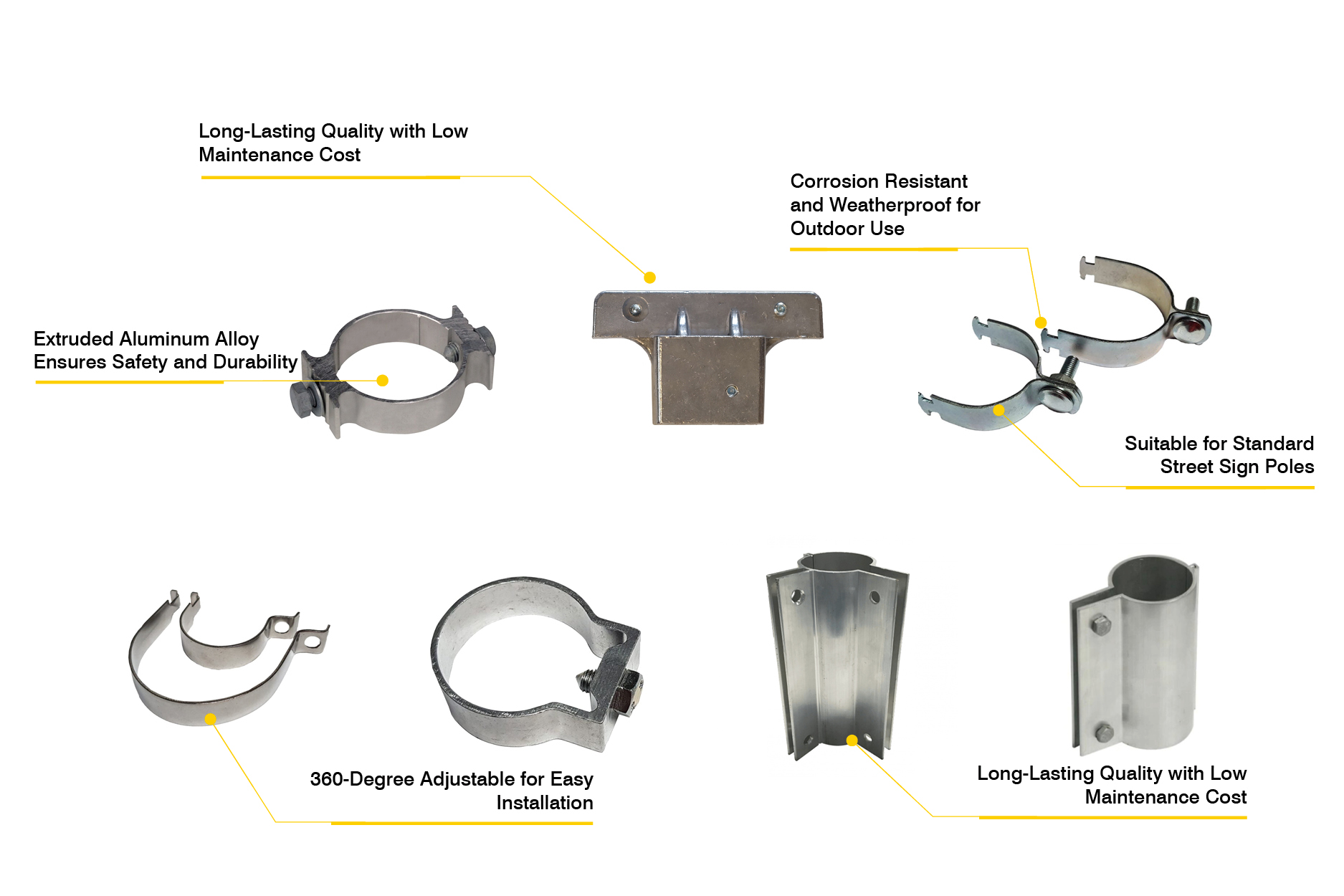

The OPTsigns 1-Way Street Name Brackets are crafted from high-quality aluminum alloy, ensuring a robust yet lightweight structure that promotes safety and durability. These aluminum sign brackets are designed to be corrosion-resistant and weatherproof, making them ideal for outdoor use in various environmental conditions. With a long-lasting quality and low maintenance cost, these street sign brackets for round post are a cost-effective solution for mounting street signs. Suitable for any standard street sign pole, they are easy to install and remove, providing flexibility for both temporary and permanent setups.

The OPTsigns 1-Way Street Name Brackets are crafted from high-quality aluminum alloy, ensuring a robust yet lightweight structure that promotes safety and durability. These aluminum sign brackets are designed to be corrosion-resistant and weatherproof, making them ideal for outdoor use in various environmental conditions. With a long-lasting quality and low maintenance cost, these street sign brackets for round post are a cost-effective solution for mounting street signs. Suitable for any standard street sign pole, they are easy to install and remove, providing flexibility for both temporary and permanent setups.

Widely utilized as a reliable bracket for street signs on post, these street name sign brackets accommodate round configurations. The design allows for compatibility with round post brackets, ensuring stability when securing signs in place. Whether you’re using a street sign post bracket or a road sign post bracket, these brackets are engineered to withstand the elements while maintaining their integrity. With their versatile application, the OPTsigns 1-Way street name sign mounting brackets are the perfect choice for municipalities and businesses looking to enhance their signage solutions.

*We respect your confidentiality and all information are protected.

| Height | 135mm, 185mm, Customizable |

|---|---|

| Hole Size | 25*12mm |

| Material | Aluminum Alloy |

| Customize | Logo, Marking and Shape |

1-way street name brackets are specialized mounting devices designed to hold street name signs indicating one-way traffic. These brackets ensure the signs are securely attached to street poles, providing clear directional guidance for drivers.Made from durable materials, such as aluminum, they offer resistance to weather conditions and corrosion.

Round metal post brackets are designed to securely attach signs to round posts. These round post brackets provide a stable mounting solution, ensuring that street signs remain visible and resistant to environmental factors.

At OPTsigns, the height of road sign post brackets is available in two sizes: 135 mm and 185 mm. These heights are designed to fit standard installations, allowing for effective visibility and proper mounting of street signs.

To attach a road sign post to a road sign post bracket, align the post with the bracket’s mounting holes. Secure the post using appropriate screws or bolts, ensuring a tight fit. Always check for level alignment before tightening completely.

Installing a sign post on a round post sign bracket typically takes about several minutes. This duration may vary based on the specific setup, tools used, and the experience level of the installer.