O Instituto Nacional Americano de Padrões, known as ANSI, establishes clear rules for workplace signage that indicate danger areas. These regulations assist companies in maintaining worker safety. ANSI compliant signs utilize specific colors and symbols, enabling workers to quickly identify risks. Businesses implement these signs to prevent fines and ensure that operations continue smoothly.

No OPTRÁFEGO, we are a trusted fabricante de sinais de trânsito specializing in high-quality, ANSI-compliant danger signage for the workplace. Our custom safety solutions ensure your business stays safe, compatível, e eficiente. Discover our wide selection of high-quality, compliant signage crafted to ensure workplace safety, meet regulatory standards, and safeguard your employees.

Takeaways -chave

- ANSI compliant signs use certain colors and symbols. These help workers spot dangers fast. This makes the workplace safer.

- Using ANSI safety sign rules can stop legal trouble and fines. Ajuda a manter o bom funcionamento do negócio e mantém os trabalhadores seguros.

- É importante fazer verificações de segurança com frequência e colocar sinais nos lugares certos. Isso ajuda as pessoas a verem sinais de perigo e as mantém funcionando bem. Reduz a chance de acidentes.

- Escolher materiais resistentes para sinalização economiza dinheiro. Ele também mantém as mensagens de segurança fáceis de ver por um longo tempo.

- A sinalização de perigos especiais no local de trabalho ajuda as pessoas a compreenderem melhor. Também ajuda todos a seguir as regras. Isso torna a segurança importante para todos os trabalhadores.

Compreendendo os padrões de sinalização de segurança ANSI

O que são sinais de perigo ANSI e seu papel no local de trabalho?

Padrões de sinalização de segurança ANSI diga-nos como devem ser os sinais de perigo no trabalho. Estas regras ajudam os trabalhadores a ver os perigos rapidamente e a saber o que fazer. ANSI Z535.3-2022 diz que símbolos de segurança são imagens que alertam ou dão instruções. A maioria dos símbolos mostra uma imagem preta sobre fundo branco, mas alguns usam formas especiais. ANSI Z535.5 diz para usar palavras de sinalização como “Perigo” para perigos graves. Materiais resistentes garantem que esses sinais durem em locais difíceis. Os sinais feitos de acordo com essas regras geralmente usam símbolos sem palavras, para que todos possam entendê-los.

Dica: Os padrões de sinalização de segurança ANSI ajudam todos os trabalhadores a identificar um perigo, mesmo que falem outro idioma.

A importância da conformidade ANSI para a segurança no local de trabalho

Os padrões de sinalização de segurança ANSI ajudam a manter os trabalhadores seguros. Os sinais que seguem estas regras têm quatro partes principais: palavra de sinalização, declaração de perigo, consequências, e instruções. Cada parte ajuda os trabalhadores a conhecerem o risco e como se manterem seguros. A tabela abaixo mostra como essas partes funcionam juntas:

| Componente | Descrição |

|---|---|

| Palavra de sinalização | Diz o quão perigoso é |

| Declaração de perigo | Diz que tipo de perigo é |

| Consequências | Lista o que pode acontecer se você ignorar |

| Instruções | Diz o que fazer para se manter seguro |

As placas com as quatro partes ajudam os trabalhadores a seguir as regras e a se manterem seguros melhor do que as placas com peças faltando. Os padrões de sinalização de segurança ANSI mudam para atender às novas regras e necessidades do local de trabalho. Novas atualizações incluem melhor correspondência com outras regras, mais fotos, e maneiras mais fáceis de comparar sinais. Acompanhar os padrões de sinalização de segurança ANSI ajuda as empresas a proteger os trabalhadores e prevenir acidentes.

Consequências legais da não conformidade com os padrões ANSI

OSHA e ANSI trabalhar juntos para promover a segurança no local de trabalho. Embora a OSHA estabeleça regulamentos para sinais de segurança, ANSI oferece diretrizes complementares. Ao adotar padrões ANSI para sinalização de segurança, OSHA os torna legalmente aplicáveis. Se uma empresa não seguir essas regras, pode receber multas ou citações. As citações mais comuns são para proteção contra quedas, comunicação de perigo, escadas, proteção respiratória, e proteção de máquinas. As empresas precisam dos padrões de sinalização de segurança ANSI para evitar problemas legais e manter os trabalhadores seguros. Seguir essas regras ajuda a prevenir acidentes e mantém o trabalho funcionando sem problemas.

