Selecting the right aluminum sheets for sale is important for good traffic signs. You want signs that last long, are easy to see, and keep people safe. Different grades of aluminum have special benefits for each place. Highway signs need strong aluminum that does not rust. Urban signs use sheets that are easy to shape. The table below shows how picking the right aluminum grade changes how long signs last and how they work:

| Aluminum Grade | Typical Use | Key Lifespan Properties | Environment |

|---|---|---|---|

| 5052-H38 | Highway Signs | High strength, excellent corrosion resistance | Harsh, high-speed |

| 6061-T6 | Regulatory Signs | Exceptional strength, long-lasting durability | Impact-prone outdoor |

| 3004-H38 | Warning Signs | Good formability, corrosion resistance | Outdoor, high visibility |

| 3003-H18 | Street Signs (Urban) | Easy to shape, strong, resists corrosion | Urban, mixed weather |

With many aluminum sheets for sale, it can be hard to pick the right one. Learning about aluminum signs and how they are used helps you choose the best aluminum sheets for your project.

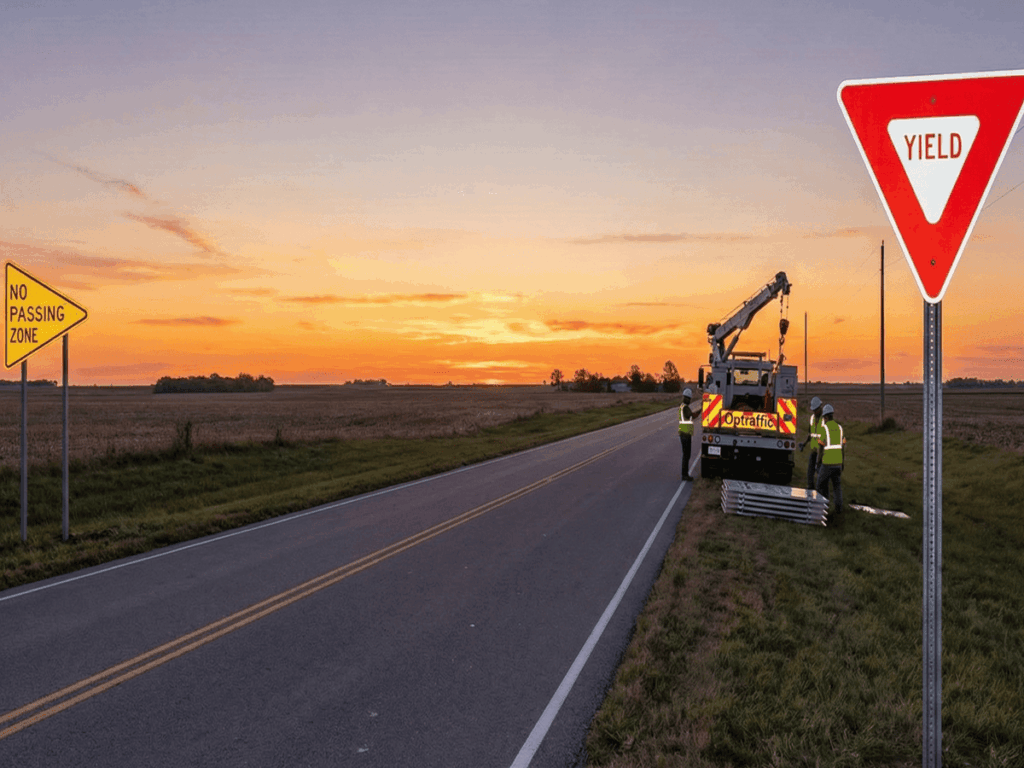

At OPTRAFFIC, we offer high-quality aluminum sheets specifically designed for durable and reliable traffic signage. Let us guide you in selecting the perfect aluminum sheets that meet your project needs, ensuring long-lasting performance and compliance with all necessary regulations.

Why Aluminum Traffic Signs

Durability and Corrosion Resistance

Aluminum traffic signs can handle tough weather. They do not rust or corrode, even in rain or snow. This helps the signs last longer outside. Aluminum is a great choice for highways and city streets. You do not have to fix or replace them often. These signs stay strong and easy to read. They help keep drivers and people safe.

Here are some reasons people like aluminum traffic signs more than steel or plastic:

- Aluminum is light, so you can put up signs fast.

- It is tough and lasts a long time.

- Aluminum does not rust, but steel needs extra protection.

- It works well in all kinds of weather.

