Warehouses and logistics centers are busy places with significant safety risks. Por 2030, there may be 2 million workers in these environments. Forklifts are responsible for 90% of pallet rack accidents, highlighting the critical importance of safety signs for sale. These signs assist workers, reduzir a confusão, and prevent injuries. Injuries can cost as much as $240,000 each year for a single warehouse. Strategically placing safety signs in smart locations enhances workplace safety and lowers risks for both workers and visitors.

OPTRAFFIC offers high-quality safety signs for sale, designed to meet the demands of warehouses, logistics centers, and industrial environments. Durável, altamente visível, and easy to install, our signs help create safer, more organized workplaces. Entre em contato conosco hoje to explore the best safety signage solutions for your facility.

Takeaways -chave

- Safety signs for sale in the right spots lower accidents and injuries. They help workers and visitors stay safe in the warehouse.

- Use clear signs to direct cars and people. This stops crashes and keeps everyone protected.

- Emergency signs should be easy to see and placed well. They help workers escape quickly and save lives during danger.

- Check safety signs for sale often and fix them if needed. Clear signs help workers know risks and follow safety rules.

- Pick the right sign materials for where they will go. Reflective signs are good outside, while regular signs work indoors.

Common Risks in Warehousing and Logistics Environments

Warehouses are busy places where many safety risks exist. Knowing these risks helps you protect workers and keep the area safe.

Vehicle-Pedestrian Collisions

Colisões entre veículos e pessoas são um grande problema de segurança. Em 2020, 16% das mortes em armazéns foram causadas por atropelamento por veículos. Empilhadeiras e caminhões são perigosos para os trabalhadores que andam nas proximidades. Sobre 37% dos acidentes mortais em armazéns acontecem quando veículos atingem pessoas. Para tornar as coisas mais seguras, marque caminhos para caminhar e dirigir claramente. Coloque sinais de alerta nas esquinas e áreas com pouca visibilidade para evitar acidentes.

Zonas de giro de empilhadeiras

Empilhadeiras são importantes mas causam muitos acidentes em armazéns. Eles estão envolvidos em 90% de falhas em porta-paletes. Zonas de viragem, especialmente em espaços apertados, são muito arriscados. Os trabalhadores enfrentam perigo quando as empilhadeiras fazem curvas bruscas ou recuam. Adicionar “Área Operacional de Empilhadeira” sinais nesses locais para melhorar a segurança. Use marcações no chão e espelhos nos cantos para ajudar os trabalhadores a enxergar melhor e evitar acidentes.

Mercadorias empilhadas e objetos em queda

Itens mal empilhados pode cair e machucar os trabalhadores. Empilhadeiras causam a maioria das falhas em porta-paletes, sobre 90%. Para parar acidentes, empilhe os itens com segurança e não sobrecarregue as prateleiras. Verifique os sistemas de armazenamento com frequência e corrija quaisquer problemas. Use protetores de rack para proteger contra impactos de empilhadeiras. Faça com que os trabalhadores usem capacetes nessas áreas para maior segurança.

Ao corrigir esses riscos, você pode tornar seu armazém mais seguro para todos.

Confusão na saída de emergência

Saídas de emergência são muito importantes para manter os trabalhadores seguros. A confusão durante emergências pode retardar as evacuações e causar ferimentos. Os trabalhadores podem ter dificuldade em encontrar ou usar saídas quando estão estressados. Caminhos bloqueados ou sinais pouco claros tornam a fuga mais difícil.

🚨 Dica: Mantenha sempre as saídas de emergência fáceis de ver e livres de obstáculos.

O NTSB encontrou problemas comuns com saídas de emergência. Por exemplo:

- Pessoas lutam para abrir janelas pesadas de ônibus durante emergências.

- Janelas que não ficam abertas sozinhas pioram as coisas.

Tipos essenciais de sinalização de segurança à venda para armazéns

Sinais direcionais para segurança em armazéns

Faixas de mão única para empilhadeiras

As empilhadeiras se movem rapidamente e carregam itens pesados. Placas de faixa de sentido único ajudam a controlar o trânsito e evitar acidentes. Estas placas mostram aos motoristas onde ir com segurança. A organização dos caminhos das empilhadeiras evita acidentes e mantém tudo funcionando perfeitamente.

