Traffic control cones are important tools for managing fleet operations. They help keep things organized, make areas safer, and lower accident risks. For instance, using over 50 traffic control cones during big highway accidents can prevent crashes. This shows how placing cones correctly helps control dangers effectively.

Fleet managers can use technology to collect data and make informed decisions. This data helps adhere to safety rules and improves fleet operations. Additionally, new smart traffic control cones with IoT technology are transforming work zones. They enhance safety and facilitate smoother operations.

OPTRAFFIC offers high-quality traffic control cones designed to meet the latest safety standards and operational needs. Explore our range of smart, durable cones today and enhance your fleet’s safety and efficiency.

Key Takeaways

- Traffic cones keep areas safe and guide vehicles to avoid accidents.

- Reflective cones at night make it easier for drivers to see.

- Check cones often and replace broken ones to keep them useful.

- Store cones neatly to make them last longer and find them fast.

- Use a tracking system to check cone use and replace them on time.

Enhancing Fleet Efficiency with Traffic Control Cones

Optimizing Parking and Docking Operations

Good parking and docking are key for fleet success. Traffic cones help organize spaces, making vehicle movement easier and faster. Marking parking spots for different vehicles saves space and avoids delays. For example, cones can separate trucks from cars to reduce confusion.

Placing traffic cones correctly also makes parking areas safer. Drivers can find their spots easily, lowering the chance of crashes. This is very helpful in busy fleet yards with many moving vehicles. Traffic cones guide drivers visually, helping them move safely in tight areas.

Cones are also useful for docking vehicles. Outlining docking zones with cones helps drivers park accurately. This saves time and prevents damage to equipment. Using cones this way improves overall operations and keeps things running smoothly.

Tip: Use bright cones with reflective strips for nighttime parking. This helps drivers see clearly in the dark.

Streamlining Loading and Unloading Processes

Loading and unloading need to be quick and organized. Traffic cones can create clear zones and guide vehicles. For example, traffic safety cones can mark loading areas so only allowed vehicles enter. This reduces crowding and speeds up work.

Using road cones also makes loading zones safer. Workers can focus without worrying about random vehicles entering. This lowers accident risks and improves efficiency. Studies show closely placed cones alert drivers faster, reducing dangers in work areas.

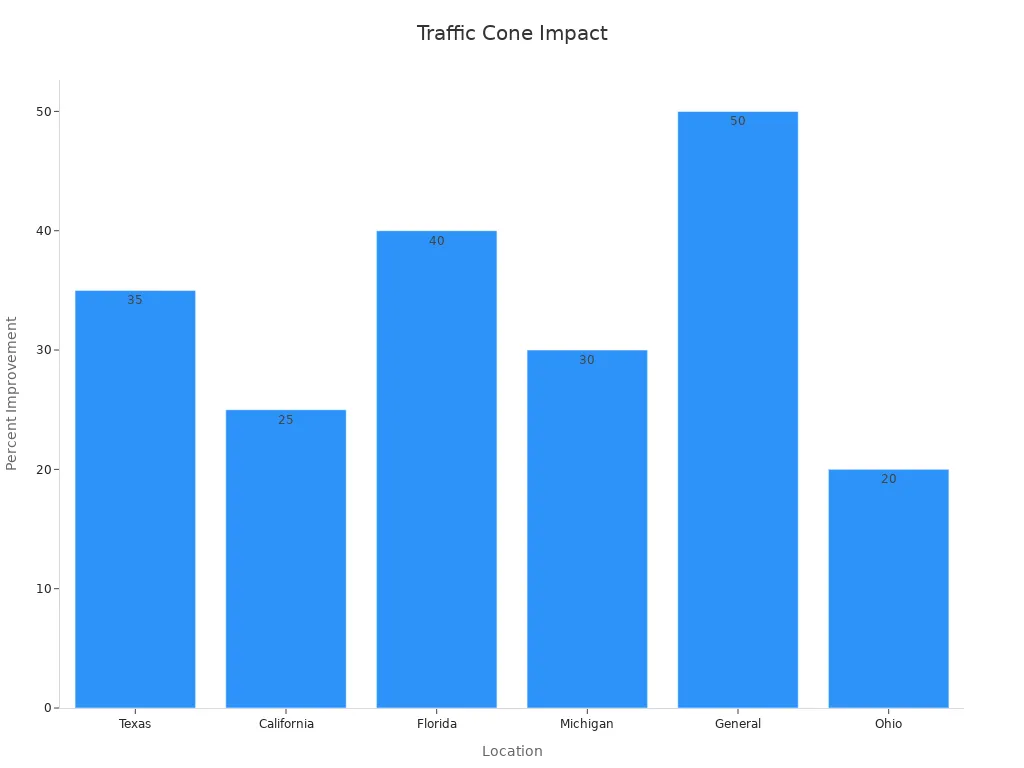

The benefits of traffic cones are shown in real-life examples:

