Composite panels in traffic control signs have layers of materials. They often use aluminium sheets with a core that is not aluminium. This layered design makes the sign light and strong. These panels work well in many places. They can stand up to bad weather and being hit. Many councils pick composite panels because they last a long time. They also help save money as years go by. Their design makes them easy to move and put up by roadsides.

OPTRAFFIC offers durable composite panel traffic signs for sale that meet Australian standards, providing long-lasting, weather-resistant solutions for your traffic control needs. Our composite panels are easy to install and cost-effective, helping to keep roads safer and projects within budget.

Composite Panels Explained

Structure and Materials

Composite panels in traffic signs have layers. Makers use two thin aluminium sheets stuck to a solid core. The core is often polyethylene, fire-safe polyethylene, or mineral-filled compounds. This makes the panel light and strong.

- Dibond aluminium composite panels have two aluminium sheets and a polyethylene core.

- These panels do not get damaged by weather, stay light, and last a long time.

- The surface can be printed on, so they work well outside.

- Panels come in many colours and finishes, so you can print in different ways.

- The top aluminium layer usually has a polyester or PVDF coating to make it last longer.

- The bottom layer often has a primer coating for more protection.

Note: Composite panels give a flat, hard surface. This helps with reflective sheeting and digital printing, which is needed for clear traffic signs.

The table below shows the main materials used in each part of a composite panel:

| Panel Component | Most Widely Used Materials | Key Properties and Usage |

|---|---|---|

| Core | Polyethylene (PE), Fire Retardant (FR) Polyethylene, Mineral Filled (MF) | Light, fire-safe, keeps the panel strong |

| Outer Layers | Aluminium sheets | Make the panel strong and tough |

| Surface Finish | PVDF coating, Powder coating | Help the panel last in bad weather and keep its colour |

Most composite panels for traffic signs are 2 mm to 6 mm thick. The aluminium skin is usually 0.12 mm to 0.50 mm thick. Common sizes are 1220 mm x 2440 mm and 1500 mm x 3050 mm. These panels are light and stiff, so they are easy to carry and put up.

To learn more about choosing the right aluminium thickness based on wind load and sign size, read our blog: How to Choose Aluminum Thickness for Traffic Control Signs Based on Wind Load and Size.

Comparison with Traditional Sign Materials

Composite panels are different from old materials like aluminium and steel. They mix the good things about metals and plastics. This makes them great for modern road signs.

- Composite panels are lighter than solid aluminium or steel, so they cost less to move and put up.

- The panels are strong like steel but bendy and light like aluminium.

- The surface does not rust, fade, or get damaged by weather, so signs last longer outside.

- Fire-safe types are made for places that need extra safety.

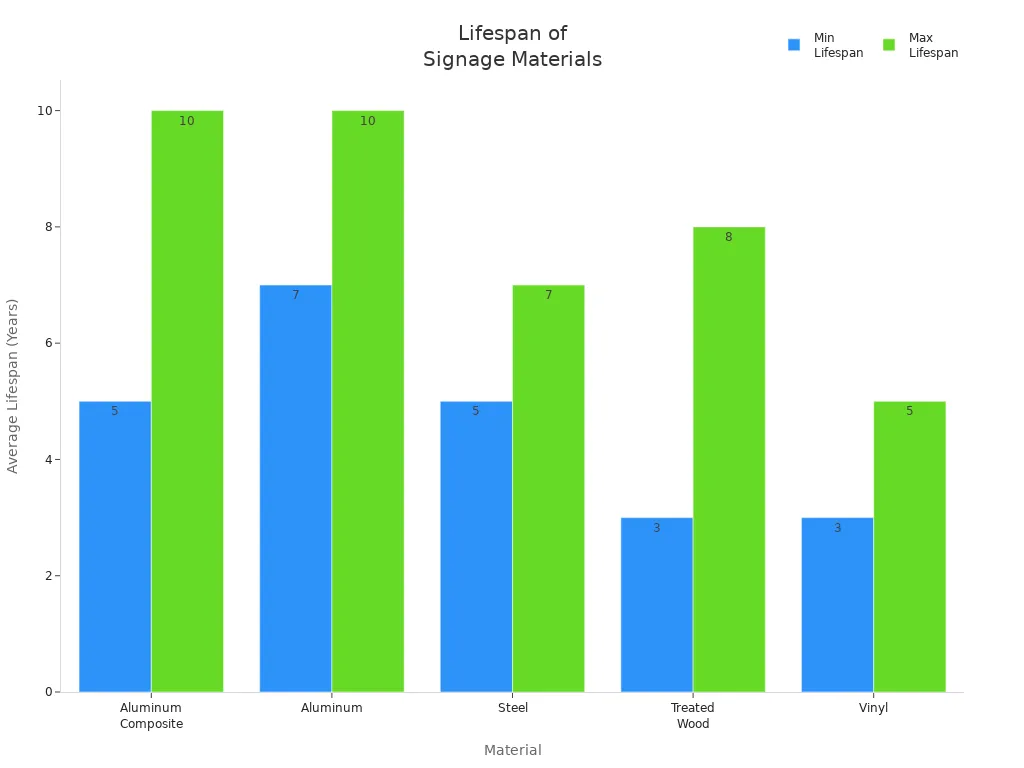

The table below compares composite panels with old sign materials:

