A segurança no local de trabalho continua sendo uma prioridade para todos os setores. Os padrões da OSHA reduziram significativamente lesões e fatalidades no local de trabalho ao longo dos anos. Por exemplo, em 1970, A taxa de lesão foi 10.9 por 100,000 trabalhadores, comparado a justo 2.7 em 2022. Essas melhorias destacam a importância da adesão às diretrizes da OSHA.

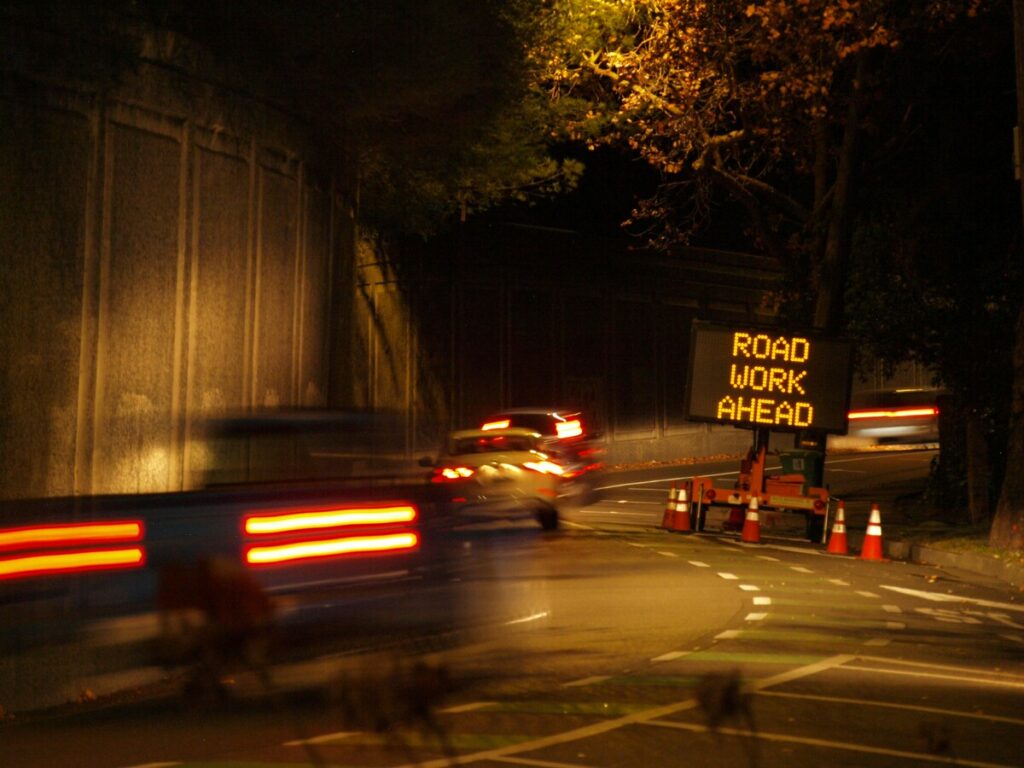

Os cones de trânsito para o trabalho rodoviário desempenham um papel vital na conformidade, aumentando a visibilidade e a segurança nas zonas de trabalho. A colocação adequada desses cones para o trabalho rodoviário garante a proteção do trabalhador e do motorista. Seguir as diretrizes da OSHA para espaçamento e colocação ajuda a criar ambientes mais seguros para todos os envolvidos.

O que é OSHA?

Visão geral da OSHA

OSHA, abreviado para o Administração de Segurança e Saúde Ocupacional, é uma agência federal dedicada a garantir condições de trabalho seguras e saudáveis para funcionários nos Estados Unidos. Foi estabelecido sob a Lei de Segurança e Saúde Ocupacional de 1970, Uma lei marcante que transformou a segurança no local de trabalho. Antes da criação da OSHA, Acidentes e doenças no local de trabalho eram comuns, com pouca regulamentação para proteger os trabalhadores.

