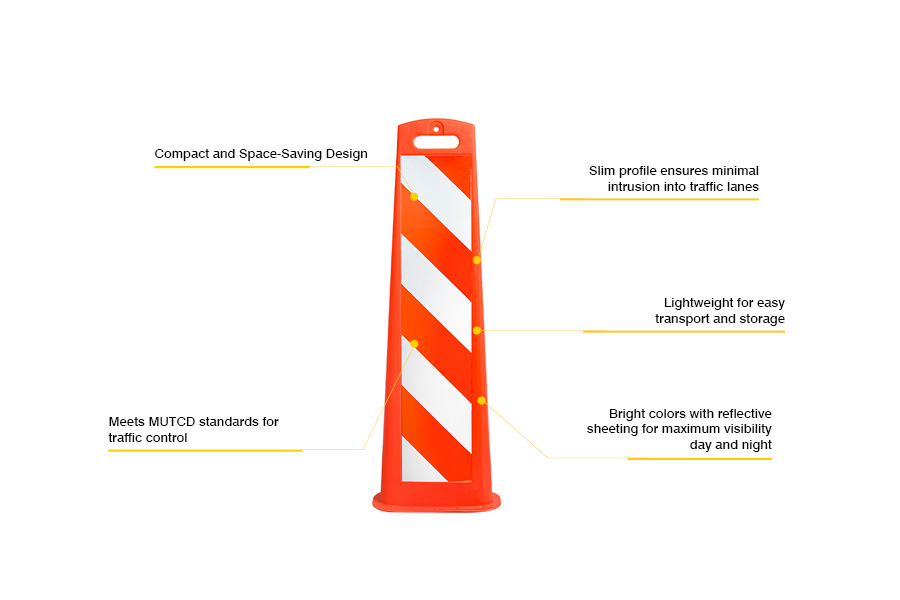

Vertical Panels for traffic control are designed to improve safety and streamline traffic management. Their tall, narrow shape is perfect for situations where space is limited, such as lane closures or urban construction zones. These panels are constructed from durable, impact-resistant materials that can withstand collisions and harsh weather, ensuring long-term usability.

The bright, UV-stabilized colors and reflective sheeting ensure visibility even in low-light or nighttime conditions. With options for weighted bases, these panels remain stable even in high-traffic areas or windy environments. Their stackable and lightweight design makes them easy to transport and store, providing a practical solution for both temporary and long-term traffic management needs.

*We respect your confidentiality and all information are protected.

| Color | White, Black, Orange |

|---|---|

| Material | PE |

Position vertical panel barricades in a straight line or pattern to guide traffic or block restricted areas. Ensure spacing aligns with MUTCD standards for maximum safety. Attach a weighted base to each panel to enhance stability. Adjust placement as needed based on traffic flow or site conditions.

A vertical panel is a slim, upright traffic control device designed to guide vehicles and pedestrians safely in areas like construction zones, road closures, or lane diversions. Made from durable materials such as high-density polyethylene (HDPE), vertical panels are lightweight, portable, and resistant to weather and impact. Their compact design ensures minimal obstruction to traffic flow, making them ideal for narrow or congested areas.

The diagonal stripes on a barricade or vertical panel are reflective markings designed to enhance visibility and convey directional information. The stripes are regulated by the Manual on Uniform Traffic Control Devices (MUTCD) and indicate the direction of traffic flow:

Stripes slanting downward to the left direct traffic to the left.

Stripes slanting downward to the right direct traffic to the right.