- You save money on repairs, even if it costs more at first.

- Aluminum can be recycled, which is good for the planet.

- Plastic signs break down faster and are not as green.

Look at the table below to see how aluminum compares to other materials:

| Material | Corrosion Resistance | Other Properties | Outdoor Use Notes |

|---|---|---|---|

| Aluminum | Does not rust or corrode | Light, strong, saves money | Handles rain, snow, sun, and heat easily |

| Stainless Steel | Best at stopping rust, even in bad weather | Strong, shiny, needs little care | Good for salty air but heavy and costs more |

| Bronze | Stops rust, gets a patina | Lasts long, looks classic | Stays good for years, needs little work |

| Alumalite | Stays strong because of aluminum sheets | Light, stiff | Works well when weather changes |

Compliance and Standards

Aluminum traffic signs must follow strict safety rules. In the United States and Canada, the MUTCD sets these rules. The MUTCD says traffic signs must be bright, clear, and last a long time. For example, stop signs need strong color contrast. Warning signs cannot use some types of sheeting. These rules help drivers see and understand signs fast. This keeps roads safe.

In Europe, the Vienna Convention tells how signs should look. It covers shapes, colors, and symbols. Both the MUTCD and Vienna Convention make sure aluminum signs are easy to see and last long. When you follow these rules, you help make roads safer for everyone.

Aluminum Grades Overview

When you pick aluminum for traffic signs, you should know about the different grades. Each grade has special features that change how your sign works outside. The right grade makes your sign last longer and follow MUTCD rules. It also helps your sign stay easy to see in any weather.

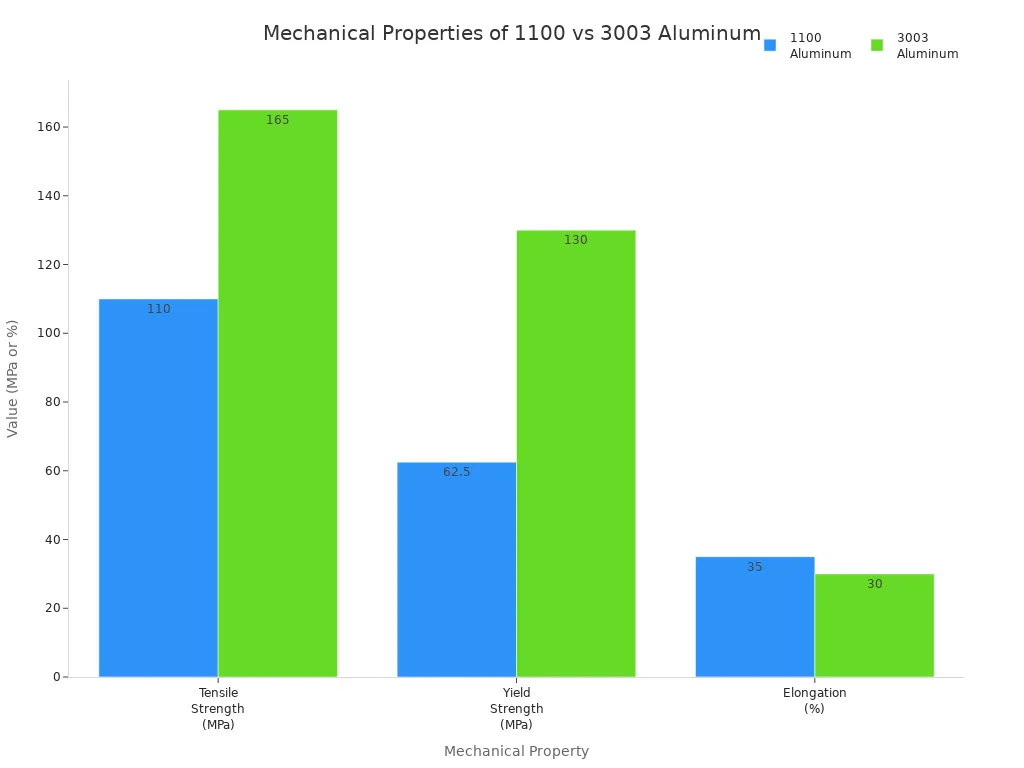

1100 and 3003 Alloys

Many city and town signs use 1100 and 3003 alloys. These alloys are easy to shape into sign blanks. They do not rust, so signs look nice after rain or snow.

