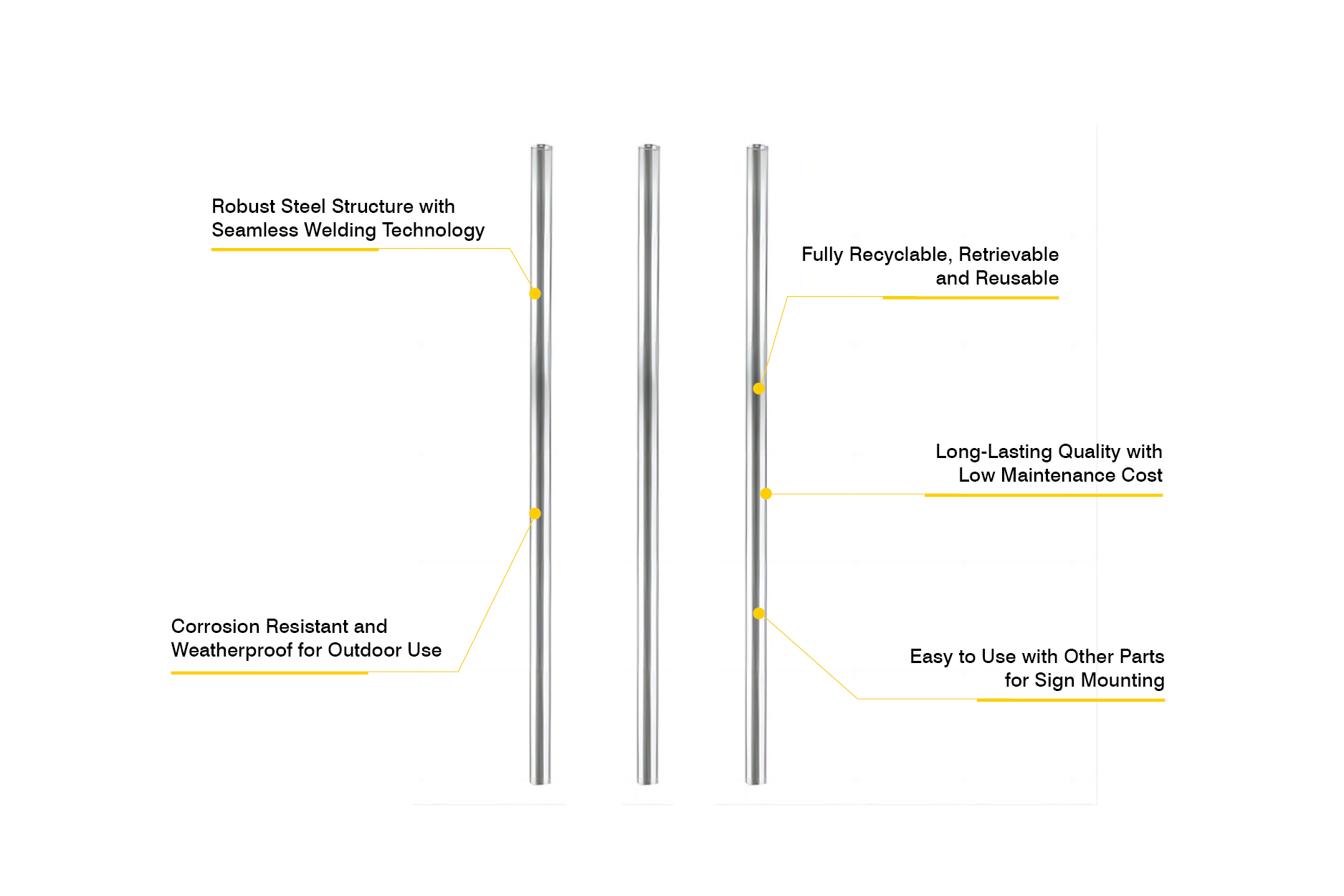

Optsigns Sign Post/Pole is constructed from galvanized steel, ensuring superior corrosion resistance for outdoor use. This durable Sign Post is ideal for mounting various signs and is commonly used with ground spikes, sign brackets, and socket sleeves. Its robust design makes it a popular choice for traffic management, safety signage, and directional guidance in both residential and commercial settings.

Optsigns Sign Post/Pole is constructed from galvanized steel, ensuring superior corrosion resistance for outdoor use. This durable Sign Post is ideal for mounting various signs and is commonly used with ground spikes, sign brackets, and socket sleeves. Its robust design makes it a popular choice for traffic management, safety signage, and directional guidance in both residential and commercial settings.

*We respect your confidentiality and all information are protected.

| O.D. | ��60.3mm, ��76.1mm, ��88.9mm, ��102mm, ��114.3mm, ��139.7mm, ��165.1mm, Customizable |

|---|---|

| Material | Galvanized Steel |

| Customize | Customized Size Available |

Using the Optsigns Sign Post/Pole is straightforward. Begin by selecting an appropriate location for your sign, ensuring it’s visible and accessible. If using ground spikes, drive the spike into the ground at your desired depth, then securely attach the steel sign post to the spike using a sign bracket. For socket sleeves, insert the steel sign post into the sleeve and ensure it’s stable. Finally, mount your sign onto the post, making sure it’s level and properly secured. This simple setup allows you to effectively display signs for traffic control, parking regulations, or informational purposes.

A Type 1 barricade is a traffic control device used to warn or direct traffic in temporary work zones, road closures, or construction areas. It features a single reflective panel (usually orange or white) mounted on a lightweight frame. Type 1 barricades are designed for low to moderate traffic areas and are often used for shorter-term applications.

Type I Barricade

Design: A lightweight, foldable barricade with one reflective panel, suitable for low-traffic areas.

Application: Often used in urban or short-term construction zones.

Type II Barricade

Design: A larger, more robust barricade with two reflective panels, providing greater visibility.

Application: Commonly used for moderate traffic control in construction sites and road work.

Type III Barricade

Design: The largest barricade, typically with three reflective panels, providing maximum visibility.

Application: Used in high-traffic areas or hazardous zones where maximum warning is needed.

The Occupational Safety and Health Administration (OSHA) sets standards for barricades used in construction and industrial settings to ensure worker safety. OSHA standards for barricades are outlined in 29 CFR 1926.200 and state that:

Barricades must be visible and clearly mark hazards to prevent accidents or unauthorized access.

The barricade must have high-visibility materials, such as reflective sheeting, and be designed to withstand environmental conditions.

Barricades must be stable enough to remain upright and prevent injury if struck by vehicles or equipment.

OSHA regulations require that warning barricades are properly maintained and positioned to protect both workers and the public.

While stable under normal conditions, sandbags or weights can be added for extra stability in windy environments.