| Case Study Location | Outcome Description | Percentage Improvement |

|---|---|---|

| Texas | Fewer vehicle-worker collisions | 35% |

| California | Fewer injuries in city work zones | 25% |

| Florida | Better communication, less traffic jams | 40% |

| Michigan | Fewer caught-in/between accidents | 30% |

| General | Fewer accidents in work zones | 50% |

| Ohio | Higher operational efficiency | 20% |

Using traffic cones can also improve routes for vehicles entering and leaving. This avoids traffic jams and keeps vehicles moving smoothly. Better routes save time and fuel, cutting costs for your fleet.

Note: Check your road cones often for damage. Broken cones are less safe and less helpful for guiding vehicles.

Using Traffic Cones for Route Optimization and Traffic Control

Temporary Road Barriers and Detours

Traffic cones are great for making temporary road barriers. These barriers help keep traffic organized during roadwork or closures. They guide vehicles through detours, keeping traffic moving smoothly. Drivers can safely pass construction zones or closed roads without confusion. Marking alternate routes with cones saves time and keeps fleets running efficiently.

Cones also protect workers and people nearby. They create clear boundaries to keep vehicles out of dangerous areas. This improves safety while letting fleets work without extra risks. Temporary cone setups are crucial when regular routes are blocked. They help optimize routes and keep operations on track.

Tip: Space cones evenly so drivers can see them clearly. This helps them follow detours without getting lost.

Managing Traffic Flow in High-Traffic Areas

Busy areas need good traffic control to avoid jams and crashes. Traffic cones help by creating lanes or zones for vehicles. For instance, traffic safety cones can separate delivery trucks from cars. This reduces crowding and makes traffic flow better.

Data shows how cones improve traffic management:

| Metric | Description |

|---|---|

| Total Crashes | Chart of crashes per 0.5 mile over 5 years in low, medium, and high crash zones. |

| Speed and Congestion Levels | Speeds grouped into high (under 30 mph), medium (30-50 mph), and low (over 50 mph) congestion levels. |

| Combined Safety and Congestion Scores | Average scores used to find areas needing better traffic control based on safety and congestion. |

Using cones smartly can improve routes and reduce traffic jams. This saves time and cuts fuel costs, helping fleets save money. Good traffic control keeps vehicles moving, even in the busiest spots.

Note: Check cones often for damage. Broken cones are less safe and less useful for guiding traffic.

Improving Safety with High-Visibility Traffic Cones

Nighttime Operations and Reflective Cones

Working at night needs extra care for safety. Reflective traffic cones are very helpful in dark areas. They shine when car lights hit them, making them easy to see. This helps drivers move safely in work zones or parking lots.

You can use reflective cones to show boundaries or warn about dangers. For example, putting cones around a loading zone keeps drivers in safe spots. This lowers crash risks and keeps work going smoothly.

Tip: Pick road safety cones with good reflective strips for better visibility. These are great for dark places with lots of moving vehicles.

Reflective cones also help work get done faster by avoiding accidents. Drivers can see safe paths quickly and finish tasks without delays. This makes nighttime traffic easier to manage and keeps fleets working well after dark.

Reducing Accident Risks in Hazardous Zones

Bright traffic cones are key to lowering accident risks in risky areas. Their colors and shiny surfaces make them easy to notice. This helps create clear boundaries around dangerous spots, keeping vehicles away from harm.

For example, cones can block off unsafe zones at construction sites or airports. They act as warnings, telling people to stay out of danger. By marking these areas clearly, you avoid crashes like cars hitting equipment or entering restricted zones.

High-visibility cones work well in risky places like airports. They make sure everyone knows where not to go. This clear warning helps keep people safe and prevents accidents.

Callout: Check your cones often for damage. Broken cones don’t work well and can be unsafe.

Using cones smartly makes traffic flow better and safer. Clear signs guide drivers, reduce jams, and keep vehicles moving. This careful planning protects workers and helps fleets run smoothly.

Choosing the Best Traffic Cones for Fleet Work

Strong Cones for Construction and Repair Areas

Picking strong traffic cones is important for construction and repair zones. These places often have heavy vehicles and tough conditions. You need cones that stay strong and visible even with wear.