Here is a table that shows how 1100 and 3003 aluminum compare:

| Property | 1100 Aluminum | 3003 Aluminum |

|---|---|---|

| Aluminum Content (%) | ~99% (commercially pure) | ~98.8% with 1.2% manganese |

| Tensile Strength (MPa) | 90–130 | 130–200 |

| Yield Strength (MPa) | 30–95 | 115–145 |

| Elongation (%) | Up to 35% | Up to 30% |

| Formability | Excellent (very malleable) | Excellent (good balance of strength and formability) |

| Corrosion Resistance | Excellent (especially to water, salt) | Very Good |

| Weldability | Excellent but softer weld area | Excellent with better post-weld strength |

| Fabrication Suitability | Ideal for decorative, non-load-bearing signs due to softness and surface finish | Better for structural, load-bearing signs due to higher strength and durability |

If you want a smooth sign that does not need much strength, 1100 aluminum is a good pick. This alloy is great for signs that are just for looks or do not hold weight. If you need a stronger sign, 3003 aluminum is better. It can handle wind and being moved around. Both alloys help you follow MUTCD rules for city and street signs.

The price of these alloys depends on what they are made of. Both 1100 and 3003 are not expensive for sign blanks. Prices can be from $0.50 to $5 for each square foot. The cost changes with thickness, finish, and how many you buy. Picking the right alloy helps you save money on your project.

5052, 5454, and 5754 Alloys

For signs outside in tough places, you need strong alloys. The 5052, 5454, and 5754 grades are good for bad weather. These alloys are used for highway signs, near the ocean, and in windy spots.

Here is a table that compares these alloys:

| Alloy | Strength | Corrosion Resistance | Special Advantages | Typical Use Case | Cost |

|---|---|---|---|---|---|

| 5052 | High | Excellent (better than 3003) | High thermal conductivity, wear resistance, withstands high wind pressure (e.g., hurricanes) | Outdoor traffic signs in storm-prone areas (e.g., USA) | N/A |

| 5454 | Very High (20% higher anti-rust than 5052) | Excellent, best for seawater corrosion resistance | High strength and corrosion resistance, widely used in Europe | Coastal and marine environments | Higher than 5754 |

| 5754 | Medium | Good | Good weldability, easy forming, cost-effective alternative to 5454 | European coastal areas with corrosive sea air | Lower than 5454 |

If your signs are close to the ocean, 5454 alloy is best for stopping saltwater damage. For highways with strong storms, 5052 alloy is a smart choice. It stands up to wind and hits. 5754 alloy is cheaper and still works well, so it is used a lot in Europe.

Using these alloys means you will not need to fix or replace signs often. This saves money and helps your signs meet MUTCD rules for lasting a long time. You can trust your aluminum sign to last for years, even in hard weather.