Principais recursos de sinalização eficaz no local de trabalho

Requisitos de cores e símbolos ANSI para sinais de perigo

Bom uso de sinalização no local de trabalho cores claras e símbolos. ANSI diz que os sinais de perigo precisam de fundos vermelhos e grandes letras brancas. Vermelho significa que há um grande risco e você deve agir rápido. Os símbolos nesses sinais são fáceis de entender por todos. Os trabalhadores conhecem o perigo mesmo que não falem inglês. Usar as mesmas cores e símbolos em todos os lugares ajuda a manter as pessoas seguras. Os funcionários podem detectar sinais de perigo imediatamente.

| Cor | Requisito de símbolo | Descrição |

|---|---|---|

| Vermelho | Perigo | Mostra importantes ferramentas de segurança e grandes perigos, como botões de parada e equipamentos de incêndio. |

| Vermelho | Sinais de perigo | Alerta sobre riscos que podem causar morte ou ferimentos graves se ignorados. |

- Vermelho é para perigos graves e ferramentas de incêndio.

- Os códigos de cores ajudam o cérebro das pessoas a trabalhar rapidamente, para que eles possam impedir acidentes.

- Usar o mesmo sistema em todos os trabalhos ajuda os trabalhadores a conhecerem os sinais de perigo sem se confundirem.

Durabilidade e opções de materiais para sinalização duradoura no local de trabalho

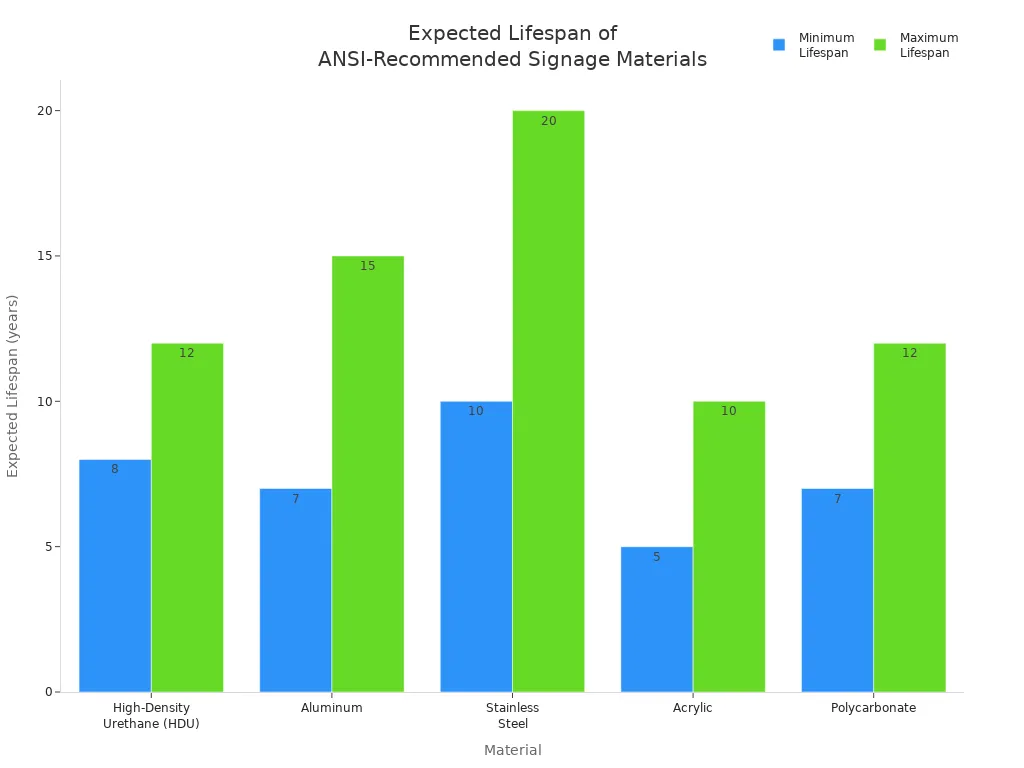

A sinalização no local de trabalho precisa durar em locais difíceis. ANSI diz para usar materiais fortes como uretano de alta densidade, alumínio, aço inoxidável, acrílico, e policarbonato. Esses materiais combatem produtos químicos, água, e luz solar. Isso mantém as mensagens de segurança fáceis de ver. Quanto tempo duram os sinais depende do material. O aço inoxidável pode durar até 20 anos. O acrílico pode durar até 10 anos.