Orientação de entrada e saída de veículos

Sinais claros de entrada e saída gerenciam melhor o movimento do veículo. Estas placas orientam caminhões e empilhadeiras para os locais certos. Colocá-los em docas de carga e entradas reduz a confusão. Esta configuração evita atrasos e melhora a segurança no armazém.

Sinais de rota de entrega interna e externa

Sinais de rota de entrega marcam caminhos para movimentação de mercadorias. Dentro, eles guiam os trabalhadores pelos corredores e áreas de armazenamento. Fora, eles direcionam os veículos para docas de carga ou vagas de estacionamento. Um bom posicionamento ajuda as mercadorias a se moverem mais rapidamente e evita erros.

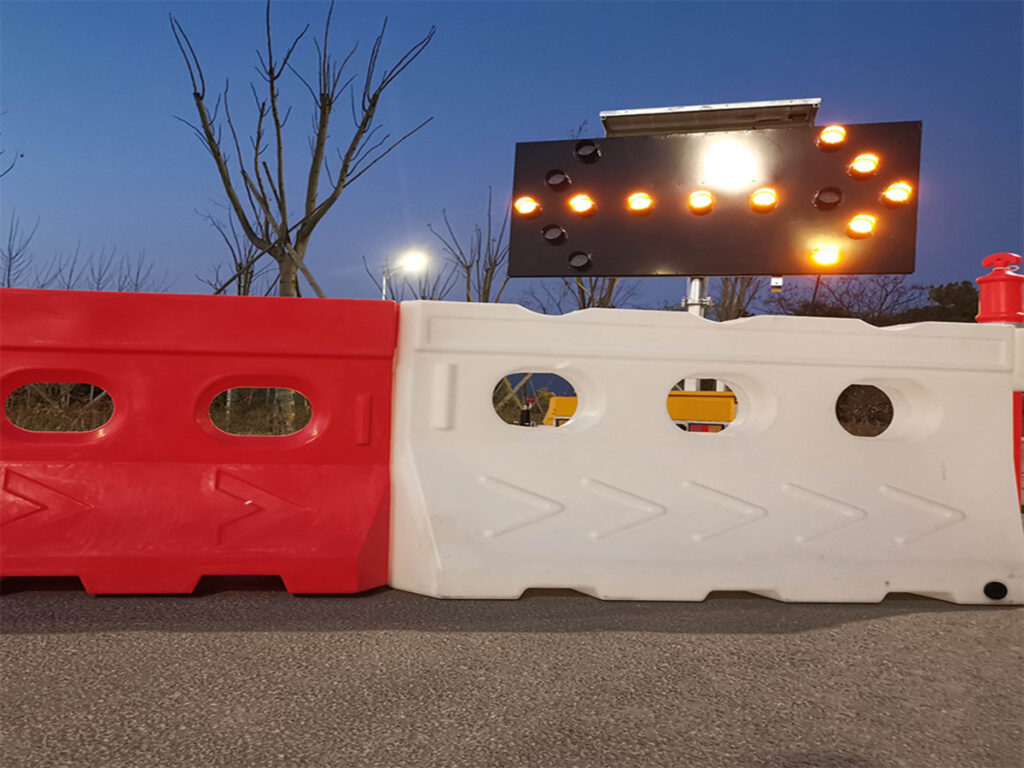

🚧 Dica: Use brilhante, sinais reflexivos do lado de fora para vê-los no escuro.

Sinais e colocação de alerta de perigo

“Área de operação de empilhadeiras,”“ Superfície escorregadia,” “Objetos em queda”

Sinais de perigo alertam os trabalhadores sobre os perigos. “Área Operacional de Empilhadeira” sinais dizem às pessoas para terem cuidado perto de empilhadeiras. “Superfície escorregadia” sinais param deslizamentos, e “Objetos caindo” sinais alertam sobre queda de itens em zonas de empilhamento.

Recomendações de posicionamento

Coloque sinais de perigo onde os perigos são maiores. Por exemplo, lugar “Área Operacional de Empilhadeira” sinais em esquinas e curvas. Usar “Superfície escorregadia” sinalização em áreas propensas a derramamentos. Lugar “Objetos caindo” sinais perto das prateleiras. Uma boa colocação mantém os trabalhadores seguros e conscientes dos riscos.

Proibição e sinalização obrigatória para melhores práticas de segurança

"Entrada proibida,”“ Somente pessoal autorizado,” “Pare e toque a buzina”

Placas de proibição bloqueiam acesso a áreas inseguras. “Entrada proibida” e “Somente pessoal autorizado” sinais impedem as pessoas de entrar em zonas restritas. “Pare e soe a buzina” sinais lembram os motoristas de empilhadeiras de avisar os outros antes de se moverem.