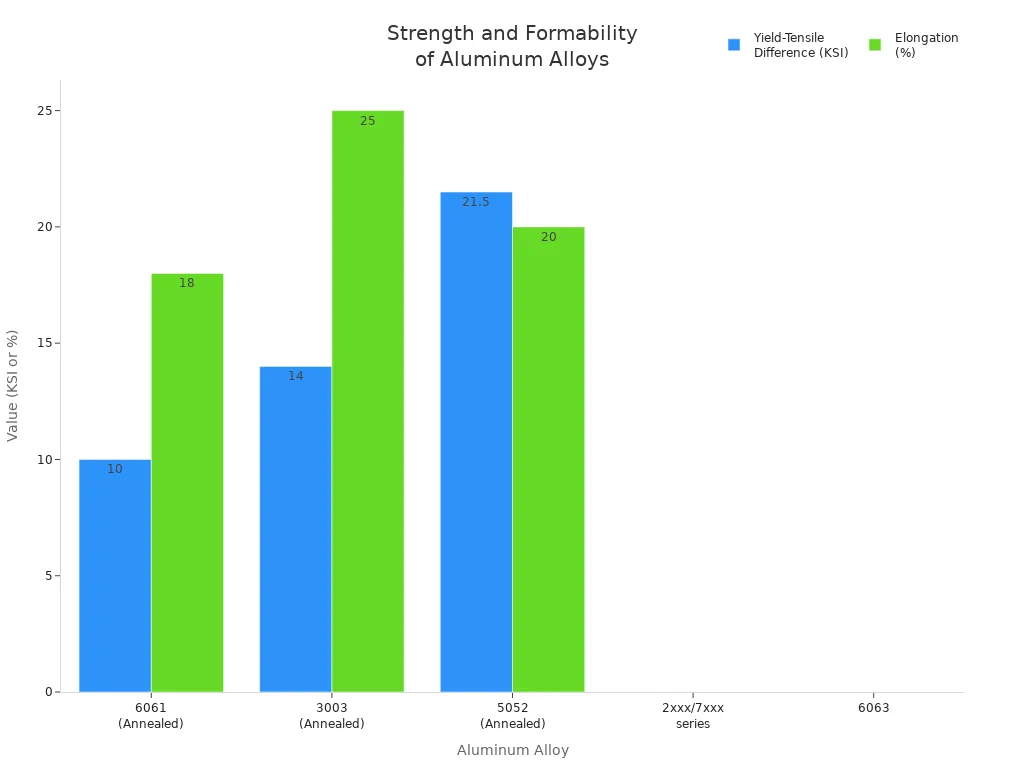

6061 Alloy

Sometimes you need a sign that is even stronger. The 6061 alloy gives you lots of strength and is easy to work with. This alloy is best for signs that might get hit or need to hold more weight.

6061 alloy is stronger than 3003 and 5052, but it is harder to bend. You can still make sign blanks with it, but you have to bend it carefully, especially when it is tempered. Here is a chart that shows how strong and bendable 6061 is compared to other alloys:

6061 alloy is good for signs in busy places or where crashes might happen. You can use it for regulatory signs, signs above roads, or signs that need to be extra strong. MUTCD rules often say to use strong alloys like 6061 for these jobs.

Tip: Always match the alloy to your sign’s location and type. This helps your signs follow MUTCD rules and last a long time.

Picking the right aluminum sign blank and grade helps you balance price, strength, and how long your sign lasts. Your signs will look nice, keep people safe, and not cost too much.

Choosing Aluminum Sheets for Sale

Application-Based Selection

You need to match the right aluminum sheets for sale to your traffic sign project. Start by thinking about where you will place the sign. Highway signs need strong materials because they face high winds and fast-moving vehicles. For these, choose grades like 5052 or 6061. These grades give you the strength and durability needed for busy roads. Urban signs do not face the same stress. You can use 1100 or 3003 alloys for city streets. These alloys are easy to shape and cost less. Custom signs, like those for parking lots or private roads, let you pick from many aluminum sign blanks. You can select the thickness and finish that fit your needs.

Tip: Always check the rules for your area. Some places require certain grades for aluminum traffic signs to meet safety standards.

Here is a quick guide to help you choose:

| Application | Recommended Grade | Key Feature |

|---|---|---|

| Highway | 5052, 6061 | High strength, corrosion resistance |

| Urban/City Streets | 1100, 3003 | Easy to form, cost-effective |

| Custom/Private | 3003, 5052 | Flexible options, good durability |

Environmental Factors

You must think about the environment where you will install your aluminum metal traffic sign. Weather can change how long your sign lasts. Aluminum sheets for sale resist rust and corrosion, so they work well outside. Signs in humid places need extra protection. High humidity can cause problems with wiring or hardware. Extreme heat or cold can warp or crack some materials. Aluminum with special coatings stands up to these changes. Dust and pollution can build up on your sign blank. This makes the sign harder to see and can cause damage over time.

- Aluminum traffic signs resist rust and corrosion, lasting about 10 years outdoors.

- High humidity can cause corrosion in wiring, leading to failures.

- Extreme temperatures can warp or crack sign materials.

- Protective coatings help block damage from rain, snow, and sun.

- Dust and debris can make signs less visible and may cause overheating.

- Regular cleaning and weather-resistant materials keep signs working longer.

If you place signs near the ocean, pick grades like 5454 or 5052. These grades fight off salt damage. For areas with lots of sun, use aluminum sign blanks with UV-resistant coatings. This keeps colors bright and easy to see.

Longevity and Maintenance

You want your signs to last as long as possible. The right aluminum sheets for sale give you durability and reduce how often you need to replace signs. Regular care helps too. Clean your signs with mild soap and water. Use a soft cloth to avoid scratches. Stay away from harsh chemicals that can harm the coating. Check your signs at least twice a year. Look for fading, dents, or loose hardware. Pay close attention to the edges and seams. Moisture can get in and cause problems.

Follow these steps to keep your aluminum traffic signs in top shape:

- Clean signs with mild soap and water.

- Use soft cloths to protect the surface.

- Avoid harsh chemicals.

- Inspect signs twice a year for damage.

- Check edges and seams for moisture.

- Add protective coatings for extra UV and moisture resistance.

- Make sure mounting hardware stays rust-free and tight.