| Material | Vida esperada |

|---|---|

| Uretano de alta densidade (Isto) | 8–12 anos |

| Alumínio | 7–15 anos |

| Aço inoxidável | 10–20 anos |

| Acrílico | 5–10 anos |

| Policarbonato | 7–12 anos |

Escolher materiais resistentes para sinalização economiza dinheiro. Também ajuda a manter os trabalhadores seguros por muito tempo.

Garantindo Visibilidade e Legibilidade para Máxima Segurança

Sinais devem ser fáceis de ver e ler. ANSI diz que os sinais de perigo devem estar entre 5 e 7 pés do chão. O tamanho da letra deve corresponder à distância que você está. A palavra “PERIGO” precisa ser pelo menos 1.75 centímetros de altura se você tiver 25 pés de distância. Todas as fontes maiúsculas e sem serifa facilitam a leitura das palavras. Os sinais precisam de espaço ao redor das palavras para que as mensagens se destaquem. Os materiais não devem ser estragados pela limpeza ou pelo clima. Isso mantém as informações de segurança claras.

| Especificação | Exigência |

|---|---|

| Altura do Sinal | Coloque o sinal central entre 5 e 7 pés do chão. |

| Altura da letra | A altura mínima da letra é o tempo de distância de visualização 0.07. No 25 pés, “PERIGO” deve ser pelo menos 1.75 polegadas de altura. |

| Estilo da fonte | Use todas as letras maiúsculas, fontes sem serifa como Helvetica, Arial, ou Rodovia Gótica. A largura do traço é 1/6 da altura da letra. |

| Zona Limpa | Deixe um espaço ao redor das palavras igual à metade da altura da letra. |

| Durabilidade dos materiais (Interior seco) | Use PVC rígido ou vinil pegajoso. Eles duram 3-5 anos. |

| Durabilidade dos materiais (Úmido/Químico) | Use plástico reforçado com fibra de vidro ou alumínio com cobertura de poliéster. |

| Durabilidade dos materiais (UV ao ar livre) | Use alumínio anodizado ou alumínio reflexivo para locais muito quentes ou frios. |

| Resistência à limpeza | Os materiais devem suportar sabão neutro sem perder tinta. For places with strong cleaners, use UV-cured or screen-printed inks. |

Dica: Putting danger signs in the right spot and making them easy to read helps stop accidents and keeps everyone safe.

How to Choose a Trusted ANSI Signage Provider

Evaluating Provider Experience and Industry Expertise

A trusted safety sign provider has many years making workplace signs. They know what different industries need. They learn about each hazard and how to fix it. Providers with good records help businesses reach safety goals. They give advice on the best signs for each spot. Their skills make sure every sign follows ANSI rules. Isso ajuda a interromper acidentes. Companies should pick providers who worked with similar businesses. These providers know how to keep people safe in tough places.

Garantia de qualidade: Ensuring ANSI Compliance and Durability

Os principais fornecedores de sinalização usam verificações de qualidade rigorosas para garantir que os sinais durem e sigam as regras.

- Uma equipe especial verifica se as placas atendem aos padrões ANSI.

- Eles encontram riscos que podem quebrar regras e fazem planos para acabar com os problemas.

- Eles ensinam os trabalhadores sobre as novas regras de segurança.

- Eles anotam cada passo para verificações futuras.

- Eles sempre tentam melhorar a segurança.

- Eles verificam os sinais com frequência e os atualizam quando necessário.

- Eles leem as atualizações da ANSI para se manterem atualizados com as novas regras.

Estas etapas ajudam todos os sinais a permanecerem claros, forte, e bom para segurança.

Personalização da sinalização do local de trabalho para necessidades específicas

Cada local de trabalho tem seus próprios perigos. Sinais personalizados ajudam com esses riscos e ainda seguem as regras ANSI.

Quase tudo na sinalização de segurança pode ser alterado. Você pode escolher palavras especiais, fotos, e o logotipo da sua empresa.

