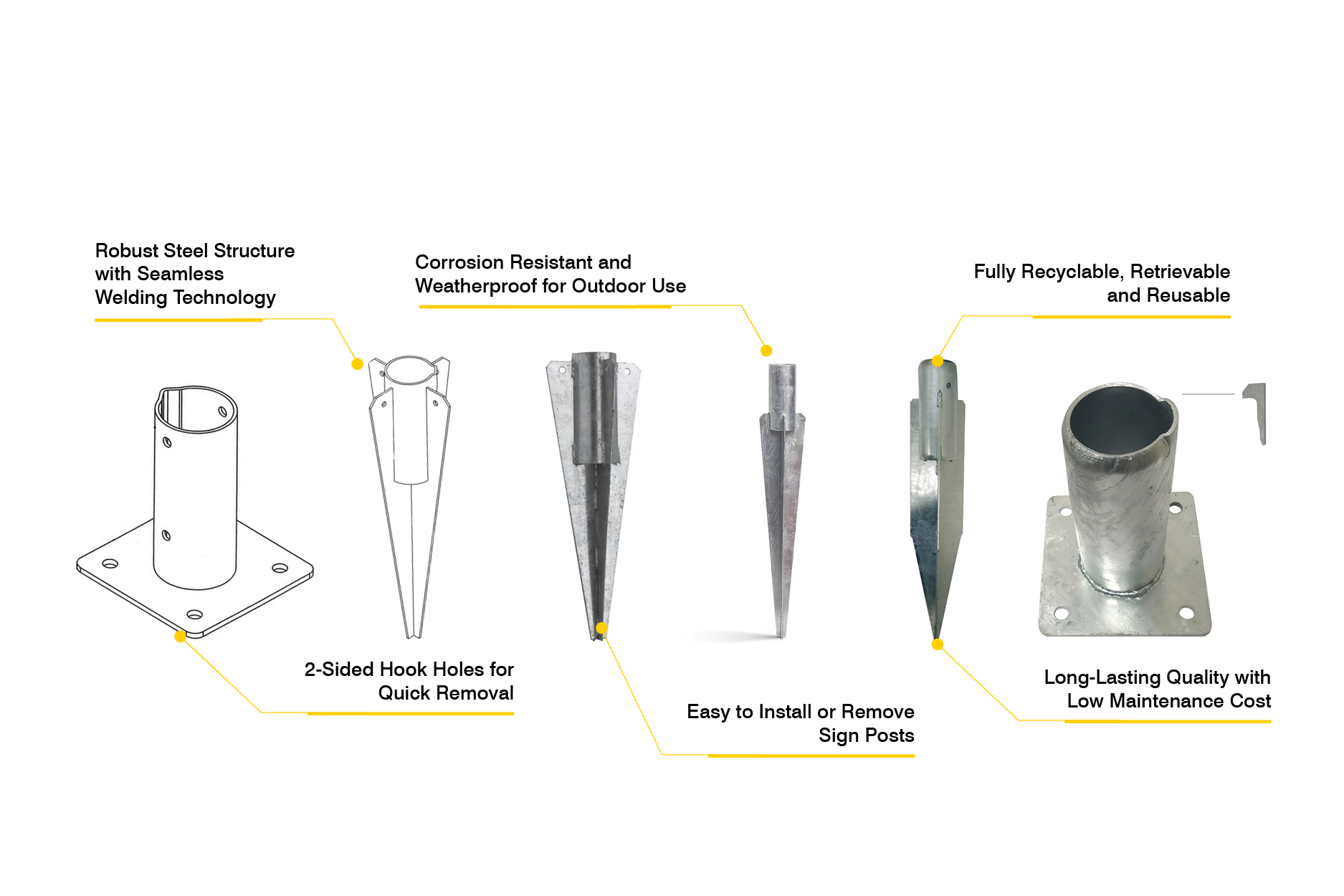

The OPTsigns sign post sleeve is engineered with a robust steel structure, utilizing seamless welding technology that enhances its durability and strength. Made from high-quality galvanized steel, this heavy-duty surface mount post base plate is corrosion-resistant and weatherproof, making it ideal for outdoor use. Its design ensures that it remains fully recyclable, retrievable, and reusable, contributing to sustainable practices. With its long-lasting quality and low maintenance cost, the stainless steel post sleeve provides an efficient solution for various signage needs.

The OPTsigns sign post sleeve is engineered with a robust steel structure, utilizing seamless welding technology that enhances its durability and strength. Made from high-quality galvanized steel, this heavy-duty surface mount post base plate is corrosion-resistant and weatherproof, making it ideal for outdoor use. Its design ensures that it remains fully recyclable, retrievable, and reusable, contributing to sustainable practices. With its long-lasting quality and low maintenance cost, the stainless steel post sleeve provides an efficient solution for various signage needs.

Installation is a breeze with this innovative steel post sleeve, which eliminates the need for digging holes or mounting posts in concrete. Instead, it can be easily fixed to the ground using bolts and nuts, ensuring maximum stability for sign post installations. Whether you are using metal post sleeves or a round sign post sleeve, the surface mount post base plate guarantees secure positioning. The ease of installing or removing sign posts with this post sleeve makes it a versatile choice for any application, delivering reliable performance while simplifying the process.

*We respect your confidentiality and all information are protected.

| Height | 165mm, 172mm, Customizable |

|---|---|

| Nominal Bore | 60mm Dia., 70mm Dia., Customizable |

| Material | Hot Galvanized Steel |

| Customize | Logo, Marking and Shape |

Slim traffic cones are typically used in areas where space is limited, such as narrow roadways or crowded events. Their lightweight design makes them easy to deploy, serving as effective caution cones for directing traffic or marking hazards.

Slim traffic cones are excellent for managing traffic flow in tight spaces, such as parking lots or construction sites. Their reduced footprint allows for efficient use in crowded areas while still providing the necessary visibility and safety that safety traffic cones offer.

The skinny cones are often referred to as slim traffic cones. These types of cones are designed for increased visibility in tight spaces and are commonly used in urban settings or for events where space is limited.

There are several types of traffic safety cone shapes: right circular cone,oblique cone,elliptical cone, etc. Each type has unique properties and applications in geometry and design.

A cone has one base, which is typically circular. However, for added stability, many cones, like the OPTsigns PVC traffic cones, feature a square black base. This design helps prevent tipping and ensures the cone remains upright in various conditions.