Vários eventos levaram à formação da OSHA. O Fogo da fábrica de camisa triângulo em 1911 expôs os perigos dos ambientes de trabalho inseguros, Sparking chama de reforma. Mais tarde, o Lei de Contratos Públicos de Walsh-Healey 1936 Introduziu proteções de trabalhadores limitados. Depois Segunda Guerra Mundial, consciência dos riscos ocupacionais, como exposição a substâncias tóxicas como amianto, cresceu significativamente. Esses desenvolvimentos culminaram na assinatura do Osh age em dezembro 29, 1970. Este ato capacitou a OSHA a criar e aplicar padrões de segurança, conduzir inspeções, e fornecer treinamento para reduzir os riscos no local de trabalho.

Hoje, OSHA desempenha um papel vital na proteção dos trabalhadores, abordando riscos e promovendo práticas de segurança. Sua missão garante que todo funcionário possa trabalhar em um ambiente livre de danos graves.

O impacto da OSHA nas indústrias

OSHA teve um impacto profundo nas indústrias em todo o país. Você pode ver sua influência na construção, fabricação, Assistência médica, e até configurações de escritório. Implementando padrões de segurança, OSHA reduziu significativamente as lesões e fatalidades no local de trabalho. Por exemplo, indústrias com atividades de alto risco, como construção, Deve seguir diretrizes estritas para proteção contra quedas, andaimes, e uso de equipamentos. Essas regras salvam vidas e evitam acidentes caros.

OSHA também exige que os empregadores forneçam treinamento adequado, Equipamento de proteção, e comunicação de perigo. Isso garante que os trabalhadores entendam riscos potenciais e saibam como permanecer seguro. As indústrias que cumprem os padrões da OSHA geralmente experimentam menos acidentes, levando a maior produtividade e custos mais baixos. Priorizando a segurança, you not only protect employees but also create a more efficient and reliable workplace.

Por que a OSHA é importante: Garantir ambientes de trabalho seguros

O papel da OSHA na proteção dos trabalhadores

OSHA desempenha um papel crítico na salvaguarda dos trabalhadores dos riscos no local de trabalho. Estabelece padrões claros para abordar riscos e garante que os empregadores os sigam. Esses padrões cobrem uma ampla gama de riscos, incluindo físico, químico, biológico, e ameaças ergonômicas. Por exemplo, OSHA aborda riscos de segurança como quedas, viagens, e escorregões, que são comuns em muitas indústrias. Ele também se concentra em riscos químicos, como exposição a líquidos inflamáveis ou substâncias nocivas como monóxido de carbono. Aplicando essas regras, OSHA ajuda a criar ambientes mais seguros para os funcionários.

Você se beneficia da abordagem proativa da OSHA para a segurança no local de trabalho. A agência realiza inspeções para identificar violações e garantir a conformidade. Quando nenhum padrão específico se aplica, OSHA usa a cláusula de serviço geral para responsabilizar os empregadores por manter condições seguras. Essa flexibilidade permite que a OSHA se adapte a ameaças emergentes, como doenças infecciosas. Por exemplo, durante o Pandemia do covid-19, A OSHA desenvolveu padrões temporários para proteger os trabalhadores e agora está trabalhando em regulamentos mais amplos para doenças infecciosas. Esses esforços demonstram o compromisso da OSHA em proteger os trabalhadores em ambientes de trabalho em evolução.

Estatísticas principais da OSHA

As estatísticas destacam o impacto da OSHA na redução de riscos no local de trabalho. Desde o seu estabelecimento em 1970, Lesões e mortes no local de trabalho diminuíram significativamente. Por exemplo, A taxa de lesão caiu de 10.9 por 100 trabalhadores em 1972 para 2.7 em 2022. Esta melhoria reflete a eficácia dos regulamentos e esforços de aplicação da OSHA.

Apesar dessas conquistas, Os desafios permanecem. Relatórios mostram que acabou 50% de empregadores não relataram os dados necessários para lesões e doenças entre 2016 e 2018. Essa falta de conformidade ressalta a necessidade de vigilância contínua. Você pode ajudar a resolver esse problema, mantendo -se informado sobre os regulamentos da OSHA e promovendo uma cultura de segurança em seu local de trabalho. Incentivar a comunicação aberta e envolver funcionários em iniciativas de segurança. Essas etapas não apenas garantem a conformidade, mas também reduzem os riscos e melhoram a produtividade geral.