“Use roupas de alta visibilidade,”“ Zona do capacete,”“É necessário calçado de segurança”

Sinais obrigatórios garantem que os trabalhadores sigam as regras de segurança. “Use roupas de alta visibilidade” sinais mantêm os trabalhadores visíveis. “Zona de capacete” e “Calçado de segurança obrigatório” sinalização protege trabalhadores em áreas de risco. Esses sinais ajudam a prevenir lesões e garantir a segurança.

🛠️ Observação: Verifique frequentemente os sinais em busca de danos para mantê-los úteis.

Sinais de Emergência para Segurança de Armazéns

A sinalização de emergência é crucial para manter os armazéns seguros. Eles ajudam os trabalhadores a agir rapidamente durante emergências. Colocar estes sinais corretamente pode salvar vidas e evitar confusões.

Fire Extinguisher and First Aid Locations

Fire extinguishers and first aid kits are very important. Use signs to show where they are located. These safety signs for sale should be easy to see and at eye level. Arrows or symbols can point to the nearest fire extinguisher or first aid kit. This helps workers act quickly during fires or injuries. Check these safety signs for sale often to make sure they are clear and not damaged.

Emergency Exits and Assembly Points

Emergency exits and assembly points are key for safe evacuations. Signs for these areas must be visible, Mesmo no escuro. Use glowing materials for emergency exit signs so they can be seen at night. Place assembly point signs in open spaces outside the warehouse. These safety signs for sale show workers where to gather during evacuations. Sinais de segurança claros à venda evitam confusão e mantêm todos seguros.

- Sinais de emergência fornecem detalhes importantes sobre perigos e planos de fuga.

- Rotas de evacuação marcadas e locais de reunião são necessários para segurança.

Setas da rota de evacuação

As setas da rota de evacuação mostram aos trabalhadores o caminho para a segurança. Coloque essas flechas nas paredes, pisos, e portas para guiar as pessoas até as saídas. Use materiais reflexivos ou brilhantes para que possam ser vistos no escuro. Atualize estes sinais se o layout do armazém mudar. Caminhos claros ajudam os trabalhadores a manter a calma e sair com segurança.

🚨 Dica: Mantenha as rotas de evacuação livres de qualquer coisa que bloqueie o caminho.

Colocando sinais de emergência de forma inteligente, você pode tornar seu armazém mais seguro e proteger sua equipe em emergências.

Práticas recomendadas de posicionamento por zona

Baias de Carregamento e Áreas de Doca

Os cais de carga estão ocupados e precisam de sinalização de segurança clara para venda. Use sinais luminosos para mostrar faixas de veículos e caminhos para pedestres. Lugar “Parar” e “Cuidado” placas nas entradas para avisar a todos.

Projetar docas seguras ajuda a prevenir acidentes. Um espaço de movimentação de 150 pés permite que os veículos se movam facilmente. Mantenha as linhas centrais das portas 12 para 14 pés afastados para evitar aglomeração. Alturas de doca de 46 para 48 polegadas cabem na maioria dos caminhões. As portas suspensas devem ter pelo menos 9 pés de largura e 10 pés de altura para carregamento seguro.

Portões de barreira e restrições melhoram a segurança. As restrições funcionam melhor do que os calços para proteger os caminhões. Um painel de controle que trava as restrições e as portas aumenta a segurança antes do início do trabalho. Essas etapas, com boa colocação de sinalização, tornar a área mais segura para todos.

Corredores Internos e Passagens Estreitas

Corredores e espaços estreitos precisam de sinalização para orientar o trânsito. Use setas no chão e nas paredes para mostrar faixas de mão única. Adicionar “Colheita” ou “Área Operacional de Empilhadeira” sinalização nos cruzamentos para alertar os trabalhadores.

Em lugares apertados, use sinais de parede e marcações de piso juntos. Sinais reflexivos ajudam os trabalhadores a enxergar melhor com pouca luz. Verifique essas áreas com frequência para manter os sinais claros e fáceis de ler. A boa colocação da sinalização reduz a confusão e mantém o trabalho em andamento com segurança.