Here are some durable cone options:

- PVC Traffic Cones: These cones last long and resist weather damage. They are sturdy and great for long-term use in busy areas.

- PE Traffic Cones: These cones are light and affordable, perfect for short jobs. They are easy to carry and quick to set up.

- Eco-Friendly Materials: Recycled or biodegradable cones are better for the planet. They stay strong while being more sustainable.

Using the right cones makes traffic control easier. Strong cones last longer, saving money and time. They also help guide vehicles safely and clearly through work zones.

Tip: Check traffic cones often to make sure they work well. Replace broken cones quickly to keep everyone safe.

Special Cones for Bad Weather

Bad weather needs special traffic cones to stay safe. Rain, snow, and wind can make cones hard to see or unstable. You need cones made for these tough conditions.

For wet or snowy weather, cones with wide bases stay steady. Reflective strips or LED lights make them easier to see in storms or fog. These features help drivers spot cones and avoid accidents.

In hot weather, heat-resistant cones won’t melt or fade. Bright colors stay clear even in strong sunlight, keeping work zones safe. Special cones also guide vehicles better, no matter the weather.

Callout: Use cones with weights or stabilizers in windy areas. This keeps them from falling over and blocking traffic.

Choosing the right cones for bad weather keeps things running smoothly. Proper cones help avoid delays and keep your fleet working efficiently.

Maintaining and Storing Traffic Control Cones

Routine Inspections and Replacements

Checking traffic cones often is very important. Look for cracks, fading, or broken reflective strips. Damaged cones don’t work well and can cause accidents. Regular checks help find problems early and avoid issues later.

Replacing bad cones on time is also important. Old or broken cones make areas less safe. New cones keep everything running smoothly and meet safety rules. Following inspection schedules helps cones last longer and stay useful.

Here are some tips for better inspections:

- Replace cones right away if they are cracked or faded.

- Clean cones often to keep them bright and easy to see.

- Check cones in the field to make sure they work well.

Tip: Write down inspection dates and replacements in a log. This keeps you organized and ensures no cone is missed.

Best Practices for Organized Storage

Storing traffic cones the right way keeps them in good shape. Put cones in a dry, clean place to avoid damage from water or heat. Sorting cones by size or type makes them easier to find when needed.

Stack cones neatly to save space and avoid damage. Use racks or shelves to keep cones upright and steady. This stops them from bending and keeps them ready for use.

Here are some storage tips to stay organized:

- Don’t stack cones too high to avoid tipping over.

- Label storage spots for different cone types for quick access.

- Check stored cones sometimes to make sure they’re still in good shape.

Callout: Cover cones stored outside to protect them from bad weather. This keeps them strong and easy to see.

By following these steps, your cones will last longer and always be ready to help with safety and traffic control.

Traffic cones are important for keeping fleet operations safe and organized. They make work zones safer, help drivers see better, and lower accident chances. Reflective cones are great for nighttime use, and placing them correctly helps during emergencies. Storing cones properly keeps them in good condition and ready to use.

To make your fleet better, follow these steps:

- Use bright cones to improve safety in risky areas.

- Check cones often and replace any that are broken.

- Keep cones stored neatly to avoid damage and find them easily.

Tip: Use a cone tracking system to monitor usage and plan replacements.

Managing traffic cones well boosts safety, avoids delays, and makes fleet operations smoother.

FAQ

1. How do traffic cones make fleets safer?

Traffic cones show clear paths and keep vehicles away from danger. They help drivers avoid accidents and protect workers. Bright cones are great for dark or risky places, keeping everyone safe.

Tip: Use cones with reflective strips at night for better safety.

2. What cones work best in bad weather?

Pick traffic safety cones with wide bottoms to stay steady in strong winds. Reflective strips or lights help drivers see cones in rain or fog. Heat-proof cones keep their shape and color in hot weather.

Callout: Weighted cones stop tipping during storms, keeping work smooth.

3. How often should cones be checked?

Check cones often for cracks, fading, or damage. Replace broken cones quickly to keep areas safe. Clean cones regularly so they stay bright and easy to see.

Note: Write down check dates to stay organized and avoid missing inspections.

4. How should cones be stored?

Keep cones in clean, dry places to avoid damage. Stack them neatly or use racks to save space. Label spots to find cones easily when needed.

Tip: Cover cones stored outside to protect them from bad weather.

5. Can cones help fleets save money?

Yes, cones improve routes and prevent accidents, saving time and fuel. Strong cones last longer, cutting replacement costs. Good placement makes work faster, lowering expenses.

Callout: Buy durable cones to save money and improve safety.