Устойчивость меняет то, как мы строим дороги и управляем движением. В Австралии, experts want safer roads and to help the environment. Water filled barriers are good for the planet. They keep people safe and do not harm nature as much. Big events around the world show people want to use greener ways to build roads. Australia is using new ideas to make roads and work zones safer. Water filled barriers help with this change. They make roads safer and support the environment. These barriers show that the industry cares about safer and greener roads.

OPTRAFFIC offers a range of eco-friendly Заполненные водой барьеры that provide effective safety solutions while supporting sustainability efforts. Our barriers are designed to be durable, Легко транспортировать, and environmentally friendly, helping you create safer and greener roadways. Explore our range today to contribute to a safer, more sustainable future.

Environmental Impact of Water Filled Barriers

Materials and Production

Water-filled road barriers are made from UV-stabilised polythene. This is a plastic that can be recycled. Makers pick this material because it is strong. It also stands up to bad weather. Making road barriers uses less energy than making concrete or steel barriers. Concrete barriers need a lot of heat and power. This makes more carbon dioxide. Steel barriers also use a lot of energy to make. Water-filled road barriers use less raw material. They also make less pollution when made. This helps the circular economy. The plastic can be recycled when the barrier is no longer needed.

The table below shows how much energy and pollution each barrier type makes during production:

| Тип барьеры | Resource Consumption & Emissions During Production | Продолжительность жизни & Частота замены | Переработка & Долговечность |

|---|---|---|---|

| Бетонные барьеры | Energy-intensive, high CO₂ emissions | Более длительный срок службы, fewer replacements | Less recyclable, более прочный |

| Water-Filled Plastic Barriers | Lower initial resource use and emissions | Более короткая продолжительность жизни, more weather effects | More recyclable, менее долговечный |

Recyclability and Reuse

Water-filled road barriers are easy to recycle and use again. После их использования, workers can empty and move them to another place. This means fewer new barriers need to be made for each job. The plastic in water-filled road barriers can be turned into new things. This cuts down on rubbish sent to landfill. Concrete barriers are hard to recycle. They often end up as waste after use. Road barriers help the environment by making it simple to reuse and recycle.

Lifecycle Analysis

Water-filled barriers have a low impact on the environment all the way through their life. Они легкие, so trucks can carry more at once. This saves fuel and makes less pollution when moving them. Workers can put them in and take them out quickly. This saves time and energy at work sites. When the job is done, teams can drain and move the barriers. This means they do not need to be thrown away. Бетонные ограждения тяжелые и их трудно перемещать.. This makes more pollution and more waste in landfill. Water-filled barriers are easier to use and help cut down on carbon and rubbish at every step.

For more information on how water-filled barriers can improve road safety and sustainability, Проверьте наш блог, Полное руководство по заполненным водой барьеры для более безопасных дорог и рабочих мест.

Water-Filled Road Barriers and Carbon Footprint

Emissions in Manufacturing

Water-filled road barriers need less energy to make than concrete ones. Factories use recyclable plastics that melt at lower heat. This means they use less power. Concrete barriers need very high heat and big machines. This makes more carbon go into the air. Water-filled road barriers are lighter, so factories use less material. This helps the circular economy and lowers harm to nature from the start.

Transport and Installation Efficiency

It is much easier to move road barriers than concrete ones. Workers can carry empty barriers by hand or with small trucks. One pickup truck can take many empty barriers at once. Concrete barriers are very heavy and need cranes and special trucks. This means water-filled road barriers save fuel and make less pollution when moved.

| Аспект | Water-Filled Road Barriers | Традиционные бетонные барьеры |

|---|---|---|

| Масса (per section) | О 40 кг (пустой) | О 1,200 кг |

| Метод установки | Manual or light equipment | Heavy machinery |

| Labour Requirement | Низкий | Высокий |

| Время установки | Быстрый | Медленный |

| Transport Emissions | Низкий | Высокий |

Setting up traffic barriers is quick and needs fewer workers. Teams can put them in place fast. This means roads do not have to close for long. It also means less use of big machines. This saves time and lowers pollution from machines.

Операционная сбережения

Water-filled road barriers help save money and protect nature. Teams can use them again on many jobs. This means fewer new barriers are needed. It also means less material is used and less pollution is made.

- Contractors say road barriers are easy to stack and store. This saves space and money when moving them.