Fazer placas personalizadas é fácil:

| Etapa | Descrição |

|---|---|

| 1 | Use um criador de sinalização para projetar sua sinalização OSHA ou ANSI. |

| 2 | Escolha o tamanho e o material que você deseja. |

| 3 | Adicione sua placa ao carrinho e faça o pedido. |

Placas personalizadas ajudam as pessoas a falar melhor, Siga as regras, e tornar a segurança mais forte. Eles ajudam com perigos que os sinais regulares não cobrem. Isso apoia a segurança e evita acidentes.

Mantendo a conformidade com a segurança no local de trabalho

Conduzindo auditorias regulares de segurança para conformidade com ANSI

Auditorias regulares de segurança ajudam as empresas a seguir as regras de sinalização de segurança. Essas verificações evitam que os trabalhadores se machuquem. Os auditores usam etapas simples para observar os sinais de segurança. Primeiro, eles encontram todos os sinais de segurança no local de trabalho. Então, eles garantem que os sinais sejam fáceis de ver e estejam no lugar certo. Os auditores verificam se as palavras e os símbolos estão claros. Eles olham para cada placa para ver se está forte e não quebrada. Auditors compare what they find to OSHA rules. They write down what they see and fix any problems.

- Find all safety signs and warning signs in the workplace.

- Make sure signs are easy to see and in the right place.

- Check if words and symbols are clear and follow the rules.

- Look at signs to see if they are strong and not damaged.

- Compare what you find to OSHA rules and guidelines.

- Write down results and fix problems to keep people safe.

Safety audits help companies follow safety sign rules. Regular checks lower risk and help keep everyone safe.

Strategic Signage Placement for Maximum Impact and Safety

Putting safety signs in smart places helps people notice dangers. Signs warn about things like slippery floors and moving machines. Eles dizem aos trabalhadores como se manterem seguros e mostram onde estão as ferramentas de emergência. Uma boa colocação de sinalização ajuda as pessoas a seguir as regras de segurança.

| Descrição da evidência | Pontos -chave |

|---|---|

| A sinalização de segurança ajuda as pessoas a ver os perigos | Placas dão pistas rápidas sobre perigos próximos. |

| Sinais ajudam as pessoas a seguir as regras de segurança | Placas lembram a todos que a segurança é importante. |

| Placas fortalecem a segurança no trabalho | Sinais ajudam as pessoas a fazer coisas seguras e evitar acidentes. |

“Os sinais de segurança sempre lembram os trabalhadores sobre os perigos. Eles ajudam as pessoas a serem cuidadosas.”

As regras de sinalização de segurança dizem para colocar sinais de alerta ao nível dos olhos. A sinalização deve estar perto das zonas de perigo. Isso ajuda os trabalhadores a verem os riscos rapidamente e a permanecerem seguros.

Manutenção de rotina e atualizações para sinalização compatível com ANSI

Verificar os sinais de segurança muitas vezes os mantém funcionando bem. Isso ajuda as empresas a seguir as regras de segurança. Problemas podem acontecer se as placas estiverem faltando ou quebradas. Palavrões ou símbolos errados podem confundir os trabalhadores. Not following ANSI or Regras da OSHA can cause trouble. Signs that are blocked or hidden are also unsafe.

| Maintenance Issue | Descrição |

|---|---|

| Sinais ausentes ou quebrados | Signs that are faded or gone can make people miss safety rules. |

| Bad Words or Wrong Symbols | If signs are not clear, workers might get confused and hurt. |

| Not Following ANSI/OSHA Rules | Not following rules can cause fines and make work unsafe. |

| Blocked or Hidden Signs | Se os sinais são difíceis de ver, it is just as bad as having no signs. |

Companies should teach workers how to read warning signs. They should check ANSI and OSHA rules for updates. Looking at signs often and fixing them quickly helps keep people safe. Training and talking about safety signs helps stop accidents and lowers risk.