Zonas de armazenamento e estantes

As áreas de armazenamento apresentam riscos como queda de itens e acidentes com empilhadeiras. As placas aqui alertam sobre perigos e lembram os trabalhadores sobre as regras de segurança. Lugar “Objetos caindo” sinais perto de prateleiras altas. Usar “Área Operacional de Empilhadeira” sinalização nas entradas.

Sinais aprovados pela OSHA fornecem avisos e regras de segurança claros. Esses sinais ajudam os trabalhadores a seguir as diretrizes de segurança e evitar acidentes. Sinais de empilhadeiras também protegem prateleiras e mercadorias contra danos. Colocar sinalização de forma inteligente nessas áreas mantém todos mais seguros.

Percursos Pedestres

Percursos pedestres em armazéns mantêm os trabalhadores seguros. Placas mostram aos trabalhadores por onde caminhar e evitar zonas de perigo. Colocar sinalização em pontos inteligentes evita confusões e acidentes. Use linhas de piso e sinais de parede juntos para marcar caminhos para caminhada. Isso ajuda os trabalhadores a ver os caminhos com clareza e a se manterem organizados.

Placas com imagens ou dois idiomas são úteis para funcionários mistos. Esses sinais tornam as regras de segurança fáceis de entender para todos. Repita frequentemente os sinais ao longo do caminho para lembrar os trabalhadores da segurança. Por exemplo, colocar “Apenas para pedestres” sinalização nas entradas e cruzamentos para manter os trabalhadores em caminhos seguros.

Luzes brilhantes facilitam a visualização dos sinais de trânsito. Sinais reflexivos funcionam bem em áreas mais escuras. Verifique as placas com frequência para ter certeza de que estão claras e não quebradas. Uma boa colocação e cuidado com a sinalização tornam o armazém mais seguro para todos os trabalhadores.

Pontos de acesso de emergência

As saídas de emergência devem permanecer sempre abertas e desimpedidas. A sinalização nessas saídas ajuda os trabalhadores a sair rapidamente durante emergências. Coloque sinais de saída e setas onde os trabalhadores possam vê-los facilmente. Use sinais brilhantes para torná-los visíveis em áreas escuras ou esfumaçadas.

As regras dizem que os sinais de emergência devem ser claros e fáceis de ver. Por exemplo:

| Regra | O que diz |

|---|---|

| OSHA 29 Cfr 1910.145 | Lista os sinais de segurança necessários e como usá-los. |

| ANSI Z535 | Explica como devem ser os sinais de segurança, como cores e símbolos. |

Siga estas regras para manter as saídas seguras:

- Não bloqueie as portas de saída com decorações ou outros sinais.

- Mostre o caminho para a saída mais próxima se não for óbvio.

- Os sinais de saída devem ser sempre fáceis de ver para evacuações rápidas.

Colocar sinalização de emergência nos lugares certos evita atrasos durante emergências. Coloque-os ao nível dos olhos e mantenha-os livres de desordem. Verifique os sinais de segurança à venda com frequência para ter certeza de que funcionam bem. Estas etapas protegem os trabalhadores e seguem as regras de segurança.

Dicas de material e durabilidade para sinalização

Sinais reflexivos vs não reflexivos: Uso interno e externo

Escolha o material de sinalização de segurança certo para sua localização. Sinais reflexivos são melhores fora ou em áreas escuras. Eles brilham de volta, tornando -os fáceis de ver à noite. Por exemplo, sinais reflexivos perto das docas de carga ajudam os motoristas à noite. Sinais não refletivos funcionam bem em ambientes internos com iluminação constante. Eles custam menos, mas ainda fornecem instruções claras em espaços claros.

Usar cores fortes e letras grandes facilita a leitura dos sinais. Isso ajuda os trabalhadores a entenderem rapidamente e evitarem acidentes.

Materiais de sinalização: PVC, Alumínio, e opções magnéticas

Combine o material do sinal de segurança com o local onde ele será colocado. Placas de PVC são leves e baratas, ótimo para uso interno. Eles resistem à água e limpam facilmente, perfeito para áreas propensas a derramamentos. As placas de alumínio são resistentes e suportam o calor, luz solar, e mau tempo. Eles são ótimos para locais ao ar livre ou áreas movimentadas. Sinais magnéticos podem ser movidos facilmente. Eles são bons para configurações temporárias ou alteração de layouts.

Materiais resistentes mantêm os sinais de segurança legíveis por muito tempo. Isso economiza dinheiro e mantém as regras de segurança em vigor.

