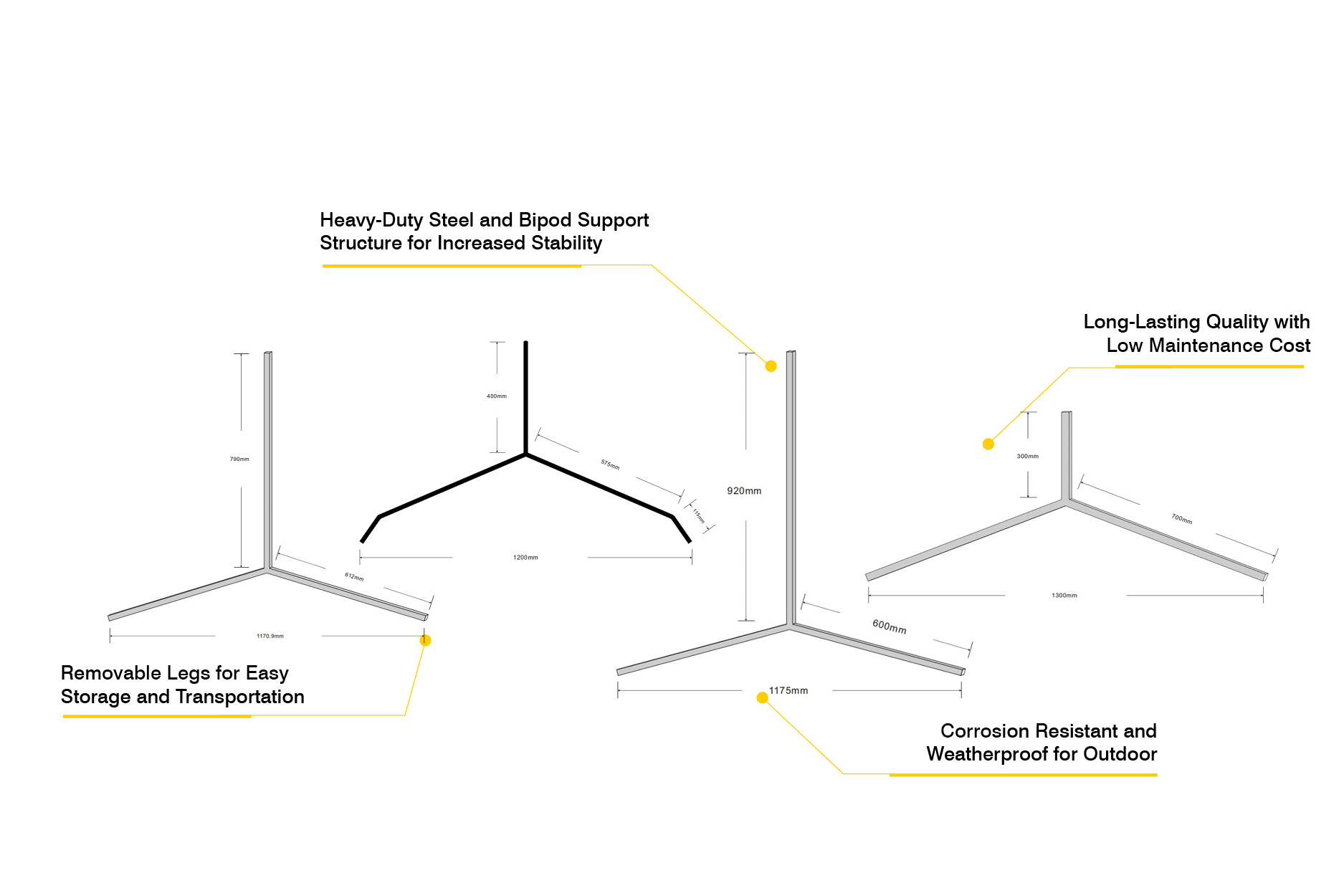

Optsigns Y Stands feature durable removable bipod steel legs designed to support multi-message frames, offering a robust and stable structure for temporary safety signs. These versatile Y Stands effectively manage traffic and alert motorists to important information, such as roadworks, roadway closures, speed reductions, and other hazardous road conditions. Their lightweight design allows for easy setup and transport, making them an essential tool for traffic management in various environments.

*We respect your confidentiality and all information are protected.

| Size | 1200*730*16mm |

|---|---|

| Material | 18mm Dia. Solid Circular Steel |

| Finish | Black Powder Coating |

| Middle Bar | 400mm |

| Ground Clearance | 330mm |

| Customize | Custom Size and Shape |

Using Optsigns Y Stands is straightforward and efficient. Start by placing the bipod legs on a flat surface where you intend to set up your temporary safety signs. Attach the multi-message frame securely to the Y Legs, ensuring it is stable and upright. Adjust the frame to display the necessary messages clearly, whether it’s for roadworks, speed reductions, or other safety alerts. Once set up, regularly check the stability of the Y Stands, especially in windy conditions, to ensure maximum visibility and safety for motorists.

To use dynabolts, first select the appropriate size based on your project’s needs. Refer to the dynabolt installation guide for detailed instructions. Ensure the installation surface, like concrete, is clean and free of debris. Place the galvanized dynabolts through the fixture and into the pre-drilled hole, then tighten using a suitable tool.

Dynabolts function by expanding within a pre-drilled hole when tightened, creating a secure anchor. This expansion mechanism allows them to hold substantial loads. The stainless steel dynabolts are particularly effective in resisting corrosion, ensuring a long-lasting hold in various environments.

To install a dynabolt, first drill a hole into the concrete of the appropriate size. Insert the dynabolt into the hole, ensuring it is aligned with the fixture. Use a wrench to tighten the nut, which will cause the dynabolt to expand and grip the surrounding material securely. Follow the dynabolt installation guide for specific instructions based on the type used.

To remove dynabolts from concrete, first, unscrew the nut and washer. Then, use a hammer to gently tap the dynabolt, loosening it from the concrete. If it resists, you may need to drill further into the hole or use a wrench to rotate the galvanized dynbolt counterclockwise until it releases.

The weight a dynabolt can hold varies based on its size and the material it is anchored into. Generally, standard galvanized dynabolts can support significant loads when properly installed.