Cobertura da OSHA: Quem está protegido sob os padrões da OSHA?

Quem é coberto por osha?

OSHA protege a maioria dos trabalhadores do setor privado e alguns no setor público. Se você trabalha em indústrias como a construção, fabricação, ou saúde, Osha provavelmente cobre você. Funcionários federais também recebe proteção sob padrões da OSHA, enquanto trabalhadores do governo estadual e local podem ser cobertos se seu estado tiver um Plano aprovado pela OSHA. Esses planos devem atender ou exceder os requisitos federais da OSHA.

No entanto, OSHA não cobre indivíduos autônomos ou familiares imediatos de empregadores agrícolas. Ele também exclui locais de trabalho regulamentados por outras agências federais, como o Departamento de Energia ou Guarda Costeira. Entender se a OSHA se aplica ao seu local de trabalho é essencial para garantir a conformidade e manter a segurança.

Responsabilidades do empregador

Os empregadores desempenham um papel crítico na manutenção de um local de trabalho seguro. OSHA exige que eles sigam responsabilidades específicas para proteger os trabalhadores contra danos. Essas responsabilidades incluem:

- Fornecendo um local de trabalho livre de riscos graves.

- Informando os trabalhadores sobre riscos químicos por meio de treinamento e etiquetas.

- Manter registros precisos de lesões e doenças relacionadas ao trabalho.

- Fornecer equipamentos de proteção individual necessários, sem nenhum custo para os trabalhadores.

- Notificação da OSHA de fatalidades e hospitalizações no local de trabalho.

Os empregadores também devem cumprir os padrões específicos do setor. Por exemplo, Os empregadores de construção devem garantir a colocação de cone de tráfego adequada para proteger trabalhadores e pedestres. Eles também devem seguir as diretrizes de proteção contra quedas e manter a segurança de andaimes. O não cumprimento dessas responsabilidades pode resultar em multas. Por exemplo, violações graves podem levar a multas que variam de $1,190 para $16,131 por violação.

Cumprindo essas responsabilidades, Você pode criar um ambiente de trabalho mais seguro e evitar penalidades caras. Colocação de cone de tráfego adequada, por exemplo, Garante a conformidade e reduz os riscos em áreas de alto tráfego. Tomar essas medidas demonstra seu compromisso com a segurança e protege sua força de trabalho.

Regras e padrões da OSHA: O que os empregadores precisam saber

Padrões essenciais da OSHA

A compreensão dos padrões da OSHA é crucial para manter um local de trabalho seguro. Esses padrões descrevem os requisitos mínimos que você deve atender para proteger os funcionários dos perigos. Alguns dos padrões mais críticos da OSHA incluem:

- A cláusula de serviço geral: Você deve garantir que seu local de trabalho esteja livre de riscos reconhecidos que podem causar danos graves.

- Padrão de comunicação de risco: Este padrão exige que você crie um programa escrito para produtos químicos perigosos e treine funcionários em seu manuseio seguro.

- Equipamento de proteção pessoal (EPI) Padrões: OSHA exige o uso de EPI para proteger os trabalhadores de possíveis perigos.

- Requisitos de manutenção de registros: Você deve documentar todas as lesões e doenças relacionadas ao trabalho com precisão.

- Planos de ação de emergência: Esses planos devem detalhar procedimentos para lidar com emergências como incêndios ou derramamentos químicos.

Adicionalmente, OSHA enfatiza a segurança contra incêndio, prontidão de primeiros socorros, e comunicação adequada sobre materiais perigosos. Seguir esses padrões não apenas garante a conformidade, mas também promove uma cultura de segurança em seu local de trabalho.