| Material Type | Typical Thickness (mm) | Weight | Durability (Years) | Maintenance Needs | Key Features |

|---|---|---|---|---|---|

| Aluminium Composite Panels | 2 – 6 | Lightweight | 5 – 10 | Low; easy to clean | Hard, weather-proof, good for printing |

| Aluminium | 1.2 – 3.0 | Light | 7 – 10 | Medium; may lose colour | Does not rust, lasts long |

| Steel | 2.5 – 3.0+ | Heavy | 5 – 7 | Medium; may rust | Very strong, needs rust protection |

| Vinyl | 3 – 6 | Very light | 3 – 5 | Low; may lose colour | Cheap, not very strong |

| Wood | 10+ | Heavy | 3 – 8 | High; needs sealing | Can rot, not good in bad weather |

Composite panels give a flat, steady surface for reflective sheeting and pictures. This is important for traffic signs, which must be easy to see and read all the time. The panels also need fewer fixing points, so it costs less to put them up.

Tip: Picking composite panels can help councils and workers save time and money when putting up and looking after signs, while still keeping them safe and easy to see.

Benefits of Composite Panels

Lightweight and Strong

Composite panels are both light and strong. Makers stick thin aluminium sheets to a solid core. The core is often made from polyethylene. This makes the panels much lighter than solid aluminium sheets. Workers can lift and put up these panels more easily. This helps them finish the job faster and saves money on work. Composite panels are strong for their weight. They stay flat and stiff, even for big signs. The panels do not bend or twist much. This is good for signs that must stay clear and steady in all weather.

Because composite panels are light, posts and supports do not get tired as quickly. This helps the whole sign last longer.

Weather and Impact Resistance

Composite panels stand up well to bad weather and hits. The aluminium outside keeps rain, wind, and sun away from the sign. The core gives extra strength, so the panel does not break or crack easily. These panels keep their shape and colour for many years outside. They do not rust or rot like steel or wood. This makes them a good choice for road signs in towns and the countryside.

- Composite panels can handle heavy rain and strong winds.

- They do not fade in the sun or get hurt by things hitting them.

- The panels do not soak up water, so they stay strong when wet.

Cost and Maintenance

Composite panels help save money over time. They are cheaper to move and put up because they are light. They last a long time, so you do not need to replace them often. Many composite panels use materials that can be recycled, which is good for the planet.

- Aluminium composite panels can be recycled. Both the core and the aluminium sheets can be used again.

- Recycling aluminium uses only about 5% of the energy needed to make new aluminium.

- The panels last for years, so councils do not need to buy new signs as often. This saves money and means less rubbish goes to landfill.

Picking composite panels helps meet green building rules and keeps the environment safe. They last a long time and can be recycled, so they are a smart choice for new traffic signs.

Types of Composite Panels

Honeycomb Panels

Honeycomb panels have a core made from aluminium foil. The foil is shaped into small hexagon cells. The outside layers are made from strong aluminium alloys. These layers can be 0.4mm to 3.0mm thick. Special coatings help the panels look good and last longer. The honeycomb core keeps the panel light but tough. This design makes the panel very stiff and hard to break.

| Structural Feature | Description |

|---|---|

| Faceplates Material | High-quality aluminium alloys (e.g., 3003-H24, 5052-H14) |

| Faceplates Thickness | 0.4mm to 3.0mm |

| Surface Treatments | Fluorocarbon coating, roll coating, oxidation, and more |

| Honeycomb Core Material | Aluminium foil (3003 or 3004 alloy) |

| Honeycomb Cell Size | 5mm, 6mm, 8mm, 10mm, 12mm |

| Mechanical Properties | High strength-to-weight ratio, excellent rigidity, impact resistance |

| Additional Properties | Lightweight, corrosion-resistant, durable, supports reflective coatings |

Honeycomb panels are used for road signs and billboards. They are light, so workers can put them up easily. The panels do not rust or get damaged by water. This makes them good for outdoor signs. Many traffic signs use honeycomb panels because they are strong and last in bad weather.

Honeycomb panels work well with reflective coatings. This helps drivers see the signs at night.

Foam-Core Panels

Foam-core panels have a foam centre between two thin layers. PVC foam boards are often used for these panels. They are light and easy to move around. The foam stops water from getting inside. This means the panels do not bend or break when it rains. They also do not get damaged by chemicals or sunlight, so colours stay bright.

- Foam-core panels are easy to cut, drill, and print on.

- The surface keeps printed words and pictures clear.

- These panels are best for indoor or short-term signs.