Maneiras de montar placas: Parede, Teto, ou Chão

A forma como você coloca sinais de segurança afeta o quão bem eles funcionam. As placas de parede são boas ao nível dos olhos para que os trabalhadores as vejam facilmente. Sinais de segurança suspensos funcionam em grandes espaços, como cais de carga. Eles ficam pendurados no teto e podem ser vistos de longe. Sinais de chão, como fita de piso Mighty Line, marcar caminhos ou pistas de empilhadeiras. Esses sinais ajudam a prevenir lesões, mostrando claramente as zonas seguras.

Cada estilo de montagem tem seus próprios benefícios. Escolha aquele que melhor se adapta ao espaço e ao perigo.

Opções de sinalização removível para configurações logísticas temporárias

Configurações logísticas temporárias precisam de ferramentas de segurança flexíveis. Placas removíveis são uma maneira inteligente de ajustar layouts e ao mesmo tempo permanecer seguro. Estas placas de segurança à venda são simples de colocar, mover, ou derrubar, tornando-os ótimos para mudar de espaço.

Por que usar placas removíveis

Sinais removíveis têm muitos benefícios:

- Flexibilidade: Mova rapidamente os sinais para se adequarem a novas áreas ou tarefas.

- Custo-efetividade: Placas reutilizáveis economizam dinheiro e duram mais.

- Facilidade de uso: Sinais magnéticos ou adesivos são fáceis de configurar e remover.

🛠️ Dica: Use placas removíveis para projetos de curto prazo ou trabalhos sazonais para permanecer seguro sem mudanças permanentes.

Tipos de sinais removíveis

Escolha o letreiro removível certo para suas necessidades:

- Sinais Magnéticos: Atenha-se a superfícies metálicas como prateleiras ou máquinas. Ótimo para marcar locais de armazenamento temporário ou equipamentos.

- Sinais com adesivo: Cole nas paredes ou no chão e retire-o de forma limpa. Use them for temporary paths or danger warnings.

- Freestanding Signs: Portable and easy to place anywhere. Ideal for marking temporary loading zones or restricted spots.

How to Use Them

Removable signs work well in many situations:

- Marking temporary walking paths during construction.

- Showing seasonal storage spots for holiday items.

- Warning about temporary dangers like wet floors or repairs.

🚧 Observação: Always make sure removable signs are clear and secure to prevent confusion or accidents.

Using removable signs keeps your workspace safe and organized, mesmo quando as coisas mudam. These signs help you adjust quickly while keeping everyone informed and safe.

Regulatory and Best Practice References for Warehouse Safety

OSHA Signage Rules

OSHA makes rules for safety signs in warehouses. These rules help workers spot dangers and stay safe. Os sinais de segurança da OSHA devem usar certas cores, formas, e símbolos para mostrar riscos. Por exemplo, sinais de perigo precisam de letras brancas sobre fundo vermelho. Estes sinais de segurança da OSHA alertam sobre perigos graves, como máquinas pesadas ou tubos de alta pressão.

Coloque sinais de segurança da OSHA onde os perigos são comuns. Os exemplos incluem áreas com empilhadeiras, pisos escorregadios, ou itens caindo. Verifique frequentemente estes sinais de segurança da OSHA para se certificar de que estão claros e não danificados. Seguir as regras da OSHA torna seu armazém mais seguro e reduz os riscos de acidentes.

ANSI Z535.2: Cores e Símbolos

Ansi dá conselhos extras sobre padrões de sinalização de segurança. A regra ANSI Z535.2 explica como usar cores e símbolos para mensagens claras. Isso ajuda os trabalhadores a entender os avisos rapidamente, mesmo em emergências.

Aqui está uma tabela mostrando os tipos de sinais e suas cores:

| Tipo de sinal | Significado | Cores usadas | Exemplos |

|---|---|---|---|

| Perigo | Alerta para riscos muito graves, como morte ou ferimentos graves. | Letras brancas, fundo vermelho | Alta tensão, máquinas pesadas |

| Aviso | Alertas sobre riscos graves, mas menos grave que os sinais de perigo. | Letras pretas, fundo laranja | Zonas de empilhadeiras, espaços apertados |

| Cuidado | Mostra riscos que podem causar lesões pequenas ou médias. | Letras pretas, fundo amarelo | Pisos escorregadios, pequenos choques |

O uso de placas ANSI mantém seu armazém atualizado com as regras de segurança. Esses sinais também ajudam os trabalhadores a perceber e evitar perigos mais rapidamente.

