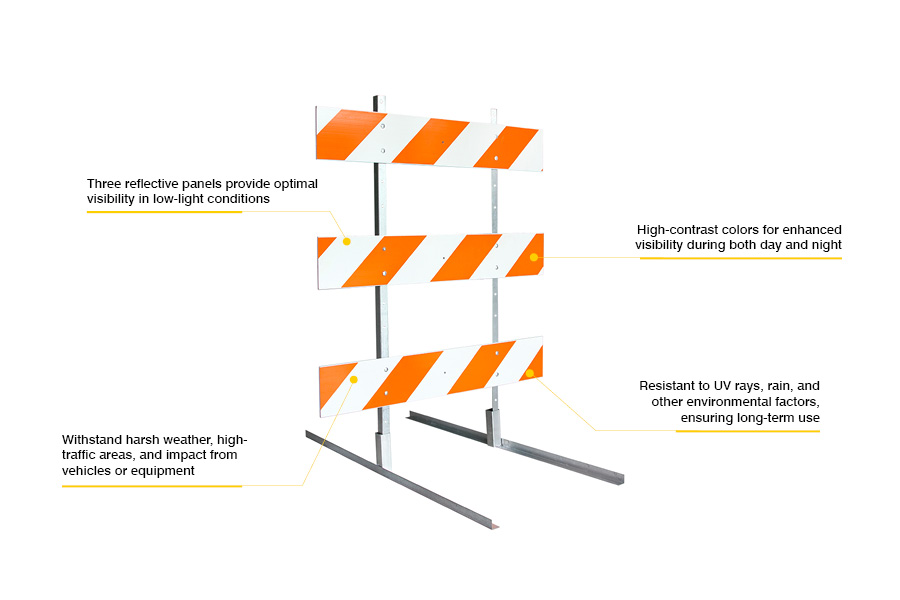

The Type III barricade is a robust and effective traffic control solution designed for high-traffic or hazardous environments. With three reflective panels, it provides superior visibility, making it suitable for both daytime and nighttime use. Whether used in roadwork zones, detours, or large-scale event spaces, the Type III barricade offers the highest level of safety and direction for motorists and pedestrians.

Made from durable, weather-resistant materials, this barricade is built to withstand the rigors of outdoor conditions. The wider base provides added stability, while the reflective panels meet MUTCD standards to ensure optimal performance. It is also portable and easy to set up, ensuring quick deployment when needed for temporary traffic management.

*We respect your confidentiality and all information are protected.

| Board Material | PE ABS |

|---|---|

| Frame Material | Angle lron Feet Steel Square Tube |

| Reflective Film | EG/HIP/DG/Customizable |

A Type 3 barricade is a traffic control device designed for use in high-traffic areas, hazardous zones, or long-term roadwork projects. It features three reflective panels (usually orange and white), providing maximum visibility both during the day and at night.

A Type 3 barricade typically stands around 36 to 48 inches tall, depending on the specific model and manufacturer. The height of the barricade ensures that the reflective panels are visible to drivers from a considerable distance, especially in high-speed traffic areas.

A Type III barricade features three reflective panels, providing optimal visibility in low-light conditions and ensuring safety in high-traffic environments.