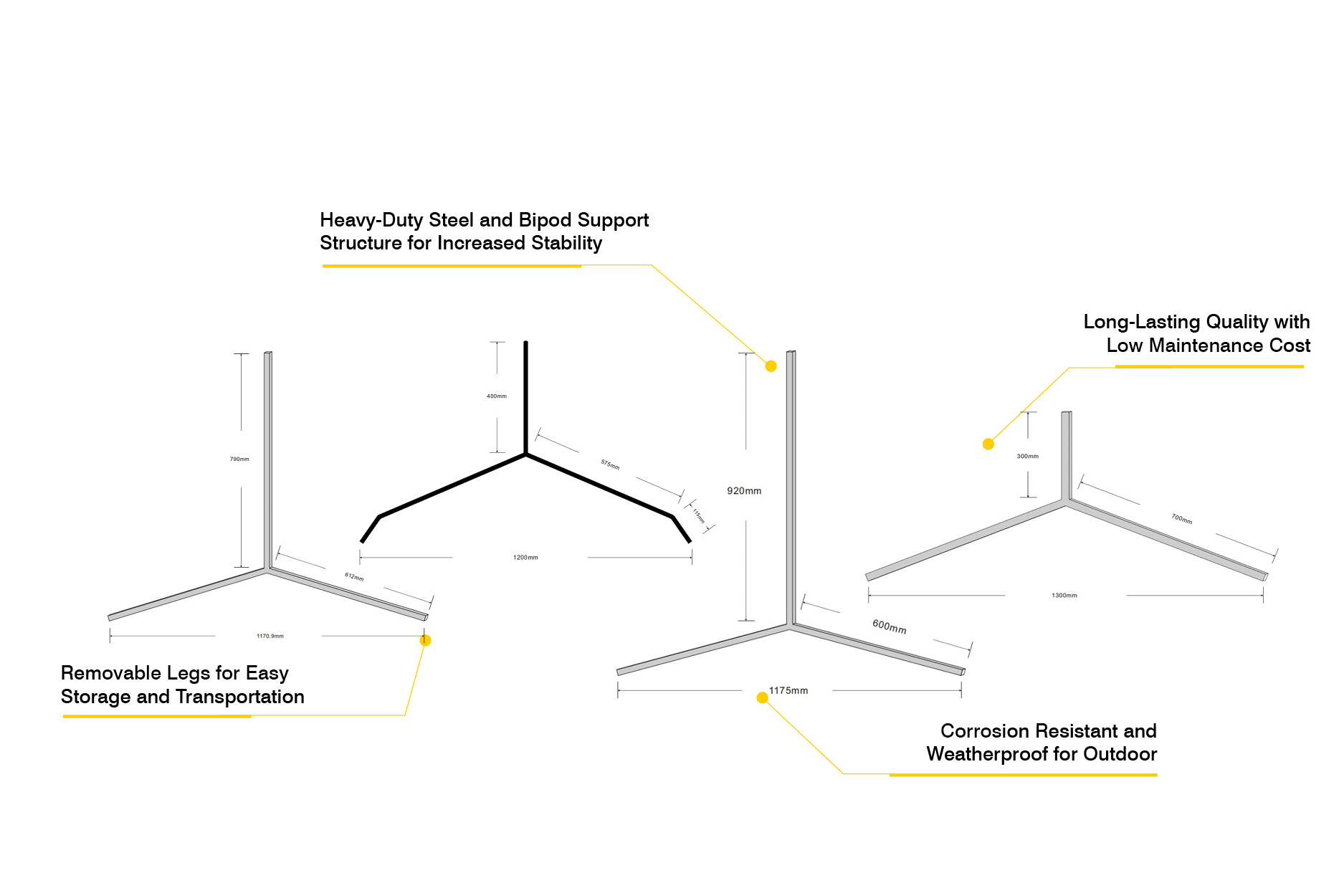

Optsigns Y Stands feature durable removable bipod steel legs designed to support multi-message frames, offering a robust and stable structure for temporary safety signs. These versatile Y Stands effectively manage traffic and alert motorists to important information, such as roadworks, roadway closures, speed reductions, and other hazardous road conditions. Their lightweight design allows for easy setup and transport, making them an essential tool for traffic management in various environments.

*We respect your confidentiality and all information are protected.

| Size | 1200*730*16mm |

|---|---|

| Material | 18mm Dia. Solid Circular Steel |

| Finish | Black Powder Coating |

| Middle Bar | 400mm |

| Ground Clearance | 330mm |

| Customize | Custom Size and Shape |

Using Optsigns Y Stands is straightforward and efficient. Start by placing the bipod legs on a flat surface where you intend to set up your temporary safety signs. Attach the multi-message frame securely to the Y Legs, ensuring it is stable and upright. Adjust the frame to display the necessary messages clearly, whether it’s for roadworks, speed reductions, or other safety alerts. Once set up, regularly check the stability of the Y Stands, especially in windy conditions, to ensure maximum visibility and safety for motorists.

Y Stands are designed to provide stable support for temporary safety signs, making them ideal for managing traffic and alerting motorists to roadworks, closures, speed reductions, and hazardous conditions.

Optsigns Y Stands are constructed from durable steel, making them suitable for outdoor use. While they are designed to withstand various weather conditions, it’s advisable to secure them properly to prevent tipping in high winds.

Setting up Y Stands is simple. Place the bipod legs on a flat surface and attach your multi-message frame securely to the stands. Adjust the frame to ensure that it is stable and clearly visible to drivers.

Yes, Y Stands are lightweight and removable, making them easy to transport and set up at various locations as needed. Their design allows for convenient storage and quick deployment.

You can purchase Y Stands directly from our website or through authorized retailers. Visit our product page for more details on specifications and to find the right Y Stands for your traffic management needs.

Yes, Y Stands are designed to accommodate multi-message frames, allowing you to display several important safety messages on a single stand. This versatility helps convey critical information efficiently.