Exemplos do mundo real: ANSI-Compliant Signage in Action

Estudos de caso: How ANSI-Compliant Signs Improve Workplace Safety

Many businesses saw good results after using ANSI-compliant signs. Esses sinais ajudam os trabalhadores a encontrar perigos e seguir as regras da OSHA. Um EUA. fabricante trabalhou com a Clarion Safety para alterar seus rótulos. Isso fez com que os acidentes acontecessem menos e o trabalho fosse mais rápido. Jarvis Products Corporation colocou rótulos fortes em máquinas de carne. Essas etiquetas impediram ferimentos causados por ferramentas afiadas e atenderam às regras da ANSI. Sturtevant, Inc. fizeram etiquetas de advertência para seus equipamentos. Esses sinais ajudaram as pessoas a não serem esmagadas. Empreiteiros de defesa como a Lockheed Martin criaram etiquetas de segurança para equipamentos militares. Esses rótulos seguiam regras rígidas e mantinham os trabalhadores seguros.

| nome da empresa | Indústria | Contribuição para a Segurança |

|---|---|---|

| Fabricante com sede nos EUA | Portões de segurança industrial | Designs de etiquetas atualizados para melhor redução de riscos e eficiência. |

| Jarvis Produtos Corporação | Máquinas para processamento de carne | Etiquetas duráveis usadas para evitar lesões e garantir a conformidade com ANSI. |

| Sturtevant, Inc. | Equipamento de processamento de materiais | Developed labels to warn users of dangers and prevent crushing accidents. |

| Defense Contractors | Military Equipment | Created labeling systems that meet specifications and safety standards. |

These stories show that good signs and warning labels lower accidents and help with OSHA rules.

Successful Implementation of Danger Signs Across Various Industries

Different jobs have their own problems with danger signs. Some workers ask where to put signs for best safety. Companies put signs at eye level and near dangers in bright spots. Reflective signs help when it is dark. Durante a COVID-19, businesses used big signs to remind workers to wash hands and stay apart. These signs followed OSHA rules and kept people safe.

Stores and restaurants also use ANSI-compliant signs. Stores got 30% more visitors after making signs look better. Os restaurantes tiveram mais pessoas vindo à noite e mais clientes recorrentes. Os menus digitais agilizaram os pedidos e mantiveram as informações de segurança atualizadas. Estes resultados mostram que sinais de alerta e etiquetas de advertência claros impedem acidentes e ajudam com as regras da OSHA.

Sinais em conformidade com ANSI ajudam todos os empregos a reduzir acidentes, siga as regras da OSHA, e manter os trabalhadores seguros com sinais claros de alerta e cautela.

A sinalização do local de trabalho em conformidade com a ANSI é muito importante para a segurança e para o cumprimento das leis. Quando as empresas usam sinais melhores, eles veem muitas coisas boas acontecerem:

- Os trabalhadores podem encontrar ferramentas e EPI rapidamente, então eles trabalham mais rápido.

- Sinais luminosos ajudam a evitar lesões e tornam as coisas menos confusas.

- Novas placas ajudam a proteger as empresas se houver problemas legais e as ajudam a evitar multas da OSHA.

- Sinais fáceis de ler melhoram o trabalho e ajudam a seguir as regras.

Now is the perfect time for companies to assess their signage needs and choose a trusted provider. Ensuring your workplace is equipped with ANSI-compliant danger signs not only keeps employees safe but also helps maintain smooth operations. By investing in high-quality, compliant signage, you protect both your team and your business from potential hazards.

No OPTRÁFEGO, Oferecemos uma ampla variedade de ANSI-compliant workplace signs designed to meet safety standards and improve workplace efficiency. Explore our solutions today to ensure your workplace is as safe as it is productive.

Perguntas frequentes

What does ANSI compliant workplace signage mean?

ANSI compliant workplace signage follows strict safety rules. Esses sinais usam cores especiais, símbolos, e palavras. They help workers see dangers fast. Companies use these signs to follow laws and keep people safe.

Why are mandatory signs important for businesses?

Mandatory signs tell workers what they must do to stay safe. These signs show rules everyone needs to follow. Businesses use mandatory signs to stop accidents and keep work safe.

How does hazard communication improve safety?

Hazard communication uses clear signs and labels to warn workers. These signs help people know about dangers at work. Good hazard communication lowers injuries and keeps everyone aware.

How often should companies update their safety signs?

Companies should check safety signs during regular audits. They need to replace faded or broken signs right away. Updates help keep signs easy to read and make sure they follow safety rules.

Who decides where to place danger signs in the workplace?

Safety managers pick where to put danger signs. They look for places with high risks. Os sinais vão ao nível dos olhos e perto dos perigos. Uma boa colocação ajuda os trabalhadores a verem os avisos e a permanecerem seguros.