- People use them for event signs, safety notices, and signs inside buildings.

Foam-core panels are picked for signs that need to be moved a lot. You can hang them from ceilings or put them on walls without trouble.

Fibreglass-Reinforced Panels

Fibreglass-reinforced panels have a plastic or resin base with fibreglass inside. The fibreglass makes the panels stronger and tougher. These panels do not get damaged by chemicals or bad weather. They last a long time outside. Studies show that fibreglass makes these panels last longer and work better.

People use these panels for stop signs, school zone signs, and warning signs. They are good for places where signs must be strong and easy to clean. Many councils use fibreglass-reinforced panels for traffic signs that face harsh weather.

Fibreglass-reinforced panels last a long time and stand up well to tough weather.

When to Use Composite Panels in Traffic Control Signs

Ideal Applications

Composite panels are good for many traffic control signs. They are best for big traffic control signs where weight is important. Workers can lift and put up these panels more easily. This is helpful on highways and country roads. These roads need large signs that people can see from far away. Composite panels are also good for projects where money is tight. Councils and builders save money on moving and putting up the signs because they are light.

Composite panels work well in places with bad weather. Roads by the sea, factories, and busy city streets often have strong winds, rain, and dirty air. The panels do not rust or break down, so they last longer in these places. Many councils use composite panels for building site signs, short-term detours, and warning signs in the countryside.

Tip: Composite panels are a clever pick for signs that must be moved or swapped often, like event signs or roadwork notices.

These points help you know when composite panels are the best for traffic signs:

- The panels must be safe in crashes. They should pass tests for breakaway sign supports without more crash tests.

- The panels must be fixed well. Washers under bolts help keep the panel in place.

- The material should be like tested and approved sign boards.

- The panels must work with breakaway supports to keep roads safe.

Environmental Considerations

Outdoor traffic signs face many tough things. Composite panels handle these problems well. They do not get hurt by sunlight, water, or dirty air. This makes them good for long use in cities, near the sea, and in factories. Special coatings help the panels keep their colour and stop cracks. The panels do not bend or rust, even after years in the sun and rain.

- Sunlight can make signs fade and crack, but special coatings protect them.

- Water from rain or wet air does not hurt the core or aluminium layers.

- Dirty air and salt near the sea do not make the panels rust.

Composite panels keep their shape and look nice for many years. Good coatings and careful making help the panels stay strong and bright, even in hard places. Fibre-reinforced cores help stop damage from sunlight and heat changes. This keeps the sign easy to read and safe for drivers.

Limitations and Alternatives

Composite panels have many good points, but sometimes other materials are better. In places with lots of bumps, like busy city centres or near schools, traffic control signs might get hit more. Composite panels can break inside, which is hard to see without special tools. In these cases, councils often pick solid aluminium or steel panels. These materials are stronger and safer in fires.

| Scenario | Recommended Material | Reason |

|---|---|---|

| Large, lightweight signs | Composite panels | Easy to put up and move |

| Coastal or polluted environments | Composite panels | Do not rust or fade |

| High-impact or high-traffic | Aluminium or steel | Stronger and last longer |

| Fire safety critical areas | Aluminium or steel | Safer in fires |

Old materials like aluminium and steel are good for signs in places with lots of bumps or strict fire rules. Solid aluminium panels are stronger and last longer in bad weather. Steel panels are very stiff but heavier. Councils often use these for signs near schools, airports, and hospitals.

Note: Composite panels are still a top pick for most outdoor signs, especially where weight, cost, and weather resistance matter most.

Composite panels are light, strong, and can handle bad weather. They work well for big traffic control signs and places with tough weather. Sometimes, aluminium or steel is better if signs might get hit a lot. Every sign project is different. Councils and builders need to think about the weather, money, and safety before picking a material. Good planning makes sure traffic signs stay clear and last a long time.

To learn more about how material choices impact the future of traffic signs, read our blog: How Material Choices Shape the Future of Traffic Signs for Sale in Australia.

FAQ

What makes composite panels suitable for outdoor traffic control signs?

Composite panels can handle rain, wind, and sun. They do not rust or rot over time. These panels are light, so workers can put them up fast. Councils pick them for signs that need to last outside for years.

Can composite panels support reflective sheeting?

Yes, composite panels have a flat, steady surface. This helps reflective sheeting stick well. Drivers can see these signs clearly, even at night or in bad weather.

Are composite panels environmentally friendly?

Many composite panels use materials that can be recycled. Aluminium and some cores can be used again. Recycling uses less energy than making new materials. This helps keep the environment safe.

How do composite panels compare to solid aluminium for traffic control signs?

| Feature | Composite Panels | Solid Aluminium |

|---|---|---|

| Weight | Lighter | Heavier |

| Durability | High | Very High |

| Cost | Lower | Higher |

| Weatherproof | Yes | Yes |

Composite panels are lighter and often cost less than solid aluminium. Both types last a long time when used outside.