Regras locais de sinalização de incêndio e emergência

Códigos de incêndio locais são importantes para a segurança do armazém. Estas regras precisam de sinais claros para saídas, extintores de incêndio, e rotas de fuga. Os sinais devem brilhar no escuro ou refletir a luz para que os trabalhadores possam vê-los durante quedas de energia ou fumaça.

Coloque sinais de emergência ao nível dos olhos e ao longo das rotas de fuga. Mantenha esses caminhos limpos para seguir as regras de segurança. Verifique frequentemente as leis locais para garantir que suas placas atendam aos padrões mais recentes. Seguir essas regras protege os trabalhadores e evita multas durante as fiscalizações.

Verificações de sinalização para inspeções de segurança em armazéns

As inspeções de segurança ajudam a garantir que os armazéns sigam as regras de segurança. Os inspetores verificam muitas coisas, incluindo onde os sinais de segurança são colocados e suas condições. Ter a sinalização correta mantém os trabalhadores seguros e evita multas.

Para se preparar para uma inspeção, use uma lista de verificação de segurança. Esta lista ajuda a confirmar se todos os sinais necessários estão em vigor e atendem às regras. Primeiro, certifique-se de que os sinais de saída de emergência sejam fáceis de ver e não bloqueados. Verifique os sinais de perigo para ver se eles estão perto de perigos, como áreas de empilhadeiras ou locais escorregadios. Substitua imediatamente quaisquer sinais que estejam desbotados ou quebrados.

Os inspetores também verificam se seus sinais seguem as regras OSHA e ANSI. OSHA diz que os sinais de segurança devem ter certas cores, formas, e palavras. Por exemplo, danger signs need red backgrounds with white letters. ANSI gives extra tips on symbols and layouts to make signs clearer. Following these rules helps signs work better and meet safety standards.

Make sure traffic safety signs match their surroundings. Reflective signs are good for dark areas, while non-reflective ones work in bright spaces. All traffic safety signs should be firmly attached and at eye level so workers can see them easily. Temporary traffic safety signs, like magnetic or sticky ones, should only be used briefly and removed when done.

Keeping traffic safety signs up to date makes your warehouse safer. It also shows you care about safety. Using a safety checklist often helps you stay ready for inspections and keeps your workplace free of hazards.

Colocar sinalização de segurança de forma inteligente torna seu armazém mais seguro e melhor. Estas placas de segurança no trânsito ajudam a organizar os espaços, mostrar perigos, e orientar durante emergências.

- Principais vantagens:

- Eles ajudam os trabalhadores a seguir as regras de segurança e ficar alertas.

- As placas alertam sobre os riscos, ajudando os trabalhadores a agir com cuidado imediatamente.

- Sinais claros criam um local de trabalho mais seguro e reduzem as chances de acidentes.

🛠️ Dica: Escolha forte, sinais de cumprimento de regras para segurança duradoura.

Quer entender melhor o papel que os sinais de segurança desempenham em todos os ambientes de trânsito e de trabalho? Confira nosso blog: “Quais são as funções dos sinais de segurança do trânsito? Uma visão geral do espectro total da regulamentação para a orientação“ para mergulhar mais fundo em suas funções essenciais.

Perguntas frequentes

Qual a altura que os sinais de segurança devem ser colocados?

Coloque sinais de onde as pessoas podem vê -las facilmente. Uma boa altura é 4-5 pés do chão. Os sinais de emergência devem brilhar para serem vistos no escuro.

Com que frequência os sinais de segurança precisam ser verificados?

Verifique as placas todos os meses quanto a danos ou desbotamento. Conserte ou substitua sinais quebrados imediatamente para mantê-los claros e seguros.

Você pode usar placas removíveis novamente?

Sim, sinais removíveis, como ímãs ou adesivos, podem ser reutilizados. Eles são ótimos para configurações temporárias e economizam dinheiro.

Quais materiais funcionam melhor para sinalização externa?

Use materiais fortes como alumínio ou PVC reflexivo. Eles lidam bem com chuva e sol, permanecendo claro e durando mais tempo.

Os armazéns devem ter sinalização bilíngue?

Sim, sinalização de segurança bilíngue ajudar trabalhadores que não falam inglês. Eles tornam as regras de segurança mais fáceis de entender para todos.