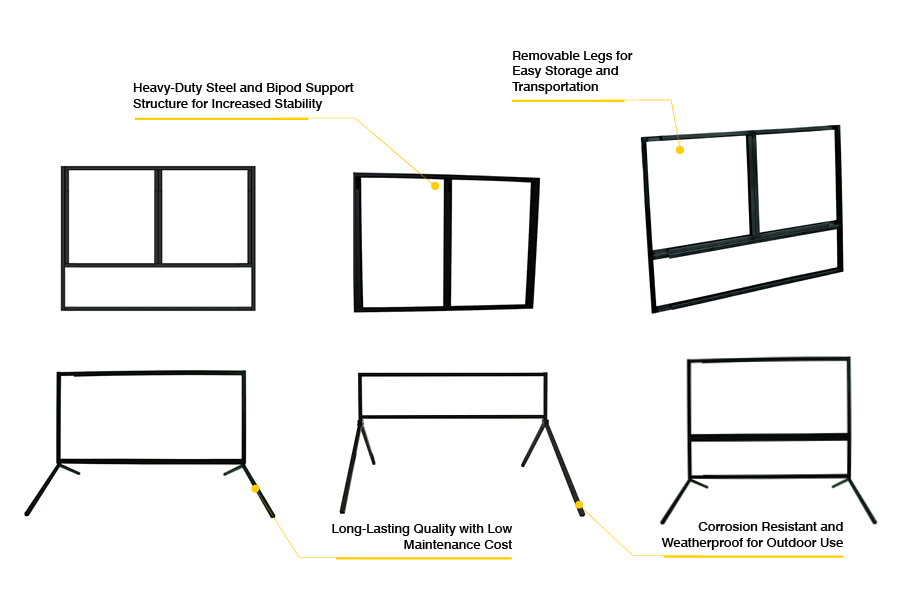

The Multi-Message Sign Frame for Traffic Management by OPTsigns is designed to enhance safety and communication in various outdoor settings. Crafted from black powder-coated steel, this frame provides a robust structure that ensures stability for temporary safety signs. Its optional bipod folding legs offer a versatile solution for managing traffic, effectively warning motorists of roadworks, roadway closures, and speed reductions. The multi-message frame is compliant with Australian standards, making it a reliable choice for safety compliance and effective traffic management.

The Multi-Message Sign Frame for Traffic Management by OPTsigns is designed to enhance safety and communication in various outdoor settings. Crafted from black powder-coated steel, this frame provides a robust structure that ensures stability for temporary safety signs. Its optional bipod folding legs offer a versatile solution for managing traffic, effectively warning motorists of roadworks, roadway closures, and speed reductions. The multi-message frame is compliant with Australian standards, making it a reliable choice for safety compliance and effective traffic management.

Installation and removal of safety signs are made effortless with the multi-message sign frame. When the need arises, the folding multi-message frame legs provide an efficient setup, ensuring that vital information reaches drivers promptly. This adaptability makes the multi-message sign frame an essential tool for any road safety application. Whether used for short-term events or extended roadworks, this frame is your go-to solution for effective traffic communication, embodying durability and ease of use

*We respect your confidentiality and all information are protected.

| Size | 1270*920mm |

|---|---|

| Material | Black Powder Coated Steel 25*25mm |

| Frame | Top Opening Frame with Middle Bar (Optional) |

| Customize | Logo and Marking |

| Options | Middle Bar, Folding Legs |

Setting up a multi-message sign frame is straightforward. Begin by extending the bipod folding legs to the desired height. Ensure the frame is stable on a flat surface. Then, insert your signs into the frame slots, making sure they are securely held in place for optimal visibility.

Absolutely! The multi-message sign frame is designed for portability. With options like folding multi-message frame legs, it can be easily transported to different locations, making it ideal for temporary traffic management or event signage.

Yes, most multi-message sign frames are built to withstand adverse weather. Materials like weather-resistant steel and corrosion-resistant finishes, combined with stable multi message sign legs, make them suitable for outdoor use in various climates.

The capacity of a multi-message sign frame varies based on its design. Typically, these frames can hold anywhere from 2 to 6 messages simultaneously, allowing for effective communication across multiple lanes of traffic.

Multi-message sign frames typically come in various sizes to accommodate different safety signage needs. At OPTsigns, the standard size is 1270 mm by 920 mm, providing a substantial display area for clear visibility of important messages. This sizing ensures that the frames can effectively manage traffic and communicate vital information to motorists, while also being portable enough for easy setup and transport.