Regras específicas para indústrias de alto risco

Certas indústrias enfrentam riscos únicos, exigindo regulamentos da OSHA personalizados. Por exemplo, na construção, Você deve implementar sistemas de proteção contra quedas para trabalhadores que operam a alturas de seis pés ou mais. Os andaimes devem atender aos requisitos específicos de projeto e uso para evitar acidentes. Você também precisa seguir as diretrizes do MUTCD para a colocação de equipamentos de segurança no trânsito para proteger trabalhadores e pedestres em zonas de construção.

Em assistência médica, Patrônicos de Bloodborne da OSHA Descreve os protocolos para lidar com materiais infecciosos. Diretrizes ergonômicas ajudam a prevenir distúrbios musculoesqueléticos, Enquanto os programas de prevenção da violência no local de trabalho abordam ameaças em potencial.

As indústrias de manufatura devem cumprir as regras de proteção de máquinas para evitar o contato com peças perigosas. Os procedimentos de bloqueio/etiqueta garantem que as máquinas permaneçam seguras durante a manutenção. A proteção respiratória é essencial em ambientes com riscos no ar.

Aderindo a essas regras, Você pode reduzir os riscos no local de trabalho e garantir a conformidade com os padrões da OSHA. Inspeções regulares e treinamento de funcionários aprimoram ainda mais a segurança e ajudam a atender aos requisitos de marcação do piso e outras diretrizes específicas do setor.

O papel dos cones de trânsito na conformidade da OSHA

Cones de trânsito como barreiras de segurança

Cones de segurança Para o trabalho rodoviário, serve como barreiras essenciais de segurança em ambientes de trabalho de alto risco. Sua função principal é fornecer orientação visual e estabelecer perímetros em torno de áreas perigosas. Você pode usá -los para proteger os trabalhadores e orientar o tráfego de maneira eficaz. Suas cores brilhantes e materiais refletivos garantem alta visibilidade, mesmo em condições de pouca luz ou clima adverso. Isso os torna indispensáveis para manter a segurança nas zonas de construção, trabalho de utilidade, e situações de emergência.

O projeto leve de cones de construção permite uma implantação rápida. Você pode configurá -los facilmente para criar perímetros seguros em torno das zonas de trabalho. Por exemplo, Cones para o trabalho rodoviário podem ser colocados para redirecionar veículos e pedestres para longe de áreas perigosas. Sua durabilidade garante que eles permaneçam eficazes em várias condições, reduzindo o risco de acidentes. Usando cones de segurança, Você pode aprimorar a segurança no local de trabalho e cumprir os regulamentos de cone de tráfego da OSHA.

Padrões da OSHA para dispositivos de controle de tráfego

OSHA enfatiza a importância de dispositivos de controle de tráfego, incluindo cones de segurança de trânsito, na manutenção da segurança durante a construção e manutenção das rodovias. De acordo com Regulamentos de cone de tráfego da OSHA, Você deve desenvolver um plano temporário de controle de tráfego antes de iniciar qualquer trabalho. Este plano garante que as medidas de segurança sejam implementadas de maneira eficaz e as responsabilidades sejam claramente definidas. Os cones adequados para a colocação do trabalho rodoviário são uma parte crítica desse processo, Orientar pedestres e trabalhadores com segurança através de zonas de construção.

OSHA também exige que todos os dispositivos de controle de tráfego atendam aos padrões de visibilidade específicos. Isso inclui o uso de cones altamente visíveis e bem mantidos. Inspeção e manutenção diária de cones de zona de trabalho são necessários para garantir seu uso correto. Os trabalhadores devem receber treinamento sobre como usar e manter adequadamente cones de segurança para evitar acidentes. Essas diretrizes ajudam você a criar zonas de controle de tráfego mais seguras e proteger os trabalhadores e o público.

Seguindo as recomendações da OSHA, Você pode garantir a conformidade e reduzir os riscos em áreas de alto tráfego. Usar os tipos certos de cones de segurança e aderir às diretrizes adequadas ajudará você a manter um ambiente de trabalho seguro e eficiente.