- The barriers can be emptied and taken to new places. This means they do not need to be replaced all the time.

- It costs less to set up and take down these barriers. This helps contractors save money over time.

- All these savings make road barriers a good choice for budgets and the planet.

Teams watch how they use water when filling and draining the barriers. Many barriers have holes to let water out slowly and safely. The barriers hold water well and do not let chemicals leak. This keeps the environment safe. When teams drain the barriers, clean water can go back into nature. This helps keep local plants and animals healthy.

Road Safety Barriers: Performance and Versatility

Safety in Collisions

Water-filled road barriers help keep roads safe. They take in the force when cars crash into them. The plastic bends, and the water inside moves around. This spreads out the crash force. It helps stop people from getting hurt badly. Concrete or steel barriers are hard and can cause more harm. Traffic road barriers are not as hard. They are safer for cars and people. Their design lets them bend a bit. This makes them good for work zones and fast roads. These barriers soften crashes and help keep workers and drivers safe.

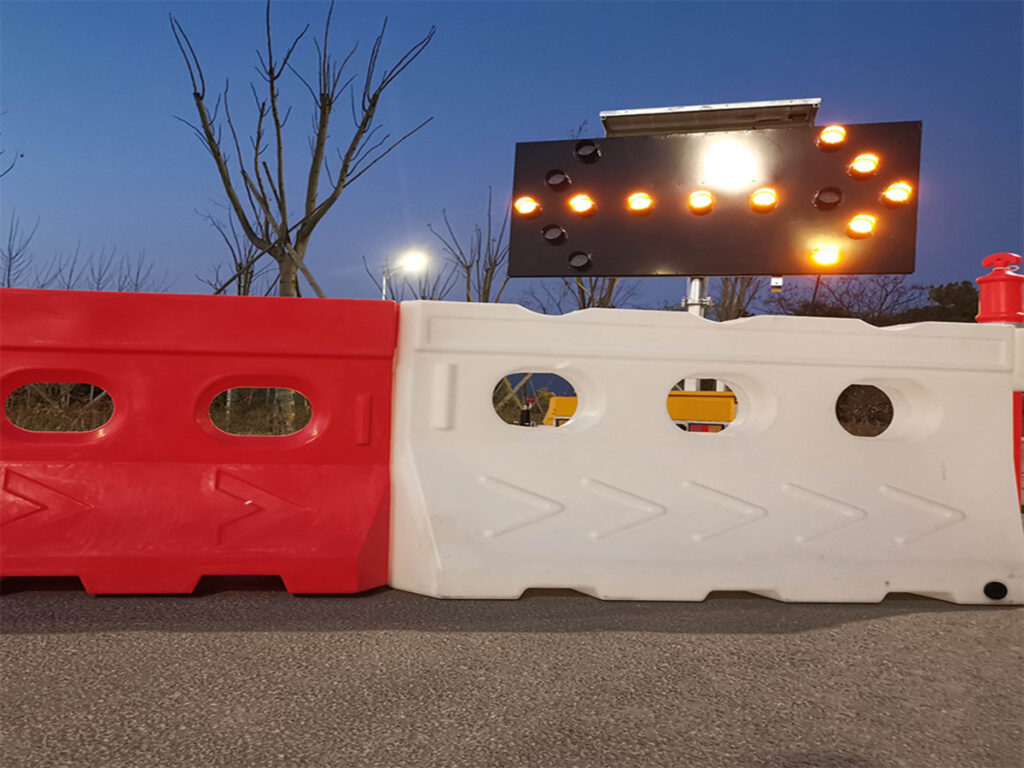

Flexibility and Application

Road safety barriers need to work in many places. Water-filled road barriers are very flexible and easy to use. Teams can join them to make long walls. They can also use them alone for crowds, аэропорты, or closed roads. Когда пусто, they are light and simple to move. Когда заполнен, они становятся тяжелыми и остаются на месте. Their bright colours help everyone see them better. Workers can set them up, empty them, and store them quickly. This makes them great for jobs that do not last long.

