Sinais de trânsito reflexivos são essenciais para garantir a segurança rodoviária, especialmente à noite e em condições de baixa visibilidade. No entanto, muitas regiões com condições climáticas adversas enfrentam o problema persistente de materiais refletivos descascando nos sinais de trânsito. Este peeling reduz a eficácia do sinal, comprometer a segurança. O problema é particularmente prevalente em áreas expostas ao frio extremo, neve, e ciclos repetidos de congelamento e descongelamento.

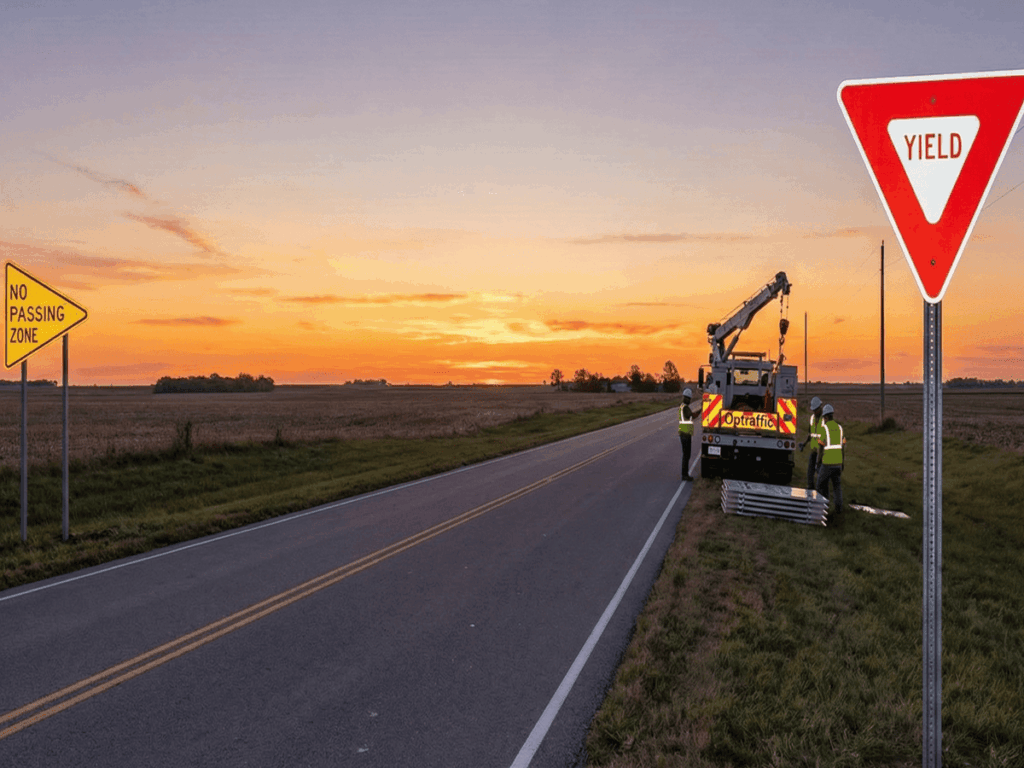

Para combater esse problema, OPTRÁFEGO oferece alta qualidade, durável Sinais de trânsito reflexivos projetado para suportar condições climáticas adversas. Com materiais como Prismático de Alta Intensidade (QUADRIL) e folhas refletivas de grau diamante, OPTRAFFIC garante desempenho duradouro, mesmo nos ambientes mais extremos.

Este blog irá se aprofundar nas causas do descascamento de materiais reflexivos, explore por que certos sinais são mais vulneráveis a danos, e oferecer soluções práticas para garantir a longevidade e a eficácia da sinalização de trânsito nestes ambientes desafiadores.

Por que os materiais reflexivos se descolam?

Delaminação de Filmes Reflexivos

As películas refletivas usadas em sinais de trânsito são projetadas para melhorar a visibilidade, refletindo a luz de volta para os motoristas., particularmente à noite. No entanto, conforme o tempo passa, as condições ambientais podem fazer com que esses filmes se descasquem, um processo conhecido como delaminação. A delaminação ocorre quando o adesivo que une a camada reflexiva ao substrato da sinalização se rompe, permitindo que o filme reflexivo separe. As causas comuns incluem exposição prolongada à umidade, mudanças de temperatura, e estresse físico causado por elementos ambientais.

