handle big impacts without breaking.

Applications in Heavy Duty Safety Bollards

Ductile iron traffic bollards are found in places needing strong protection. These include busy streets, factories, and crash-prone areas. They absorb energy and resist damage to protect people and buildings. They also block vehicles from entering restricted areas. Their toughness keeps them working well, even in bad conditions.

Overview of Gray Cast Iron Bollards

Material Properties of Gray Cast Iron

Gray cast iron is an old material with special features. It has graphite flakes that affect its strength and look. This material resists rust, so it works well outdoors. It is also cheaper because it costs less per pound. But, it needs thicker walls to stay strong. Its strength is not as good as other materials. The table below shows some of its key properties:

| Property | Value |

|---|---|

| Tensile Strength (Rm) | ≥250 N/mm² |

| Yield Point (Rel) | N/A |

| Break Elongation (A) | N/A |

Gray cast iron works fine for still uses. But, it is not good for moving or high-stress situations.

Brittleness and Limitations Under Impact

Gray cast iron breaks easily when hit hard. Tests show cracks form quickly because of its structure. A bending test showed three steps of crack growth. This test also showed how strain affects the cracks. Its brittleness makes it bad for handling crashes. It cannot absorb energy well, so it fails under heavy hits.

Common Applications in Decorative Bollards

Even with its flaws, gray cast iron is used for decoration. Its classic style fits old-fashioned and fancy designs. You can find these bollards in parks and historic areas. They are also in places with little car traffic. They last long outside because they resist rust. Plus, they are cheap, making them good for low-impact uses.

Comparative Analysis

Impact Resistance: Ductile Iron vs. Gray Cast Iron

Ductile iron is better at handling impacts than gray cast iron. Its special structure, with nodular graphite, helps absorb energy well. When hit by a vehicle, ductile iron bends slightly instead of breaking. This bending keeps the bollard strong during crashes and heavy impacts.

Gray cast iron does not have this flexibility. Its graphite flakes make it brittle and easy to break. When hit hard, gray cast iron cracks or shatters quickly. This makes it a poor choice for places needing strong safety. For busy or crash-prone areas, ductile iron is the safer option.

Durability and Longevity

Ductile iron lasts longer because it bends instead of breaking. This reduces damage and makes it a smart choice for tough conditions. It handles bad weather and heavy loads without losing strength. Over time, ductile iron stays reliable and saves money on repairs.

Gray cast iron works fine for still uses but struggles under stress. Its brittleness means it needs fixing or replacing often in busy areas. While it resists rust, it is not strong enough for long-term safety. For bollards that face tough challenges, ductile iron is the better pick.

Real-World Performance in Bollard Applications

Ductile iron traffic bollards perform well in busy places like streets or factories. They block vehicles and stay strong after crashes. Their ability to absorb energy keeps them working even after impacts.

Gray cast iron traffic bollards are mostly used for decoration. They look nice in parks or historic areas but cannot handle crashes. While they add style, they are not good for modern safety needs. If you want to protect people and buildings, ductile iron bollards are the stronger choice.

Application Scenarios

High-Traffic Areas and Security Applications

Safety is very important in busy areas. Bollards must handle strong impacts to protect people and property. Ductile iron is a great material for these needs. It absorbs energy without breaking, making it perfect for secure places. For example, ductile iron grade 60-40-18 is made to survive vehicle crashes. It lowers the chance of failure and keeps protection reliable.

You can find ductile iron bollards in places like:

- Around government buildings for security.

- At airport or transit checkpoints.

- In factories where vehicles move fast.

These bollards stop heavy vehicles, even at high speeds. They are strong and dependable for areas where safety is critical.

| Material Type | Impact Resistance | Mechanical Properties | Good for High-Impact Use? |

|---|---|---|---|

| Ductile Iron Grade 60-40-18 | High | Excellent | Yes |

| Decorative Bollards (Low-Impact) | Low | Average | No |

Decorative and Low-Impact Use Cases

Not all road bollards need to handle crashes. In some areas, looks matter more than strength. Gray cast iron is often used for these purposes. Its classic design fits well in parks, old towns, and fancy buildings. These bollards look nice and act as visual barriers.

But gray cast iron is not good for strong impacts. It cracks easily under pressure. In places with little vehicle traffic, it works fine. You might use gray cast iron bollards for:

- Making pedestrian zones look better.

- Marking boundaries in historic areas.

- Adding style to quiet commercial spaces.

These bollards are cheap and look good but are not tough enough for heavy-duty safety.

Cost Considerations and Material Selection

Cost is important when picking traffic bollards for sale. Ductile iron costs more upfront but lasts longer. It saves money over time because it needs fewer repairs. Its durability makes it worth the investment for safety.

Gray cast iron is cheaper at first. This makes it good for decorative or low-impact uses. But in busy areas, it breaks more often and costs more to replace. For strong safety needs, ductile iron is the better choice.

To sum up:

- Pick ductile iron for high-impact and secure areas.

- Use gray cast iron for decorative, low-impact spaces.

- Think about long-term costs when choosing materials.

By knowing your needs, you can choose the right heavy-duty safety bollards for safety and function.

Ductile iron bollards are the best for impact protection. They bend and absorb energy, so they don’t break easily. This makes them perfect for busy places and safety zones. Gray cast iron bollards, however, are better for decoration. They look nice in old-style areas but break under strong impacts. If you need strong protection, choose ductile iron bollards for tough situations.

While iron offers a classic appeal and substantial weight, many modern infrastructure and safety projects now turn to galvanized or stainless steel bollards for better impact absorption, corrosion resistance, and design flexibility.

Explore OPTRAFFIC high-impact steel traffic bollards designed for long-term durability and compliance with international crash safety standards.

FAQ

Why is ductile iron better for impact protection?

Ductile iron bends instead of breaking when hit. Its special graphite design absorbs energy during crashes. This makes it great for busy or accident-prone places. It stays strong and safe in tough conditions.

Can gray cast iron bollards survive vehicle crashes?

No, gray cast iron cracks easily under heavy hits. It works best in places with little traffic or for decoration. For crash safety, ductile iron or steel bollards are much better.

Are ductile iron bollards more costly than gray cast iron?

Yes, ductile iron costs more at first. But it lasts longer and needs fewer repairs. This makes it a smart choice for areas with strong impacts. Gray cast iron is cheaper but breaks more often, costing more later.

Where should gray cast iron bollards be used?

Gray cast iron bollards are good for decoration or old-style areas. They fit well in parks, historic places, or spots with little car traffic. They look nice but are not strong enough for crashes.

Do ductile iron bollards have crash ratings?

Some ductile iron heavy-duty safety bollards are crash-rated, like K4 or K12. These ratings show how they stop vehicles at certain speeds. Always check the maker’s details to know their crash strength.