Note: Good maintenance and the right grade of aluminum help your signs last longer and keep people safe.

Choosing the best aluminum sheets for sale means you get signs that stand up to weather, stay bright, and keep traffic moving safely. You save money on repairs and replacements. You also meet all the rules for traffic safety.

Reflective Traffic Signs and Coatings

Reflective Sheeting Types

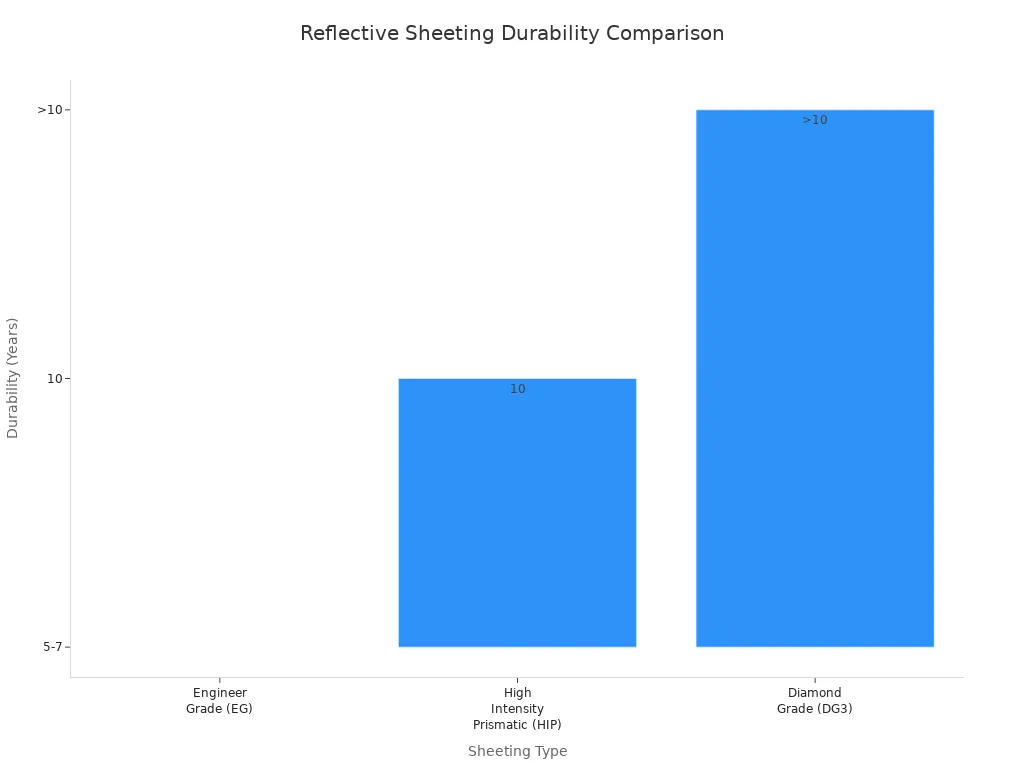

You want your reflective traffic signs to be easy to see all the time. Reflective sheeting helps signs shine at night and during the day. The kind of reflective sheeting you pick changes how well your sign works. There are three main types for traffic signs: Engineer Grade, High Intensity Prismatic, and Diamond Grade.

Here is a table that shows how each reflective sheeting type compares:

| Reflective Sheeting Type | ASTM Standard Compliance | Reflectivity & Optical Technology | Durability (Years) | Typical Applications | Additional Notes |

|---|---|---|---|---|---|

| Engineer Grade (EG) | ASTM D4956 Type 1 | Glass beads or prismatic; lower reflectivity | 5-7 | Non-critical signs (parking, way-finding) | Printable, cuttable; less durable; used for decals |

| High Intensity Prismatic (HIP) | ASTM D4956-09 Type III/IV, Type X | Micro prismatic lens; higher reflectivity than EG | ~10 | Permanent traffic signs, work zones, barricades | More environmentally friendly manufacturing; scratch resistant |

| Diamond Grade (DG3) | ASTM Type XI | Full cube prismatic; reflects ~60% of available light (about double HIP) | Long-term (typically >10) | Critical traffic control signs (stop, speed limit) | Required for new critical signs; optimized for modern headlights and older drivers |

Engineer Grade sheeting is good for parking and way-finding signs. High Intensity Prismatic sheeting is brighter and works well for main road signs and work areas. Diamond Grade sheeting is the brightest and is best for stop signs and speed limit signs. This type gives the most shine for important traffic signs.

