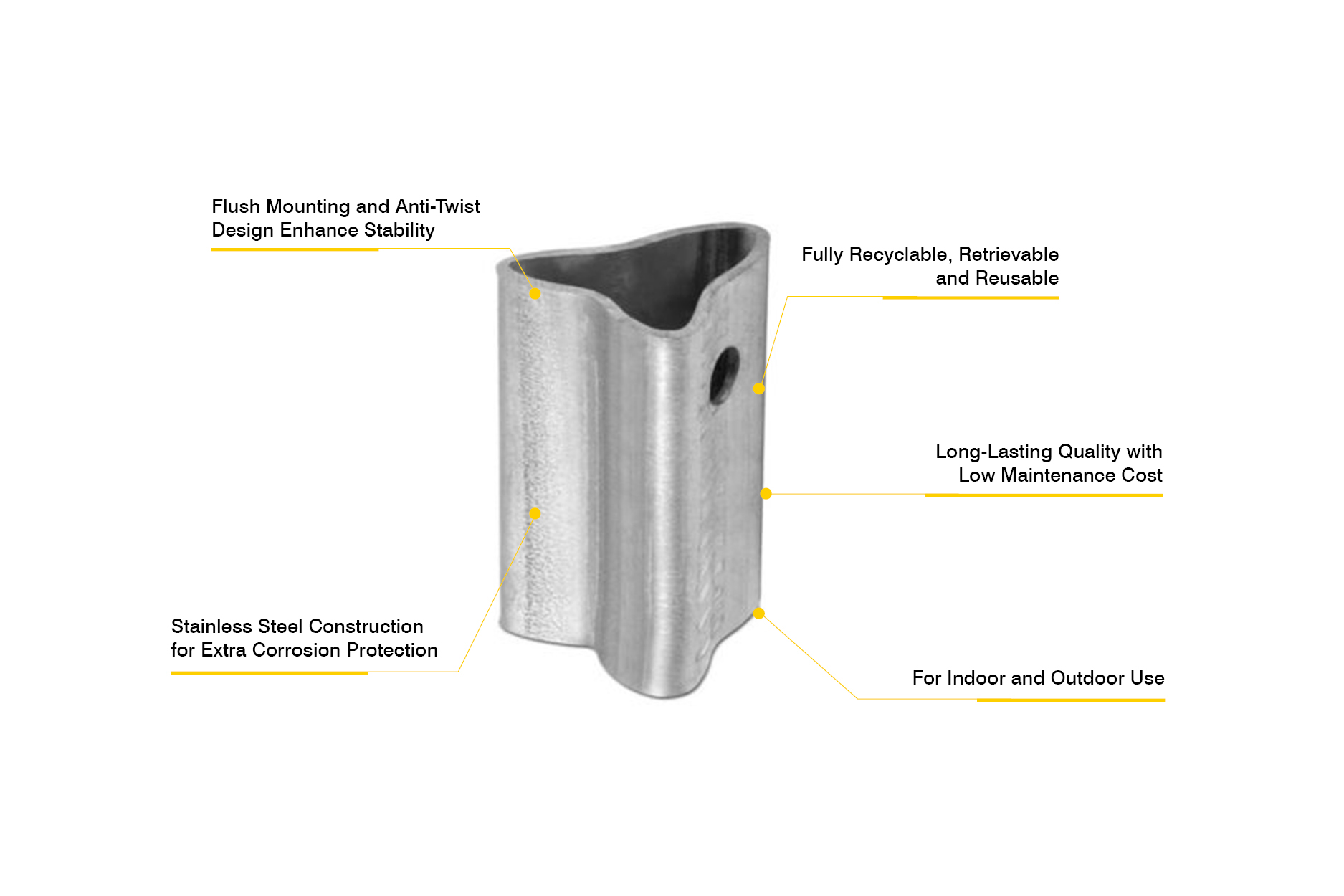

Optsigns V-Loc Wedges are expertly crafted from high-quality stainless steel, providing a durable and reliable anchoring solution. Designed for reuse after vehicle impact, these wedges ensure that sign posts, mailboxes, and fences can release or break down at ground level, significantly reducing the risk of accidents. Their robust construction makes wedges ideal for various applications, ensuring safety and stability in any environment.

Optsigns V-Loc Wedges are expertly crafted from high-quality stainless steel, providing a durable and reliable anchoring solution. Designed for reuse after vehicle impact, these wedges ensure that sign posts, mailboxes, and fences can release or break down at ground level, significantly reducing the risk of accidents. Their robust construction makes wedges ideal for various applications, ensuring safety and stability in any environment.

*We respect your confidentiality and all information are protected.

| Size | 4*2*4 inches, Customizable |

|---|---|

| Material | Stainless Steel |

| Colour | Silver |

| Mounting Type | Flush Mounting |

| Customize | Custom Logo, Marking and Shape |

Using V-Loc steel wedge is straightforward and effective. Begin by selecting the appropriate size for your sign post, mailbox, or fence. Position the steel wedge under the base of the post and securely drive it into the ground using a mallet or hammer. Ensure the post is upright and stable before applying any pressure. In the event of a vehicle impact, the V-Loc steel wedge will allow the post to release or break away safely, minimizing potential hazards. Regularly check the stability of the steel wedge to maintain optimal performance.

A Type 1 barricade is a traffic control device used to warn or direct traffic in temporary work zones, road closures, or construction areas. It features a single reflective panel (usually orange or white) mounted on a lightweight frame. Type 1 barricades are designed for low to moderate traffic areas and are often used for shorter-term applications.

Type I Barricade

Design: A lightweight, foldable barricade with one reflective panel, suitable for low-traffic areas.

Application: Often used in urban or short-term construction zones.

Type II Barricade

Design: A larger, more robust barricade with two reflective panels, providing greater visibility.

Application: Commonly used for moderate traffic control in construction sites and road work.

Type III Barricade

Design: The largest barricade, typically with three reflective panels, providing maximum visibility.

Application: Used in high-traffic areas or hazardous zones where maximum warning is needed.

The Occupational Safety and Health Administration (OSHA) sets standards for barricades used in construction and industrial settings to ensure worker safety. OSHA standards for barricades are outlined in 29 CFR 1926.200 and state that:

Barricades must be visible and clearly mark hazards to prevent accidents or unauthorized access.

The barricade must have high-visibility materials, such as reflective sheeting, and be designed to withstand environmental conditions.

Barricades must be stable enough to remain upright and prevent injury if struck by vehicles or equipment.

OSHA regulations require that warning barricades are properly maintained and positioned to protect both workers and the public.

While stable under normal conditions, sandbags or weights can be added for extra stability in windy environments.