- Road barriers work well in many places:

- Fast road work areas

- Around events

- В аэропортах

- For crowd and traffic control

Comparison with Traditional Barriers

There are different types of road safety barriers. Concrete and steel barriers are strong and push cars away in crashes. But they are heavy and hard to move. They can hurt people and cars more. Road barriers are made to take in crash energy and cause less harm. They are easier to put in place and move around. This helps keep people safe when work areas change. Concrete barriers do not move much in a crash. Traffic road barriers are better for short jobs where you need to move them fast. Both types help keep roads safe, but water-filled ones are easier to use again and again.

| Особенность | Water-Filled Road Barriers | Concrete/Steel Barriers |

|---|---|---|

| Поглощение воздействия | Высокий | Низкий |

| Гибкость | Высокий | Низкий |

| Повторный использование | Высокий | Низкий |

| Installation Speed | Быстрый | Медленный |

| Пригодность для временного использования | Отличный | Ограничен |

Water-filled road barriers help stop accidents and make roads safer. They are a safer and more flexible choice for today’s roadworks.

Australian Regulations and Traffic Barriers

Стандарты и соответствие

Australian road safety barriers must follow strict rules. These rules help keep people safe and protect the environment. The most important rules are КАК 1742.3:2019 и AS/NZS 3845:1999. КАК 1742.3:2019 talks about traffic control at work sites. AS/NZS 3845:1999 explains what road safety barriers must do. Ас 1742 series gives advice about traffic control devices. AS/NZS 1906.2:2007 is about making barriers easy to see with special materials. These rules make sure water-filled barriers work well on real roads. They help keep roadwork areas safe for everyone.

| Standard Number | Заголовок / Описание | Relevance to Water-Filled Road Barriers |

|---|---|---|

| КАК 1742.3:2019 | Traffic control devices and traffic management at worksites | Covers traffic control measures around worksites where water-filled barriers are used |

| AS/NZS 3845:1999 | Road safety barrier systems | Directly relevant to road safety barriers including water-filled barriers |

| КАК 1742 ряд (общий) | Manual of uniform traffic control devices | Provides guidance on traffic control devices but not specific to water-filled barriers |

| AS/NZS 1906.2:2007 | Retroreflective materials and devices for road traffic control | Relevant for visibility aspects of barriers |

Government Incentives

Australian governments want roadworks to be better for the planet. They support using new materials that are light and do not rust. These materials make it cheaper and easier to put up and look after barriers. Many projects now use barriers that can sense crashes right away. This helps teams fix things before they break. Правительства, universities, and companies work together to find new ideas for safer roads. More projects use barriers that are easy to move and set up. This helps save time and lowers harm to the environment.

Australian road rules also think about the land and soil when picking barriers. Barriers must last a long time and not need much fixing. This saves resources and helps the planet.

Local Case Studies

Some Australian projects use traffic barriers to help the environment. В Мельбурне, new city projects use these barriers to guide traffic. The barriers keep workers and drivers safe and make less rubbish. Sydney roadworks also use water-filled barriers to help the planet. These projects show that barriers can be safe and good for nature. The barriers can be used again and moved to new places. This makes them great for busy cities and changing work zones.

Water-filled barriers are good for the environment because they use materials that can be recycled and water. This helps with goals to protect nature. They are also a cheap way to make roadworks safer in Australia. These barriers are easy to use, быстро настроить, и сделать дороги более безопасными. Experts say they save money, can be used in many ways, and fit different jobs

Часто задаваемые вопросы

What materials do water-filled barriers use?

Manufacturers make barriers from UV-stabilised polyethylene. This plastic is strong and does not break easily. It can handle sun and rain without getting weak. When the barrier is old, it can be recycled. Using this material helps builders care for the environment.

How do traffic barriers improve road safety?

Traffic barriers take in the force when cars crash into them. The water inside spreads out the hit, so people get hurt less. Their bright colours help drivers and workers see them better. These things help stop accidents in work areas.

Can contractors reuse water-filled barriers on different projects?

Да, contractors can empty the barriers and move them to new places. They can fill them up again when needed. This means teams can use the same barriers on many jobs. Using them again makes less rubbish and saves money.

Do barriers meet Australian standards?

Water-filled barriers follow important Australian rules like AS 1742.3:2019 и как/nzs 3845:1999. These rules make sure the barriers work well for traffic control and safety at roadwork sites.

Являются ли водонаполненные барьеры экологически безопасными??

Water-filled barriers are good for green building. Their plastic can be recycled and they can be used again. This means less rubbish goes to landfill. Moving and setting them up makes less pollution. These things make them a smart choice for today’s roadworks.