Ciclos de congelamento e descongelamento

Regiões com invernos rigorosos enfrentam desafios únicos quando se trata de Manutenção do sinal de trânsito. Os ciclos de congelamento e descongelamento – quando a neve derrete e congela novamente – podem ter um impacto profundo no adesivo que mantém o material reflexivo no lugar. À medida que a neve se acumula e derrete, a umidade se infiltra nas bordas da placa. Quando as temperaturas caem, essa umidade congela, expandindo e colocando pressão sobre o filme reflexivo. À medida que o gelo descongela, contrai, causando estresse e eventual descascamento do material reflexivo, especialmente no topo do sinal.

O processo repetido de congelamento e descongelamento é particularmente prejudicial aos materiais refletivos devido à constante exposição à umidade e às tensões mecânicas criadas pelo congelamento e descongelamento..

Impacto do clima severo na sinalização reflexiva de trânsito

Exposição à neve e ao gelo

Em muitas partes dos Estados Unidos, fortes nevascas são comuns todo inverno. Regiões como o Nordeste (Por exemplo, norte do estado de Nova York, Vermont, Nova Hampshire), o Alto Centro-Oeste (Por exemplo, Minnesota, Wisconsin, Michigan), e áreas montanhosas do Ocidente (Por exemplo, Colorado, Montana) experimenta regularmente neve profunda e ciclos repetidos de congelamento e descongelamento. Nessas áreas, os sinais de trânsito muitas vezes ficam enterrados sob a neve por longos períodos. Esta exposição prolongada à umidade da neve – juntamente com o subsequente derretimento e congelamento – pode causar danos significativos aos materiais reflexivos. Neve e gelo podem penetrar nas bordas das placas, enfraquecendo o adesivo que segura a camada reflexiva. À medida que a umidade congela novamente, ele se expande e acelera ainda mais o descascamento e a delaminação de cima para baixo.

Exposição prolongada à umidade

Não são só regiões frias que apresentam problemas de sinalização. Áreas com chuva frequente ou alta umidade, como o noroeste do Pacífico (Por exemplo, Washington e Oregon), também sujeita os sinais de trânsito à exposição prolongada à umidade. Condições molhadas constantes, combinado com oscilações de temperatura, quebrar gradualmente a ligação entre o material reflexivo e o substrato do sinal. Ao longo do tempo, esta exposição prolongada à umidade pode degradar o adesivo e fazer com que a camada reflexiva se solte – causando descamação e redução da visibilidade.

Soluções para evitar o descascamento de materiais reflexivos

Atualize para materiais reflexivos duráveis

Uma das maneiras mais eficazes de evitar o descascamento é atualizar para materiais refletivos de maior qualidade.. Os materiais refletivos padrão de nível de engenharia geralmente não são projetados para suportar as condições adversas presentes em áreas com condições climáticas extremas. Materiais de alta qualidade, como Prismático de Alta Intensidade (QUADRIL) ou Folhas Refletivas de Grau Diamante são projetadas especificamente para ambientes difíceis. Esses materiais são mais duráveis, oferecem maior resistência à umidade, e tolerar melhor temperaturas extremas. Eles mantêm sua refletividade e adesão por períodos mais longos, mesmo sob condições climáticas desafiadoras.

Ao optar por estes materiais avançados, as autoridades de trânsito podem garantir que sua sinalização permaneça eficaz, reduzindo a necessidade de reparos ou substituições frequentes. Se você quiser saber mais sobre como escolher os melhores materiais refletivos para sinais de trânsito, fique à vontade para conferir nosso blog, Como selecionar os melhores materiais reflexivos para sinais de trânsito.

Use cartazes impressos em vez de letras de vinil

As letras tradicionais cortadas em vinil são uma das principais causas de descascamento nas bordas. Bordas de vinil são vulneráveis ao desgaste, o que aumenta o risco de delaminação. Sinais impressos, no entanto, oferecem uma superfície reflexiva perfeita sem bordas vulneráveis. Os materiais refletivos impressos são mais resistentes a danos porque não possuem fendas ou cortes por onde a água pode entrar. Esta superfície contínua garante melhor adesão e desempenho mais duradouro. Ao mudar para sinais reflexivos impressos, as autoridades de trânsito podem reduzir significativamente o risco de descascamento, particularmente em áreas com condições climáticas severas.

