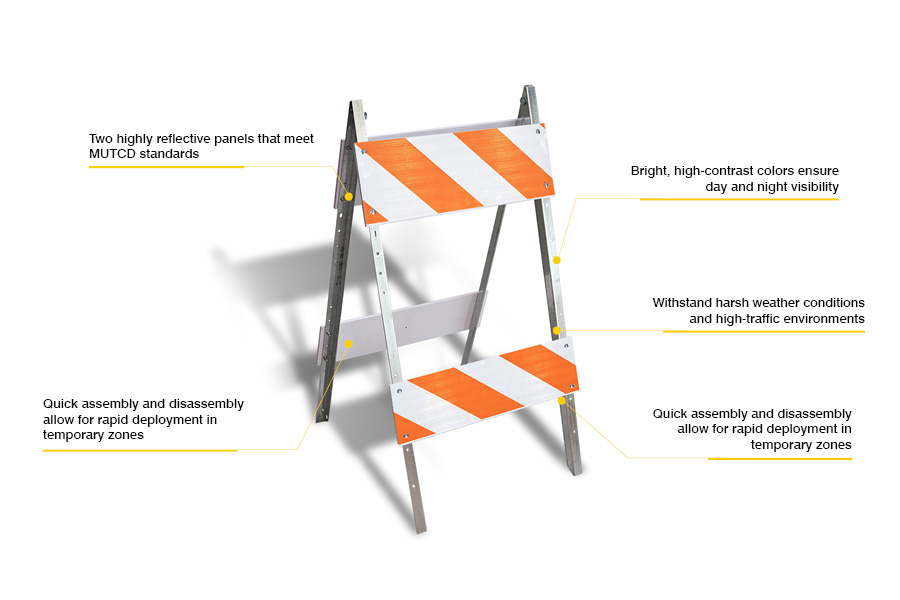

The Type II barricade is a versatile and highly effective solution for directing traffic or marking hazardous areas. With two reflective panels, this barricade provides improved visibility compared to the Type I barricade, making it suitable for moderate to high-traffic zones. Constructed from durable materials like high-density plastic or steel, it can withstand environmental challenges such as rain, wind, and UV exposure, ensuring long-lasting use.

The barricade’s stable base prevents tipping, and it can be weighted further for use in areas with high winds or traffic speeds. Designed for portability, the Type II barricade is lightweight and foldable, making it easy to transport and store. Its reflective panels meet MUTCD guidelines, ensuring compliance with safety standards for optimal performance in guiding traffic.

*We respect your confidentiality and all information are protected.

A Type II barricade is a traffic control device used to warn and direct traffic in moderate to high-traffic environments, such as construction zones, road closures, and events. It features two reflective panels mounted on a frame, providing increased visibility compared to a Type I barricade.

Visibility: Type I has one panel, Type II has two panels, and Type III has three panels for maximum visibility.

Size and Stability: Type III barricades are larger and more stable, suitable for high-traffic areas, while Type I and II are more portable and suited for lower to moderate traffic conditions.

Application: Type I is best for temporary, low-traffic applications, Type II for moderate traffic, and Type III for high-traffic and hazardous zones.

The Type II barricade typically features two large reflective panels (typically 24 inches high) for high visibility in both day and night conditions.