Surface Treatments

Surface treatments help your aluminum sign last longer and keep its shine. Alodine treatment puts a thin layer on the aluminum. This layer protects the sign from water and chemicals. It also helps paint and reflective vinyl stick better. Outdoor coatings keep the white color safe from sun, fading, and cracking.

You can add overlaminates like Seton UltraTuff™ for more protection. These coatings stop graffiti, chemicals, and scratches from hurting your sign. Your sign stays bright and easy to read, even in bad weather.

Tip: Pick the right aluminum grade and surface treatment. This helps your reflective traffic signs stay bright and last longer.

Here is a table showing how reflective coatings interact with different aluminum grades:

| Aluminum Grade | Treatment | Reflective Coating Types | Properties and Benefits |

|---|---|---|---|

| 5052-H32 | Bare, routable | N/A | Durable, corrosion resistant, suitable for traffic signage |

| 5052-H38 | Alodine treated | Advanced Engineer Grade (AEG), High Intensity Prismatic (HIP), Diamond Grade (DG3 & DGO) | Harder aluminum, less corrosive finish, not bendable; supports long-term durability and adhesion of coatings |

Aluminum signs with the right surface treatments and reflective sheeting shine bright and last a long time. These signs help drivers see the road signs clearly and keep everyone safe.

Custom Aluminum Signs and Supplier Tips

Supplier Selection

You want your custom aluminum signs to last and look great. Picking the right supplier makes a big difference. Reliable suppliers have certifications like ISO 9001:2015. These certifications show that factories follow strict rules for quality. Suppliers test aluminum sheets for strength and surface finish. They meet standards from groups like ASTM, EN, and DIN. You get sign blanks that pass government checks for durability and readability. Coatings stick well and resist weather, so your signs stay bright. Good suppliers also offer design choices and help you match your needs. You can trust their aluminum custom sign blanks for tough jobs and harsh weather.

- Suppliers with certifications give you consistent quality.

- Quality programs include careful inspections and records.

- You get flexible designs without losing strength.

- High-quality finishes help your signs last longer.

- Reliable suppliers make sure your custom aluminum signs meet all rules.

Bulk Orders and Cost

Ordering custom aluminum signs in bulk saves you money. You pay less for each sign when you buy more at once. Bulk orders also help you keep your project on budget. The cost depends on where you live, the type of sign, and the quality of materials. Labor and installation add to the price. You can choose aluminum custom sign blanks and traffic sign posts that fit your needs. Bulk buying gives you the same quality for every sign. You get signs faster and avoid delays.

- Bulk orders lower the price per sign.

- You control costs by picking the right materials.

- Buying in bulk gives you steady quality.

- You get your signs on time for big projects.

Future Trends

You will see more custom aluminum signs as cities grow and roads get busier. Traffic congestion and new vehicles increase the need for clear signs. Governments want safer roads, so they spend more on traffic sign posts and signs. Urban growth and tourism also raise demand for good signs. Technology brings new features like LED lights and smart coatings. People care about the environment, so suppliers use greener methods to make aluminum signs. You can expect more choices and better performance in the future.

- More cars and buses mean more signs.

- Governments push for safer roads and better signs.

- Cities and tourism boost the need for custom aluminum signs.

- New tech and green practices shape the future of aluminum custom sign blanks.

When you pick the right aluminum grade, your traffic sign gets safer and lasts longer.

- The right grade helps your sign stand up to rain, salty air, and sun.

- Aluminum signs with special coatings need less fixing and last more years.

- Good materials keep sign colors bright and help follow safety rules.

- Experts say to use aluminum that works well in tough weather and stays strong for a long time.

You can ask trusted suppliers or experts to help you choose aluminum traffic signs that follow all safety and traffic rules.

FAQ

What aluminum grade should you use for highway traffic signs?

You should use 5052 or 6061 aluminum for highway signs. These grades give you high strength and resist corrosion. They help your signs last longer in tough weather and heavy traffic.

How do you keep aluminum traffic signs looking new?

Clean your signs with mild soap and water. Use a soft cloth. Check for damage twice a year. Add protective coatings to block sun and rain. This helps your signs stay bright and easy to read.

Why do traffic signs need reflective coatings?

Reflective coatings help drivers see your signs at night or in bad weather. These coatings bounce light from headlights back to drivers. This keeps roads safer for everyone.

Can you recycle old aluminum traffic signs?

Yes, you can recycle old aluminum signs. Aluminum is 100% recyclable. Recycling saves energy and helps the environment. You can ask your supplier about recycling programs.