Benefícios do uso de cones de tráfego de qualidade para segurança da OSHA

Reduzindo acidentes e lesões

Cones de segurança de alta qualidade desempenham um papel crucial na redução de acidentes e lesões no local de trabalho. Suas cores brilhantes e materiais refletivos garantem que permaneçam visíveis em todas as condições, incluindo pouca luz ou clima adverso. Essa visibilidade ajuda a orientar veículos e pedestres com segurança em áreas perigosas, minimizar o risco de colisões. Cones de segurança certificados atendem aos rigorosos padrões de segurança, tornando-os ferramentas confiáveis para proteger os trabalhadores em ambientes de alto risco, como zonas de construção de rodovias.

Você pode usar cones de segurança em vários cenários para melhorar a segurança. Nas zonas de trabalho urbanas, Eles criam caminhos de pedestres dedicados, reduzindo as chances de acidentes envolvendo pedestres e motoristas. Durante a manutenção da utilidade, Eles agem como barreiras visuais, Prevenindo intrusões acidentais em áreas perigosas. Para gerenciamento de tráfego de eventos, Cones de segurança ajudam a estabelecer faixas temporárias, Melhorando o fluxo de tráfego e reduzindo o congestionamento. Em emergências, Eles criam perímetros seguros, proteger os respondentes e prevenir acidentes secundários. Essas aplicações destacam a importância dos cones de segurança para manter um ambiente seguro para todos os envolvidos.

Sinais OPT Os cones de segurança são projetados com maior durabilidade e alta visibilidade, tornando -os a escolha ideal para todos esses cenários. Se você está gerenciando o tráfego em zonas urbanas, configurando barreiras durante a manutenção da utilidade, ou direcionando veículos em um evento, OpTsigns Segurança cones Certifique -se de claro, limites visíveis.

Economia de custos de longo prazo e redução de responsabilidade

Investir em cones de segurança de alta qualidade oferece economia significativa de custos a longo prazo. Seus materiais duráveis, como PVC e borracha, verifique se eles suportam condições adversas e uso frequente. Essa durabilidade reduz a necessidade de substituições constantes, economizando seu dinheiro com o tempo. Por exemplo, Os cones de PVC resistem ao intemperismo, produtos químicos, e abrasão, Enquanto os cones de borracha fornecem excelente absorção de choque e estabilidade em condições de vento.

O uso de cones de segurança compatíveis também reduz seus riscos de responsabilidade. Aderindo aos padrões da OSHA, Você reduz a probabilidade de acidentes de trabalho no local, o que pode levar a questões legais caras. Cones de segurança adequadamente colocados protegem os trabalhadores e o público, demonstrando seu compromisso com a segurança. Essa abordagem proativa não apenas garante a conformidade, mas também promove a confiança entre funcionários e clientes.

A tabela abaixo destaca as diferenças entre os materiais usados em cones de segurança:

| Material | Durabilidade | Recursos de segurança |

|---|---|---|

| PVC | Alta durabilidade, flexível | Resiste a intemperismo, produtos químicos, abrasão |

| Borracha | Excelente absorção de choque | Alta tração, estabilidade no vento |

| Plástico | Menos durável sob forte impacto | Resistência a UV, leve para armazenamento |

Escolhendo cones de segurança de alta qualidade, você aprimora a segurança no local de trabalho, reduzir acidentes, e economizar em custos de longo prazo. Esses benefícios enfatizam a importância dos cones de segurança na criação de um ambiente de trabalho mais seguro e eficiente.

Os padrões da OSHA são essenciais para criar locais de trabalho mais seguros. Eles reduzem os riscos e protegem os funcionários de danos. Você pode melhorar a conformidade mantendo -se informado, envolvendo funcionários em iniciativas de segurança, e melhorando continuamente os programas de segurança. Os cones de segurança desempenham um papel crítico nesse processo. Sua alta visibilidade reduz acidentes e garante a conformidade com os requisitos de marcação do piso da OSHA. Investir em cones de segurança certificados e treinamento adequado ajuda a evitar penalidades e promove uma cultura de segurança. Priorize a segurança hoje, equipando seu local de trabalho com as ferramentas e conhecimentos certos para proteger sua equipe.

🛠️ Dica: Avalie regularmente suas práticas de segurança e atualize equipamentos como cones de segurança para atender aos padrões da OSHA.