Para entender melhor os padrões regulatórios para impressão de sinalização rodoviária e garantir a conformidade com as diretrizes do setor, você pode explorar nosso blog, Compreendendo os padrões regulatórios para impressão de sinais de trânsito. Isso ajudará a orientar seu processo de tomada de decisão ao selecionar os melhores materiais e métodos para suas necessidades de sinalização de trânsito..

Vedação e cobertura de bordas

Uma das maneiras mais eficazes de evitar que a umidade se infiltre nas bordas dos sinais de trânsito é através da vedação ou cobertura das bordas.. A umidade normalmente entra pelas bordas superiores dos sinais de trânsito, onde o material reflexivo encontra o substrato do sinal. A aplicação de tampas de alumínio nas bordas - semelhantes às usadas em portas automotivas - pode proteger as bordas da sinalização e evitar que a água vaze por baixo da camada reflexiva. Isto é especialmente importante para sinais expostos à neve e ao gelo por longos períodos. A vedação das bordas evita o acúmulo de umidade que pode causar descamação, ajudando a prolongar a vida útil do material reflexivo.

Inspeções Regulares e Manutenção Proativa

As inspeções de rotina são essenciais para detectar sinais precoces de descamação ou delaminação. Após tempestades de neve significativas ou períodos de degelo, é importante inspecionar os sinais em busca de sinais de danos. A detecção precoce permite reparos ou substituições antes que o problema piore. A manutenção proativa também é essencial. Crie um cronograma para inspeções regulares, especialmente após o inverno ou fortes nevascas. Por aqui, sinais danificados podem ser tratados imediatamente, garantindo a segurança nas estradas.

Revestimentos Protetores e Laminados

Aplicar uma camada protetora ao material reflexivo pode ajudar a protegê-lo da umidade, Raios UV, e desgaste físico. Esses revestimentos atuam como uma camada adicional de proteção, reduzindo o impacto das tensões relacionadas com o clima. Os laminados também podem ajudar a preservar a integridade do material reflexivo. Essas camadas protetoras evitam que o material entre em contato direto com a umidade, minimizando as chances de descascar.

Melhores práticas para manter sinais de trânsito reflexivos

Seleção adequada de adesivo

O adesivo usado para unir o filme reflexivo ao substrato é crucial. Certifique-se de que o adesivo seja projetado para suportar temperaturas e umidade extremas. Adesivos de baixa qualidade podem quebrar sob estresse, levando à descamação. Use adesivos resistentes às intempéries, formulados especificamente para o frio, condições úmidas para garantir uma adesão duradoura.

Colocação correta de sinais

A localização do sinal desempenha um papel crítico na sua longevidade. Em áreas onde a neve se acumula, pode ser útil posicionar sinais em áreas com menor probabilidade de serem soterradas. Alternativamente, considere instalar sinalização em ângulo para reduzir o acúmulo de neve ou usar postes de sinalização que permitam que a neve deslize com mais facilidade.

Cronograma de Manutenção Preventiva

Crie um cronograma de manutenção preventiva que inclua verificações regulares de descamação, rachaduras, ou outro dano. Isto deve envolver a inspeção dos sinais após cada tempestade de neve e período de degelo. Avaliando regularmente as condições dos sinais, as autoridades de trânsito podem tomar medidas oportunas para evitar maiores danos.

Conclusão: Garantindo durabilidade a longo prazo para sinais de trânsito

Descascar materiais reflexivos é um problema comum, particularmente em regiões com condições climáticas extremas. Atualizando para materiais refletivos de alta qualidade, como HIP ou Diamond-Grade, mudando para sinalização impressa, e aplicar vedação ou cobertura nas bordas são formas eficazes de evitar descascamento e prolongar a vida útil dos sinais de trânsito. Adicionalmente, selecionando fabricantes de sinais de trânsito de primeira linha, como OPTRÁFEGO, especializados em materiais duráveis e resistentes às intempéries, pode reduzir significativamente o risco de descamação. Inspeções regulares, usando os adesivos corretos, e a adoção de uma abordagem de manutenção proativa garantirá ainda mais que a sinalização de trânsito permaneça eficaz e segura a longo prazo.